Beruflich Dokumente

Kultur Dokumente

Video-Based Thermography For Combustion Processes

Hochgeladen von

Heri SetyantoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Video-Based Thermography For Combustion Processes

Hochgeladen von

Heri SetyantoCopyright:

Verfügbare Formate

Video-based Thermography for

Combustion Processes

Sensor 2

Boiler

Sensor 1

Control

Field Control Cabinet

Video Signal

Digital Video- and

Data Link

(Fiber Optic Cable)

Video Signal

Field Control Cabinet

Control

Digital Video- and

Data Link

(Fiber Optic Cable)

Control Room

Video

Monitor 1

Video

Monitor 2

ThermographyMonitor

System PC

smart solutions for combustion and environment

Video Monitoring

Thermography

The Video-based D-VTA 100-10

Thermography System

The Field Components

The Thermography Analysis System

is a modular system for monitoring industrial

high temperature processes. Intelligent sensors

allow contactless, optical and thermal online analysis of processes in the combustion chamber.

Applications include:

Pneumatically operated retraction system

with monitoring units for the cooling and

flushing media, including integrated air accumulator

Field control cabinet for control of the sensors, signal processing for the data and video

transmission via fibre-optic cable to the control room.

The thermography system comprises the components of the video system plus the system

computer with software modules.

It operates as a spatial optical pyrometer on the

basis of image data processing and offers, in addition to the video system:

Detection of the Temperature Distribution in

side combustion chambers; analysis of unbalanced combustion processes

Burning analysis and slag monitoring in

power plants

Visualization of flame post combustion chambers and flame front monitoring in waste

incineration plants

Monitoring ore calcination and hazardous

waste disposal in the chemical industry

Annealing and pusher furnace monitoring in

the steel industry

Scale formation and melting charge control in

the glass industry.

The Sensors

The Control Room Equipment

Linux based system computer for temperature calculation, thermography presentation

Video monitor for online colour display

The Video System

The basic system comprises the above-mentioned system components, without system

computer. It enables visual monitoring through

real-time colour video display.

Temperature determination of each visible

image point of the video sensor

Thermal analysis of the local temperature distribution

Temperature definition within freely definable

measuring window and lines (ROI = Region of

Interest / LOI = Line Of Interest).

Analysis of thermal samples to identify anomalies in the combustion process

All data of the thermography system can be

transmitted to the process control system via a

standardized data interface.

have been specially developed for the harsh working conditions in industrial combustions.

The sensor housing contains the special boroscope as optical system, or the videoscope and

the industrial CCD camera. In this design all electronic components are operated outside the kiln

area, in the cooled camera housing.

The slim, air or water-cooled sensor shaft

(43mm) minimises the mechanical stress (abrasive dust) and the thermal influence on the

sensor parts in the combustion chamber.

The optical system is protected against mechanical and thermal damage by a sapphire lens at

the sensor tip, in addition to air flushing. As no

moving parts (no mirrors, prisms or motors) are

located in the process-oriented area, the sensors

achieve a high availability with minimum service

requirement.

Furnace Camera with Retraction Unit (water-cooled)

Waste Incineration Plant

Power Plant

Chemical Industry

Analysis System

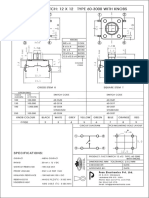

Technical Data

Video system

Thermography

Temperature range

from total radiation 1000C 2000C

Flame temperature distribution shown in a

colour-coded thermographic picture

Optical alignment

Sensor 0: axially-parallel to

sensor axis,

Sensor45: angled 45 to

sensor axis

Optical field of

view

Sensor 0:

horizontal 72, vertical 54,

diagonal 90;

Sensor 45:

horizontal 48, vertical 36,

diagonal 60

Data interfaces on

the system PC

RS232, RS422, RS485:

ASCII, MODBUS, Siemens RK512;

