Beruflich Dokumente

Kultur Dokumente

Jcos-6zptsk R1 en

Hochgeladen von

ImpactianRajenderOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Jcos-6zptsk R1 en

Hochgeladen von

ImpactianRajenderCopyright:

Verfügbare Formate

APC

APPLICATION NOTE #133

Cable Trough, Ladder, and Partition

Configuration Guide

By Bob Oliver

Abstract

Management of power and data cabling is critical for data center installation and long-term maintenance. APC has developed

a line of products designed to contain and manage this array of cabling and piping. These products include cable troughs,

ladders, and partitions. The following application note contains guidelines on positioning these products within a data center,

determining cable capacity / fill of each product, planning for location of different services (power, data, cooling) within the

data center, and installing these products.

Introduction

Generally speaking, data centers are made up of IT equipment housed in racks / enclosures or other physical structure (such

as open frame racks). Data and power cabling are required to interconnect IT equipment in a single rack as well as across

multiple racks in the data center. In addition, electrical conduits and piping are often required for cooling equipment. All

cabling and piping must be supported, organized, and managed. The overhead trough / cabling system offered by APC is

designed to serve this function. The system has three basic components: cable troughs, cable ladders, and partitions. The

system is designed for quick, tool-less installation and can be configured in many different ways using the same basic set of

components to offer maximum flexibility to meet the requirements and needs of each particular data center.

Planning

In most cases, the design and layout of the data center is driven by the physical dimensions of the space and additional

considerations such as entry and exit locations for users, power source, and the amount and type of IT equipment to be

installed. Since trough / cabling systems are flexible and can be adapted to many different data center configurations, the

trough / cabling system layout is generally left until the above issues have been resolved. In most cases, when layout of the

trough / cabling system begins, the physical locations of IT equipment, racks, and cooling equipment have already been

determined.

First determine cabling requirements for the data center

The first consideration when designing a trough system for a data center is to determine the volume and type of cabling and

piping that will need to enter and exit each rack or piece of cooling equipment. For example, for a rack populated with 40

1

____________________________________________________________________________________________________

2007 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com Rev 2007-1

APPLICATION NOTE

APC

servers, the number of cables exiting the rack can be as many as 120 data cables and 2 power cables. For a rack populated

with switches and patch panels, the number of cables exiting the rack can be as many as 1,000 data cables and 1 power

cable. The number and type of cabling can vary widely and should be determined as accurately as possible to ensure the

most optimized trough system solution. Once the number of cables and piping that are passing in and out of each rack has

been identified, the next objective is to determine the total volume and type of cables and piping that must pass over each

rack (also over aisle ways and from row to row). Consider the following example. Figure 1 shows an example datacenter

layout with four rows of three racks with two rows separated by an aisle way. For each rack, the number of data cables

entering and / or exiting the rack is shown.

Figure 1 Example data center layout with racks and data / power cable entering / leaving each rack

Rack 1A

60 Data

2 Power

Rack 2A

327 Data

1 Power

Rack 1B

60 Data

2 Power

Rack 2B

231 Data

1 Power

Rack 1C

48 Data

2 Power

Rack 2C

60 Data

2 Power

Rack 3A

48 Data

4 Power

Rack 4A

60 Data

2 Power

Rack 3B

60 Data

2 Power

Rack 4B

48 Data

4 Power

Rack 3C

48 Data

2 Power

Rack 4C

60 Data

2 Power

2

___________________________________________________________________________________________________

2007 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com Rev 2007-1

APPLICATION NOTE

APC

Figure 2 shows that same example datacenter with cable volume passing over each rack and over each row or aisle way.

Figure 2 Quantities of cables passing over each rack from row to row and over the aisle way

