Beruflich Dokumente

Kultur Dokumente

MeasurIT KTek AT100 Level Transmitter 0910

Hochgeladen von

cwiejkowskaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MeasurIT KTek AT100 Level Transmitter 0910

Hochgeladen von

cwiejkowskaCopyright:

Verfügbare Formate

measurIT technologies

AT100

High Accuracy Magnetostrictive Level Transmitter

FEATURES

- SIL2 Certified IEC 61508*

- High Accuracy: .01% of Full Scale

- Superior Piezo Ceramic Sensor (Patent # 5,473,245)

- Local Indication with LCD Display

- Never Requires Re-Calibration: Set It & Forget It

- Dual Compartment Housing with Separate Field Terminal Compartment

- Loop Powered to 75’ (22M) Probe Length

- Total and/or Interface Level Measurement

- Pressure to 3000psig (207 bar), Std. 1800 psig (124.1 bar)

- Temperature Range: -320 to 800º F (-196 to 427ºC) with options

- Field Replaceable / Upgradable Electronics Module

- Built In RFI / EMI Filter

- Digital Communications

OPTIONS

- Two Level Indications

- Temperature Indications

- Foundation Fieldbus Output

- Honeywell DE Output

- Glass Viewing Window

- 316L Stainless Steel Enclosure

-20 Point Strapping Table

SPECIFICATIONS

Electronic Transmitter

Housing type Explosion Proof Powdered Coated Cast Aluminum or Stainless Steel, Dual Compartment

Electrical Connection 1/2” FNPT or M20

Repeatability 0.005% of full scale or 0.015”, whichever is greater

Non-Linearity 0.01% of full scale or 0.035”, whichever is greater

Accuracy 0.01% of full scale or 0.050”, whichever is greater

Supply Voltage 13.5 to 36 VDC - Loop Powered; 9 to 32 VDC - Foundation Fieldbus

Reverse Polarity Protection Diode in series with loop

Output/Communications Standard 4-20 mA DC Loop

HART protocol (standard)

Foundation Fieldbus (optional)

- ITK 5.1.0 Compliant

- 5 AI and 1 PID blocks

- 12.5 mA Quiescent Current Draw

- LAS Capable

Honeywell DE (optional)

Damping Field adjustable by means of pushbuttons. Range: 0.1 to 36 seconds

Burnout Jumper selectable upscale (21 mA) or downscale (3.6 mA)

Temperature -40 to 170ºF (-40 to 77ºC) Ambient

Humidity 0 to 100% R.H., non-condensing

* Transmitters equipped with 4-20mA/HART module option only

* Refer to “Ordering Information”, Section F

MeasurIT Technologies Ltd.

Craan, Craanford, email: info@measurIT.com Phone: +353 (0) 53 942 8962

Gorey, Co. Wexford, Ireland www.measurIT.com Fax: +353 (0) 53 942 8963

measurIT technologies

SPECIFICATIONS

Sensor Tube

Standard Options

Material 316L SS Alloy 20, HSC-276, Teflon Jacketed 316L SS, Electro-

Process Temp. -320 to 250ºF (-196 to 121ºC) 800ºF (427ºC)

Max. Press. 1800 psig @ 300ºF (124.1 bar @ 149ºC) 3000 psig (206.8bar)

Probe Length 1 to 30 feet (304.8mm to 9.14m) 75 ft (22.3m)

Mounting 3/4 in MNPT compression fitting Loose and welded flanges, plugs and tri-clamp fittings

Approvals:

FM Factory Mutual Research Corporation CSA Canadian Standards Association

XP / I / 1 / ABCD / T6; DIP / II, III / 1 / EFG / T6 1 XP / I / 1 / ABCD / T6; DIP / II, III / 1 / EFG / T6 1

IS / I / 1 / ABCD / T4 - ELE0001 and ELE1036 2,3 IS / I / 1 / ABCD / T4 - ELE0001 2

NI / I / 2 / ABCD / T4 NI / I / 2 / ABCD / T4

TYPE 4X TYPE 4X

ATEX GOST Russia

FP: ITS08ATEX15869X FP: 1ExdIICT6 1

II 1/2 G/D Ex d IIC T6 IS: 0ExiaIICT6 2

Ex tD 20/A21 IP6X T80°C Ingress protection: IP67

0539 IS: ITS08ATEX15866X Sanitary Hygienic Certificate

0036

II 1/2 GD Ex ia IIC T4 (-40°C ≤ Tamb ≤ 66°C )