Ethernet: TCP/IP: FTP, MODBUS

Auxiliary energy

230 V / 50 Hz, 500 VA

Gas temperature

in combustion

chamber

Water-cooled sensor

<2000C

Ambient

temperature

Sensor / Retraction: 0C60C,

Field control cabinet: 0C55C

Material

Sensor: stainless steel 1.4571

/ 1.4301, Field control cabinet:

steel sheet, painted in RAL 7035

Dimensions /

Weights

Diameter of sensor tip:

water-cooled 43 mm

Immersion depth

in combustion

chamber

max. 450 mm from welding

plate, other lengths optional

Determination of the flame front

position on the grid

Trend curves of the flame front and

temperatures from 3 selected regions

Thermography screen (waste incineration plant)

Thermography system in a waste

incineration plant.

Two separate furnace sensors allow for

optimal grate monitoring in all zones.

Boiler

Sensor 1

Waste

Feeder

Control

Field Control Cabinet

Space requirement

for sensor /

1450 x 500 x 800 mm (LxWxH)

retraction device

Field cabinet

600 x 380 x 210 mm (HxWxD)

Cable length

Sensor/Retraction Field control

cabinet 10 m

Connection Site /

Control Room

Optical Fiber, max. 1000 m

System PC

19 industrial housing, 4 HE,

depth 450 mm

Weights

Sensor with retraction and

carrier 70 kg,

Field control cabinet 15 kg

Cooling water

volume

350 l/h, 1.58 barg

Cooling water

temperature

Inlet: <45C, Outlet: Temperature

increase <10 C

Cooling water

quality

Clean, chemically neutral,

non-corrosive,

Hardness: <5dH / <28 mMol/l

Compressed air

volume

max. 25 Nm3/h

Compressed air

pressure

5 8 barg

Compressed air

temperature

540C

Compressed air

quality

dry, free from dust, aerosols, oil

Digital Video- and Data Link

Video Signal

(Fibre Optics)

Sensor 2

Control

Field Control Cabinet

Video Signal

Digital Video- and

Data Link

(Fibre Optics)

Control Room

Video

Monitor 1

Video

Monitor 2

Graphic

Monitor

System PC

D-VTA 100-10 System in a Waste Incineration Plant

Steel Industry

Paper Industry

PAL, picture elements:

752(H) x 582(V), fixed focus

Glas Industry

DURAG Inc.

DURAG UK

DURAG France

DURAG Germany

DURAG Italy

DURAG

India

DURAG Japan

DURAG Brazil

DURAG GmbH

Kollaustrae 105

22453 Hamburg, Germany

Tel. +49 (0)40 55 42 18-0

Fax +49 (0)40 58 41 54

E-Mail: info@durag.de

DURAG, Inc., USA

1355 Mendota Heights Road Suite 200

Mendota Heights MN 55120, USA

Tel. +1 651 451-1710

Fax +1 651 457-7684

E-Mail: durag@durag.com

DURAG Niederlassung Nord

Kollaustrae 105

22453 Hamburg, Germany

Tel. +49 (0)40 55 42 18-0

Fax +49 (0)40 58 41 54

E-Mail: DURAG-Nord@durag.de

DURAG India Instrumentation Ltd

#143/16, Ground Floor, 4th Main Road

Industrial Town, Rajajinagar

Bengalooru 560 044, India

Tel. +91 (0)80 23 14 56 26

Fax +91 (0)80 23 14 56 26 Ext. 30

E-Mail: info@duragindia.com

DURAG Niederlassung Ost

Meiner Ring 4

09599 Freiberg, Germany

Tel.+49 (0)3731 30 04-0

Fax+49 (0)3731 30 04-22

E-Mail: DURAG-Ost@durag.de

DURAG France S.a.r.l.