Rack 1A

Total

14 Power

Rack In/Out

60 Data

2 Power

Total

324 Data

14 Power

Rack 2A

Total

6 Data

14 Power

Rack In/Out

327 Data

1 Power

Total

330 Data

12 Power

Rack 1B

Rack 1C

Rack In/Out

60 Data

2 Power

Total

264 Data

12 Power

Rack In/Out

48 Data

2 Power

Total

204 Data

10 Power

Rack 2B

Rack In/Out

231 Data

1 Power

Total

231 Data

11 Power

Rack 2C

Rack In/Out

60 Data

2 Power

Total

228 Data

10 Power

Rack 3A

Rack 3B

Rack 3C

Rack In/Out

48 Data

4 Power

Total

156 Data

8 Power

Rack In/Out

60 Data

2 Power

Total

108 Data

4 Power

Rack In/Out

48 Data

2 Power

Total

48 Data

2 Power

Rack 4A

Rack In/Out

60 Data

2 Power

Total

168 Data

8 Power

Rack 4B

Rack In/Out

48 Data

4 Power

Total

108 Data

6 Power

Rack 4C

Rack In/Out

60 Data

2 Power

Total

60 Data

2 Power

Next determine cable volume at each location within the data center

Once the cable volumes passing over each rack are known, the amount of trough space required at each rack can be

determined. To prevent the risk of noise within data cables, power and data cables should be separated. Therefore, cable

volume (or cable fill area) required for power and data cable should be considered separately.

Calculations are made based on Article 392 of the National Electric Code which is the section which governs cable tray.

According to the NEC, cable tray is defined as a rigid structural support system used to securely fasten or support cables and

raceways. APCs cable trough, cable ladder, and partitions fall under this definition since they are a rigid system when

installed and are designed to support cabling. Calculations should be made as indicated in Table 1. Each APC cable trough

is considered to be Solid Bottom Cable Tray with the width of the bottom equal to 6.25 inches. In some instances, a cable

trough is not large enough to accommodate all of the cables required. In these instances, data partitions can be attached

direction to the top of each rack. Data partitions can be attached at different locations on the rack so that the cable fill area

can be increased.

3

___________________________________________________________________________________________________

2007 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com Rev 2007-1

APPLICATION NOTE

APC

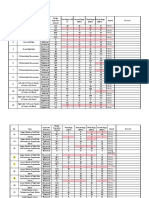

Table 1 Calculation of cable fill for power and data cable in either a cable trough or between cable partitions

Type of

Cable

Power Cable

Formula for

Cable Fill Area

Required

CFA =

(Max. # Cables) * pi *

((Cable diameter) / 2)

Allowable Cable Fill

Area per Trough

Calculations for Example

Data Center

Lookup from Table 392.9 of the

NEC based on:

Assume we are using 12 AWG (20A)

cables so cable diameter = 0.471 in.

- Cable size

- The fact that cable troughs are

considered solid bottom tray

- The width of the cable trough

bottom is 6.25 in

CFA = (14 Cables) * 3.14 * (0.471 / 2) =

2.43 in

Width of cable trough bottom = 6.5 in

Cable is < 4/0 so maximum fill area from

Table 392.9 is 5.5 in.

2.43 in < 5.5 in so maximum number of

power cables will fit in one trough.

Data Cable

CFA =

(Max. # Cables) * pi *

((Cable diameter) / 2)

Allowable Cable Fill Area = 50%

* (Cable Trough Usable Cross

Sectional Area)

Or

Allowable Cable Fill Area 50%

* (Total Usable Area Between

Cable Partitions)

Assume we are using Cat 6 cables so

cable diameter = 0.23 in.

CFA = (330 Cables) * 3.14 * (0.23 / 2) =

26.5 in.

Cable Trough Usable Cross Sectional

Area = 30 in.

Allowable Cable Fill Area = 50% * (30 in.)

= 15 in.

Cable will not fit into one trough. Use

data partitions instead.

Plan to set data partitions so they are a

minimum of 11.5 inches apart at the base

to achieve 26.5 in. of Allowable Cable Fill

Area.

In many cases, cable ladders are required to bridge the gap between racks over aisle ways or between rows of racks. The

cable capacity must be calculated for cable ladders as well to make sure the width and quantity of cable ladders is

determined accurately. To prevent the risk of noise, it is considered good practice to make separate cable ladder runs for

power and data cable. Perform calculations as indicated in Table 2.

4

___________________________________________________________________________________________________

2007 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com Rev 2007-1

APPLICATION NOTE

APC

Table 2 Calculation of cable fill for power and data cable on a cable ladder

Type of

Cable

Power Cable

Formula for

Cable Fill Area

Allowable Cable

Capacity per Ladder

CFA =

Lookup from Table 392.9 of the

NEC based on:

Assume we are using 12 AWG (20A)

cables so cable diameter = 0.471 in.