Ex iaD 20/21 IP6X T80°C (-40°C ≤ Tamb ≤ 66°C ) GOST Kazakhstan

IExdIICT6; 0ExiaIIBT6

Ingress protection: IP66 and IP67 Fieldbus: 1ExdIICT6, 0ExiaIICT6

IEC International Electromechanical Commission Chinese Approvals Available

IS: IECEx ITS 08.0032X 2,3 when purchased through

Ex ia IIC T4 K-TEK (Tianjin) Level Co. LTD.

Ex iaD 20/21 IP6X T80°C TEDA-Tianjin, China +86 (22) 598 13078

FP: IECExITS 08.0035

II 1/2G/D Ex d IIC T6

Notes: 1. Excludes Probe F1 and SW3 options.

2. Excludes RI (secondary analog output) & Honeywell DE options.

3. Fieldbus & FISCO

Safety Third Party Certified Safety Integrity Level (SIL 2) data (FMEDA analysis) for Safety Instrumented Systems

PRINCIPLE OF OPERATION:

The AT100 is based upon the magnetostrictive principle. The sensing tube contains a wire which is pulsed at fixed

time intervals creating a magnetic field around the wire. The interaction of the magnetic field around the wire and the

magnetic float causes a torsional stress wave to be induced in the wire. This torsion propagates along the wire at a

known velocity, from the position of the magnetic float and toward both ends of the wire. A patented piezo ceramic

sensing element placed in the transmitter assembly converts the received mechanical torsion into an electrical return

pulse. The microprocessor-based electronics measures the elapsed time between the start and return pulses and

converts it into a position measurement which is proportional to the level of the float.

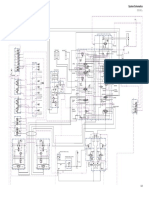

AT100 Components Principle of Operation AT100 Dimensions

SENSOR PIEZO CERAMIC

WIRE SENSOR*

AT100

MIN 8"

CURRENT PULSE

L1=1"TYP

START PULSE

TORSIONAL

WAVE

NO MIN

Float RETURN PULSE FLOAT

SEPARATION

MAGNETIC

FLOAT

ASSEMBLY ML

EC

Chamber

(option) *Patent # 5,473,245 L2=2.5" MIN.

MeasurIT Technologies Ltd.

Craan, Craanford, email: info@measurIT.com Phone: +353 (0) 53 942 8962

Gorey, Co. Wexford, Ireland www.measurIT.com Fax: +353 (0) 53 942 8963

measurIT technologies

ORDERING INFORMATION

AT100/a/b/c/d/e/f/g/h/I/j/k:

Example: AT100/S6/LW/A/R1/H0/M4A/X/FM/CF/F1B/48”

/a Probe Material

S6 316L Stainless Steel Standard

A2 Alloy 20

HC Hastelloy C-276 (1/2” OD SW1 Probe without Sensor Well)

TF PFA Jacket (1/16” thick) over 316L SS (Max 350ºF (177ºC) & 50 psig (3.4bar))

/b Transmitter Configuration

L Standard Local Transmitter

LW Standard Local Transmitter with Window Cover

T Local Transmitter with Top Access or Readout

TW Local Transmitter with Top Access or Readout and Window Cover

C Offset Transmitter with Vapor Seal for Service Below Ambient

CW Offset Transmitter with Vapor Seal for Service Below Ambient and Window Cover

/c Transmitter Housing

A Standard Dual Compartment Aluminum Housing

S Dual Compartment 316L Stainless Steel Housing

/d Probe Type

R1 Standard Rigid Probe, 5/8” OD

Notes: 1. 30 ft. (9.14m) maximum probe length

2. 1400 psig ( 96.5bar) @ 800ºF (427ºC)

3. 1600 psig (110.3bar) @ 700ºF (371ºC)

4. 1800 psig (124.1bar) @ 300ºF (149ºC)

F1 Flexible Teflon Sensor Inserted into 1” OD Segmented Sensor Well

Notes: 1. Only available with /S6, /A2, /HC options.

