Beruflich Dokumente

Kultur Dokumente

Fiber Optics Used To Support Reservoir Temperature Duri SteamfloodSPE-93240-MS

Hochgeladen von

M Galih Adi SamuderaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fiber Optics Used To Support Reservoir Temperature Duri SteamfloodSPE-93240-MS

Hochgeladen von

M Galih Adi SamuderaCopyright:

Verfügbare Formate

SPE 93240

Fiber Optics Used To Support Reservoir Temperature Surveillance in Duri Steamflood

D.K. Nath, Halliburton Energy Services Inc.

Copyright 2005, Society of Petroleum Engineers Inc.

This paper was prepared for presentation at the 2005 Asia Pacific Oil & Gas Conference and

Exhibition held in Jakarta, Indonesia, 5 7 April 2005.

This paper was selected for presentation by an SPE Program Committee following review of

information contained in a proposal submitted by the author(s). Contents of the paper, as

presented, have not been reviewed by the Society of Petroleum Engineers and are subject to

correction by the author(s). The material, as presented, does not necessarily reflect any

position of the Society of Petroleum Engineers, its officers, or members. Papers presented at

SPE meetings are subject to publication review by Editorial Committees of the Society of

Petroleum Engineers. Electronic reproduction, distribution, or storage of any part of this paper

for commercial purposes without the written consent of the Society of Petroleum Engineers is

prohibited. Permission to reproduce in print is restricted to a proposal of not more than 300

words; illustrations may not be copied. The proposal must contain conspicuous

acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P.O.

Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

Abstract

In thermal fields, temperature profiles usually are acquired

as part of a sound reservoir surveillance plan to manage heat

in the ground. The conventional method used to acquire a

temperature profile is to run a wireline log across the interval

of interest, usually through tubing or casing in observation

wells.

In Duri Steam Flood (DSF) production wells, it is not

possible to run conventional temperature logs in producers

without pulling out tubing pumps due to the complexity of the

completion. One alternative to the real-time temperature

profile in DSF producers is to use an optical fiber enclosed

inside a steel tube strapped onto the outside of the tubing

string and passed through the tubing hanger and top flange at

the wellhead. The tubing hanger must be modified to

accommodate the pre-installed fiber-tube installation.

The survey will collect temperature data that can be used

to determine the temperature and extent of a steam chest and

the temperature gradient in both overburden and underburden. This information is necessary to set steam injection

target rates using the Vogel and Neumann methodologies. The

data are also useful in mitigating steam breakthroughs and

eruptions, and to identify bypassed oil.

Introduction

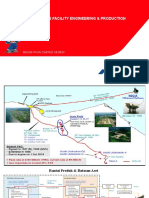

The DSF field is a multi-billion-barrel, heavy-oil-producing

field that lies on the central Sumatra basin, Indonesia (Fig. 1).

It is operated by Caltex Pacific Indonesia (CPI), a

ChevronTexaco affiliate. The field consists of 4,114

producers, 1,610 steam injectors, and 450 temperature

observation wells. Thermal-enhanced oil-recovery (EOR)

methods are implemented to reduce oil viscosity, improving

oil recovery from this heavy oil bearing formation.

The current total production of the field is approximately

215,000 BOPD, making the average production per well about

60 BOPD. With 35,000 acres total, the field is divided into 13

smaller areas, and areas 1 to 11 have been fully developed and

placed under an extensive steamflooding program.

Active steam flooding began in 1985, and typically, one

steam injector well is surrounded by a pattern of producing

wells. One temperature observation well is often set in the

pattern to monitor formation temperature response to the

steamflood.

The DSF field has three primary oil producing sands,

namely the Rindu sand, the Pertama sand and the Kedua sand.

The Rindu sand is the shallowest interval produced in DSF.

The deeper Pertama and Kedua (PK) sands have a combined

pay thickness of approximately 140 ft and range from 400- to

700 ft in true vertical depth (TVD). These two sands are the

principal oil-bearing sands, accounting for approximately two

thirds of the original oil in place (OIP). These two sand layers

are the primary steam injection targets.

The producing sands are unconsolidated with formation

liquid permeability ranging from 100 to 4,000 mD. Formation

porosity ranges from 15- to 45%. The crude oil is heavy with

an API gravity ranging from 18 to 22API at 60F.

Because of the highly unconsolidated formations of the

DSF field, completing the wells with sand-control equipment

is standard. The conventional completion methods used to

control sand production are cased-hole gravel packs (CHGP),

openhole gravel packs (OHGP), and cased-hole frac pack

(CHFP) (Fig. 2). In each completion, a 6 5/8- or 4-in. screen

liner, depending on the casing size, is installed prior to

performance of the gravel pack or frac-pack treatment.

