Beruflich Dokumente

Kultur Dokumente

Consumable Electrode Type D.C. Arc Welder

Hochgeladen von

Ian McNairOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Consumable Electrode Type D.C. Arc Welder

Hochgeladen von

Ian McNairCopyright:

Verfügbare Formate

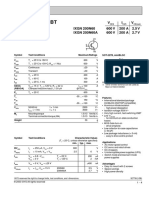

USO05272314A

United States Patent [191

[11]

[45]

Moriguchi et a1.

[54] CONSUMABLE ELECTRODE TYPE D.C.

4,665,299

ARC WELDER

[75] Inventors: Haruo Moriguchi, Itami; Tetsurou

Ikeda, Osaka; Kenzo Danjo, Kizu;

Masahiro Aoyama, l-ligashi; Karino

Kunio, Suita, all of Japan

[73] Assignee: Sansha Electric Manufacturing Co.,

Ltd., Osaka, Japan

[21] Appl. No.: 991,436

[22] Filed:

[30]

Dec. 16, 1992

Foreign Application Priority Data

Dec. 16, 1991 [JP]

Japan ................................ .. 3453356

[51]

[52]

1m.c1.-< .............................................. .. B23K 9/10

u.s.c1. .............. ..

219/130.33;219/130.21

[58]

Field ofSearch .................... ..219/13o.21,13o.31,

[56]

2l9/l30.32, 130.33, 137 PS

References Cited

U.S. PATENT DOCUMENTS

3,792,225 2/1974

4,476,376 10/1984

4,521.672 6/1985

Needham et a1. ............ .. 2l9/l30.2l

Mizuno et al, ........... .. 219/1301]

Fronius ........................ .. 219/130.33

Patent Number:

Date of Patent:

5,272,314

Dec. 21, 1993

5/1987 Iwata ............................ ..2l9/l30.2l

FOREIGN PATENT DOCUMENTS

61-216859

9/1986 Japan .

Primary Examiner-Clifford C. Shaw

Attorney, Agent, or Firm-Wegner, Cantor, Mueller &

Player

[5 7]

ABSTRACT

A consumable electrode type d.c. arc welder including

an inverter, which is arranged to rectify an a.c. power

from a power supply, once convert a resultant d.c.

power into a high frequency a.c. power by the invertor

and again rectify it to obtain a d.c. power for welding,

and provided with means for detecting a current ?ow

ing through its welding load to certainly discriminate

shortening and arcing states between a welded base

material and a welding electrode rod and controlling

the invertor with a resultant discrimination signal to

reduce its output voltage during the shortening period,

thereby preventing spattering produced by an over-cur

rent.

2 Claims, 3 Drawing Sheets

9p 12

10p

13

11

.._1.a

Va

33

9n

r] [1011 E14

VOLTAGE

DETECT \16

DRIVING

CIRCUIT

US. Patent

Dec. 21, 1993

Sheet 1 of 3-

5,272,314

FIG. 1(a)

FIG. 1(b)

.3

.8._

Tw

WAN.

4.

.||3

. 3

FIG. 3

/V(4.

_|. l k

32

US. Patent

FIG. 2

Dec. 21,1993

Sheet ,2 of 3

5,272,314

US. Patent

Dec. 21, 1993

FIG. 4 (a) 0

Sheet 3 of 3

5,272,314

MG

FIG. 4 (b)

FIG. 4 (c)

FIG. 4(d)

FIG.

4(e)"" """

FIG. 4(f) '1" ----

'

'1

'

'

'

'

4*

?v

'

?HGV

5,272,314

CONSUMABLE ELECTRODE TYPE D.C. ARC

WELDER

BACKGROUND OF THE INVENTION

This invention relates to a consumable electrode type

d.c. are we and, especially,to an improved invertor type

do. arc welder with a consumable welding electrode,

which is provided with novel means for preventing

occurrence of undesirable spattering.

The inverter type do. are welder, which has been

developed for making a welding power source device

small in size and weight, is arranged to effect voltage

transformation with a lightweighted inverter compsoed

of semi-conductor switching elements without use of a

heavy input transformer. More speci?cally, as disclosed

in the Japanese patent opening gazette No. S6l-2l6859

for example, in a welder of this kind, its welding dc.

power is produced by once rectifying and smoothing an

input a.c. power, then converting it into a high fre

quency a.c. power by the inverter, reducing its voltage

Accordingly, an object of this invention is to provide

an improved inverter type d.c. arc welder with a con

sumable electrode, including novel means for effec

tively preventing spattering without any troublesome

5 operation as above.