2. 75 ft. (22.86 m) maximum probe length.

3. 300 psig (20.7bar) maximum & 170ºF (77°C) maximum.

4. Specify maximum segment length, 10ft. (3.05m) standard.

5. Not suitable for explosion proof service.

6. Suitable for intrinsically safe installation.

7. Not suitable for cryogenic applications.

HP High Pressure Rigid Probe, 5/8” OD

Notes: 1. Not available with /TF probe material option.

2. 30 ft. (9.14m) maximum probe length.

3. 3000 psig (206.8 bar) maximum.

4. Not available with /H3 Process Temperature Option.

SW1 1/2” OD Rigid Probe for Insertion Into 5/8” OD x 0.049” Wall Sensor Well

Notes: 1. Specify and order sensor well separately.

2. 20 ft. (6.10m) maximum probe length.

3. Not available with /H3 Process Temperature Option.

SW2 5/8” OD Rigid Probe for Insertion Into 3/4” Sch. 40 or 80 Sensor Well

Notes: 1. Specify and order sensor well separately.

2. 30 ft. (9.14m) maximum probe length.

SW3 1/2” OD Flexible Probe for Insertion Into 5/8” OD x 0.49” wall Sensor Well

Notes: 1. Max 300ºF (149ºC) @ 1 hour Clean.

2. 15 ft. (4.57m) maximum probe length.

3. Available with /S6 probe material only.

4. Not suitable for explosion proof service.

5. Probe is not hermetically sealed. For use in conditioned (non-condensing) indoor locations only.

6. Only available with H0 process temperature option.

/e Process Temperature Options

H0 < 170ºF (77ºC) Maximum; Top of transmitter is 8” (200mm) above process connection

H1 < 250ºF (121ºC) Maximum; Top of transmitter is 16” (406mm) above process connection

H2 < 450ºF (232ºC) Maximum; Top of transmitter is 26” (660mm) above process connection

H3 < 800ºF (427ºC) Maximum; Top of transmitter is 26” (660 mm) above process connection

Note: 15 ft. (4.57m) maximum probe length.

MeasurIT Technologies Ltd.

Craan, Craanford, email: info@measurIT.com Phone: +353 (0) 53 942 8962

Gorey, Co. Wexford, Ireland www.measurIT.com Fax: +353 (0) 53 942 8963

measurIT technologies

ORDERING INFORMATION (continued)

/f Electronic Module

X None

HART M4A One Level, LCD Indicator & SIL 2 rated 4-20 mA Output

Protocol: M4B Two Levels, LCD Indicator & SIL 2 rated 4-20 mA Output

M4AS One Level, LCD Indicator & SIL 2 rated 4-20 mA Output & 20 point Strapping Table

M4BS Two Levels, LCD Indicator & SIL 2 rated 4-20 mA Output & 20 point Strapping Table

M5A One Level, One temperature point, LCD indicator, and Communications

M5B Two Levels, One temperature point, LCD indicator, and Communications

Foundation M4AF One Level & LCD Indicator

Fieldbus M4BF Two Levels & LCD Indicator

Protocol: M4AFS One Level & LCD Indicator & 20 point Strapping Table

M4BFS One Level & LCD Indicator & 20 point Strapping Table

Honeywell M4AD One Level & LCD Indicator

DE M4BD Two Levels & LCD Indicator

Protocol:

/g Second Analog Output (Not SIL Rated)

X None

RI Second electronic module with 1 ea. Analog output and LCD indication

Notes: 1. Only for use with HART Protocol equipped electronics modules

2. The RI100 is only approved as an Explosion Proof device

3. Analog output field selectable to any of the two levels or temperature

4. Housing type will be same as primary transmitter housing (/c above)

/h Approvals1,2

FM Factory Mutual

CSA Canadian Standards Association

CEX ATEX Flameproof

CEI ATEX I.S.

IEI International Electromechanical Commission I.S.