With all enhanced recovery techniques, breakthrough of

the injected fluid at a producing well is major issue. This

problem is detrimental to the individual wells production.

Uneven radial flooding of multiple-producing zones within a

steamflood can become costly to the operator. In DSF, steam

management is critical to the economic operation of all

steamfloods. As the areas mature and start their ramp down,

careful attention must be paid to injection rates, or there will

be a significant loss in value.

The process for determining heat requirements for patterns

is complicated, especially with low-density observation wells.

Setting injection rates too low will lead to slow steam-chest

growth, possible collapse of the steam chest, loss of reserves,

and overall lower production. However, setting injection rates

too high will lead to wasted heat in the casing, higher fuel

costs, sanding problems in producers, liner failures, pump

failures, and overall lower field reliability in the casing vapor

collection systems, well test stations, and central gathering

D.K. NATH

stations. In some cases, higher rates may contribute to surface

steam eruptions.

Based on these challenging problems, periodic temperature

surveys need to be taken throughout the field. Fiber-optic

application is one surveillance tool that can be used to

improve heat management and ultimately improve

profitability by knowing which sands are actually producing

steam.

Technology

Distributed temperature sensing (DTS) provides a technique to

measure temperature distribution along a fiber-optic line at

any time. A laser light pulse traveling along the fiber length

excites the atoms on the lattice structure, causing them to emit

small bursts of light pulses that travel back along the same

fiber. An instrument box analyzes the backscattered light

pulses to determine the temperature of the point from which

these lights are emitted. As the light is backscattered

continuously along the fiber length, a temperature profile is

obtained. Since the laser light pulse moves along the fiber

length with a constant velocity, measuring time from the

incident pulse to the time the backscattered light reaches the

instrument box, it determines the position of the recorded

temperature along the fiber length.

As the backscattered light reaches the instrument box, it is

normally weak and has poor signal-to-noise ratio. By pulsing

the laser light pulse at a high rate, the returning signals can be

stacked to achieve better signal-to-noise ratio, and hence,

better resolution. Thus, the resolution is dependent upon the

fiber length and time taken for the log.

As stated above, the back-scattered pulse represents

temperature. These pulses return in the form of a wave. The

components of waveform have wavelengths as that of incident

wave, wavelength above and below the incident wavelength.

The strongest wave component is called the Raleigh band and

is used for quality control and is filtered. The next waves are

called Brillouin lines, are caused by lattice vibration, and are

difficult to isolate, as they are close to Rayleigh bands. The

weakest of the backscattered waves are the Ramon bands.

The Ramon bands are used for temperature evaluation.

These bands have wavelengths that differ greatly from the

Raleigh peak and Brillouin peaks and are easily isolated. The

Ramon signal has two bandsstrokes and anti-strokes

having higher and lower wavelengths. The ratio of the area or

energy of the anti-stroke to that of the stroke band gives the

temperature of the fiber optics line at the depth these signals

are generated.

Application

There are three primary ways that fiber-optic cable is used in

well surveys in the Duri Steam Flood. The capillary tubing is

clamped along the production tubing, then, on to the tubing

pump and plugged off at the bottom. The wellhead is modified

to allow the passage of the capillary tubing. On the surface, a

high-pressure release valve is installed, and the well is put on

production. The release valve is closed and acts as a safety

device in the event that steam breakthrough occurs through the

capillary tubing. When production has been stable for a few

days, the fiber (in form of a flexible rod) is inserted into the

capillary tubing by means of a specially designed box until the

SPE 93240

end of the capillary tubing and the DTS box are connected to

the fiber. Data are recorded continuously from the start of the

base line, the cooling down period, and following the

production period. Since the wells are high-temperature wells,

reaching temperatures close to 350F, this method was

developed to facilitate retrieval of fiber optics sensing device

(fiber rod) upon completion of the survey and can be inserted

again for another survey. In this way, the fiber optics material

will not be exposed to a high-temperature environment for a

long time, increasing life of the fiber optics material. The fiber

rod is then available for a survey at another well, reducing

significant cost and time. Using this procedure, temperature

data can be acquired at a relatively low cost.

The second most common method uses a 0.156-in-OD

steel tube with pre-installed multimode fiber material. The

physical dimension of the fiber is a 50 micron core surrounded

by a 125 micron cladding or jacket. The preinstalled fiber tube

is used as a retrievable survey in production wells with openended tubing and pressure equipment. The fiber tube is

spooled back into a cable drum like wireline and moved from

one location to another as required. The retrievable fiber tube

is also used for surveys in observation wells.