Parc GIP Charles de Gaulle

49, rue Lonard de Vinci, BP 70166

95691 Goussainville CEDEX, France

Tel. +33 (0)1 301 811 80

Fax +33 (0)1 393 383 60

E-Mail: info@durag-france.fr

DURAG Niederlassung Sd

Weidenweg 16

73087 Bad Boll, Germany

Tel.+49 (0)7164 912 25-0

Fax+49 (0)7164 912 25-50

E-Mail: DURAG-Sued@durag.de

DURAG Niederlassung West

An der Pnt 53a

40885 Ratingen, Germany

Tel.+49 (0)2102 74 00-0

Fax+49 (0)2102 74 00 28

E-Mail: DURAG-West@durag.de

www.durag.de

DURAG GROUP 08/2010 Subject to change without notice

DURAG Italia S.r.l.

Via Carlo Panseri, 118

28100 Novara, Italy

E-Mail: info@durag.it

DURAG UK Oce

Suite 17, Brookside Business Park

Cold Meece, Stone, Staffordshire

ST15 0RZ, United Kingdom

Tel. +44 (0)1785 760 007

Fax +44 (0)1785 760 014

E-Mail: durag.uk@durag.de

DURAG Japan Oce

c/o TMS Planning Inc.

291-2 Umena, Mishima-shi, Shizuoka-ken,

411-0816 Japan

Tel./Fax: +81 (0)55 977 3994

E-Mail: saito@durag.jp

DURAG Brazil Oce

Rua Jos Amaro Pecanha, 58

05126-150 Sao Paulo - SP, Brazil

Tel: +55 11 3902 3306

Fax: +55 11 3902 2382

E-Mail: ednaldo@durag.com.br

DURAG data systems GmbH

Kollaustrae 105,

22453 Hamburg, Germany

Tel. +49 (0)40 55 42 18-3000

Fax +49 (0)40 55 42 18-3099

E-Mail: info@durag-data.de

DURAG process & systems technology gmbh

Kollaustrae 105

22453 Hamburg, Germany

Tel. +49 (0)40 55 42 18-0

Fax +49 (0)40 58 41 54

E-Mail: info@durag-process.de

VEREWA Umwelt- und Prozessmesstechnik

GmbH

Kollaustrae 105

22453 Hamburg, Germany

Tel. +49 (0)40 55 42 18-0

Fax +49 (0)40 58 41 54

E-Mail: verewa@durag.de

Hegwein GmbH

Am Boschwerk 7

70469 Stuttgart, Germany

Tel. +49 (0)711 135 788-0

Fax +49 (0)711 135 788-5

E-Mail: info@hegwein.de

SMITSVONK Holland B.V.

P.O. Box 180, 2700 AD Zoetermeer

Loodstraat 57, 2718 RV Zoetermeer

Netherlands

Tel. +31 (0)79 361 35 33

Fax +31 (0)79 361 13 78

E-mail: sales@smitsvonk.nl

smart solutions for combustion and environment

Das könnte Ihnen auch gefallen

- Video and Thermography Analyzing System For Cement PlantsDokument4 SeitenVideo and Thermography Analyzing System For Cement PlantshamidkatebiNoch keine Bewertungen

- 8388 Mmy170Dokument56 Seiten8388 Mmy170thotalnNoch keine Bewertungen

- Memmert CO2-incubator ICO105 ENDokument4 SeitenMemmert CO2-incubator ICO105 ENMoh. andi sulaimanNoch keine Bewertungen

- Memmert CO2 Incubator ICO105med - enDokument4 SeitenMemmert CO2 Incubator ICO105med - enRenaldo MoontriNoch keine Bewertungen

- Prospekt Ersa Hammerpreise Productronica 2013 en WebDokument12 SeitenProspekt Ersa Hammerpreise Productronica 2013 en WebbehzadNoch keine Bewertungen

- Securisens Adw 535: Product InformationDokument2 SeitenSecurisens Adw 535: Product Informationanak1n888Noch keine Bewertungen

- GST Fire Alarm System-CatalogDokument72 SeitenGST Fire Alarm System-Catalogadityapraztt75% (4)

- E-Series Folder PMDokument4 SeitenE-Series Folder PMqxyzNoch keine Bewertungen

- 4 S200A Series Detectors India Made Morley IAS DatasheetDokument6 Seiten4 S200A Series Detectors India Made Morley IAS DatasheetingeniouNoch keine Bewertungen