- Cable size

- The fact that cable ladders are

considered ventilated / ladder

bottom tray

- The width of the cable trough

bottom is 6.00 in. or 12.00 in.

CFA = (14 Cables) * 3.14 * (0.471 / 2) =

2.43 in

(Max. # Cables) * pi *

((Cable diameter) / 2)

Calculations for Example

Data Center

Width of cable trough bottom = 6.0 in

Cable is < 4/0 so maximum fill area from

Table 392.9 is 5.5 in.

2.43 in < 5.5 in so maximum number of

power cables will fit on one cable ladder.

Data Cable

CFA =

(Max. # Cables) * pi *

((Cable diameter) / 2)

Allowable Cable Fill Area = 50%

* (Ladder Width * 6 Max Fill

Depth)

Assume we are using Cat 6 cables so

cable diameter = 0.23 in.

CFA = (168 Cables) * 3.14 * (0.23 / 2) =

6.97 in.

6 Cable Ladder Allowable Fill Area = 50%

* 6.00 * 6.00 = 18 in.

6.97 in. < 18 in. so maximum number of

data cables will fit on one cable ladder.

Once the cable fill area and the type of cable management solution required have been determined, the next step is to

determine where the cables, troughs, ladders and partitions will be located within the data center.

Area on top of the rack

APC cable troughs and partitions are attached to the roof of each APC rack. As a rule of thumb, the top of each rack has

different areas reserved for different types of services (data, power, and piping). The layout of each rack top is shown in

Figure 3. When a particular service type is not required or requires less space than indicated, this space can be used by

another service.

5

___________________________________________________________________________________________________

2007 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com Rev 2007-1

APPLICATION NOTE

APC

Figure 3 Designated cable areas atop APC racks

REAR (HOT AISLE)

Front and Rear Shaded Areas NOT

Usable

Cooling Power / Piping Zone

Power Trough Zone

Cooling Power / Data

Cable Zone

Data Partition Zone

Cooling Power / Data

Cable Zone

SX Rack Frame

RC

Frame

SX Wide Rack Frame

SX Deep Rack

Frame

FRONT (COLD AISLE)

IN-ROW BASED COOLING PRODUCTS SHOWN

For our example data center and based on Figure 3, cable troughs will be installed in the Power Trough Zone while data

partitions will be installed in the Data Partition Zone. Six inch cable ladders will extend across the aisle way and from the

rack row to the wall for cabling exiting the data center. One six inch cable ladder will connect the two rows of racks. The

layout has been updated to show the cable troughs, partitions, and ladders included in the datacenter layout (See Figure 4).

Some cooling products (such as several offered by APC) are designed to be installed in-row with racks. In those cases,

space must be allocated above the racks for electrical conduits to the cooling equipment as well as piping for the coolant.

6

___________________________________________________________________________________________________

2007 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com Rev 2007-1

APPLICATION NOTE

APC

Figure 4 Data center configured with troughs, partitions, and cable ladders

Rack 1A

Rack 1B

Rack 1C

Rack 3A

Rack 3B

Rack 3C

Rack 4A

Rack 4B

Rack 4C

Troughs

Partitions

6 Ladders

Rack 2A

Rack 2B

Rack 2C

Installation

The following are some installation details showing how troughs, partitions, and ladders connect to APC racks as well as how

they interconnect with one another.

Attachment of cable troughs and partitions

APC cable troughs and partitions are attached to APC racks without tools. Tabs on the bottom of each trough or partition

snap into square holes in the rack roof.

Ground wires are included with each trough and partition to chain all individual

units together and then attach to a common ground (which is generally on the racks in the row). See Figure 5.

7

___________________________________________________________________________________________________

2007 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com Rev 2007-1

APPLICATION NOTE

APC

Figure 5 Cable trough and partition attachment

Attachment of cable ladders to cable troughs and partitions (over aisle ways and between rows)

APC cable ladders are generally used to span aisle ways and rows. They are designed to attach to cable troughs and

partitions without tools. Each trough and partition has slots in each side that can accommodate either a 6 or 12 wide cable

ladder fitted with a Ladder Bracket Kit (Part Number AR8166ABLK). Figure 6 shows the addition of a 12 wide cable ladder

between rows and attached to either a partition or a trough.

