Beruflich Dokumente

Kultur Dokumente

876

Hochgeladen von

Usama PerwezCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

876

Hochgeladen von

Usama PerwezCopyright:

Verfügbare Formate

Rapid DNA Amplification in Bouyancy Driven Closed Loop Microfluidic Systems

Nitin Agrawal, Victor M. Ugaz

3122 TAMU, Department of chemical engineering, Texas A&M University, College Station, TX 77843 USA

Phone: 979-458-1002 Fax: 979-845-6446 Email: nitin.agrawal@chemail.tamu.edu, ugaz@tamu.edu

ABSTRACT

Bouyancy driven polymerase chain reaction (PCR) is

emerging as a simplified version of thermally driven bioanalysis systems. In this paper, we have designed,

fabricated and modeled a simplified closed loop

thermocycler (CLTC) that can perform PCR in as little as

10 mins. Robustness and generality of the CLTC was

demonstrated by performing PCR amplification of single as

well as multiplex systems containing 5 different human

respiratory infection associated virus targets. We present a

quantitative analysis of PCR yields and observe consistent

performance over several orders of magnitude of initial

template loading dilution. We also demonstrate the use of

convective flows in a variety of closed loop systems

designed to create extensional flow fields and to execute

tunable thermocycling and pumping operations in a format

suitable for integration into miniaturized chemical and

biochemical analysis systems.

INTRODUCTION

Many modern genomic and molecular biology assays

involve selective amplification of specific regions of

interest within a larger DNA template to extremely high

concentration levels, followed by extraction and

purification of the amplified products for subsequent

analysis. The polymerase chain reaction (PCR) is typically

used to perform this amplification, and is a key component

in a wide variety of assays encompassing genomic analysis

and sequencing, detection of infectious disease agents (e.g.,

influenza, E. coli, influenza, SARS), analysis of forensic

samples, and medical diagnostic tests. In each of these

applications, the current inability to perform PCR

amplification in a rapid and inexpensive format continues to

pose significant challenges to efforts aimed at moving DNA

analysis technology out of the laboratory and directly into

settings where the information is most needed.

The underlying mechanics associated with PCR

are fundamentally simple. A typical protocol involves first

pipeting a PCR reagent cocktail (template DNA, primers,

dNTPs, thermostable Taq polymerase enzyme, etc.) into

plastic reaction tubes or multiwell plates. These tubes or

plates are then inserted into a programmable thermocycling

machine that repeatedly heats and cools the static reaction

volume to temperatures corresponding to denaturation of

the double-stranded target DNA (95 C), annealing of

primers to complimentary locations on the denatured

single-stranded fragments (50 60 C), and enzyme

catalyzed extension to synthesize the complimentary strands

(72 C). Under ideal conditions, this scheme yields a

620

doubling of dsDNA (double-stranded DNA) copies of the

target region upon completion of each cycle (Y = (1 + x)n;

where Y is the copy yield, n is the number of cycles, and x

is the mean efficiency per cycle). The total time required to

complete one cycle of amplification includes the time over

which the temperature of the reaction mixture must be held

constant at each temperature step (hold time), as well as

the time required to heat and cool the reaction mixture

between successive steps (ramping time). In conventional

benchtop thermocyclers, cycling times are primarily limited

by the rate at which inactive hardware elements (e.g. metal

blocks) can be heated and cooled, rather than the kinetics of

the reaction itself. Consequently, it is not uncommon for a

30 40 cycle amplification reaction to require 2 to 3 hours

of total time to complete, thereby limiting achievable

throughput. Because this often imposes a serious bottleneck

in many genomic analysis applications, the development of

novel strategies to reduce the thermocycling time associated

with the PCR process continues to be an active area of

research.

Convective flow-based thermocycling systems offer a

novel and highly effective approach toward satisfying

these demanding requirements[1-5]. In addition to all the

benefits of scaling down (e.g. faster heating and cooling

rates, reduced reagent consumption), these devices

completely eliminate the electronic control component

necessary to perform dynamic temperature cycling.