SUMMARY OF THE INVENTION

This invention is based upon output current detection

in view of the above mentioned shortcom of output

voltage detection. More particularly, the inverter type

do arc welder with a consumable electrode /according

to this invention is provided with feedback control

means for detecting a difference between the output

voltage and a predetermined reference voltage and

controlling the invertor in accordance with this differ

ence to constantly maintain average output voltage and

arranged to excessively reduce the average output volt

age only during the shorting period of the welding load

by detecting the dc. output current of the welder to

produce a detection signal and differentiating the detec

tion signal to reduce the above-mentioned reference

to a suitable level by a small-sized and lightweighted

voltage by a predetermined value during a positive

output transformer and again rectifying it to produce a

dc. power for welding. In the cited device, its average

level of the resultant signal.

output voltage is stabilized by detecting variation of the

tion will be described in more detail below with refer

ence to the accompanying drawings in connection with

output voltage and controlling a conduction time of the

switching elements of the inverter with a resultant de

'

These and other features and operation of this inven

an embodiment thereof.

tection signal.

While consumable electrode type do. arc welding

such as CO; welding, MAG welding and MIG welding

is effected by supplying the above-mentioned stabilized

dc power from the welder to a welding load formed

with a continuously fed welding electrode rod and a

base material to be welded, separating the electrode rod

shorted to the base material therefrom to form an arc

and, thereafter, similarly repeating shorting and arcing,

undesirable spattering may occur if the dc. power sup

plied to the welding load becomes excessive at the time

of shorting. It has been a general practice for suppress

ing this spattering to provide a large d.c. reactor in the

output side of the welder for preventing sudden in

crease of the welding current, but it has been a bar to

small-sizing and lightweighting of the device.

BRIEF DESCRIPTION OF THE DRAWINGS

In the drawings:

FIGS. 1(a) and (b) are waveform diagrams showing

variation of the output terminal voltage of a dc. arc

welder.

FIG. 2 is a schematic circuit diagram showing an

embodiment of a consumable electrode type do. arc

welder including spattering preventing means accord

ing to this invention.

FIG. 3 is a schematic circuit diagram showing an

embodiment of an essential portion of the spattering

preventing means according to this invention.

FIGS. 4(a) to (f) are waveform diagrams for explain

ing operation of the above embodiment of this inven

tion.

In order to prevent spattering without a larger reac 45

DESCRIPTION OF PREFERRED EMBODIMENT

tor, it is considered to detect a shorting period from

variation of the output voltage and control the inverter

Referring to FIG. 2, an a.c. power supplied from a

as above-mentioned on the basis thereof to reduce the

commercial power supply of three-phase and 200 volt

a.c., for example, through input terminals 1a, lb and 1c

the welder varies originally as shown in FIG. 1(a) and, 50 of the welder is recti?ed by an input 3-phase recti?er 2

therefore. it should be easy to distinguish therefrom a

of diode bridge type, for example, smoothed by a

shorting period Ts and an arcing period Ta. In practice,

smoothing capacitor 3 and supplied to an inverter 4.

however, noises are superimposed thereon to make

The inverter 4 is composed of semiconductor switching

their transitional points unclear. In other words, the

elements, such as bipolar transistors and ?eld effect

voltage across the output terminals of the welder in

transistors, and produces a high frequency a.c. power

cludes high frequency ripples as shown in FIG. 1(b)

through its high frequency switching operation under

since the output terminals and the welding load are

control of an inverter driving circuit 5. The high fre

mutually connected through long cables of 10 to 20

quency power is suitably reduced in voltage by an out

meters long, for example. Therefore, erroneous detec

put transformer 6, recti?ed by an output recti?er 7 of

tion is liable to occur and complete prevention of spat

diode bridge con?guration, for example, and then deliv

tering is difficult. Although it is possible to reduce in?u

ered through a smoothing and current limiting d.c.

ence of the high frequency ripples by using the voltage

reactor 8 from positive and negative output terminals 9p

across the welding load instead of the voltage between

and 9n. The positive output terminal 9p is connected

output voltage during this period. The output voltage of

the output terminals, it is necessary to change connec

through an insulated cable 10p to an electrode rod 11

tion of a voltage detector every time the electrode or 65 continuously supplied from a hoop 12 through a feeding

base material is changed and this operation is not only

troublesome but also dangerous since conductors of the

mechanism 13 and the negative output terminal 9n is

detector may break to cause electrical leakage.

be welded. The electrode rod 11 and base material 14

connected through a cable Min to a base material 14 to

5,272,314

form a welding load 15 which produces an arc therebe

tween.

