Beruflich Dokumente

Kultur Dokumente

GR00001700 32 PDF

Hochgeladen von

Nicu PascalutaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

GR00001700 32 PDF

Hochgeladen von

Nicu PascalutaCopyright:

Verfügbare Formate

32-1

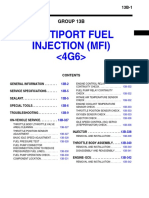

GROUP 32

POWER PLANT

MOUNT

CONTENTS

GENERAL INFORMATION . . . . . . . .

32-2

SERVICE SPECIFICATION . . . . . . . .

32-3

SPECIAL TOOL . . . . . . . . . . . . . . . . .

32-3

ENGINE MOUNTING . . . . . . . . . . . . .

32-4

REMOVAL AND INSTALLATION . . . . . . . .

32-4

TRANSMISSION MOUNTING . . . . . .

32-5

REMOVAL AND INSTALLATION . . . . . . . .

32-5

ENGINE ROLL STOPPER,

CENTERMEMBER . . . . . . . . . . . . . . .

32-7

REMOVAL AND INSTALLATION . . . . . . . .

32-7

CROSSMEMBER . . . . . . . . . . . . . . . .

32-8

REMOVAL AND INSTALLATION . . . . . . . .

32-8

POWER PLANT MOUNT

32-2

GENERAL INFORMATION

GENERAL INFORMATION

M1321000100340

The engine mounting system employs the inertial

axis four-point suspension method, which is field

proven.

The optimised locations of the front and rear roll

mounts well distribute their loads thereby

reducing engine idling vibrations.

The fore-and-aft, liquid-filled engine mount of

cylinder type is adopted to reduce engine shake

for improved riding comfort.

CONSTRUCTION DIAGRAM

Transmission mounting

body side bracket

Engine front

mounting bracket

Y0290AU

Engine rear roll stopper bracket

Engine front roll stopper bracket

AC107318

AC303563AB

POWER PLANT MOUNT

32-3

SERVICE SPECIFICATION

SERVICE SPECIFICATION

M1321000300333

Item

Standard value

Protruding length of stabilizer link thread part mm

22 1.5

SPECIAL TOOL

M1321000600378

Tool

AC106827

Number

Name

Use

MB991897

Ball joint remover

Knuckle and tie rod end ball joint

disconnection

NOTE: Steering linkage puller

(MB990635 or MB991113) is also

available to disconnect knuckle and

tie rod end ball joint.

POWER PLANT MOUNT

32-4

ENGINE MOUNTING

ENGINE MOUNTING

REMOVAL AND INSTALLATION

M1321001100440

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

Raise the engine and transmission assembly until its weight

is not applied to the insulator, and support it securely.

<4G1>

<4G6>

44 10 Nm*

12 2 Nm

67 7 Nm*

2N

44 10 Nm*

1

67 7 Nm*

2N

3

3

AC303999

1.

Removal steps

Pressure hose clamp <4G6>

AC303968

AC304304AB

2.

3.

Removal steps (Continued)

Self-locking nuts

Engine front mounting bracket

POWER PLANT MOUNT

32-5

TRANSMISSION MOUNTING

TRANSMISSION MOUNTING

REMOVAL AND INSTALLATION

M1321001400430

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

Raise the engine and transmission assembly until its

weight is not applied to the insulator, and support it

securely.

Battery and Battery tray Removal

Air Cleaner Removal (Refer to GROUP 15, Air Cleaner

P.15-2).

Engine Rear Roll Stopper Bracket Removal (Refer to

P.32-7).

Post-installation Operation

Engine Rear Roll Stopper Bracket Installation (Refer to

P.32-7).

Air Cleaner Installation (Refer to GROUP 15, Air Cleaner

P.15-2).

Battery and Battery tray Installation

<M/T>

<A/T>

80 7 Nm*

80 7 Nm*

47 7 Nm*

47 7 Nm*

2

2

1

2

1

AC303988

AC303989

AC304258AB

1.

>>A<< 2.