Though PCR microchips have achieved a significant

reduction in process time compared to their macroscopic

counterparts, their speed of operation is still limited by the

heating and cooling rates of inactive hardware components.

Convection-based thermocyclers, on the other hand, do not

suffer from these constraints, thereby providing the

opportunity to perform PCR at speeds limited solely by the

kinetics of the reaction. These flows occur throughout

nature and play a central role in a wide variety of transport

processes occurring in the Earths atmosphere and oceans,

and in industrial processes involving chemical reactions,

heat transfer, and crystal growth[6, 7]

Bouyancy driven convection can be induced in several

formats, either by applying a temperature gradient parallel

or orthogonal to gravity. The vertical gradient case is often

studied in the context of toroidal flow loops

(thermosyphons) in which the upper half of the loop is

cooled at a constant temperature while the lower half is

heated with a constant flux. Here, the onset of convective

motion generally occurs in the vicinity of 1 < Racrit < 100,

depending on the geometry and heat transfer characteristics

of the loop. Flow direction is randomly determined by the

overall dominating forces for unique conditions. Fluid flow

in such toroidal geometries occurs solely due to the

Rayleigh Bernard convective forces[8]. On the other hand,

NSTI-Nanotech 2005, www.nsti.org, ISBN 0-9767985-0-6 Vol. 1, 2005

a controlled unidirectional fluid motion can be induced by

applying horizontal temperature gradients.[3, 4, 9].

Consequently, a new length scale is introduced into the

system where, Racrit depends on both the difference in

thermal conductivity between the fluid and bounding

sidewalls and the spacing between the vertical arms and

corresponds to a value of 36 or less[9]. Rayleigh number

Ra =

g (T L )r 4

can be defined in terms of the channel radius r and

horizontal temperature gradient (T/L). This critical value

decreases as the side wall conductivity decreases and the

spacing between vertical arms increases.

The inherent structure and ability of horizontally

controlled closed loop geometry to circulate fluid between

various temperature zones makes it ideally suited to

perform temperature sensitive biochemical reactions like

PCR. The self-actuated simplified mechanism of this

system offers a complete passive thermocycling scheme. To

optimize the reaction kinetics and the time spent by the

fluid elements at various temperature zones, flow rates can

be precisely tuned by controlling the independent variables

such as channel radius (r), temperature gradient (T) and

spacing between the vertical arms (L). Another key

advantage of such systems is that all fluid elements follow

similar flow trajectories and are exposed to the various

temperature zones for identical time frames thereby

enhancing the amplification efficiency.

In this paper, we extend our studies of closed loop

thermocyclers and investigate harnessing convective flows

to perform tunable pumping and thermocycling operations

potentially suitable for integrated lab-on-chip devices. In

each of these applications, the flow can be easily and

precisely manipulated by adjusting the magnitude of the

applied temperature gradient and/or the fluidic network

geometry. The inherent simplicity of these components

makes them ideally suited for construction of inexpensive

portable chemical and biochemical analysis systems.

EXPERIMENTAL METHODS

A simple Closed Loop Thermocycler (CLTC) was

constructed using fluorinated ethylene propylene tubing

(FEP; Zeus Industrial Products Inc.) and two independently

controlled Peltier heaters (Melcor Corp.) assembled in a

triangular configuration supported by a hollow aluminum

block as shown in Figure 1. The choice of FEP tubing was

58 C (anneal)

72 C

(extend)

aluminum block

motivated by its attractive combination of properties

including low cost, mechanical flexibility, optical

transparency, and biocompatibility. Consequently, no

surface treatments were necessary in order to perform PCR.

FEP tubing of three different diameters (24-gauge, 26gauge and 28-gauge) was used to perform flow

characterization and PCR amplification. A 9 cm tubing

segment of each diameter was used to form the CLTC

reactor. Tubing was filled with PCR reagents and the two

open ends of the segment were joined together using a short

segment of lower gauge PVC tubing. Slightly overfilling

the tube before sealing largely alleviated bubble formation

within the channel. The total volume of the closed loops

was approximately 10 L, 20 L and 32 L for 28-gauge,

26-gauge and 24-gauge tubings respectively. Aluminum

adhesive tape was used to affix the tubing directly to the

Peltier surfaces to ensure good thermal contact.