The fiber pumping method, the third method of deploying

fiber, is where the fiber optics material is pumped through

capillary tubing. The check valve installed below the capillary

tubing allows pumping of the fiber once the capillary tubing is

placed as a semi-permanent or permanent (cemented in place

with casing), either as a single-ended or double-ended. In this

type of installation, the fiber is left in place after it is pumped.

Candidate Selection for Fiber Optic Installation

For optimizing the fiber-optic survey budget, every area in

DSF has developed a guideline for selecting well candidates to

run fiber-optic surveys in both observation and production

wells.

The surveys in observation wells are simple temperature

surveys. Temperature surveys are normally run twice per year

in observation wells, once as a fiber-optic (FIBO) survey and

once as a service provided with TDT/TMDL logging.

Four candidates in producer wells were selected based on

the following criteria:

Steam breakthrough, where oil production has dropped

due to breakthrough. The rule of thumb for identifying

steam breakthrough is WHT > 250F and/or casing

pressure > 50 psi.

High frequency failure, with pump stuck due to

overheating > 3 times/year. FIBO data should be acquired

in these wells to facilitate executing steam isolation jobs.

Low confidence in determining steam zones using the

existing available surveillance data.

Multiple zone sand production, used for identifying crossflow and lost circulation.

Shallow hazard indications, such as bubbling at surface,

wellhead dancing, or steam anomaly based on seismic

data.

Example 1 shows the base-line temperature while the well

is on production. This is followed by temperature data

retrieved during wellbore cool down when cold water (about

40 bbls @ 2 bpm) is pumped through the casing and tubing

SPE 93240

FIBER OPTIC USED TO SUPPORT RESERVOIR TEMPERATURE SURVEILLANCE IN DURI STEAM FLOOD

annulus. Upon completion of the pumping water, notice the

sudden change in temperature peak (example 2, well B). This

increase in temperature is due to the steam breakthrough into

the wellbore. This example shows the areas where steam

breakthrough has occurred.

In this example, the capillary tubing was strapped to the

outside of the production tubing in the annulus, the fiber rod

was inserted, and the temperature measurements were

retrieved.

In Example 2, the well was completed using openhole

gravel packing (OHGP). The wellbore was cooled down as

described in the first example, and temperature profile was

taken. The profile shown for this well was generated after the

water was pumped and during waiting for the change of

temperature profile to happen. However, notice the change in

the profile in the surface casing string. Further investigation

suggests that the casing was perforated (2 spf/2 ft) to do the

cement squeeze job to improve cement bond. The bonding

was improved and the well was completed with OHGP.

However, it is suspected that the bonding could have broken

down due to steam injection as the casing went through both

vertical and horizontal expansion. This unwanted

breakthrough was a source of heat loss, and if not fixed, could

lead to casing damage and to wellbore loss.

In Example 3, the temperature survey was taken during

well shut-in condition in an OHGP completion. Abnormal

temperature in a shallow interval was observed.

This well was identified as a potential shallow hazard case.

Further investigation is needed to identify the cause.

For this survey, a retrievable pre-installed fiber tube was

not used. The fiber tube was run through the production tubing

and pulled out on completion of the survey.

In Example 4, a retrievable fiber tube is used as in the

previous example to record temperature data in a steam

injector well. The basic purpose again was to determine any

shallow steam-zone presence. As in example 1 (well A), the

wellbore was cooled down by pumping water and observing

the temperature profile during shut-in condition. Notice the

high temperature peak below the casing shoe, which is above

the actual steam injection interval.

Once again, this wellbore condition requires further

investigation to identify the cause of its effects.

Economic Analysis

The survey will collect temperature data that can be used to

manage heat in the ground, mitigate steam breakthroughs,

eruption, and identify areas of bypassed oil.

The economic values of fiber-optic survey in production

and observation wells are broken down into four categories:

1. steam optimization,

2. profile improvement,

3. steam isolation, and

4. eruption/shallow hazard mitigation.

All areas in DSF use fiber optic data to identify steam zone

development and upswept zones and also to identify steam

breakthrough zones in production wells. Based on fiber optic

data and other surveillance data such as krypton and 4Dseismic, the engineers conduct on average 135-profile

improvement works (shut off steam zones and reperforate cold

zones) in injection wells and 32 steam isolation jobs in

production wells per year.

Temperature surveys are also used to prevent and control

surface eruptions of steam. During a steam eruption, nearby

observation and production wells are surveyed to identify

steam migration into shallow sand.

Conclusions

1. Fiber optic technology with a DTS system and singleended installation is applicable for determining the

realtime temperature profile in Duri Steam Flood

production wells. Use of the technology has shown a

significant improvement in understanding of steam

breakthrough zones along the pay zone interval of

production wells.