Removal steps

Transmission mounting body side

bracket

Transmission mounting stopper

POWER PLANT MOUNT

32-6

TRANSMISSION MOUNTING

INSTALLATION SERVICE POINT

>>A<< TRANSMISSION MOUNTING STOPPER

INSTALLATION

Engine side

Transmission

mounting body

side bracket

Transmission

mounting

stopper

AC200645 AB

Install the transmission mounting stopper so that its

arrow points upward.

POWER PLANT MOUNT

32-7

ENGINE ROLL STOPPER, CENTERMEMBER

ENGINE ROLL STOPPER, CENTERMEMBER

REMOVAL AND INSTALLATION

M1321002300287

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal and Post-installation Operation

Under Cover Removal and Installation

11 1 Nm

45 5 Nm*

69 10 Nm

<4G1>

<4G6>

45 5 Nm*

45 5 Nm*

52 7 Nm*

52 7 Nm*

52 7 Nm*

69 10 Nm

69 10 Nm

AC303978

AC304309AB

1.

>>B<< 2.

>>A<< 3.

4.

5.

6.

7.

Engine front roll stopper bracket

and centremember removal

steps

Engine front roll stopper bracket

connecting bolt

Centremember and engine front roll

stopper bracket assembly

Engine mounting cushion stopper

<4G6>

Engine front roll stopper bracket

Centremember

Engine rear roll stopper bracket

removal steps

Engine rear roll stopper bracket

connecting bolt

Transmission case rear roll stopper

bracket

Engine rear roll stopper bracket

INSTALLATION SERVICE POINTS

>>A<< ENGINE FRONT ROLL STOPPER

BRACKET INSTALLATION

Hole

Front of vehicle

AC005918AC

Install the engine front roll stopper bracket so that its

hole points towards the front side of the vehicle.

POWER PLANT MOUNT

32-8

CROSSMEMBER

>>B<< ENGINE MOUNTING CUSHION STOPPER

INSTALLATION <4G6>

Install the engine mounting cushion stopper as

shown.

Engine mounting

cushion stopper

Hole

Front of vehicle

AC304315 AB

CROSSMEMBER

REMOVAL AND INSTALLATION

M1321003200368

CAUTION

Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B Service Precautions P.52B-4, Air bag Module and Clock Spring P.52B-207. Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

*1: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

*2: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the earth in the unladen condition.

Pre-removal Operation

Centremember Removal (Refer to P.32-7).

Front Exhaust Pipe Removal (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

Steering Wheel Air Bag Module Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37A-15).

Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service P.37A-12).

Post-installation Operation

Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

Centremember Installation (Refer to P.32-7).

Clock Spring Centreing (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-207).

Steering Wheel Air Bag Module Assembly Installation

(Refer to 37, Steering Wheel P.37A-15).

Power Steering Fluid Supplying (Refer to GROUP 37A,

On-vehicle Service P.37A-12).

Power Steering Fluid Line Bleeding (Refer to GROUP 37,

On-vehicle Service P.37A-12).

Press the dust cover with a finger to check whether the

dust cover cracked or damaged.

Checking Steering Wheel Position with Wheels Straight

Ahead.

Front Wheel Alignment Check and Adjustment (Refer to

GROUP 33, On-vehicle Service P.33-5).

POWER PLANT MOUNT

32-9

CROSSMEMBER

<L.H. drive vehicles>

12 2 Nm

10

18 2 Nm

70 10 Nm

11 N

12

57 7 Nm

45 5 Nm* 1

70 10 Nm

13 N

14

16

25 4 Nm

21 4 Nm

15

21 4 Nm

7

52 7 Nm* 1

2N

108 10 Nm

3

17

1

186 10 Nm* 2

167 9 Nm

49 10 Nm

1.

>>B<< 2.

3.

4.

5.

6.

7.

8.

Removal steps

Lower arm and knuckle connection

Self-locking nut

Lower arm assembly

Shaft cover

Steering shaft assembly and gear

box connecting bolt

Engine rear roll stopper bracket

connection bolt

Engine rear roll stopper bracket

Return hose connection

9.

10.

11.

12.

13.

<<A>>

14.

<<B>>

>>A<< 15.

16.

17.

