Beruflich Dokumente

Kultur Dokumente

Product Characteristics Classification

Hochgeladen von

80ALLA86iCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Product Characteristics Classification

Hochgeladen von

80ALLA86iCopyright:

Verfügbare Formate

KSS Global Standard

Product Characteristic Classification

KSS GLOBAL STANDARD

Product Characteristics Classification

(CC/SC Standard)

KSS 050

Document No: 1033079

Authors:

Gnther Hilbich

Approved by:

Andreas Staub

Approved by:

Dieter Hahn

Document History

Revision:

Release Date

ECP No.

Modification

Changed wording from Guideline to Standard

Removed Scarpa and Jost as Approvers

3

2

2 Mar 2012

50982

5.1- Note deleted; 5.2: Owners of CC/SC list columns

corrected; 5.4.2: D- FMEA added; 7: Attachment 2 added;

22 Sep 2011

47830

Fully revised standard

Doc. No: 1033079 Rev. 3

Page 1 of 9

Uncontrolled copy printed: 06-Dec-2012

(KSS template no. 1033844 Rev. 2)

KSS Global Standard

Product Characteristic Classification

Table of Content

INTRODUCTION ................................................................................................................................................. 3

1

PURPOSE................................................................................................................................................... 3

SCOPE........................................................................................................................................................ 3

RESPONSIBILITY ...................................................................................................................................... 3

DEFINITIONS / ABBREVIATIONS ............................................................................................................ 3

DETERMINATION OF SPECIAL CHARACTERISTICS ............................................................................ 4

REFERENCES (RELATED DOCUMENTS) ............................................................................................... 9

APPENDICES ............................................................................................................................................. 9

Doc. No: 1033079 Rev. 3

Page 2 of 9

Uncontrolled copy printed: 06-Dec-2012

(KSS template no. 1033844 Rev. 2)

KSS Global Standard

Product Characteristic Classification

Introduction

This KSS Standard outlines requirements for how to control potential risks related to

product and process through the identification and management of special product

and process characteristics (named Critical Characteristics and Significant

Characteristics).

Purpose

The purpose of this standard is to facilitate and to harmonize the use of special

characteristics within drawings and other documentation throughout the KSS group.

It explains the management and handling of special characteristics to fulfill

functional and regulatory requirements.

Scope

All KSS sites, organizations, and suppliers must adhere to this standard.

Responsibility

The Engineering Manager or Director of each KSS engineering department is

responsible to ensure that the CC/SC standard is followed, monitored and

observed during development.

The Product Engineer is responsible to define the CC/SC for all engineering

documentation associated with development for the assigned programs.

The Quality Manager/ Director is responsible to ensure that requirements defined in

this standard are implemented.

The Procurement Director and Director of Supplier Quality are responsible to

communicate this standard and enforce compliance at the supplier level.

Definitions / Abbreviations

A characteristic is a dimension or a physical, chemical, electrical, mechanical or

visual property. A characteristic must be measurable, either directly or indirectly,

either variable or attribute.

Attribute characteristics are qualitative data that is measured or checked and

results in conformance or non-conformance, pass or fail.

Doc. No: 1033079 Rev. 3

Page 3 of 9

Uncontrolled copy printed: 06-Dec-2012

(KSS template no. 1033844 Rev. 2)

KSS Global Standard

Product Characteristic Classification

Variable characteristics are quantitative data which can be measured, and the

result is an absolute measurement reading eg. Millimeters, Inches, Newtons, etc.

There are two different types of special characteristics:

Critical Characteristics (CC)

are product characteristics that may affect the

safety of product or operator

compliance with legal requirements

environmental requirements.

These characteristics are designated in the D- or PFMEA, having a causal

relationship to the effect of potential failure modes rated 9-10 for severity.

Significant Characteristics (SC)

are product characteristics that may affect

form, fit or function of the product

the production (assembly) process

These characteristics are designated in the D- or PFMEA having a causal

relationship to the effect of potential failure modes rated 5-8 for severity, or where

agreed by the cross-functional team, having severity rated less than 5.

SC characteristics may be influenced by the manufacturing process (KSS and/or

suppliers) and may require special control to maintain the required process

capability and customer requirements.