- Dew Point Meter XentourDokument4 SeitenDew Point Meter XentourBhaskar KumarNoch keine Bewertungen

- Auto Distillation AnalyserDokument4 SeitenAuto Distillation AnalyserVijayraj ThangarajuNoch keine Bewertungen

- Greenline 8000 Basic Price and InfoDokument6 SeitenGreenline 8000 Basic Price and InfoRobson SantosNoch keine Bewertungen

- Mmy 170Dokument4 SeitenMmy 170thotalnNoch keine Bewertungen

- Asoma Model 682t HPDokument2 SeitenAsoma Model 682t HPJairo SotomayorNoch keine Bewertungen

- WTM V10 - eDokument2 SeitenWTM V10 - ejamal009Noch keine Bewertungen

- Temperature Recorder: Service Address: Termoplus S.C. Ul..brandwicka 104 37-464 Stalowa WolaDokument23 SeitenTemperature Recorder: Service Address: Termoplus S.C. Ul..brandwicka 104 37-464 Stalowa WolaLászló AcsaiNoch keine Bewertungen

- Hatch Data SheetDokument4 SeitenHatch Data SheetRay CastNoch keine Bewertungen

- STULZ Wall-Air Displacement Evolution 0712 enDokument8 SeitenSTULZ Wall-Air Displacement Evolution 0712 enAnonymous MVbaaUBSZTNoch keine Bewertungen

- Desmon Scientific Catalogo Ult PDFDokument8 SeitenDesmon Scientific Catalogo Ult PDFEnrique Gonzales MontesNoch keine Bewertungen

- TB7300 Series Communicating Fan Coil Thermostats: 24 Vac For Commercial and Lodging Hvac ApplicationsDokument4 SeitenTB7300 Series Communicating Fan Coil Thermostats: 24 Vac For Commercial and Lodging Hvac ApplicationsCarlos BarrazaNoch keine Bewertungen

- WDG Insitu 210 ObsoleteDokument2 SeitenWDG Insitu 210 ObsoleteChinna ThambiNoch keine Bewertungen

- 5753 LDokument7 Seiten5753 LYousuf IbrahimNoch keine Bewertungen

- Automatic Fire Detectors SIEMENSDokument10 SeitenAutomatic Fire Detectors SIEMENSEmir PanjetaNoch keine Bewertungen

- AutoclavesDokument4 SeitenAutoclavesMohammad SaadNoch keine Bewertungen

- FLIR A325sc DatasheetDokument2 SeitenFLIR A325sc Datasheetlegato13Noch keine Bewertungen

- Memmert Environmental Test Chambers CTC256.enDokument5 SeitenMemmert Environmental Test Chambers CTC256.enanil nsNoch keine Bewertungen

- Lorentz Solarparks Pi enDokument4 SeitenLorentz Solarparks Pi enapi-36492444Noch keine Bewertungen

- Portable Air Quality Monitor: SpecificationsDokument1 SeitePortable Air Quality Monitor: SpecificationsZoel AsNoch keine Bewertungen

- KB 53 (E3.1) - Refrigerated Incubator With Program ControllerDokument4 SeitenKB 53 (E3.1) - Refrigerated Incubator With Program ControllerDavid EguezNoch keine Bewertungen

- Sand Bath For Cathodic Disbondment TesterDokument2 SeitenSand Bath For Cathodic Disbondment TesterNova Instruments Pvt LtdNoch keine Bewertungen

- Data Sheet GCEM40 SeriesDokument6 SeitenData Sheet GCEM40 SerieskaicyemNoch keine Bewertungen

- Flir c2 PDFDokument2 SeitenFlir c2 PDFOmar LeonNoch keine Bewertungen

- Uv Aging Test ChamberDokument5 SeitenUv Aging Test Chamberlisun008Noch keine Bewertungen

- Uv Aging Test ChamberDokument5 SeitenUv Aging Test ChamberLisun GroupNoch keine Bewertungen