Temperatures were monitored using flat thermocouple

probes affixed to the Peltier surfaces. The heaters were

independently maintained at 95 C (denaturing) and 72 C

(extension) while the average temperature in the third arm

of the loop was passively maintained at 58C. A small

window was cut in the aluminum tape at the top location of

the triangular setup for flow imaging purpose.

2.1 PCR Conditions

Several reaction systems were tested in order to

evaluate PCR performance. All reagents were supplied in

kits from Maxim Biotech, Inc. Reactions involving

amplification of the following targets were studied: a) 191base target associated with the membrane channel proteins

M1 and M2 of the influenza-A virus, b) 242-base target

associated with the human L32 gene sequence, c) 474-base

target associated with the human -Actin gene sequence,

and d) a multiplex system containing 5 different respiratory

infection associated virus targets (264-base respiratory

syncytial virus (RSV), 315-base corona virus, 390-base

influenza virus, 484-base adenovirus, and 547-base rhino

virus). Standard 50 L reaction mixes contained 30 L of

optimized buffer/dNTP mix, 10 L of primer mix, 8.75 L

of ddH2O, 1 L of template DNA and 0.25 L of 5 units/L

AmpliTaq polymerase. After the reactions were complete,

products were aspirated from the reaction chambers, run on

a 2% agarose gel at 60 V for 1 hour, and stained with 100x

SYBR-Green I. Product yields were measured from purified

PCR products (QIAquick PCR Purification Kit; Qiagen)

using a NanoDrop ND-1000 spectrophotometer.

3

94 C

(denature)

RESULTS AND DISCUSSION

3.1 Flow Characterization and Modeling

peltiers

FEP flow

loop

Figure 1. Schematic and actual picture of CLTC

To demonstrate the capabilities and advantages of the

self-actuated convective PCR system, 2-D flow

visualization in CLTC was carried out by filling the reactor

with a suspension of 6 m diameter fluorescent latex

spheres. FEP reactors of three different diameters and a

NSTI-Nanotech 2005, www.nsti.org, ISBN 0-9767985-0-6 Vol. 1, 2005

621

fixed loop length of 9 cm were simultaneously loaded into

the CLTC. Initially, temperature of one of the two heaters

was raised gradually, after which the second heater was also

activated to maintain PCR conditions on all the three sides.

Due to the existing parabolic flow profile through out the

loop, spheres close to the wall were observed to be moving

at lower velocities as compared to those near the center line

of the tubing along the x-axis. However, some of the

spheres along the center line also moved slowly presumably

due to their close vicinity towards the wall in z-direction.

Average velocities were calculated by monitoring the

sphere motion over a fixed distance throughout the

crossection for successive steady state temperature

gradients.

As depicted by the low value of the critical Rayleigh

number, the onset of fluid motion was observed at a very

low temperature gradients on the order of 1C. Under PCR

conditions, flow velocities of the order of 1.14 mm/sec,

1.74 mm/sec and 2.67 mm/sec were obtained corresponding

to 28, 26 and 24-gauge tubings respectively. It was also

observed that increase in temperature gradient increases the

flow rate in a manner that scales with Ra/Pr, where Pr is the

Prandtl number (/). Using this scaling, flow rates

obtained in channels of different diameter collapse onto a

master curve that can further be generalized to predict flow

characteristics for any similar system.

thermocycler-based protocols were necessary in the loopbased PCR device presented here. Further optimization and

scale-down of the reactor volume are likely to yield

improved performance.