2. Fiber-optic technology through the DTS system using

fiber tube is also applicable to processes run to determine

the temperature profile in observation wells. These

surveys can identify steam zone development and

upswept zones in the pattern.

3. Survey results from this work indicated very identifiable

temperature anomalies over very small temperature

changes. Therefore, real time temperature profile with

other surveillance data provide valuable information for

steam breakthrough management on a layer-by-layer basis

and eruption mitigation. Thus, well integrity can be

maintained if remedial measures are taken in time.

Acknowledgment

The author wishes to thank the management of PT Caltex

Pacific Indonesia and Halliburton Energy Services, Inc. for

their permission and encouragement to write and present this

paper.

Nomenclature

BOPD

CHGP

CPI

CHFP

DSF

EOR

OHGP

WHT

BSPD

DTS

TVD

= Barrel Oil per Day

= Cased Hole Gravel Pack

= Caltex Pacific Indonesia

= Cased Hole Frac Pack

= Duri Steam Flood

= Enhanced Oil Recovery

= Open Hole Gravel Pack

= Well Head Temperature

= Barrel Steam per Day

= Distributed Temperature Sensing

= True Vertical Depth

References

1. D.O Johnson, Pruett Industries and Riki Sugianto, Caltex Pacific

Indonesia: Identification of Steam Breakthrough Intervals

Using DTS Technology, paper SPE 77460 presented at the

2002 SPE Annual Technical Conference and Exhibition held in

San Antonio, Texas, 29 September-2 October 2002.

2. Sigit, R., Satriana, D., Peifer, J.P., and Linawati, A.: Seismically

Guided Bypassed Oil Identification in A Matured Steamflood

Area, Duri Field, Sumatra, Indonesia, paper SPE 57261

presented at the 1999 SPE Asia Pacific Improved Oil Recovery

Conference held in Kuala Lumpur, Malaysia, 25-26 October

1999.

D.K. NATH

SPE 93240

Malaysia

Singapore

Future Wells

Existing Area on

Steam Flood

Sumatra

Java

N

Figure 1 - Duri Steam Flood Location Map

SPE 93240

FIBER OPTIC USED TO SUPPORT RESERVOIR TEMPERATURE SURVEILLANCE IN DURI STEAM FLOOD

Figure 2 Conventional Completion methods used to control sand production

D.K. NATH

SPE 93240

400

Base Line

09:58

300

Wellbore during cool

down by pumping water

through the annulus

and casing

Base-line Temp

taken while well is

on production

10:02

10:03

10:05

200

10:06

10:08

10:10

647 -

csg shoe @ 243'

567 -

549' -

375' -

100

355' -

Temperature (oF)

10:04

10:14

0

0

100

200

300

400

Depth (ft)

Example 1 Well A

500

600

700

SPE 93240

FIBER OPTIC USED TO SUPPORT RESERVOIR TEMPERATURE SURVEILLANCE IN DURI STEAM FLOOD

400

10:15

10:16

10:19

10:21

10:23

10:26

Steam breakthrough

interval

300

10:29

10:34

10:45

10:49

10:55

200

11:00

11:10

11:19

POP 11:21

11:25

11:30

100

647 - 666

567 - 596'

549' - 562'

csg shoe @ 243'

375' - 392'

355' - 361'

11:40

11:45

11:50

12:00

12:20

12:45

0

0

100

200

300

400

500

600

700

Depth (ft)

Example 2 Well A

350

10:44

10:45

Steam breakthrough from

squeeze perforation interval

(used for improving bonding)

10:46

10:47

10:49

10:51

10:54

10:58

250

11:01

11:04

Temperature (oF)

11:14

11:16

11:20

11:24

11:31

11:36

11:48

150

12:02

12:26

12:50

PBTD 731'

TBA @ 463'

Temperature (oF)

10:40

POP 13:06

13:10

13:18

13:20

13:34

50

0

100

200

300

400

500

Depth (ft)

Example 2 Well B

600

700

800

D.K. NATH

SPE 93240

Base Line

6:11

Abnormal temperature

profile at a very

shallow interval in a

producer well.