An output voltage Va between the output terminals

9p and 9n is detected by a voltage detector 16 and sup

plied as a negative output voltage signal Sv through a

resistor 17 to a negative input terminal of an operation

ampli?er 18 whose positive input terminal is grounded

To the negative input terminal of the operation ampli

?er 18, a positive reference voltage signal Sr of a prede

termined level is also applied through a resistor 20 from

a reference voltage setting potentiometer 19. Accord

4

operation ampli?er 18. Accordingly, the input signal of

the operation ampli?er 18 becomes (Sr-Sv-Sx) in total

and its output error signal Se drops from the aforemen

tioned normal value by a value corresponding to the

value of Sx. Consequently, the output voltage of the

inverter 8 and, accordingly, the output voltage Va

drops and the capacity of the d.c. reactor 8 increases

equivalently to suppress production of spattering. The

above-mentioned gating signal Gv is shown in FIG.

4(2).

On the other hand, a detection signal Si produced by

the current detector 33, which is proportional to the

sum of both inputs, to produce an error signal Se which

welding current la, is converted into a voltage signal by

is supplied to the inverter driving circuit 5 as its control

the convertor 34, ampli?ed by the ampli?er 35 and

signal. The driving circuit 5 responds to the error signal 5 applied to the differentiation circuit 36. While the out

Se and controls a conduction time of the switching

put terminal voltage Va of the welder varies as shown

elements so that the error signal Se becomes zero,

in FIG. 4(a) as described above, the welding current Ia

thereby stabilizing the output voltage. 21 denotes a

varies as shown in FIG. 4(b) at a delay from the voltage

feedback resistor of the operation ampli?er 18.

due to the dc. reactor 8 Therefore, the rising period of

In the drawing, a phantom block 22 denotes a correc 20 the welding current Ia corresponds to the shorting per

ingly, the operation ampli?er l8 ampli?es (Sr-Sv), the

tion commanding circuit for spattering prevention, in

cluding a Zener diode 23, a light emitting diode 24, a

phototransistor 25, a resistor 26 and a diode 27. and the

light emitting diode 24 and phototransistor 25 form a

photocoupler. As shown, the output of the voltage

detector 16 is grounded through the Zener diode 23 and

light emitting diode 24 and a +B source is grounded

through the resistor 26 and phototransistor 25. A junc

tion of the resistor 26 and phototransistor 25 is con

nected through a diode 27 to a relay 28 provided with a

normally-open switch 29. The switch 29 connects a

negative voltage ofa correction voltage setting potenti

ometer 30 through a resistor 31 to the negative input

iod and the dropping period corresponds to the arcing

period. Since the input of the differentiation circuit 36

also assumes similar variation, its output Ai has a wave

form as shown in FIG. 4(0) and its positive and negative

output levels correspond to the shorting and arcing

periods, respectively. Accordingly, if the Zener voltage

of the Zener diode 43 of the gating signal generator 39

is preset at a little positive value, the Zener diode 43 is

put in conduction during the shorting period by the

output voltage of the ampli?er 41 through the base

emitter path of the transistor 44 to produce a gating

signal Gi as shown in FIG. 4(d) through the diode 40.

The gating signal Gi energizes the relay 28 to effect

terminal of the operation ampli?er 18.

decremental correction of the output voltage as same as

The relay 28 is driven also by a second correction 35 the above-mentioned voltage-dependent gating signal

commanding circuit 32 provided with a current detec

tor 33 for detecting a welding current Ia. As shown in

FIG. 3. the circuit 32 includes a current-to-voltage

convertor 34 for converting the current detected by the

current detector 33 into a voltage. an ampli?er 35 for

Gv.