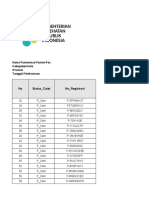

3.3 Quantification of CLTC Product Yields

In order to quantitatively verify PCR performance in

the CLTC, product purification was carried out to remove

unused primers followed by spectrophotometric

measurement of the final nucleotide concentration. Table 1

summarizes the yields obtained in the three reactors for

different reaction times. It is clearly demonstrated that the

CLTC efficiency is over 5 times better than the

conventional benchtop thermocyclers both in terms of yield

as well as reaction times.

Table 1.

24 AWG

(g/mL)

26 AWG

(g/mL)

28 AWG

(g/mL)

Time/Cycle

10 mins

15 mins

20 mins

25 mins

30 mins

40 mins

50 mins

2.5 hrs

33.75 sec

3.96

4.8

7.37

-

51.75 sec

5.03

6.97

8.57

-

78.75 sec

6.97

8

8.9

11.07

Benchtop

thermocycler

(g/mL)

300 sec

2.1

1.8

1.9

2.03

2.13

2.03

2.8

12

3.2 PCR in closed loop systems

The feasibility of performing PCR in a convective loop

format was illustrated using similar reactors used for flow

characterization in closed flow circuits. Flow velocities up

to 2.67 mm/s were achieved under these conditions,

corresponding to a cycle time of approximately 34 seconds.

When the flow loop was loaded with PCR reagents, a

successful amplification of the 191 base pair fragment (3.9

kb template) could be performed in as little as 10 minutes

(Figure 2a.) Simultaneous amplification of a mixture

containing primers and template for the 191-bp influenza-A

virus and 242-bp human L32 gene targets was also

achieved in 50 minutes (Figure 2b). We have also

demonstrated the amplification of a 295-bp -Actin target

and a multiplex mixture of targets associated with 5

different respiratory viruses in 26-gauge tubing within 50

minutes of reaction time (Figure 2c). It is notable that no

modifications to the reagent mixtures used in conventional

Figure 2. a) PCR of 191 bp in 24 AWG reactor

b) 2-Plex PCR C) Multiplex PCR

622

OTHER CONVECTIVE SYSTEMS AND

APPLICATIONS

In addition to performing biochemical reactions, these

devices can also be used to generate extensional flow fields

in a cross-slot geometry or to perform on chip pumping and

thermocycling operations when integrated with microfluidic

systems. Figure below shows a closed cross-slot pattern

fabricated in a Plexiglas block which, when heated from

any two opposite sides while keeping the other two sides at

a lower temperature, can generate extensional flow patterns

at the stagnation point of the cross-slot. Flow visualization

using fluorescent spheres confirmed that microspheres

become trapped at the stagnation point for 4-5 seconds

experiencing elongational forces in the opposite directions.

These non-pulsatile continuous flow fields can be harnessed

to stretch DNA/polymers and to study single molecule

behavior.

NSTI-Nanotech 2005, www.nsti.org, ISBN 0-9767985-0-6 Vol. 1, 2005

4.1 Convectively Driven Micropumps

We have also investigated the use of these flow loops

to pump fluids in the horizontal plane by constructing

devices where the lower horizontal segment of the loop is

replaced by a longer segment creating a 3-D flow path.

Similar flow rates are observed in these devices, indicating

that sufficient pumping capacity exists to drive flows in a

variety of microfluidic channel networks.

A few general guidelines for the scale-down of

convective flow systems in miniaturized loops can be

derived. We can use the flow rate data in Figure 5b to

extract a rough estimate of the minimum channel diameter

for flow to occur by extrapolating to the conditions

corresponding to zero flow rate. This analysis indicates that

channel diameters can be scaled down to at least 180 m at

this tubing diameter (28 gauge) for a particular loop length,

maintaining a temperature difference of 35 C between

annealing and denaturing temperatures. This minimum

diameter can be further reduced through the use of shorter

flow loops because the corresponding decrease in

hydrodynamic resistance allows higher flow rates to be

achieved under the same thermal driving force.

CONCLUSIONS

Exploiting convective flow fields to perform PCR

amplification of DNA is an emerging area of research with

the potential to offer a simple low-cost alternative to

conventional thermocycling

equipment.