250

6:39

Temperature (oF)

6:49

9:35

9:42

9:48

150

9:51

9:55

6:46

6:49

50

0

100

200

300

400

500

600

Depth (ft)

Example 3 - Well C Base Line & Shut-in Survey

700

800

SPE 93240

FIBER OPTIC USED TO SUPPORT RESERVOIR TEMPERATURE SURVEILLANCE IN DURI STEAM FLOOD

550

17:36

17:37

17:38

450

Shallow Steam zone

below casing shoe in

an injector well

17:39

17:40

17:42

17:44

17:45

250

17:46

17:47

150

17:48

PBTD 540'

Perforation

584'-595'

595'-602'

616'-624'

624'-630'

643'-647'

652'-663'

664'-675'

675'-687'

689'-690'

Temperature (oF)

17:41

350

17:49

17:50

17:52

50

0

100

200

300

400

500

Depth (ft)

Example 4 - Well D

600

700

800

Das könnte Ihnen auch gefallen

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesVon EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- QO390-SS200025 Technical Sheet (Actuated On Off Valve & RESDVForel Bronang)Dokument2 SeitenQO390-SS200025 Technical Sheet (Actuated On Off Valve & RESDVForel Bronang)Iqbal MatondangNoch keine Bewertungen

- Pertamina PitchDokument20 SeitenPertamina Pitchsupport busdevNoch keine Bewertungen

- Fpso Anoa Natuna - Modec Fpso - Fso ProjectDokument2 SeitenFpso Anoa Natuna - Modec Fpso - Fso ProjectjeffreymacaseroNoch keine Bewertungen

- Petroleum Geology (Fieldtrip) of Cepu AreaDokument31 SeitenPetroleum Geology (Fieldtrip) of Cepu AreaPradipta Gora KusumaNoch keine Bewertungen

- 10 Combine Foundation Layout Overall Layout Field Sukowati Pad A&bDokument6 Seiten10 Combine Foundation Layout Overall Layout Field Sukowati Pad A&bDimas FirmanNoch keine Bewertungen

- PETRONAS Group of Companies 2019Dokument7 SeitenPETRONAS Group of Companies 2019Din ThorpeNoch keine Bewertungen

- 04.layout Oral PresentationDokument2 Seiten04.layout Oral PresentationDoni SujanaNoch keine Bewertungen

- Acid Gas Treatment - PT. Gasuma PDFDokument1 SeiteAcid Gas Treatment - PT. Gasuma PDFalfipincukNoch keine Bewertungen

- PDFDokument162 SeitenPDFMuslim SiregarNoch keine Bewertungen

- Maintaining The Oil Andgas Production ofWKSanga SangaDokument1 SeiteMaintaining The Oil Andgas Production ofWKSanga SangaEliyanto E BudiartoNoch keine Bewertungen

- Target Issuance 30 May 2023Dokument4 SeitenTarget Issuance 30 May 2023Achmad OktafionoNoch keine Bewertungen

- Form PQDokument33 SeitenForm PQFerlianto Dwi PutraNoch keine Bewertungen

- Meeting Mingguan Pembangunan Epf Lokasi Jati Asri, Akasia Bagus Dan Bambu BesarDokument38 SeitenMeeting Mingguan Pembangunan Epf Lokasi Jati Asri, Akasia Bagus Dan Bambu BesarAditya FathurachmanNoch keine Bewertungen

- SPE 54369 Sepinggan Field Development: A Cross-Functional Team Effort To Develop Bypassed Attic OilDokument12 SeitenSPE 54369 Sepinggan Field Development: A Cross-Functional Team Effort To Develop Bypassed Attic OilHeru Dewanto100% (1)

- Proposed Rate Service: Construction of Sukowati Pad #C Well PadDokument11 SeitenProposed Rate Service: Construction of Sukowati Pad #C Well PadReza WahyuantoNoch keine Bewertungen

- Update Procedure PECIKO 8Dokument1 SeiteUpdate Procedure PECIKO 8Ferdie OSNoch keine Bewertungen

- Gas For Energy Transition: Presented at High Level Summit On Human Capital Development Toward Net Zero EmissionDokument12 SeitenGas For Energy Transition: Presented at High Level Summit On Human Capital Development Toward Net Zero Emissionmineral geologistNoch keine Bewertungen

- Recovering Gas From Low Pressure Gas Wells PDFDokument9 SeitenRecovering Gas From Low Pressure Gas Wells PDFAZZAF ChannelNoch keine Bewertungen

- Bentu and Korinci PSCDokument1 SeiteBentu and Korinci PSCSuhendraNoch keine Bewertungen

- 2 PPT Sumpal Compression Project Copy PasteDokument6 Seiten2 PPT Sumpal Compression Project Copy PasteboypardedeNoch keine Bewertungen

- F13EDR-A F13WDR-A: E11 Hub Development SchematicDokument2 SeitenF13EDR-A F13WDR-A: E11 Hub Development SchematicAgam Duma Kalista WibowoNoch keine Bewertungen

- Black Platinum Energy Announces Preparation of The Dara East Gas Field PPoD in The North Sokang PSCDokument3 SeitenBlack Platinum Energy Announces Preparation of The Dara East Gas Field PPoD in The North Sokang PSCWahyudin IlyasNoch keine Bewertungen