Although the gating signal Gi is not affected by the

high frequency ripple noise of the output signal Va

since it is based upon the differentiated value i of the

welding current Ia its high level period is a little nar

rower than the shorting period, as shown in FIG. 4(d),

due to nonzero value of the Zener voltage of the Zener

amplifying the output voltage of the convertor 34, a

differentiation circuit 36 composed of a resistor 37 and

a capacitor 38 for differentiating the output voltage of

diode 43. However, by using it together with the above

the ampli?er 35, and a gating voltage generator 39 re

mentioned voltage-dependent gating signal Gv, the

sponsive to the differentiated output from the circuit 36 45 gating signal Gi +Gv applied to the relay 28 becomes as

for supplying a command signal through a diode 40 to

shown in FIG. 4(}) and the above-mentioned problem is

the relay 28. The gating signal generator 39 includes an

deleted. If this problem is allowed as insigni?cant, how

operation ampli?er 41, a resistor 42. a Zener diode 43

ever, the circuit 22 for producing the gating signal Gv

and a transistor 44 which are connected as shown. The

can be omitted, thereby simplifying the device.

diodes 27 and 40 constitute an OR gate.

50

The embodiment as described above has been given

Next, the description will be made on the operation of

the ?rst and second correction commanding circuits 22

and 32. In the arcing period in which the voltage be

tween the output terminals 9p and 9n of the welder,

which is detected by the voltage detector 16, exceeds a

predetermined level, the Zener diode 23 conducts to

energize the light emitting diode 24 and, as a result, the

phototransistor 25 conducts and its collector voltage

becomes zero. Therefore the signal Gv becomes 0"

and the relay 28 is not actuated. In the shorting period

in which the output voltage is below the predetermined

level, however, the Zener diode 23 is nonconductive

and. therefore, the phototransistor 25 is also noncon

only for the purpose of illustration of the invention and

does not mean any limitation thereof. It should be obvi~

ous to those skilled in the art that various modi?cations

and changes can be made on this embodiment without

leaving the spirit and scope of the invention as de?ned

in the apended claims.

We claim:

1. A consumable electrode do are welder compris

ing an input recti?er for rectifying an a.c. supply power,

an inverter for converting an output of said input recti

?er into a high frequency a.c. power, an output recti?er

for rectifying an output of said inverter. means for sup

plying an output of said output recti?er to a welding

load. and feedback control means for detecting an out

ductive. Accordingly, the collector voltage of the pho

totransistor 25, that is, the gating signal Gv becomes a 65 put voltage of said output recti?er and driving said

high level 1" and actuates the relay 29 to close the

invertor based upon a difference between said voltage

switch 28. Thus. a negative voltage preset by the poten

and a predetermined reference voltage; wherein said

tiometer 30 is applied as a correction signal Sx to the

welder further comprises:

5,272,314

means for detecting a current ?owing through said

welding load and generating a detection signal

mmed value-

'

2. An arc welder as set forth in claim 1, wherein said

corresponding thereto,

.

correcting means responsive to said ?rst gating signal

for reducing said reference voltage by a predeteb

5 welder further comprises:

.

means for producing a second gating signal when said

a differentiation circuit means for differentiatlng said

output voltage of said on1p t recti?er is below a

detection signal,

predetermined level, and

means for producing a ?rst gating signal when an 10

output level of said differentiation circuit means is

positive, and

means for supplying said second gating signal to said

correcting means in order to reduce said reference

voltage by sald predetermmed value 1" response to

a logic sum of said ?rst and second gating signals.

*

15

20

25

55

60

Das könnte Ihnen auch gefallen

- Si5351A VFO/Signal Generator: 2.1 Modes of OperationDokument9 SeitenSi5351A VFO/Signal Generator: 2.1 Modes of OperationIan McNairNoch keine Bewertungen

- Main Combi 24 HE User ManualDokument12 SeitenMain Combi 24 HE User ManualsleepyninjitsuNoch keine Bewertungen

- IXGN200N60ADokument4 SeitenIXGN200N60AIan McNairNoch keine Bewertungen

- Making Inverter Welder - IRFDokument18 SeitenMaking Inverter Welder - IRFShaun Dwyer Van Heerden0% (1)

- Catalog AmorDokument25 SeitenCatalog AmorIan McNairNoch keine Bewertungen

- Method and Apparatus For Welding With RestrikeDokument9 SeitenMethod and Apparatus For Welding With RestrikeIan McNairNoch keine Bewertungen