- Proforma Invoice Nr. 158725: Our Ref: Date: Your RefDokument26 SeitenProforma Invoice Nr. 158725: Our Ref: Date: Your RefmbstutextileNoch keine Bewertungen

- Autoclave With Fully-Automated Process For Easy & Quick ControlDokument13 SeitenAutoclave With Fully-Automated Process For Easy & Quick ControlAthar Ali Khan SuperintendentNoch keine Bewertungen

- Univario Tech Data CombinedDokument10 SeitenUnivario Tech Data CombineddbrodarNoch keine Bewertungen

- Manual 1 PDFDokument31 SeitenManual 1 PDFdarrel_julioNoch keine Bewertungen

- Marathon MM, MR, FA, FRDokument4 SeitenMarathon MM, MR, FA, FRpenityNoch keine Bewertungen

- Fire AlarmDokument52 SeitenFire Alarmduybac-spkhcmNoch keine Bewertungen

- Elcometer 319 - Dewpoint MeterDokument5 SeitenElcometer 319 - Dewpoint MeterArya KamiNoch keine Bewertungen

- TH1 TH2 Ecolog Catalogo eDokument8 SeitenTH1 TH2 Ecolog Catalogo eMarco GuzmánNoch keine Bewertungen

- Memmert - Vacuum Oven VO29Dokument4 SeitenMemmert - Vacuum Oven VO29Indah Nur FadhilahNoch keine Bewertungen

- Etuva Binder EdDokument7 SeitenEtuva Binder EdGiurgi IoanNoch keine Bewertungen

- Memmert CO2 Incubator ICO50med - enDokument4 SeitenMemmert CO2 Incubator ICO50med - enLuis Alberto Díaz OlmedoNoch keine Bewertungen

- Heat Detector PDFDokument1 SeiteHeat Detector PDFKiran VankudreNoch keine Bewertungen

- Meteo Dataloggers & Sensors: Automatic Measuring StationsDokument12 SeitenMeteo Dataloggers & Sensors: Automatic Measuring StationsMilton Damián Cornejo ReyesNoch keine Bewertungen

- Technical Data Sheets C CHA4082 ADokument5 SeitenTechnical Data Sheets C CHA4082 AmsinanacikgozNoch keine Bewertungen

- Incubator If30Dokument4 SeitenIncubator If30ThabetNoch keine Bewertungen

- Onesense Sun - THDokument7 SeitenOnesense Sun - THBeanAirNoch keine Bewertungen

- Cat HygroGuard E PDFDokument4 SeitenCat HygroGuard E PDFWilbur SuandingNoch keine Bewertungen

- Jumo Tecline Ci-S Inductive Conductivity and Temperature Sensor For General Process EngineeringDokument9 SeitenJumo Tecline Ci-S Inductive Conductivity and Temperature Sensor For General Process EngineeringvkmsNoch keine Bewertungen

- Fire Alarm System-Catalog PDFDokument33 SeitenFire Alarm System-Catalog PDFHoaithu Nguyen100% (1)

- System 8000Dokument10 SeitenSystem 8000ayad60Noch keine Bewertungen

- Memmert Climate Chamber ICH110.EnDokument4 SeitenMemmert Climate Chamber ICH110.EnHythamMidaniNoch keine Bewertungen

- KELVIN 350 BrochureDokument2 SeitenKELVIN 350 Brochuretanto_deep_15Noch keine Bewertungen

- Service Manual Prothermii en 08 2004Dokument49 SeitenService Manual Prothermii en 08 2004Radu IstodorescuNoch keine Bewertungen

- Submittal Asd872aDokument9 SeitenSubmittal Asd872ajibanez003Noch keine Bewertungen

- Gasmet CX4000 Technical Data (v1.7)Dokument2 SeitenGasmet CX4000 Technical Data (v1.7)mohammedelamenNoch keine Bewertungen

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionVon EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Hy Turbo Generator enDokument18 SeitenHy Turbo Generator enHeri SetyantoNoch keine Bewertungen

- Industrial Penstocks Catalogue 2013Dokument21 SeitenIndustrial Penstocks Catalogue 2013Heri SetyantoNoch keine Bewertungen