AC304000 AB

Removal steps (Continued)

Eye bolt

Pressure hose connection

Gasket

Clamp

Self-locking nut

Tie rod end and knuckle connection

Crossmember assembly

Stabilizer bar

Steering gear and linkage

Crossmember

POWER PLANT MOUNT

32-10

CROSSMEMBER

<R.H. drive vehicles>

57 7 Nm

18 2 Nm

5.0 1.0 Nm

70 10 Nm

45 5 Nm*

12

25 4 Nm

11

15

N 10

14

21 4 Nm

2N

13

52 7 Nm*

3

16

108 10 Nm

1

186 10 Nm*

167 9 Nm

49 10 Nm

AC101614 AE

1.

>>B<< 2.

3.

4.

5.

6.

7.

8.

9.

Removal steps

Lower arm and knuckle connection

Self-locking nut

Lower arm assembly

Eye bolt

Pressure hose connection

Gasket

Return hose connection

Shaft cover

Steering shaft assembly and gear

box connecting bolt

Removal steps (Continued)

10. Self-locking nut

<<A>>

11. Tie rod end and knuckle connection

12. Engine rear roll stopper bracket

connection bolt

<<B>>

Crossmember assembly

13. Engine rear roll stopper bracket

>>A<< 14. Stabilizer bar

15. Steering gear and linkage

16. Crossmember

POWER PLANT MOUNT

32-11

CROSSMEMBER

REMOVAL SERVICE POINTS

<<B>> CROSSMEMBER ASSEMBLY REMOVAL

<<A>> TIE ROD END AND KNUCKLE

DISCONNECTION

!

CAUTION

Do not remove the nut from ball joint. Loosen

it and use special tool to avoid possible

damage to ball joint threads.

Hang special tool with a cord to prevent it

from falling.

Piece of wood

Transmission

jack

Cord

MB991897

Nut

AC102600 AD

1. Use a transmission jack to hold the crossmember,

and then remove the crossmember mounting nuts

and bolts.

2. Lower the crossmember with the engine rear roll

stopper bracket, the stabilizer bar, the return tube,

and the steering gear.

Bolt

Ball joint

AC208247AD

1. Install the special tool ball joint remover

(MB991897) as shown in the figure.

INSTALLATION SERVICE POINTS

>>A<< STABILIZER BAR/BUSHING/FIXTURE

INSTALLATION

Outside of

vehicle

Approximately

10 mm

Bolt

Identification

mark

Parallel

Knob

Good

Bushing (LH)

Bad

Fixture (LH)

AC006141AD

AC106821AB

2. Turn the bolt and knob as necessary to make the

jaws of the special tool parallel, tighten the bolt by

hand and confirm that the jaws are still parallel.

NOTE: When adjusting the jaws in parallel, make

sure the knob is in the position shown in the

figure.

3. Tighten the bolt with a wrench to disconnect the

tie rod end.

Align the stabilizer bar identification mark with the

right end of the bushing (LH).

>>B<< SELF-LOCKING NUT INSTALLATION

A

AC101741 AC

Tighten the self-locking nut until the stabilizer link

thread part protruding length meets the standard

value.

Standard value (A): 22 1.5 mm

127(6

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Data Industri JabodetabekDokument669 SeitenData Industri JabodetabekBudy Nugraha88% (24)

- Safety Issues Report - FINAL DRAFTDokument12 SeitenSafety Issues Report - FINAL DRAFTCitizens who careNoch keine Bewertungen

- GR00005100 23a PDFDokument152 SeitenGR00005100 23a PDFNicu PascalutaNoch keine Bewertungen

- Alternators and Starter Motors 2003 PDFDokument106 SeitenAlternators and Starter Motors 2003 PDFjovopavlovic100% (4)

- Concrete Coating of Line Pipe PDFDokument19 SeitenConcrete Coating of Line Pipe PDFZadeh Norman100% (1)

- Properties and Changes of Matter Guided NotesDokument5 SeitenProperties and Changes of Matter Guided Notesapi-337287913100% (1)

- GR00007900 52B PDFDokument242 SeitenGR00007900 52B PDFNicu PascalutaNoch keine Bewertungen