0539

IEX International Electromechanical Commission Flameproof 0036

GR GOST Russia

GK GOST Kazakhstan

Notes: 1. All Explosion Proof Approvals exclude Probe F1 and SW3.

2. All Intrinsically Safe Approvals exclude RI (secondary analog output) & Honeywell DE options.

/i Process Connection

X None (use with /SW1, /SW2 and /SW3 probe types)

CF Standard adjustable compression fitting 3/4” MNPT (1”MNPT with /F1 probe type)

FL Flange or plug (shipped loose) with FNPT thread for use with compression fitting

(specify type, material and rating from SLG-0001-1 Flange Designation Chart)

WP Flange or Plug welded to the sensor tube without compression fitting

(specify type, material and rating from SLG-0001-1 Flange Designation Chart)

/j Float Type

X None (Use this selection with /SW1, /SW2, & /SW3 probe types)

Fnn Selection from Standard Float Chart (SLG-0003-1) or specify /FXX for custom float

/k Insertion Length

L Specify inserted length from process connection to end of probe in inches or millimeters or meters

Consult factory for ML, L1 & L2. There is an unusable range of 2.5 inches minimum (12” for /F1) at the bottom of the

sensing tube (which can be reduced depending upon float dimensions).

The unusable range at the top of the sensor tube will be affected by the float dimensions.

NOTE: Consult factory for special application requirements.

Available Accessories:

M20 ISO FITTING: M20 Female Electrical Connection (MM - Brass or MMS - Stainless Steel)

For fastest response to inquiries provide a completed AT100 Application Data Sheet of the Serial Number of an existing AT100.

MeasurIT Technologies Ltd.

Craan, Craanford, email: info@measurIT.com Phone: +353 (0) 53 942 8962

Gorey, Co. Wexford, Ireland www.measurIT.com Fax: +353 (0) 53 942 8963

Das könnte Ihnen auch gefallen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Electrical and Electronics Engineering Interview Questions and AnswersDokument55 SeitenElectrical and Electronics Engineering Interview Questions and Answerstowfiqeee87% (30)

- Esquema Hidráulico Sany SY215C-AND-SY235Dokument1 SeiteEsquema Hidráulico Sany SY215C-AND-SY235juanchis650100% (1)

- Vectron Elektronik Manual DatasheetDokument8 SeitenVectron Elektronik Manual DatasheetGetulio CamarottoNoch keine Bewertungen

- MeasurIT KTek AT200 Level Transmitter 0910Dokument4 SeitenMeasurIT KTek AT200 Level Transmitter 0910cwiejkowskaNoch keine Bewertungen

- Abb MT 5000Dokument12 SeitenAbb MT 5000FIRMANSYAHNoch keine Bewertungen

- External Mounted Magnetostrictive Level TransmitterDokument6 SeitenExternal Mounted Magnetostrictive Level Transmitterjuan vazquezNoch keine Bewertungen

- YTA70Dokument4 SeitenYTA70jamesrickynNoch keine Bewertungen

- Technical Specification: DescriptionDokument2 SeitenTechnical Specification: DescriptionAnonymous RcxX0FcNoch keine Bewertungen

- Datasheet BTL2F7P 260351 enDokument3 SeitenDatasheet BTL2F7P 260351 enSamy FouadNoch keine Bewertungen

- BRT21H - Digital RelayDokument7 SeitenBRT21H - Digital RelaySilas PutraNoch keine Bewertungen

- Spesifikasi Magang SensornyaDokument3 SeitenSpesifikasi Magang Sensornyasyafia aisyah keumalaNoch keine Bewertungen

- FL3100H and FL3101H UV IR and UV Unitized Flame DetectorsDokument2 SeitenFL3100H and FL3101H UV IR and UV Unitized Flame DetectorsRomdhoni Widyo BaskoroNoch keine Bewertungen

- Hornet Hot Cathode Miniature-Ionization Vacuum Gauge With Dual Convection Data SheetDokument2 SeitenHornet Hot Cathode Miniature-Ionization Vacuum Gauge With Dual Convection Data SheetInstruTech, Inc.Noch keine Bewertungen

- ACS712 DatasheetDokument15 SeitenACS712 DatasheetejmelchiorsNoch keine Bewertungen