- Gt13e2 Gas Turbine PosterDokument1 SeiteGt13e2 Gas Turbine PosterHeri SetyantoNoch keine Bewertungen

- Voith Small Hydro PDFDokument10 SeitenVoith Small Hydro PDFHeri SetyantoNoch keine Bewertungen

- Wasserkraft Prospekt - EnglischDokument16 SeitenWasserkraft Prospekt - EnglischHeri SetyantoNoch keine Bewertungen

- Ansaldo Solution For Geothermal Power PlantsDokument8 SeitenAnsaldo Solution For Geothermal Power PlantsHeri SetyantoNoch keine Bewertungen

- Small Hydroelectric Power Plant - Project Summary PDFDokument6 SeitenSmall Hydroelectric Power Plant - Project Summary PDFHeri SetyantoNoch keine Bewertungen

- Mavel Delivers Five Kaplan Turbines To 24 MW Polotstkaya Project in The Republic of BelarusDokument2 SeitenMavel Delivers Five Kaplan Turbines To 24 MW Polotstkaya Project in The Republic of BelarusHeri SetyantoNoch keine Bewertungen

- Foreign ManufacturersDokument8 SeitenForeign ManufacturersHeri SetyantoNoch keine Bewertungen

- No Product Description Qty Remarks: IMCIS22 Adalah Control I/O Module 4AI, 3DI, 4DO, 2AODokument1 SeiteNo Product Description Qty Remarks: IMCIS22 Adalah Control I/O Module 4AI, 3DI, 4DO, 2AOHeri SetyantoNoch keine Bewertungen

- HDRM OverviewsDokument8 SeitenHDRM OverviewsHeri SetyantoNoch keine Bewertungen

- Driving Directions - Sky HarborDokument1 SeiteDriving Directions - Sky HarborHeri SetyantoNoch keine Bewertungen

- CMI ENERGY Industrial Boilers HRSGDokument2 SeitenCMI ENERGY Industrial Boilers HRSGHeri SetyantoNoch keine Bewertungen

- Catalogue: Automatic Control ValvesDokument44 SeitenCatalogue: Automatic Control ValvesHeri SetyantoNoch keine Bewertungen

- Bro Smitsvonk Products en PDFDokument24 SeitenBro Smitsvonk Products en PDFHeri SetyantoNoch keine Bewertungen

- Catalogue: Automatic Control ValvesDokument44 SeitenCatalogue: Automatic Control ValvesHeri SetyantoNoch keine Bewertungen

- Delatite Vs VtiDokument2 SeitenDelatite Vs VtiHeri SetyantoNoch keine Bewertungen

- HDRM Series PDFDokument2 SeitenHDRM Series PDFHeri SetyantoNoch keine Bewertungen

- Whoer Hydr Car ParkDokument45 SeitenWhoer Hydr Car ParkHeri SetyantoNoch keine Bewertungen

- APV-LLK-2 Ball Valve BrochureDokument13 SeitenAPV-LLK-2 Ball Valve BrochureHeri SetyantoNoch keine Bewertungen

- OTC 19114 GIFT (Gas Import Floating Terminal) : A New Concept of Floating LNG TerminalDokument1 SeiteOTC 19114 GIFT (Gas Import Floating Terminal) : A New Concept of Floating LNG TerminalHeri SetyantoNoch keine Bewertungen

- C2DP-40CP OptexDokument12 SeitenC2DP-40CP OptexFernando EspinosaNoch keine Bewertungen

- Determination of Trace Sulfur Method With Non-Dispersive Gas PDFDokument4 SeitenDetermination of Trace Sulfur Method With Non-Dispersive Gas PDFRuben Perez AyoNoch keine Bewertungen

- Solutions - JEE Main 2024 January Question Bank - MathonGoDokument7 SeitenSolutions - JEE Main 2024 January Question Bank - MathonGoLeo UzumakiNoch keine Bewertungen