- Maleevat 2013Dokument11 SeitenMaleevat 2013cmkohNoch keine Bewertungen

- BMH-FED-SYN-00-L0-DS-001 - Datasheet For Manual Valve - Rev A - ANDokument20 SeitenBMH-FED-SYN-00-L0-DS-001 - Datasheet For Manual Valve - Rev A - ANAfif FadhliNoch keine Bewertungen

- Spe Workshop: Brownfield Optimisation and Marginal Asset DevelopmentDokument20 SeitenSpe Workshop: Brownfield Optimisation and Marginal Asset DevelopmentPrimaresa UtamaNoch keine Bewertungen

- Analysis of Sand Transportability in Bekapai Pipelines (Presentation)Dokument15 SeitenAnalysis of Sand Transportability in Bekapai Pipelines (Presentation)Laras Wuri D.Noch keine Bewertungen

- Offshore North West Java (ONWJ) Block at Java Sea - Mande BlogDokument4 SeitenOffshore North West Java (ONWJ) Block at Java Sea - Mande BlogwidiNoch keine Bewertungen

- TSB Gas Development ProjectDokument24 SeitenTSB Gas Development ProjectMarlon Moncada100% (2)

- 2005 - Success Story To Produce 200 MMSCFD Gas From MutiaraDokument5 Seiten2005 - Success Story To Produce 200 MMSCFD Gas From MutiaraRamandaRakaNoch keine Bewertungen

- OGE 60 SmallDokument100 SeitenOGE 60 Smallari wiliamNoch keine Bewertungen

- CASAKHA May 2023Dokument14 SeitenCASAKHA May 2023Aditya Jalasena JiwandhonoNoch keine Bewertungen

- PDFDokument12 SeitenPDFMaya ShankarNoch keine Bewertungen

- Project Execution Strategy (LPG Terminal) 21-11-15Dokument26 SeitenProject Execution Strategy (LPG Terminal) 21-11-15Yosses Sang NahkodaNoch keine Bewertungen

- 2017 Donggi-Senoro LNG PJTDokument15 Seiten2017 Donggi-Senoro LNG PJTproscokeNoch keine Bewertungen

- FORM 137 Document FrontDokument2 SeitenFORM 137 Document FrontJocelyn Che Che PanerNoch keine Bewertungen

- TS 6 - 1 Popi A. NafisDokument14 SeitenTS 6 - 1 Popi A. NafisAsep FirmansyahNoch keine Bewertungen

- Kakap PSCDokument2 SeitenKakap PSCAulia FadhinaNoch keine Bewertungen

- Outstanding IssuesDokument4 SeitenOutstanding IssuesYoga RiKumoroNoch keine Bewertungen

- ListDokument155 SeitenListarisNoch keine Bewertungen

- 5004 Mechel Suban Phase 2 Gas PlantDokument1 Seite5004 Mechel Suban Phase 2 Gas PlantYoga Septefa NurisNoch keine Bewertungen

- SO Jasa Survey Topografi Lahan Sumur Kinanti - 5Dokument2 SeitenSO Jasa Survey Topografi Lahan Sumur Kinanti - 5ajaemma288Noch keine Bewertungen

- Final PresentationDokument39 SeitenFinal PresentationReinaldo Ongky Billy AnandoNoch keine Bewertungen

- Ateneo Grade School - Schedule of T&F For SY23-24 v2Dokument1 SeiteAteneo Grade School - Schedule of T&F For SY23-24 v2Richard Joseph DoriaNoch keine Bewertungen

- Madura BD Gas and Condensate Field Development - Offshore Technology - Oil and Gas News and Market Analysis PDFDokument13 SeitenMadura BD Gas and Condensate Field Development - Offshore Technology - Oil and Gas News and Market Analysis PDFbobyNoch keine Bewertungen

- Work Schedule Cleaning TANKER - PT AKR NILAMDokument1 SeiteWork Schedule Cleaning TANKER - PT AKR NILAMnhariwijayaNoch keine Bewertungen

- Overview Kerja PraktekDokument42 SeitenOverview Kerja PraktekAmanda Talia LumentutNoch keine Bewertungen

- RDMP Ru V Balikpapan: Piping and Instrument Diagram Plant No. 8 - Hydrogen Unit Battery Limits Process LinesDokument1 SeiteRDMP Ru V Balikpapan: Piping and Instrument Diagram Plant No. 8 - Hydrogen Unit Battery Limits Process Linesdian yuristiaNoch keine Bewertungen

- Arun Daniel Purba PresentationDokument14 SeitenArun Daniel Purba PresentationIlham HakimNoch keine Bewertungen