Moreover,

convective flow systems are capable of achieving rapid

cycling times, even approaching those attainable in

microfluidic systems, while still operating within a

convenient format. Natural convection systems can also

serve as a useful platform to perform a variety of thermally

activated biochemical reactions where temperature cycling

is required (e.g., real time PCR, cycle sequencing of DNA).

Devices can be easily constructed using optically

transparent substrates to provide in situ fluorescence

detection capability. Elimination of external electronic

controls and pumping equipments considerably reduces

power consumption making them ideally suited for

developing battery operated portable bio-analysis systems.

REFERENCES

1.

2.

3.

4.

5.

6.

7.

8.

9.

Krishnan, M., et al., Reactions and fluidics in

miniaturized natural convection systems. Analytical

Chemistry, 2004. 76(21): p. 6254-6265.

Braun, D., N.L. Goddard, and A. Libchaber,

Exponential DNA replication by laminar convection.

Physical Review Letters, 2003. 91(15): p. 158103.

Chen, Z., et al., Thermosiphon-based PCR reactor:

experiment and modeling. Analytical Chemistry, 2004.

76: p. 3707-3715.

Wheeler, E.K., et al., Convectively driven polymerase

chain reaction thermal cycler. Analytical Chemistry,

2004. 76: p. 4011-4016.

Krishnan, M., V.M. Ugaz, and M.A. Burns, PCR in a

Rayleigh-Bnard convection cell. Science, 2002. 298:

p. 793.

Chandrasekhar, S., Hydrodynamic and Hydromagnetic

Stability.

1961,

Clarendon,

Oxford:

Dover

Publications.

Cross, M.C. and P.C. Hohenberg, Pattern Formation

Outside of Equilibrium. Reviews of Modern Physics,

1993. 65: p. 851-1112.

Greif, R., Natural circulation loops. Journal of Heat

Transfer, 1988. 110: p. 1243-1258.

Gershuni, G.Z. and E.M. Zhukovitskii, Convective

stability of incompressible fluids (translated from

Russian). Israel Program for Scientific Translations.

1976, Jerusalem.

NSTI-Nanotech 2005, www.nsti.org, ISBN 0-9767985-0-6 Vol. 1, 2005

623

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Betz Columbia 0054D 10409Dokument87 SeitenBetz Columbia 0054D 10409arv86Noch keine Bewertungen

- Water PropertiesDokument6 SeitenWater PropertiesJeric PonterasNoch keine Bewertungen

- Condense Last FreedomDokument1 SeiteCondense Last FreedomUsama PerwezNoch keine Bewertungen

- Anx C Templet of PresDokument11 SeitenAnx C Templet of PresUsama PerwezNoch keine Bewertungen

- Thesis SeminarDokument3 SeitenThesis SeminarUsama PerwezNoch keine Bewertungen

- Chapter 05 Total Pressure MeasurementDokument43 SeitenChapter 05 Total Pressure MeasurementUsama PerwezNoch keine Bewertungen

- Maj Muhammad Ali - MS80 - Assignment 1Dokument2 SeitenMaj Muhammad Ali - MS80 - Assignment 1Usama PerwezNoch keine Bewertungen

- Assignment 2Dokument2 SeitenAssignment 2Usama PerwezNoch keine Bewertungen

- Section 3 7 PDFDokument12 SeitenSection 3 7 PDFUmer YounasNoch keine Bewertungen

- Introduction To The Stiffness (Displacement) Method: Analysis of A System of SpringsDokument43 SeitenIntroduction To The Stiffness (Displacement) Method: Analysis of A System of SpringsmmgaribayNoch keine Bewertungen

- Assignment 1Dokument2 SeitenAssignment 1muneebulqayyumNoch keine Bewertungen

- Assignment 3Dokument2 SeitenAssignment 3Usama PerwezNoch keine Bewertungen

- Chapter 1Dokument19 SeitenChapter 1Usama PerwezNoch keine Bewertungen

- Advanced Mathematics: DR Mazhar IqbalDokument25 SeitenAdvanced Mathematics: DR Mazhar IqbalShahid IqbalNoch keine Bewertungen