- ACS713-Datasheet - Current Sensor ICDokument14 SeitenACS713-Datasheet - Current Sensor ICphase90Noch keine Bewertungen

- Allen-Bradley 1783-US5T Switch, Unmanaged, 5 Ports, RJ45 Copper, AC or DCDokument4 SeitenAllen-Bradley 1783-US5T Switch, Unmanaged, 5 Ports, RJ45 Copper, AC or DCJairo Alfonso Molina SantosNoch keine Bewertungen

- General Specifications: YTA Series Fieldbus CommunicationDokument4 SeitenGeneral Specifications: YTA Series Fieldbus CommunicationIsrael BolañosNoch keine Bewertungen

- SS2 GTX00D 0100 21 PDFDokument24 SeitenSS2 GTX00D 0100 21 PDFtjahyo02Noch keine Bewertungen

- Catalogue - LT Type DP Transmitter - Azbil - JapanDokument24 SeitenCatalogue - LT Type DP Transmitter - Azbil - JapanReza Pratama NugrahaNoch keine Bewertungen

- Product AI830ADokument4 SeitenProduct AI830Aธรรมรักษ์ โทนาอรรถNoch keine Bewertungen

- Product AI830ADokument4 SeitenProduct AI830AVijaya BhaskerNoch keine Bewertungen

- Hart Field Temperature Transmitter Models TIF50, TIF52, TIF62Dokument9 SeitenHart Field Temperature Transmitter Models TIF50, TIF52, TIF62jmenesesmNoch keine Bewertungen

- Wika Il-10Dokument4 SeitenWika Il-10José MelâneoNoch keine Bewertungen

- ACS712 DatasheetDokument15 SeitenACS712 DatasheetHernan PorriniNoch keine Bewertungen

- 756ac Double Barrier, 1 Channel: FunctionDokument2 Seiten756ac Double Barrier, 1 Channel: FunctiongoviaNoch keine Bewertungen

- DS B4B7 EN PressostatDokument2 SeitenDS B4B7 EN PressostatmarouaneNoch keine Bewertungen

- 000 RF Surge Datsheet - UnlockedDokument2 Seiten000 RF Surge Datsheet - UnlockedWasapol PooritanasarnNoch keine Bewertungen

- Tokyo Keiki - Radar Level GaugeDokument41 SeitenTokyo Keiki - Radar Level GaugeFerry YusufNoch keine Bewertungen

- Azbil - KXDQNDNJSS2-GTX00D-0500-05 - 0616Dokument24 SeitenAzbil - KXDQNDNJSS2-GTX00D-0500-05 - 0616Mario Landeta PérezNoch keine Bewertungen

- MKD0074 - 1V0 ATEX MODA DatasheetDokument3 SeitenMKD0074 - 1V0 ATEX MODA Datasheetนวเรศ สุวรรณมงคลNoch keine Bewertungen

- Carbon Monoxide DM-100-CO PDSDokument2 SeitenCarbon Monoxide DM-100-CO PDSroyvindasNoch keine Bewertungen

- Gs01c50h01-01en 001Dokument13 SeitenGs01c50h01-01en 001Alvaro Quinteros CabreraNoch keine Bewertungen

- Tongyu TMADokument3 SeitenTongyu TMARogersNoch keine Bewertungen

- AT200VPDokument2 SeitenAT200VPROGELIO QUIJANONoch keine Bewertungen

- ACS714Dokument15 SeitenACS714connect2nsNoch keine Bewertungen

- Ashcroft - Pressure Switch PDFDokument2 SeitenAshcroft - Pressure Switch PDFAnand SinhaNoch keine Bewertungen

- CMCP422VT DdsDokument2 SeitenCMCP422VT DdsGabriel ArevaloNoch keine Bewertungen

- GTX-F Catalog PDFDokument20 SeitenGTX-F Catalog PDFWilliam YoungNoch keine Bewertungen

- Datasheet ET1100Dokument10 SeitenDatasheet ET1100Manal FeghaliNoch keine Bewertungen

- Digital and Analog Modules in S800L MechanicsDokument4 SeitenDigital and Analog Modules in S800L MechanicsgeovannycarpioNoch keine Bewertungen