Determination of Special Characteristics

5.1

Identification

Source of special

characteristics

Criteria

Outcome

DFMEA

Severity rating = 9, 10

CC

DFMEA

Severity Rating = 5 8

Occurrence= 4-10

Severity rating = 9, 10

SC

PFMEA

PFMEA

Severity Rating = 5 8

Occurrence = 4 10

Customer or internal

requirements

Legal, environmental

requirements

Doc. No: 1033079 Rev. 3

CC

SC

CC or SC

CC

Page 4 of 9

Uncontrolled copy printed: 06-Dec-2012

(KSS template no. 1033844 Rev. 2)

KSS Global Standard

Product Characteristic Classification

5.2

CC/SC List

Each DFMEA/PFMEA requires a CC/SC list as a controlled document (see

appendix) and is to be understood as a subset of the DFMEA.

The purpose of the CC/SC list is to monitor and assure that all special

characteristics are effectively controlled and documented during development and

ongoing production. It is a mandatory document and shall be used for each product.

Task

Responsible

Owner of the CC/SC List *)

List all CC/SC (column A- I)

Input of data (column J-M )KSS Process

Input of Data (components level) (column N-R)

Input of data (module level) ( column N- R)

Product Engineer

Product Engineer

Process Engineer

SQE

SQA, (SQE)

*): In case of not timely deliverable of data, immediate escalation to Program

Manager (PM) is indicated. PM to escalate latest in TG review.

5.3

Control of CC/SC

5.3.1 During Development

All special characteristics determined as CC/SC during FMEA process shall

be carried forward to the CC/SC list, the drawings, the control plans, and to

standard work instructions.

All CC/SC shall be verified and validated during Design Validation (DV).

The supplier shall evaluate and implement the measurement method

approved by KSS and other appropriate controls on characteristics related to

their processes.

The supplier shall evaluate their processes and further identify, document,

and control additional contributing characteristics.

All CC/SC shall be verified prior to any DV or customer builds.

5.3.2 During PPAP and Product Validation (PV)

All CC/SC on the drawings, control plans and other documents shall be

referenced in the PPAP documentation and proven capable.

Process capability must be proven for each special characteristic

If capability cannot be demonstrated, 100% check must be performed

with proven detection of non-compliance

If this is not possible other methods must be applied (e.g Poka-yoke)

Compliance of attribute characteristics can be proven by using a

certificate.

Doc. No: 1033079 Rev. 3

Page 5 of 9

Uncontrolled copy printed: 06-Dec-2012

(KSS template no. 1033844 Rev. 2)

KSS Global Standard

Product Characteristic Classification

The initial process capability study is to evaluate:

The conformity of characteristics to the specified requirement and the

effect of tool/process variation on these characteristics.

If material is identified as a CC a material certificate must be included in

PPAP submission and must be available for each batch/lot during mass

production.

Capability studies shall be performed according to the AIAG manual

Statistical Process Control (SPC), and measurement equipment shall be

proven acceptable according to the AIAG manual Measurement Systems

Analysis (MSA)/ ISO/TS 16949, latest editions.

Suppliers shall demonstrate their ability to perform capable measurement of

special characteristics according to methods agreed by KSS.

Evidence shall be provided during supplier APQP process.

5.3.3 During Serial Production

All CC/SC on the drawings, D- and PFMEA, and/or specifications shall be

verified during serial production and reflected in approved control plans.

5.4

CC/SC List Management

5.4.1 All CC/SC lists shall be written in English. Dual language (local language and

English) can be applied as applicable.

5.4.2 Distribution of the complete CC/SC list data outside of KSS (customer or supplier)

is prohibited, as well as D- and PFMEA, but can be presented upon request. The

supplier shall be provided with the CC/SC list for his component.

5.5

Documentation of Special Characteristics

CC/SCs must be marked on the drawing according to the global KSS drafting

standard.

General numbering of characteristics (dimensions)

or

Doc. No: 1033079 Rev. 3

Page 6 of 9

Uncontrolled copy printed: 06-Dec-2012

(KSS template no. 1033844 Rev. 2)

KSS Global Standard

Product Characteristic Classification

5.6

Table on the drawing specifying the identification number of the characteristics

Some more examples

Documentation/Record retention

All documents referring to special characteristics shall be written in English or in

dual language (local language and english)

Record Retention is mandatory for each document and/or report referring to

special characteristics.