- Mechanics of MaterialsDokument21 SeitenMechanics of MaterialsUbaid Ahmed Mughal100% (1)

- Group Incentives & Pay Satisfication, Understanding The Relationship Through An Identity Theory PerpectiveDokument23 SeitenGroup Incentives & Pay Satisfication, Understanding The Relationship Through An Identity Theory PerpectiveUsama PerwezNoch keine Bewertungen

- End Term Exam Format 1. No Reseach Paper/Case Study Review 2. Everything From Lecture 1 To Lecture Slides On Lecture 5-6 3. Weightages of PSDMDokument1 SeiteEnd Term Exam Format 1. No Reseach Paper/Case Study Review 2. Everything From Lecture 1 To Lecture Slides On Lecture 5-6 3. Weightages of PSDMUsama PerwezNoch keine Bewertungen

- Project Name Program Manager Project Manager: Communication MatrixDokument2 SeitenProject Name Program Manager Project Manager: Communication MatrixUsama PerwezNoch keine Bewertungen

- Variational Iteration Method For Vibration ProblemsDokument32 SeitenVariational Iteration Method For Vibration ProblemsUsama PerwezNoch keine Bewertungen

- Strang - Introduction To Linear Algebra 3rd Edition 0961408898Dokument578 SeitenStrang - Introduction To Linear Algebra 3rd Edition 0961408898Angel MedinaNoch keine Bewertungen

- Grad Student ExpectationsDokument4 SeitenGrad Student ExpectationsMahesh ParitNoch keine Bewertungen

- A Dictionary For Linear AlgebraDokument7 SeitenA Dictionary For Linear Algebradavierang8362Noch keine Bewertungen

- Eview Guide 24 PageDokument24 SeitenEview Guide 24 PageHimanshu GuptaNoch keine Bewertungen

- Assignment#1 Solve The Problems at The End of Chapter#1,2,3 of The Book Emailed To YouDokument1 SeiteAssignment#1 Solve The Problems at The End of Chapter#1,2,3 of The Book Emailed To YouUsama PerwezNoch keine Bewertungen

- Assignment in Lieu of QuizDokument1 SeiteAssignment in Lieu of QuizUsama PerwezNoch keine Bewertungen

- How To Read Data From Pivots Using VbaDokument14 SeitenHow To Read Data From Pivots Using VbaUsama PerwezNoch keine Bewertungen

- How To Read Data From Pivots Using VbaDokument14 SeitenHow To Read Data From Pivots Using VbaUsama PerwezNoch keine Bewertungen

- 2001, The Impact of Total Productive Maintenance Practices On Manufacturing Performance (20) - Kathleen E.mckone A, Roger G.schroeder B, Kristy O.cuaDokument20 Seiten2001, The Impact of Total Productive Maintenance Practices On Manufacturing Performance (20) - Kathleen E.mckone A, Roger G.schroeder B, Kristy O.cuaDiego RojasNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- PDA 2018 Web Interactive Publication CatalogDokument32 SeitenPDA 2018 Web Interactive Publication CatalogmmmmmNoch keine Bewertungen

- Bab 6 Sruktur Dan Fungsi Sel Bakteria (I)Dokument9 SeitenBab 6 Sruktur Dan Fungsi Sel Bakteria (I)Shakira AmiraNoch keine Bewertungen

- B.tech. BiotechDokument23 SeitenB.tech. BiotechSandhyaNoch keine Bewertungen

- Bioinformatics - Theory and PracticeDokument2 SeitenBioinformatics - Theory and Practicevirusgene1Noch keine Bewertungen

- Bone Tissue EngineeringDokument352 SeitenBone Tissue EngineeringKeri Gobin SamarooNoch keine Bewertungen

- SureCycler 8800 PCR BrochureDokument6 SeitenSureCycler 8800 PCR Brochurelordoflovely100% (1)