- AT9000 - GTX-G CatalogDokument20 SeitenAT9000 - GTX-G CatalogJose Gustavo Robles MoralesNoch keine Bewertungen

- En 09 15 Eng Rev.5 Servo Gauge 854 XTGDokument6 SeitenEn 09 15 Eng Rev.5 Servo Gauge 854 XTGJoaquin LunaNoch keine Bewertungen

- Crouse Hinds MTL tp48 Catalog PageDokument3 SeitenCrouse Hinds MTL tp48 Catalog Pageinstrument.assist.slpNoch keine Bewertungen

- Sensor de Presión de Acete Marca Tecsis Serir 3354Dokument5 SeitenSensor de Presión de Acete Marca Tecsis Serir 3354Luis G. JaramilloNoch keine Bewertungen

- Product Di810Dokument4 SeitenProduct Di810rogeliobarNoch keine Bewertungen

- Sem210 Series: Programmable In-Head Universal Temperature TransmitterDokument5 SeitenSem210 Series: Programmable In-Head Universal Temperature TransmitterjhuskanovicNoch keine Bewertungen

- PMC 1031Dokument3 SeitenPMC 1031saikiranNoch keine Bewertungen

- SVP3000 Alphaplus: Smart Valve Positioner With HART Communication Protocol Model AVP302Dokument8 SeitenSVP3000 Alphaplus: Smart Valve Positioner With HART Communication Protocol Model AVP302鄭元豪Noch keine Bewertungen

- Datasheet ATM - Eco NDokument7 SeitenDatasheet ATM - Eco NbasileiouspyrosNoch keine Bewertungen

- St420 Users Manual Rev DDokument4 SeitenSt420 Users Manual Rev DSherif M. DabourNoch keine Bewertungen

- 1 Vs Csa Atex Overview DsDokument1 Seite1 Vs Csa Atex Overview DsrodrurenNoch keine Bewertungen

- Sitranst th300 Fi01enDokument7 SeitenSitranst th300 Fi01enLuis GuillermoNoch keine Bewertungen

- Hornet Hot Cathode Bayard-Alpert Miniature-Ionization Vacuum Gauge Data SheetDokument2 SeitenHornet Hot Cathode Bayard-Alpert Miniature-Ionization Vacuum Gauge Data SheetInstruTech, Inc.Noch keine Bewertungen

- Single Data Sheet Plug 100 ADokument3 SeitenSingle Data Sheet Plug 100 AbenNoch keine Bewertungen

- Ds Uhp Wuc 1x en Us 20710Dokument10 SeitenDs Uhp Wuc 1x en Us 20710behnamatgNoch keine Bewertungen

- Field Device Coupler 9410-34-330-40 DatasheetDokument5 SeitenField Device Coupler 9410-34-330-40 DatasheetanggietzoaNoch keine Bewertungen

- Endress-Hauser iTEMP TMT162 VIDokument3 SeitenEndress-Hauser iTEMP TMT162 VITang BvNoch keine Bewertungen

- TA8248KDokument12 SeitenTA8248Ksontuyet82100% (1)

- 11 - 819EN Rev BDokument8 Seiten11 - 819EN Rev Bvinodk335Noch keine Bewertungen

- TS014 - EcoSource+Dokument2 SeitenTS014 - EcoSource+felipe pintoNoch keine Bewertungen

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsVon EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNoch keine Bewertungen

- MeasurIT Red Valve Pressure Sensors Series 42 0806Dokument1 SeiteMeasurIT Red Valve Pressure Sensors Series 42 0806cwiejkowskaNoch keine Bewertungen

- MeasurIT KTek KM26 Application Power Plants 0807Dokument2 SeitenMeasurIT KTek KM26 Application Power Plants 0807cwiejkowskaNoch keine Bewertungen

- MeasurIT OilSpy Extended Brochure 1003Dokument5 SeitenMeasurIT OilSpy Extended Brochure 1003cwiejkowskaNoch keine Bewertungen

- MeasurIT Meaco RX Receiver 0911Dokument1 SeiteMeasurIT Meaco RX Receiver 0911cwiejkowskaNoch keine Bewertungen