Doc. No: 1033079 Rev. 3

Page 7 of 9

Uncontrolled copy printed: 06-Dec-2012

(KSS template no. 1033844 Rev. 2)

KSS Global Standard

Product Characteristic Classification

5.7

Summary and FAQ

CC

1

When to apply a CC/ SC

Is a deviation approval

possible in case out of

spec.?

For new design and new

tool after 31 Oct 2011

Evidence for PPAP

approval

3

3.1

3.2

Evidence in serial

production

Existing design or tools

before 31 Oct. 2011

Evidence for PPAP

approval

4.1

Doc. No: 1033079 Rev. 3

SC

Affects product and

operator safety and/or

compliance with

regulatory requirements.

No

Affects product form, fit

or function (other than

safety and regulatory) or

has other valid reasons

to classify significant

Yes, temporarily

Initial capability Ppk>2.0

or

Poka-Yoke

or

100% detection

If the CC applies to

material, a material

certificate is required

Continuous capability

Cpk >1.67, if verification

indicated by SPC

(Statistical Process

Control)

or

Poka-Yoke

or

100% detection

If the CC applies to

material, a material

certificate is required on

request.

Init. capability Ppk >1.67

or

Poka-Yoke

or

100% detection

(material spec. applies to

CC classification)

Continuous capability

Cpk >1.33, if verification

indicated by SPC

(Statistical Process

Control)

or

Poka-Yoke

or

100% detection

(material spec applies to

CC classification)

Initial capability Ppk>1,67 Init. capability Ppk >1.33

or

or

Poka-Yoke

Poka-Yoke

or

or

100% detection

100% detection

If the CC applies to

(material spec. applies to

material, a material

CC classification)

certificate is required

Page 8 of 9

Uncontrolled copy printed: 06-Dec-2012

(KSS template no. 1033844 Rev. 2)

KSS Global Standard

Product Characteristic Classification

4.2

Evidence in serial

production

Continuous capability

Cpk >1.33, if verification

indicated by SPC

(Statistical Process

Control)

or

Poka-Yoke

or

100% detection

If the CC applies to

material, a material

certificate is required on

request.

Continuous capability

Cpk >1.33, if verification

indicated by SPC

(Statistical Process

Control)

or

Poka-Yoke

or

100% detection

(material spec

applies to CC

classification)

References (Related Documents)

- KSS Quality First Manual

- KSS Global Drafting Standard

Appendices

1: CC/SC list template (Doc. No:1033080)

2: List of CC/SC Symbols (Doc. No:1011538)

Doc. No: 1033079 Rev. 3

Page 9 of 9

Uncontrolled copy printed: 06-Dec-2012

(KSS template no. 1033844 Rev. 2)

Das könnte Ihnen auch gefallen

- Fmea Alignment Aiag and VdaDokument14 SeitenFmea Alignment Aiag and Vdahaitem100% (1)

- Seminar On Statistical Process Control On Cylinder LinersDokument56 SeitenSeminar On Statistical Process Control On Cylinder LinersSatadru BeraNoch keine Bewertungen

- CEM 515 SPC Quiz Student Name: - Student NoDokument2 SeitenCEM 515 SPC Quiz Student Name: - Student NodjNoch keine Bewertungen

- Design Failure Mode and Effect Analysis - Case StuDokument13 SeitenDesign Failure Mode and Effect Analysis - Case Stusanjay chamoliNoch keine Bewertungen

- Peration Anagement: Concept of Quality Juran's PrincipleDokument24 SeitenPeration Anagement: Concept of Quality Juran's PrincipleAyushi BisenNoch keine Bewertungen

- Effects of Radiation On PlantsDokument35 SeitenEffects of Radiation On PlantsOkaroFrankNoch keine Bewertungen

- Legal Concerns in Drafting A Policy For Reporting FraudDokument6 SeitenLegal Concerns in Drafting A Policy For Reporting FraudFrancisco BraganzaNoch keine Bewertungen

- Basic Business Statistics: Statistical Applications in Quality and Productivity ManagementDokument67 SeitenBasic Business Statistics: Statistical Applications in Quality and Productivity ManagementToufiq Khan MajlisNoch keine Bewertungen