Figure 6 Cable ladder attachment

8

___________________________________________________________________________________________________

2007 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com Rev 2007-1

APPLICATION NOTE

APC

Cable ladders can also be attached over aisle ways to partitions or troughs. Figure 7 shows a cable ladder attached to

partitions using the AR8166ABLK Ladder Bracket Kit. Attachment to a cable trough is completed in the same way.

Grounding kits are provided to allow a grounded connection between the trough / partition and the cable ladder.

Figure 7 Cable ladder attachment to partitions using ladder brackets

Figure 8 shows attachment of a 6 cable ladder to a cable trough.

Figure 8 Cable ladder attachment to trough using ladder brackets

9

___________________________________________________________________________________________________

2007 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com Rev 2007-1

APPLICATION NOTE

APC

Additional kits and accessories are available from APC. Please visit www.apc.com for additional details. See Table 3 for a

partial list of available products:

Table 3 APC product listing for cable troughs, ladders, partitions, and accessories

Part Number

Description

Use

For 600mm Wide

Racks

For 750mm Wide

Racks

AR8160ABLK

AR8178BLK

Power Shielding Trough Black

Facilitates overhead power cabling

distribution. Has protective grounding

provisions. Tool-less mounting. Includes

Installation Guide and (1) 20 cm grounding

strap.

AR8161ABLK

AR8171BLK

Power / Data Shielding Trough

for Racks Black

Facilitates overhead power or data cabling

distribution. Has protective grounding

provisions. Tool-less mounting. Includes

Installation Guide and (1) 20 cm grounding

strap.

AR8162ABLK

AR8172BLK

Solid Shielding Partition for

Racks Black

Facilitates overhead cable management.

Has protective grounding provisions. Toolless mounting. Includes Installation Guide

and (1) 20 cm grounding strap.

AR8163ABLK

AR8173BLK

Pass-Through Shielding

Partition for 600mm Wide Racks

Black

Provides the ability to pass cables in and

out of the cabling area contained by two

partitions. Facilitates overhead cable

management. Has protective grounding

provisions. Tool-less mounting. Includes

Installation Guide and (1) 20 cm grounding

strap.

AR8164ABLK

6 Wide Cable Ladder with

Bracket Kit Black

Support data or power cabling across aisle

ways or between rack rows.

AR8165ABLK

12 Wide Cable Ladder with

Bracket Kit Black

Support data or power cabling across aisle

ways or between rack rows.

AR8166ABLK

Ladder Bracket Kit - Black

Allows tool-less attachment of cable

ladders to troughs and partitions. Includes

Installation Guide.

AR8168BLK

Ladder to Rack Attachment

Brackets Black

Allows a cable ladder to attach direction to

a rack. Tool-less mounting. Includes

Installation Guide and (1) 20 cm grounding

strap.

10

___________________________________________________________________________________________________

2007 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com Rev 2007-1

APC

APPLICATION NOTE

Conclusion

With careful planning, cabling and piping can be accommodated within the data center. APC offers many products that install

quickly and easily and can be adapted to many different layouts to help make this process more efficient and effective.

About the Author:

Bob Oliver is the Engineering Manager for Racks and Enclosures for APC. He is responsible for design and development of

racks and enclosures as well as rack accessories. Bob received a Bachelors degree in Mechanical Engineering from the

University of Missouri Columbia in 1992 and a Masters degree in Engineering Management from the University of Missouri

Rolla in 1999.

11

___________________________________________________________________________________________________

2007 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com Rev 2007-1

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- CamScanner 05-19-2021 11.22.34Dokument1 SeiteCamScanner 05-19-2021 11.22.34ImpactianRajenderNoch keine Bewertungen

- 25 - 06 - 2020 MACHAPUR GP UPDATED Htaxregisters - DoDokument101 Seiten25 - 06 - 2020 MACHAPUR GP UPDATED Htaxregisters - DoImpactianRajenderNoch keine Bewertungen

- GP Teams - Annexure - IDokument109 SeitenGP Teams - Annexure - IImpactianRajenderNoch keine Bewertungen

- 16Dokument1 Seite16ImpactianRajenderNoch keine Bewertungen

- GoodDokument22 SeitenGoodhari sharma100% (1)