- MeasurIT Flexim Sound Velocity and Density 0910Dokument1 SeiteMeasurIT Flexim Sound Velocity and Density 0910cwiejkowskaNoch keine Bewertungen

- MeasurIT Amcor Dehumidifiers D850 D950 0911Dokument1 SeiteMeasurIT Amcor Dehumidifiers D850 D950 0911cwiejkowskaNoch keine Bewertungen

- MeasurIT OilSpy Project River Faughan 0803Dokument1 SeiteMeasurIT OilSpy Project River Faughan 0803cwiejkowskaNoch keine Bewertungen

- MeasurIT OilSpy Project Rosny Sur Seine 0909Dokument1 SeiteMeasurIT OilSpy Project Rosny Sur Seine 0909cwiejkowskaNoch keine Bewertungen

- MeasurIT Meaco STX Transmitter 0911Dokument1 SeiteMeasurIT Meaco STX Transmitter 0911cwiejkowskaNoch keine Bewertungen

- MeasurIT Brune B500 Humidifier 0911Dokument8 SeitenMeasurIT Brune B500 Humidifier 0911cwiejkowskaNoch keine Bewertungen

- MeasurIT Quadbeam Product Spill Monitor Calibration Guide 0810Dokument2 SeitenMeasurIT Quadbeam Product Spill Monitor Calibration Guide 0810cwiejkowskaNoch keine Bewertungen

- MeasurIT Quadbeam Application Activated Sludge 0809Dokument1 SeiteMeasurIT Quadbeam Application Activated Sludge 0809cwiejkowskaNoch keine Bewertungen

- MeasurIT Quadbeam MSSD53 Transmitter 0803Dokument2 SeitenMeasurIT Quadbeam MSSD53 Transmitter 0803cwiejkowskaNoch keine Bewertungen

- MeasurIT Quadbeam S20 Suspended Solids Sensor 0803Dokument2 SeitenMeasurIT Quadbeam S20 Suspended Solids Sensor 0803cwiejkowskaNoch keine Bewertungen

- MeasurIT Quadbeam S10 Suspended Solids Sensor 0803Dokument2 SeitenMeasurIT Quadbeam S10 Suspended Solids Sensor 0803cwiejkowskaNoch keine Bewertungen

- MeasurIT Quadbeam Project Quarry 0809Dokument1 SeiteMeasurIT Quadbeam Project Quarry 0809cwiejkowskaNoch keine Bewertungen

- MeasurIT Quadbeam Application Diary Product Loss Monitoring 0809Dokument2 SeitenMeasurIT Quadbeam Application Diary Product Loss Monitoring 0809cwiejkowskaNoch keine Bewertungen

- MeasurIT Quadbeam Application Mixed Liquor 0809Dokument1 SeiteMeasurIT Quadbeam Application Mixed Liquor 0809cwiejkowskaNoch keine Bewertungen

- MeasurIT Quadbeam Application de Sludging 0803Dokument2 SeitenMeasurIT Quadbeam Application de Sludging 0803cwiejkowskaNoch keine Bewertungen

- MeasurIT Barben PH Sensors FAQ 0803Dokument3 SeitenMeasurIT Barben PH Sensors FAQ 0803cwiejkowskaNoch keine Bewertungen

- Practical No. 8 (A) : Address Label Mnemonics Hexcode CommentDokument4 SeitenPractical No. 8 (A) : Address Label Mnemonics Hexcode CommentSwapnil KansaraNoch keine Bewertungen

- M6 Series Diagnostic Ultrasound System Service ManualDokument266 SeitenM6 Series Diagnostic Ultrasound System Service ManualBruno AraújoNoch keine Bewertungen

- Kromschroder Ifd 258 Ifs258 ManualDokument36 SeitenKromschroder Ifd 258 Ifs258 ManualJesus MirelesNoch keine Bewertungen

- Group Delay As I Understand It by JOHN ORAMDokument2 SeitenGroup Delay As I Understand It by JOHN ORAMDávid BaltaváriNoch keine Bewertungen