- PCP & FmeaDokument4 SeitenPCP & FmeaDaniela AscolaniNoch keine Bewertungen

- Xfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following FormsDokument6 SeitenXfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following FormsRoland JoldisNoch keine Bewertungen

- IATF Rules 5th Edition - FAQs 1 3 - 23jan2017 - FINAL PDFDokument6 SeitenIATF Rules 5th Edition - FAQs 1 3 - 23jan2017 - FINAL PDFsathyabalaramanNoch keine Bewertungen

- The 5-Whys' Method: Example 1Dokument3 SeitenThe 5-Whys' Method: Example 1initiative1972Noch keine Bewertungen

- Communication On Progress (Cop) : The Ten Principles of The United Nations Global CompactDokument46 SeitenCommunication On Progress (Cop) : The Ten Principles of The United Nations Global CompactVikrant KambleNoch keine Bewertungen

- PFD, Pfmea & CPDokument482 SeitenPFD, Pfmea & CPnadi gobinda0% (1)

- G3 1 Index and ChecklistDokument123 SeitenG3 1 Index and ChecklistWendy Al SyabanaNoch keine Bewertungen

- Cause & Effect TypesDokument5 SeitenCause & Effect TypesArun BiswalNoch keine Bewertungen

- 15 Mistake ProofingDokument4 Seiten15 Mistake ProofingSteven Bonacorsi100% (2)

- Cost of QualityDokument10 SeitenCost of QualityPatricia MandiNoch keine Bewertungen

- Variation and DefectsDokument16 SeitenVariation and DefectssushmaxNoch keine Bewertungen

- MSA (Measurement System Analys)Dokument19 SeitenMSA (Measurement System Analys)Dazslam New VersionNoch keine Bewertungen

- QSG Quality Support Group Angelo Scangas Laura Halleck AIAG VDA FMEA IEEEDokument35 SeitenQSG Quality Support Group Angelo Scangas Laura Halleck AIAG VDA FMEA IEEEEvandro MinatoNoch keine Bewertungen

- Common Cause Failure Analysis of EUROMAC SLITTING MachineDokument10 SeitenCommon Cause Failure Analysis of EUROMAC SLITTING MachineKhuzaima AbidNoch keine Bewertungen

- Apqp MiniDokument14 SeitenApqp MiniSudhagarNoch keine Bewertungen

- Repeatability and Reproducibility StudyDokument4 SeitenRepeatability and Reproducibility Studysivaseeni100% (1)

- AS9100 Quality Manual: Origination Date: January 25, 2007Dokument37 SeitenAS9100 Quality Manual: Origination Date: January 25, 2007Abd ZouhierNoch keine Bewertungen

- Rules 5 Edition Changes Presenter: Mrs. Michelle Maxwell, IAOBDokument20 SeitenRules 5 Edition Changes Presenter: Mrs. Michelle Maxwell, IAOBsmallik3Noch keine Bewertungen

- 2020 Annual Report Melexis enDokument156 Seiten2020 Annual Report Melexis enAnthonyWittendorpNoch keine Bewertungen

- Rms Quality CounterfeitDokument24 SeitenRms Quality CounterfeitFrancis LewahNoch keine Bewertungen

- Are We Doing Well SlidesDokument10 SeitenAre We Doing Well SlidessahajNoch keine Bewertungen

- TS Gap AuditDokument17 SeitenTS Gap Auditputu_adiNoch keine Bewertungen

- Audit Plan 审核计划: To be completed by theDokument3 SeitenAudit Plan 审核计划: To be completed by thegeorge liuNoch keine Bewertungen

- Aiag Fmea TrainingDokument10 SeitenAiag Fmea TrainingJohn OoNoch keine Bewertungen

- IATF Rules 5th Edition Sanctioned Interpretations November 2018Dokument7 SeitenIATF Rules 5th Edition Sanctioned Interpretations November 2018Desmond MahadeoNoch keine Bewertungen

- Work Instruction FOR: Spectro AnalysisDokument3 SeitenWork Instruction FOR: Spectro AnalysismahendraNoch keine Bewertungen

- QA-REC-122 Attiribute MSADokument4 SeitenQA-REC-122 Attiribute MSAsunita choudharyNoch keine Bewertungen