- Toshiba VFS15 User ManualDokument361 SeitenToshiba VFS15 User ManualdanyNoch keine Bewertungen

- The Periodic TableDokument16 SeitenThe Periodic TableKayla HerdsmanNoch keine Bewertungen

- Communicating With The MicroprocessorDokument13 SeitenCommunicating With The MicroprocessorRyan John de LaraNoch keine Bewertungen

- Supply - Chain - Master - Data - SAP IBPDokument12 SeitenSupply - Chain - Master - Data - SAP IBPharry4sapNoch keine Bewertungen

- Cast Iron Gate Valve Non Rising Stem PN16: Features & BenefitsDokument1 SeiteCast Iron Gate Valve Non Rising Stem PN16: Features & BenefitsMohamed RaafatNoch keine Bewertungen

- Thermowax Issues Reparation Autochoke Som fastnat-GCV140-160-190Dokument6 SeitenThermowax Issues Reparation Autochoke Som fastnat-GCV140-160-190coyote556Noch keine Bewertungen

- Rectangular Flange DesignDokument6 SeitenRectangular Flange DesignTAHIR MAHMOODNoch keine Bewertungen

- BS 01916-3-2009Dokument34 SeitenBS 01916-3-2009pacoNoch keine Bewertungen

- Oracle Database: Performance Tuning Guide 12c Release 1 (12.1)Dokument340 SeitenOracle Database: Performance Tuning Guide 12c Release 1 (12.1)sanjayid1980Noch keine Bewertungen

- Manual - Book-Vektor Ablerex - MsiiDokument24 SeitenManual - Book-Vektor Ablerex - MsiiIndonesian's LOVENoch keine Bewertungen

- Must-On Board Diagnostics II PCED PDFDokument19 SeitenMust-On Board Diagnostics II PCED PDFRopama BraNoch keine Bewertungen

- P521 OrderForm - V18 - 09 - 2014Dokument11 SeitenP521 OrderForm - V18 - 09 - 2014Pakde NdokNoch keine Bewertungen

- Acr 1 Final 2021Dokument5 SeitenAcr 1 Final 2021CAROLYN RhoeNoch keine Bewertungen

- Tact Micro Switch 12X12Dokument1 SeiteTact Micro Switch 12X12Solin CozNoch keine Bewertungen

- Traffic Flow Theory and Delay - Part6Dokument5 SeitenTraffic Flow Theory and Delay - Part6Sai Kumar0% (1)

- A Presentation On ER-DiagramDokument9 SeitenA Presentation On ER-DiagramLee Kally100% (1)

- P 278 - GN 1007Dokument25 SeitenP 278 - GN 1007Doben DalisayNoch keine Bewertungen

- Setting Up SSL On Oracle WebLogic Server (Configuración de Certificado SSL en PeopleSoft)Dokument17 SeitenSetting Up SSL On Oracle WebLogic Server (Configuración de Certificado SSL en PeopleSoft)Jesús ArredondoNoch keine Bewertungen

- Govindarajulu Computer ArchitectureDokument4 SeitenGovindarajulu Computer ArchitectureLori0% (2)

- Datasheet PDFDokument15 SeitenDatasheet PDFperro sNoch keine Bewertungen

- Mercer 9100Dokument16 SeitenMercer 9100dtmgoNoch keine Bewertungen

- P30 Drivetrain Repair - Sports CarDokument104 SeitenP30 Drivetrain Repair - Sports CarAllan Cancino100% (1)

- RN Nemo Outdoor 7 6 0 7 30th June 2015Dokument55 SeitenRN Nemo Outdoor 7 6 0 7 30th June 2015yatishjainkotaNoch keine Bewertungen

- Micro-2407 User Must ReadDokument124 SeitenMicro-2407 User Must ReadShyam SundarNoch keine Bewertungen

- LinuxDokument16 SeitenLinuxJon ExcaliburNoch keine Bewertungen

- BETL STR Offshore Wind E-Book - FINALDokument9 SeitenBETL STR Offshore Wind E-Book - FINALir_zainalNoch keine Bewertungen