- Load Flow - CompleteDokument4 SeitenLoad Flow - CompleteJohn Cristouv CortezNoch keine Bewertungen

- APOS Introduction Course (Mars - 09)Dokument77 SeitenAPOS Introduction Course (Mars - 09)RoyNoch keine Bewertungen

- Sage University Indore: Department of Computer Science and Information TechnologyDokument50 SeitenSage University Indore: Department of Computer Science and Information TechnologyAbhishek PatelNoch keine Bewertungen

- SBA (S) 2512 Rev 4Dokument4 SeitenSBA (S) 2512 Rev 4jvnraoNoch keine Bewertungen

- 18 A - Novel - 0.8-V - 79-nW - CMOS-Only - Voltage - Reference - With - 55-dB - PSRR - 100 - HZDokument5 Seiten18 A - Novel - 0.8-V - 79-nW - CMOS-Only - Voltage - Reference - With - 55-dB - PSRR - 100 - HZBalaramamurty SannidhiNoch keine Bewertungen

- Supplier Document Cover Sheet: RNP DCU Plant ProjectDokument12 SeitenSupplier Document Cover Sheet: RNP DCU Plant ProjectSlobodan MilosavljevicNoch keine Bewertungen

- Multi Player: This Manual Is Applicable To The Following Model (S) and Type (S)Dokument97 SeitenMulti Player: This Manual Is Applicable To The Following Model (S) and Type (S)Esmir MarinNoch keine Bewertungen

- M2710 Depliant ENG PDFDokument2 SeitenM2710 Depliant ENG PDFForTestNoch keine Bewertungen

- Quick Quiz 28Dokument29 SeitenQuick Quiz 28Hồng NhơnNoch keine Bewertungen

- FEC Mod1 1Dokument37 SeitenFEC Mod1 1Balaji Raja RajanNoch keine Bewertungen

- EA08A ManualDokument6 SeitenEA08A ManualDavid MoyaNoch keine Bewertungen

- Module 1 - Intro To Communication PDFDokument15 SeitenModule 1 - Intro To Communication PDFMark junnel NorberteNoch keine Bewertungen

- Embedded System Project - Khadija MuhammadDokument25 SeitenEmbedded System Project - Khadija MuhammadKhadija JaanNoch keine Bewertungen

- Wireless Set - ILB BT ADIO MUX-OMNI - 2884208: Key Commercial DataDokument20 SeitenWireless Set - ILB BT ADIO MUX-OMNI - 2884208: Key Commercial DataWander Mateus Dias PiresNoch keine Bewertungen

- As and A Level Physics Core Practical 6 SpeeDokument5 SeitenAs and A Level Physics Core Practical 6 SpeeHady JawadNoch keine Bewertungen

- 1SDA066701R1 A1b 125 TMF 40 400 3p F FDokument3 Seiten1SDA066701R1 A1b 125 TMF 40 400 3p F FOscar Jairo Reyes MezaNoch keine Bewertungen

- General InformationDokument4 SeitenGeneral InformationAferNoch keine Bewertungen

- EXPERIMENT 1 - Pre-Lab - Kit + Oscilloscope PDFDokument9 SeitenEXPERIMENT 1 - Pre-Lab - Kit + Oscilloscope PDFIsmail HamadNoch keine Bewertungen

- SERVOsoft v4 HelpDokument5 SeitenSERVOsoft v4 HelpDhrubajyoti BoraNoch keine Bewertungen

- Ta-Pt100 and Ta-Pt1000: Ambient Temperature Sensor With Platinum ResistanceDokument2 SeitenTa-Pt100 and Ta-Pt1000: Ambient Temperature Sensor With Platinum ResistanceEduardus PandikNoch keine Bewertungen

- Luvia Lumosa Lighting SpecsheetDokument4 SeitenLuvia Lumosa Lighting Specsheetingeniero.arv16Noch keine Bewertungen

- Stencil Confirm PleaseDokument2 SeitenStencil Confirm PleaseMECHANIC HONGKONGNoch keine Bewertungen

- S.E.S. Polytechnic, Solapur: CertificateDokument7 SeitenS.E.S. Polytechnic, Solapur: CertificateDeath noteNoch keine Bewertungen