- Work Breakdown Structure (WBS)Dokument4 SeitenWork Breakdown Structure (WBS)Munir A. SakhaniNoch keine Bewertungen

- Risk Management TemplateDokument8 SeitenRisk Management TemplatefroymnNoch keine Bewertungen

- Trailer IATF DocumentsDokument77 SeitenTrailer IATF DocumentsSridharan VenkatNoch keine Bewertungen

- Potential Failure Modes and Effects AnalysisDokument15 SeitenPotential Failure Modes and Effects AnalysisPrakash RanjanNoch keine Bewertungen

- S1 P1 Kiar Ai AngDokument27 SeitenS1 P1 Kiar Ai AngDarren TanNoch keine Bewertungen

- QA Processes, Tools and Metrics: Group 1Dokument18 SeitenQA Processes, Tools and Metrics: Group 1Rhea AgulayNoch keine Bewertungen

- MSA For AttributesDokument54 SeitenMSA For AttributesdesurkarbNoch keine Bewertungen

- CF 601 1 Purchasing Quality Assurance RequirementsDokument3 SeitenCF 601 1 Purchasing Quality Assurance RequirementsTrent CockerhamNoch keine Bewertungen

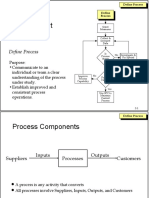

- Basics of Defining ProcessesDokument18 SeitenBasics of Defining ProcessesFaried Putra SandiantoNoch keine Bewertungen

- UDL Pharmaceuticals: (A Division of First UDL Modaraba)Dokument10 SeitenUDL Pharmaceuticals: (A Division of First UDL Modaraba)NesanNoch keine Bewertungen

- SGS CBE ISO 45001 Brochure A4 en InteractiveDokument7 SeitenSGS CBE ISO 45001 Brochure A4 en InteractiveTatiana RiloNoch keine Bewertungen

- Meenakshi Molding Private Limited Process FMEA: O C C U RDokument4 SeitenMeenakshi Molding Private Limited Process FMEA: O C C U Rilaya raja100% (1)

- SPCDokument49 SeitenSPCJosephi_abbasNoch keine Bewertungen

- Risk Management (MBA General, 1st Semester) by Sir Aftab ParvezDokument17 SeitenRisk Management (MBA General, 1st Semester) by Sir Aftab ParvezAsjad JamshedNoch keine Bewertungen

- Marriage - FMEADokument1 SeiteMarriage - FMEAHariramNoch keine Bewertungen

- ATTRIBUTE MSADokument2 SeitenATTRIBUTE MSADINESHCHOUDHARY880% (1)

- Process Capability - ToolDokument26 SeitenProcess Capability - ToolFouzan SoniwalaNoch keine Bewertungen

- CorrectSPC PresentationDokument90 SeitenCorrectSPC Presentationpkj009Noch keine Bewertungen

- VDA AIAG FMEADokument59 SeitenVDA AIAG FMEA576410% (1)

- Controlling The Assembly Process With The Use of SPCDokument6 SeitenControlling The Assembly Process With The Use of SPCSRIDHAREEE61Noch keine Bewertungen

- As 9100 D AssenceDokument5 SeitenAs 9100 D Assencemhk665Noch keine Bewertungen

- Measurement System AnalysisDokument80 SeitenMeasurement System AnalysisVasant bhoknalNoch keine Bewertungen

- Quality Management System Process A Complete Guide - 2020 EditionVon EverandQuality Management System Process A Complete Guide - 2020 EditionNoch keine Bewertungen

- Quality Management System Software A Complete Guide - 2019 EditionVon EverandQuality Management System Software A Complete Guide - 2019 EditionNoch keine Bewertungen

- Summary of Main Changes For Applicators and SpecifiersDokument20 SeitenSummary of Main Changes For Applicators and Specifiersمحمد مقلدNoch keine Bewertungen

- Sparkle-15 6inch PDFDokument2 SeitenSparkle-15 6inch PDF80ALLA86iNoch keine Bewertungen

- National - Immunization - Schedule PDFDokument3 SeitenNational - Immunization - Schedule PDF80ALLA86iNoch keine Bewertungen