- Integrated Assurance - Checklist DetailsDokument438 SeitenIntegrated Assurance - Checklist DetailsSyed AhmadNoch keine Bewertungen

- Completamiento AngsiDokument8 SeitenCompletamiento Angsimafe_0830Noch keine Bewertungen

- Ucc 900 Sor em Wpi 0001 - B01Dokument73 SeitenUcc 900 Sor em Wpi 0001 - B01JonesNoch keine Bewertungen

- Lay Out Plan Rig Nyt#08 Akatara#2Dokument2 SeitenLay Out Plan Rig Nyt#08 Akatara#2Bayu SaputraNoch keine Bewertungen

- Fsru BaliDokument56 SeitenFsru Balimahera wijaksaraNoch keine Bewertungen

- Schematic Diagram NSB-NSODokument18 SeitenSchematic Diagram NSB-NSOandriNoch keine Bewertungen

- Worldwide Production: - Offshore (C) CondensateDokument48 SeitenWorldwide Production: - Offshore (C) Condensatembw0000123780% (1)

- Company Profile PT - PHE-WMODokument30 SeitenCompany Profile PT - PHE-WMOHendri Anur100% (2)

- SPE-187441-MS Improved Monitoring System For Heavy Oil SAGD WellsDokument14 SeitenSPE-187441-MS Improved Monitoring System For Heavy Oil SAGD WellsalexlakimikapestaNoch keine Bewertungen

- Spe 174521 MSDokument17 SeitenSpe 174521 MSDavid MontoyaNoch keine Bewertungen

- 1956 - Colinese - Boiler Efficiencies in SugarDokument7 Seiten1956 - Colinese - Boiler Efficiencies in SugarPaul DurkinNoch keine Bewertungen

- Chapter - 01 Geography The Earth in The Solar SystemDokument10 SeitenChapter - 01 Geography The Earth in The Solar SystemKarsin ManochaNoch keine Bewertungen

- Plasterboard FyrchekDokument4 SeitenPlasterboard FyrchekAlex ZecevicNoch keine Bewertungen

- Water Quality MonitoringDokument3 SeitenWater Quality MonitoringJoa YupNoch keine Bewertungen

- 311762en WDokument36 Seiten311762en WOprisor CostinNoch keine Bewertungen

- An1914 PDFDokument56 SeitenAn1914 PDFUpama Das100% (1)

- Youth and Moral ValuesDokument6 SeitenYouth and Moral ValuesAlka SinghNoch keine Bewertungen

- Agribusiness Magazine August 2019 EditionDokument42 SeitenAgribusiness Magazine August 2019 EditiondowntopNoch keine Bewertungen

- Learner Cala Guide: PART A: Identification of Knowledgeable Elderly Part BDokument5 SeitenLearner Cala Guide: PART A: Identification of Knowledgeable Elderly Part BPrimrose MurapeNoch keine Bewertungen

- Syllabus (2020) : NTA UGC-NET Computer Science and ApplicationsDokument24 SeitenSyllabus (2020) : NTA UGC-NET Computer Science and ApplicationsDiksha NagpalNoch keine Bewertungen

- ĐÁP ÁN ĐỀ THI THỬ SỐ 03 (2019-2020)Dokument8 SeitenĐÁP ÁN ĐỀ THI THỬ SỐ 03 (2019-2020)Đào VânNoch keine Bewertungen

- Boomer L2 D - 9851 2586 01Dokument4 SeitenBoomer L2 D - 9851 2586 01Pablo Luis Pérez PostigoNoch keine Bewertungen

- Practical Econometrics Data Collection Analysis and Application 1st Edition Hilmer Test BankDokument27 SeitenPractical Econometrics Data Collection Analysis and Application 1st Edition Hilmer Test Bankdavidhallwopkseimgc100% (28)

- Bearing Repeater CompassDokument4 SeitenBearing Repeater CompassJohn PerdyNoch keine Bewertungen

- Internet in My LifeDokument4 SeitenInternet in My LifeАндріана ПрусNoch keine Bewertungen

- Holiday Assignment (Dussehra Vacation) - 2022-23Dokument3 SeitenHoliday Assignment (Dussehra Vacation) - 2022-23yogeshNoch keine Bewertungen

- Pay Scale WorkshopDokument5 SeitenPay Scale WorkshopIbraNoch keine Bewertungen

- Week 5 Teradata Practice ExerciseDokument14 SeitenWeek 5 Teradata Practice ExerciseWooyeon ChoNoch keine Bewertungen

- REF615 PG 756379 ENs PDFDokument96 SeitenREF615 PG 756379 ENs PDFandi mulyanaNoch keine Bewertungen