- CC Kas PaymentOrderExpenditure - 2020-11-12.pdf (2) PoDokument4 SeitenCC Kas PaymentOrderExpenditure - 2020-11-12.pdf (2) PoImpactianRajenderNoch keine Bewertungen

- Maths Book 2 FinalDokument18 SeitenMaths Book 2 FinalAjal P100% (1)

- M 1 L 2Dokument14 SeitenM 1 L 2Sandeep AngaraNoch keine Bewertungen

- General Format 1Dokument2 SeitenGeneral Format 1ImpactianRajenderNoch keine Bewertungen

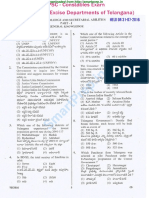

- TSPSC Transport Excise Constables Exam Revised Final Answer Key-2016Dokument4 SeitenTSPSC Transport Excise Constables Exam Revised Final Answer Key-2016ImpactianRajenderNoch keine Bewertungen

- GE6351 EVS125pagesDokument125 SeitenGE6351 EVS125pagesImpactianRajenderNoch keine Bewertungen

- 2 UMTS Radio Interface Physical LayerDokument56 Seiten2 UMTS Radio Interface Physical LayerKuldeep KashyapNoch keine Bewertungen

- Tspscappl462017.Tspsc - Gov.in AtResponse - TSPSCDokument1 SeiteTspscappl462017.Tspsc - Gov.in AtResponse - TSPSCImpactianRajenderNoch keine Bewertungen

- TSPSC Vro Vao Question Paper 2016Dokument21 SeitenTSPSC Vro Vao Question Paper 2016ImpactianRajenderNoch keine Bewertungen

- Bank Exam Clerks Previous PapersDokument11 SeitenBank Exam Clerks Previous PapersAllExamPapersNoch keine Bewertungen

- TSPSC Transport Excise Constables Exam Revised Final Answer Key-2016Dokument4 SeitenTSPSC Transport Excise Constables Exam Revised Final Answer Key-2016ImpactianRajenderNoch keine Bewertungen

- National Parks and SanctuariesDokument41 SeitenNational Parks and Sanctuariesamoda19906186100% (2)

- OTM Domain Knowledge - NaveenDokument38 SeitenOTM Domain Knowledge - NaveenImpactianRajenderNoch keine Bewertungen

- Raspberry PP TDokument25 SeitenRaspberry PP TImpactianRajenderNoch keine Bewertungen

- Energy Resources: GE 2211 Environmental Science and Engineering Unit - IDokument27 SeitenEnergy Resources: GE 2211 Environmental Science and Engineering Unit - IImpactianRajenderNoch keine Bewertungen

- Bank Exam Clerks Previous PapersDokument11 SeitenBank Exam Clerks Previous PapersAllExamPapersNoch keine Bewertungen

- Bank Exam Clerks Previous PapersDokument11 SeitenBank Exam Clerks Previous PapersAllExamPapersNoch keine Bewertungen

- Items Are Things That You Manufacture and Sell Such As ChemicalsDokument36 SeitenItems Are Things That You Manufacture and Sell Such As ChemicalsImpactianRajenderNoch keine Bewertungen

- Itr-1 Sahaj Individual Income Tax ReturnDokument5 SeitenItr-1 Sahaj Individual Income Tax ReturnImpactianRajenderNoch keine Bewertungen

- Introduction To Digital Communications and Information TheoryDokument8 SeitenIntroduction To Digital Communications and Information TheoryRandall GloverNoch keine Bewertungen

- Curriculam Vitae: BjectiveDokument3 SeitenCurriculam Vitae: BjectiveImpactianRajenderNoch keine Bewertungen

- 69Dokument3 Seiten69ImpactianRajenderNoch keine Bewertungen

- Curriculam Vitae: BjectiveDokument3 SeitenCurriculam Vitae: BjectiveImpactianRajenderNoch keine Bewertungen

- Irda Renewal LetterDokument1 SeiteIrda Renewal LetterImpactianRajenderNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Manual ILC 151Dokument132 SeitenManual ILC 151Cristian PisitelloNoch keine Bewertungen

- What Is A Surge TankDokument13 SeitenWhat Is A Surge TankAnikateNoch keine Bewertungen