- Ts-2 Production of 5-Aminolevulinic Acid by Propionibacterium Acidipropionici Tistr442Dokument4 SeitenTs-2 Production of 5-Aminolevulinic Acid by Propionibacterium Acidipropionici Tistr442Giang Huy DiệmNoch keine Bewertungen

- Modern Synthesis (20th Century)Dokument18 SeitenModern Synthesis (20th Century)Jason FryNoch keine Bewertungen

- Microbial Sources of AntibioticsDokument23 SeitenMicrobial Sources of AntibioticsLiveonBiolabsNoch keine Bewertungen

- 4727 Whatman DNA - OmniSwab Appnote - v15Dokument6 Seiten4727 Whatman DNA - OmniSwab Appnote - v15Alejandra Torres100% (1)

- Nascsa - Sponsor Solicitation List: January 06, 2021Dokument35 SeitenNascsa - Sponsor Solicitation List: January 06, 2021Prasoon SimsonNoch keine Bewertungen

- Constantes LIO HILLDokument6 SeitenConstantes LIO HILLRoberto Vega FloresNoch keine Bewertungen

- Quiz On Mendelian GeneticsDokument2 SeitenQuiz On Mendelian GeneticsslytheraineNoch keine Bewertungen

- 10.1007/978 1 4419 9029 7Dokument675 Seiten10.1007/978 1 4419 9029 7Donato FormicolaNoch keine Bewertungen

- Programme Core Programme Elective University Core University Elective Total CreditsDokument3 SeitenProgramme Core Programme Elective University Core University Elective Total CreditsMN11 GamingNoch keine Bewertungen

- KDPMADokument10 SeitenKDPMASusheelNoch keine Bewertungen

- 14 Juli 2021 SD BatubulanDokument71 Seiten14 Juli 2021 SD Batubulanni ketut martiniNoch keine Bewertungen

- Molecular Basis of Inheritance, Class 12, Cbse NotesDokument33 SeitenMolecular Basis of Inheritance, Class 12, Cbse NotesSubho Bhattacharya50% (4)

- Fresher From Cranfield ICRI Clinical - Research Looking For CRA and CRC JobDokument3 SeitenFresher From Cranfield ICRI Clinical - Research Looking For CRA and CRC Jobpatel_ishitaNoch keine Bewertungen

- Patenting in Biological Invention in India: Amity Law School, Amity University Sector-125, Uttar PradeshDokument12 SeitenPatenting in Biological Invention in India: Amity Law School, Amity University Sector-125, Uttar Pradeshsmalhotra2414Noch keine Bewertungen

- Group 3 SPDokument7 SeitenGroup 3 SPLawrence CezarNoch keine Bewertungen

- Midterm 2 Practice Exam 2Dokument9 SeitenMidterm 2 Practice Exam 2Shiroo AshtariNoch keine Bewertungen

- O A Breast CancerDokument559 SeitenO A Breast CancerAlex Perez100% (1)

- All About DnaDokument65 SeitenAll About DnaPeopwdNoch keine Bewertungen

- GSK Market ShareDokument9 SeitenGSK Market ShareOmair KhanNoch keine Bewertungen

- F Plasmids PDFDokument2 SeitenF Plasmids PDFNickNoch keine Bewertungen

- Gmobrd Gwi: XMG Moymvrb "Gmobrd Gwimmm' Eh$ Emór' - MjmodmDokument7 SeitenGmobrd Gwi: XMG Moymvrb "Gmobrd Gwimmm' Eh$ Emór' - MjmodmprofavinashNoch keine Bewertungen

- Module 2 Task 1, 2 and 3Dokument3 SeitenModule 2 Task 1, 2 and 3Ylaine NavaltaNoch keine Bewertungen

- Scientific Revolutions (1962), Which Attributed: Children of InventionDokument6 SeitenScientific Revolutions (1962), Which Attributed: Children of Inventionvini euharaNoch keine Bewertungen

- B1 FrenchDokument126 SeitenB1 FrenchSofiko ChanturidzeNoch keine Bewertungen