- Aarati SangrahaDokument84 SeitenAarati Sangrahaapi-3764320Noch keine Bewertungen

- 2997 ArtiDokument4 Seiten2997 Artikulkarni278Noch keine Bewertungen

- WhitePaper 120240VACSingleSplitPhaseandMultiWireBranchCircuits PDFDokument6 SeitenWhitePaper 120240VACSingleSplitPhaseandMultiWireBranchCircuits PDFRobNoch keine Bewertungen

- Screw Driver SetsDokument18 SeitenScrew Driver Sets80ALLA86iNoch keine Bewertungen

- Critical ThinkingDokument181 SeitenCritical ThinkingAhmed Ali HNoch keine Bewertungen

- Tariff Amendment Order Eng 3032017Dokument4 SeitenTariff Amendment Order Eng 303201780ALLA86iNoch keine Bewertungen

- Mudras For MeditationDokument14 SeitenMudras For Meditationdeepul_s100% (4)

- Quality Planning ArticleDokument76 SeitenQuality Planning Article80ALLA86iNoch keine Bewertungen

- Bhartiya ScripturesDokument6 SeitenBhartiya ScripturesVande Mataram100% (1)

- Digital Timer: Ordering InformationDokument4 SeitenDigital Timer: Ordering Information80ALLA86iNoch keine Bewertungen

- 12 - Chapter 3 PDFDokument45 Seiten12 - Chapter 3 PDF80ALLA86iNoch keine Bewertungen

- Forging New Generations of EngineersDokument20 SeitenForging New Generations of Engineers80ALLA86iNoch keine Bewertungen

- Delo Syn-Gear HD Chevron 75W90Dokument2 SeitenDelo Syn-Gear HD Chevron 75W9080ALLA86iNoch keine Bewertungen

- With What (Infrastructure) With Who (Personnel) Risk Assessment ModelDokument3 SeitenWith What (Infrastructure) With Who (Personnel) Risk Assessment Model80ALLA86i100% (2)

- Castrol Syngear: Americas DescriptionDokument2 SeitenCastrol Syngear: Americas Description80ALLA86iNoch keine Bewertungen

- Vitamin D Deficiency en inDokument2 SeitenVitamin D Deficiency en in80ALLA86iNoch keine Bewertungen

- FMEA GuidelinesDokument9 SeitenFMEA Guidelines80ALLA86iNoch keine Bewertungen

- FMEA GuidelinesDokument9 SeitenFMEA Guidelines80ALLA86iNoch keine Bewertungen

- Dish Antenna CableDokument2 SeitenDish Antenna Cable80ALLA86iNoch keine Bewertungen

- Automotive World - Battery Award ArticleDokument2 SeitenAutomotive World - Battery Award Article80ALLA86iNoch keine Bewertungen

- Canon LR - FA - MF4750 - V9 - 2 PDFDokument2 SeitenCanon LR - FA - MF4750 - V9 - 2 PDF80ALLA86iNoch keine Bewertungen

- Gripco CatalogueDokument31 SeitenGripco Catalogue80ALLA86iNoch keine Bewertungen

- Bearing Preload of Main Reducer of Rear Drive PDFDokument4 SeitenBearing Preload of Main Reducer of Rear Drive PDF80ALLA86iNoch keine Bewertungen

- Automotive World - Battery Award ArticleDokument2 SeitenAutomotive World - Battery Award Article80ALLA86iNoch keine Bewertungen

- AIAG 2016 CatlogDokument96 SeitenAIAG 2016 Catlog80ALLA86iNoch keine Bewertungen

- AtoZ Benchmarking KendallDokument44 SeitenAtoZ Benchmarking Kendall80ALLA86iNoch keine Bewertungen

- College Invitation Letter - Managedia 2023Dokument2 SeitenCollege Invitation Letter - Managedia 2023Sandeep DeyNoch keine Bewertungen

- BZY Series Tension Meter ManualDokument29 SeitenBZY Series Tension Meter ManualJORGE SANTANDER0% (1)

- Appendicitis Case StudyDokument6 SeitenAppendicitis Case StudyKimxi Chiu LimNoch keine Bewertungen