- Development and Application of "Green," Environmentally Friendly Refractory Materials For The High-Temperature Technologies in Iron and Steel ProductionDokument6 SeitenDevelopment and Application of "Green," Environmentally Friendly Refractory Materials For The High-Temperature Technologies in Iron and Steel ProductionJJNoch keine Bewertungen

- Rastriya Swayamsewak SanghDokument60 SeitenRastriya Swayamsewak SanghRangam Trivedi100% (3)

- SOP For Production DepartmentDokument5 SeitenSOP For Production DepartmentDaniel SusantoNoch keine Bewertungen

- Free DMAIC Checklist Template Excel DownloadDokument5 SeitenFree DMAIC Checklist Template Excel DownloadErik Leonel LucianoNoch keine Bewertungen

- GEODynamics CONNEX Brochure 2008.10 - Rev2 Final PDFDokument12 SeitenGEODynamics CONNEX Brochure 2008.10 - Rev2 Final PDFSusin LimNoch keine Bewertungen

- Theories of GrowthDokument33 SeitenTheories of Growthdr parveen bathlaNoch keine Bewertungen

- MC-8002 Mixer 2Dokument1 SeiteMC-8002 Mixer 2JAIDEV KUMAR RANINoch keine Bewertungen

- Ga-Ta10 (LHH)Dokument181 SeitenGa-Ta10 (LHH)Linh T.Thảo NguyễnNoch keine Bewertungen

- Final Report of BBSMDokument37 SeitenFinal Report of BBSMraazoo1967% (9)

- 1st Quarter 2016 Lesson 5 Powerpoint With Tagalog NotesDokument25 Seiten1st Quarter 2016 Lesson 5 Powerpoint With Tagalog NotesRitchie FamarinNoch keine Bewertungen

- PmtsDokument46 SeitenPmtsDhiraj ZanzadNoch keine Bewertungen

- D2165151-003 Preliminary SGRE ON SG 6.0-170 Site Roads and HardstandsDokument46 SeitenD2165151-003 Preliminary SGRE ON SG 6.0-170 Site Roads and HardstandsMarcelo Gonçalves100% (1)

- ICH Quality Guidelines: An Implementation GuideVon EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNoch keine Bewertungen

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsVon EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsBewertung: 5 von 5 Sternen5/5 (3)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactVon EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactBewertung: 5 von 5 Sternen5/5 (5)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincVon EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincBewertung: 3.5 von 5 Sternen3.5/5 (137)

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideVon EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideNoch keine Bewertungen

- Chemistry for Breakfast: The Amazing Science of Everyday LifeVon EverandChemistry for Breakfast: The Amazing Science of Everyday LifeBewertung: 4.5 von 5 Sternen4.5/5 (14)

- AP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeVon EverandAP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeBewertung: 5 von 5 Sternen5/5 (1)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeVon EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeBewertung: 5 von 5 Sternen5/5 (4)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactVon EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactBewertung: 5 von 5 Sternen5/5 (1)

- It's Elemental: The Hidden Chemistry in EverythingVon EverandIt's Elemental: The Hidden Chemistry in EverythingBewertung: 4 von 5 Sternen4/5 (10)

- Chemistry: a QuickStudy Laminated Reference GuideVon EverandChemistry: a QuickStudy Laminated Reference GuideBewertung: 5 von 5 Sternen5/5 (1)

- Guidelines for Defining Process Safety Competency RequirementsVon EverandGuidelines for Defining Process Safety Competency RequirementsBewertung: 3 von 5 Sternen3/5 (1)

- AP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeVon EverandAP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeNoch keine Bewertungen

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeVon EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeBewertung: 4 von 5 Sternen4/5 (1)

- The Production of Volatile Oils and Perfumery Plants in the United StatesVon EverandThe Production of Volatile Oils and Perfumery Plants in the United StatesNoch keine Bewertungen

- Essential Chemistry for Formulators of Semisolid and Liquid DosagesVon EverandEssential Chemistry for Formulators of Semisolid and Liquid DosagesBewertung: 5 von 5 Sternen5/5 (2)

- Taste: Surprising Stories and Science About Why Food Tastes GoodVon EverandTaste: Surprising Stories and Science About Why Food Tastes GoodBewertung: 3 von 5 Sternen3/5 (20)

- The Nature of Drugs Vol. 2: History, Pharmacology, and Social ImpactVon EverandThe Nature of Drugs Vol. 2: History, Pharmacology, and Social ImpactNoch keine Bewertungen

- Hazardous Materials Transportation: A Guide to Success for Environmental, Health, & Safety Students and ProfessionalsVon EverandHazardous Materials Transportation: A Guide to Success for Environmental, Health, & Safety Students and ProfessionalsNoch keine Bewertungen