- GR00005900 54C PDFDokument436 SeitenGR00005900 54C PDFNicu PascalutaNoch keine Bewertungen

- GR00007800 54a PDFDokument98 SeitenGR00007800 54a PDFNicu PascalutaNoch keine Bewertungen

- General Manual Sections OverviewDokument32 SeitenGeneral Manual Sections OverviewNicu Pascaluta100% (1)

- Lancer Wire DiagDokument2 SeitenLancer Wire DiagNicu Pascaluta100% (1)

- GR00006400 35B PDFDokument70 SeitenGR00006400 35B PDFNicu PascalutaNoch keine Bewertungen

- GR00008000 55 PDFDokument102 SeitenGR00008000 55 PDFNicu PascalutaNoch keine Bewertungen

- GR00005800 54B PDFDokument414 SeitenGR00005800 54B PDFNicu Pascaluta100% (1)

- GR00000900 13a PDFDokument402 SeitenGR00000900 13a PDFNicu PascalutaNoch keine Bewertungen

- GR00007600 31 PDFDokument8 SeitenGR00007600 31 PDFNicu PascalutaNoch keine Bewertungen

- Power Steering Maintenance and Repair GuideDokument40 SeitenPower Steering Maintenance and Repair GuideNicu PascalutaNoch keine Bewertungen

- GR00006500 36 PDFDokument10 SeitenGR00006500 36 PDFNicu PascalutaNoch keine Bewertungen

- GR00006900 00e PDFDokument12 SeitenGR00006900 00e PDFNicu PascalutaNoch keine Bewertungen

- GR00006000 33 PDFDokument16 SeitenGR00006000 33 PDFNicu PascalutaNoch keine Bewertungen

- GR00006300 35a PDFDokument26 SeitenGR00006300 35a PDFNicu PascalutaNoch keine Bewertungen

- GR00006100 34 PDFDokument20 SeitenGR00006100 34 PDFNicu PascalutaNoch keine Bewertungen

- GR00001100 13B PDFDokument342 SeitenGR00001100 13B PDFNicu PascalutaNoch keine Bewertungen

- GR00005400 27 PDFDokument6 SeitenGR00005400 27 PDFNicu PascalutaNoch keine Bewertungen

- GR00005300 26 PDFDokument22 SeitenGR00005300 26 PDFNicu PascalutaNoch keine Bewertungen

- GR00004700 52a PDFDokument36 SeitenGR00004700 52a PDFNicu Pascaluta100% (1)

- GR00003800 23B PDFDokument58 SeitenGR00003800 23B PDFNicu PascalutaNoch keine Bewertungen

- GR00003000 11D PDFDokument60 SeitenGR00003000 11D PDFNicu PascalutaNoch keine Bewertungen

- GR00005200 21a PDFDokument10 SeitenGR00005200 21a PDFNicu Pascaluta100% (1)

- GR00004900 22a PDFDokument18 SeitenGR00004900 22a PDFNicu PascalutaNoch keine Bewertungen

- Engine Overhaul Manual Section for 4G1 EngineDokument50 SeitenEngine Overhaul Manual Section for 4G1 EngineNicu Pascaluta100% (2)

- GR00004500 42 PDFDokument60 SeitenGR00004500 42 PDFNicu PascalutaNoch keine Bewertungen

- GR00004000 22B PDFDokument58 SeitenGR00004000 22B PDFNicu PascalutaNoch keine Bewertungen

- Interior and Supplemental Restraint System (SRS) : Group 52Dokument2 SeitenInterior and Supplemental Restraint System (SRS) : Group 52Nicu PascalutaNoch keine Bewertungen

- GR00004600 51 PDFDokument44 SeitenGR00004600 51 PDFNicu PascalutaNoch keine Bewertungen

- Lec 6Dokument5 SeitenLec 6Abderrahim HAMDAOUINoch keine Bewertungen

- Olive Oil InfrastructuresDokument5 SeitenOlive Oil InfrastructuresShahzad ShameemNoch keine Bewertungen