- Mazda rx7Dokument3 SeitenMazda rx7Jon WestNoch keine Bewertungen

- Expansion Indicator Boiler #1Dokument6 SeitenExpansion Indicator Boiler #1Muhammad AbyNoch keine Bewertungen

- Discussion Lab 2Dokument2 SeitenDiscussion Lab 2nazrin0% (1)

- GSM Underlaid Overlaid Frequency Allocation and ConfigurationDokument3 SeitenGSM Underlaid Overlaid Frequency Allocation and ConfigurationrajNoch keine Bewertungen

- Yamaha A-S2000 PDFDokument90 SeitenYamaha A-S2000 PDFpeti5_1Noch keine Bewertungen

- Chemical EarthingDokument18 SeitenChemical EarthingDivay ChadhaNoch keine Bewertungen

- Mamuli N22Dokument28 SeitenMamuli N22doubeNoch keine Bewertungen

- Hotel Cleaning Equipment Used byDokument9 SeitenHotel Cleaning Equipment Used byLeonardo ViridisNoch keine Bewertungen

- Common-Airbus Tooling PDFDokument67 SeitenCommon-Airbus Tooling PDFChris Calnan100% (1)

- SOP For Handling of Rejected Raw MaterialDokument6 SeitenSOP For Handling of Rejected Raw Materialanoushia alviNoch keine Bewertungen

- Saturation Height FunctionDokument27 SeitenSaturation Height Functionpahlawankemaleman100% (1)

- 10039030M00 - PB560 System Final Test Procedure PDFDokument12 Seiten10039030M00 - PB560 System Final Test Procedure PDFDaniel MarquesNoch keine Bewertungen

- Switch Yard & Protection SystemDokument48 SeitenSwitch Yard & Protection SystemDharmendra GargNoch keine Bewertungen

- Turban 02Dokument88 SeitenTurban 02Ayu Saida ZulfaNoch keine Bewertungen

- IT418 - C# Programming Project: Lottery Number GeneratorDokument41 SeitenIT418 - C# Programming Project: Lottery Number GeneratorCarmenLim07100% (5)

- Fauzan Ariq Santoso From Marine Electrical Engineering ShipsDokument11 SeitenFauzan Ariq Santoso From Marine Electrical Engineering ShipsFauzan Ariq SantosoNoch keine Bewertungen

- Euro Ncap Aeb Test Protocol v11 PDFDokument31 SeitenEuro Ncap Aeb Test Protocol v11 PDFRTCNNoch keine Bewertungen

- ENSET Buea 2019 - 1ere Annee Du 2nd Cycle - enDokument5 SeitenENSET Buea 2019 - 1ere Annee Du 2nd Cycle - enStéphanie Océane NadjiNoch keine Bewertungen

- Harry BerryDokument2 SeitenHarry BerryLuisNoch keine Bewertungen

- Mica PDFDokument2 SeitenMica PDFomarNoch keine Bewertungen

- Boostherm DWV 01 2017 ENDokument6 SeitenBoostherm DWV 01 2017 ENCarlos LehmanNoch keine Bewertungen

- Proses Manufaktur: Machining Operation and Machine ToolsDokument34 SeitenProses Manufaktur: Machining Operation and Machine ToolsLyndaNoch keine Bewertungen

- Om Facility LayoutDokument9 SeitenOm Facility LayoutBrein Symon DialaNoch keine Bewertungen

- Thermal Modeling and Design Considerations of Lithium-Ion BatteriesDokument8 SeitenThermal Modeling and Design Considerations of Lithium-Ion BatteriesVarun Gupta100% (1)

- Comp Reflection Short 1Dokument10 SeitenComp Reflection Short 1api-295784162Noch keine Bewertungen

- The Age of Exploration/Age of Discovery: Countries InvolvedDokument6 SeitenThe Age of Exploration/Age of Discovery: Countries InvolvedRocky RayoNoch keine Bewertungen

- Muhammad Ali - CHRP (Canada)Dokument8 SeitenMuhammad Ali - CHRP (Canada)Muhammad AliNoch keine Bewertungen

- Unit Plan: Economics Educated: Submitted By: Nancy Vargas-CisnerosDokument4 SeitenUnit Plan: Economics Educated: Submitted By: Nancy Vargas-CisnerosNancy VargasNoch keine Bewertungen