- Department of Labor: BC Retaining Wall CodeDokument2 SeitenDepartment of Labor: BC Retaining Wall CodeUSA_DepartmentOfLaborNoch keine Bewertungen

- CH 4 Naac PPT 07-12Dokument13 SeitenCH 4 Naac PPT 07-12Arshad MohammedNoch keine Bewertungen

- ProposalDokument17 SeitenProposalKhairul AkmalNoch keine Bewertungen

- UNIT 4 Digital Integrated CircuitsDokument161 SeitenUNIT 4 Digital Integrated CircuitssimhadriNoch keine Bewertungen

- Review of Related Literature and Related StudiesDokument23 SeitenReview of Related Literature and Related StudiesReynhard Dale100% (3)

- AC AMMETER / Moving Iron: Model AECDokument33 SeitenAC AMMETER / Moving Iron: Model AECRoonar Aponte NoaNoch keine Bewertungen

- Kitchen Equipment Handling and Maintaining Standard Procedure and PoliciesDokument2 SeitenKitchen Equipment Handling and Maintaining Standard Procedure and PoliciesChef Chef75% (4)

- Grange Fencing Garden Products Brochure PDFDokument44 SeitenGrange Fencing Garden Products Brochure PDFDan Joleys100% (1)

- Crusher 4Dokument39 SeitenCrusher 4kediliterapiNoch keine Bewertungen

- G2A Glitch DONT LEAK 2Dokument7 SeitenG2A Glitch DONT LEAK 2qDeficiencyNoch keine Bewertungen

- Stating Like and DislikesDokument2 SeitenStating Like and DislikesDavid ArdiantoNoch keine Bewertungen

- Project Proposal DraftDokument1 SeiteProject Proposal DraftCarl Axel M. FajardoNoch keine Bewertungen

- Advanced Power Electronics Corp.: AP70T03GH/JDokument4 SeitenAdvanced Power Electronics Corp.: AP70T03GH/JVolodiyaNoch keine Bewertungen

- Esp Kelompok 2Dokument19 SeitenEsp Kelompok 2Taufiq DiNoch keine Bewertungen

- FCC O Cials Denounce Lawmakers' Attempts To Censor NewsroomsDokument52 SeitenFCC O Cials Denounce Lawmakers' Attempts To Censor NewsroomsKeithStewartNoch keine Bewertungen

- Grade 8 Mathematics Checkpoint Booklet AY 23-24Dokument270 SeitenGrade 8 Mathematics Checkpoint Booklet AY 23-24Arta riaNoch keine Bewertungen

- Calculate Breakeven Point in Units and Revenue Dollars: Intermediate Cost Analysis and ManagementDokument52 SeitenCalculate Breakeven Point in Units and Revenue Dollars: Intermediate Cost Analysis and ManagementNavice Kie100% (1)

- Probecom 11.3M Antenna System Datasheet 2Dokument2 SeitenProbecom 11.3M Antenna System Datasheet 2Hugo MateoNoch keine Bewertungen

- Ken Holt 06 The Secret of Hangman's InnDokument216 SeitenKen Holt 06 The Secret of Hangman's InnPastPresentFuture100% (2)

- C305 - QTO Workshop PDFDokument90 SeitenC305 - QTO Workshop PDFJason SecretNoch keine Bewertungen

- RCD ManagementDokument6 SeitenRCD ManagementPindoterONoch keine Bewertungen

- Hybrid Neural-Network - Genetic Algorithm Technique For Aircraft Engine Performance Diagnostics Developed and DemonstratedDokument4 SeitenHybrid Neural-Network - Genetic Algorithm Technique For Aircraft Engine Performance Diagnostics Developed and Demonstratedmohamad theibechNoch keine Bewertungen

- CalculusDokument101 SeitenCalculuskusnoNoch keine Bewertungen

- 88 Year Old Man Missing in SC - Please ShareDokument1 Seite88 Year Old Man Missing in SC - Please ShareAmy WoodNoch keine Bewertungen

- Applied Computational AerodynamicsDokument15 SeitenApplied Computational AerodynamicsjoereisNoch keine Bewertungen

- SLHT Grade 7 CSS Week 5 Without Answer KeyDokument6 SeitenSLHT Grade 7 CSS Week 5 Without Answer KeyprinceyahweNoch keine Bewertungen