- KLINGER AUSTRALIA BrochureDokument8 SeitenKLINGER AUSTRALIA BrochureMichael PhamNoch keine Bewertungen

- Building material thermal properties tableDokument19 SeitenBuilding material thermal properties tablehansleyNoch keine Bewertungen

- Katherine Davis, Gary Eddy, Alex Johannigman, Nathan ValdezDokument1 SeiteKatherine Davis, Gary Eddy, Alex Johannigman, Nathan Valdezanon_760617705Noch keine Bewertungen

- Rock Proof: Liquid Water Integral WaterproofDokument2 SeitenRock Proof: Liquid Water Integral Waterproofimran jamalNoch keine Bewertungen

- DOE Guidance WBSDokument20 SeitenDOE Guidance WBSShowki WaniNoch keine Bewertungen

- Jotamastic 70Dokument9 SeitenJotamastic 70Muhammad HanafiNoch keine Bewertungen

- Using Lock-N-Stitch Procedures For Casting Repair (0676, 0685) (SEBF8882)Dokument20 SeitenUsing Lock-N-Stitch Procedures For Casting Repair (0676, 0685) (SEBF8882)Chrisdian FaraniNoch keine Bewertungen

- Impact of Covid-19 On The Automotive Industry: By: Raman ATUL (19109029) RohitDokument14 SeitenImpact of Covid-19 On The Automotive Industry: By: Raman ATUL (19109029) RohitRaman BansalNoch keine Bewertungen

- Operation & Maintenance Manual: For Vahterus Plate & Shell Heat ExchangersDokument32 SeitenOperation & Maintenance Manual: For Vahterus Plate & Shell Heat ExchangersMarkNoch keine Bewertungen

- R5000 PriceInfoSheetDokument2 SeitenR5000 PriceInfoSheetDominique OnealNoch keine Bewertungen

- SS2205 Material SpecificationDokument4 SeitenSS2205 Material SpecificationCh FaiNoch keine Bewertungen

- Tutorial 2 Chapter 2Dokument2 SeitenTutorial 2 Chapter 2Marko IrwinNoch keine Bewertungen

- D173 PDFDokument2 SeitenD173 PDFArnold RojasNoch keine Bewertungen

- pd10196 Tetra Alsafe PDFDokument2 Seitenpd10196 Tetra Alsafe PDFEusebio NavarroNoch keine Bewertungen

- Properties of Fluids ExplainedDokument13 SeitenProperties of Fluids ExplainedGie Andal0% (3)

- Product Data Sheet: Current Limiter, Tesys U / Tesys Gv2, 32A/690V, Activation 1ka, Iq 100Ka@440V, Din Rail MountingDokument2 SeitenProduct Data Sheet: Current Limiter, Tesys U / Tesys Gv2, 32A/690V, Activation 1ka, Iq 100Ka@440V, Din Rail MountingJorge MartinsNoch keine Bewertungen

- Effects of On-Line Melt Blending of Polypropylene With Polyamide 6 On The Bulk and Strength of The Resulting BCF YarnDokument10 SeitenEffects of On-Line Melt Blending of Polypropylene With Polyamide 6 On The Bulk and Strength of The Resulting BCF YarnianNoch keine Bewertungen

- Breviar de Calcul - Cos C.R.Dokument63 SeitenBreviar de Calcul - Cos C.R.tulvyNoch keine Bewertungen

- Condenser Bushings 25 KVDokument8 SeitenCondenser Bushings 25 KVOktafian PrabandaruNoch keine Bewertungen

- 10 ElectrochemistryDokument77 Seiten10 ElectrochemistrySyamil Adzman100% (1)

- Process of P-Xylene Production by Highly Selective Methylation of Toluene PDFDokument8 SeitenProcess of P-Xylene Production by Highly Selective Methylation of Toluene PDFMarco Antonio FeriaNoch keine Bewertungen

- List of Oil ZF PDFDokument16 SeitenList of Oil ZF PDFJhon SyalfiandyNoch keine Bewertungen

- Filtro Bacteriologico Puritan BennetDokument24 SeitenFiltro Bacteriologico Puritan BennetRonald David ReyesNoch keine Bewertungen