- US 20130092673A1 - Wire Feed Motor Speed Control System and MethodDokument13 SeitenUS 20130092673A1 - Wire Feed Motor Speed Control System and MethodIan McNairNoch keine Bewertungen

- SUR2x100 06Dokument3 SeitenSUR2x100 06Ian McNairNoch keine Bewertungen

- IXGN320N60A3Dokument5 SeitenIXGN320N60A3Ian McNairNoch keine Bewertungen

- Controlled Waveform Welding Wire Feeder US20130327753Dokument27 SeitenControlled Waveform Welding Wire Feeder US20130327753Ian McNairNoch keine Bewertungen

- DC Fastmig MF MSF MXF MXP enDokument1 SeiteDC Fastmig MF MSF MXF MXP enIan McNairNoch keine Bewertungen

- Sizing Your Power Converter's Magnetics (Part 1) : Inductor Power Rating With Fixed Input VoltageDokument5 SeitenSizing Your Power Converter's Magnetics (Part 1) : Inductor Power Rating With Fixed Input VoltageIan McNairNoch keine Bewertungen

- ESAB Puls Mig Welding Hand BookDokument20 SeitenESAB Puls Mig Welding Hand BookLeonardo De La HudiNoch keine Bewertungen

- High Performance Drive StructureDokument7 SeitenHigh Performance Drive StructureIan McNairNoch keine Bewertungen

- G3RJV Harmonic - Filters Calculation PDFDokument3 SeitenG3RJV Harmonic - Filters Calculation PDFIan McNairNoch keine Bewertungen

- Current Transformer Circuits For Power ElectronicslDokument213 SeitenCurrent Transformer Circuits For Power ElectronicslJason RobinsonNoch keine Bewertungen

- Patent US20060226131-1Dokument18 SeitenPatent US20060226131-1Ian McNairNoch keine Bewertungen

- Design of Inductors and HF TransformersDokument6 SeitenDesign of Inductors and HF TransformersIan McNairNoch keine Bewertungen

- Ss-40ht Assembly Manual v1.1fDokument30 SeitenSs-40ht Assembly Manual v1.1fIan McNairNoch keine Bewertungen

- Newcastle Metro MapDokument1 SeiteNewcastle Metro MapIan McNairNoch keine Bewertungen

- Newcastle Metro MapDokument1 SeiteNewcastle Metro MapIan McNairNoch keine Bewertungen

- Newcastle Metro MapDokument1 SeiteNewcastle Metro MapIan McNairNoch keine Bewertungen

- Isolated IGBT Gate-Drive Push-Pull Power Supply With 4 OutputsDokument41 SeitenIsolated IGBT Gate-Drive Push-Pull Power Supply With 4 OutputsIan McNairNoch keine Bewertungen

- Zxgd3004e6 8a 40v Gate DriverDokument8 SeitenZxgd3004e6 8a 40v Gate DriverIan McNairNoch keine Bewertungen

- DDS RF Signal Generator Design GuideDokument9 SeitenDDS RF Signal Generator Design GuideIan McNairNoch keine Bewertungen

- SMD Relay 60-1278Dokument6 SeitenSMD Relay 60-1278Ian McNairNoch keine Bewertungen

- LM5030 100V Push-Pull Current Mode PWM Controller: Features ApplicationsDokument19 SeitenLM5030 100V Push-Pull Current Mode PWM Controller: Features ApplicationsIan McNairNoch keine Bewertungen

- Scale eDokument0 SeitenScale eMallickarjunaNoch keine Bewertungen

- Making Inverter Welder - IRFDokument18 SeitenMaking Inverter Welder - IRFShaun Dwyer Van Heerden0% (1)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- D84365GC10 SG PDFDokument444 SeitenD84365GC10 SG PDFAamir MalikNoch keine Bewertungen

- IDEO's customer-centered design approachDokument10 SeitenIDEO's customer-centered design approachLasitha NawarathnaNoch keine Bewertungen

- Info CPXDokument119 SeitenInfo CPXpacheco_com2161Noch keine Bewertungen

- HSSP 12 InfotechDokument3 SeitenHSSP 12 InfotechAlicia MadridNoch keine Bewertungen

- Sekonda UputstvoDokument2 SeitenSekonda Uputstvohellios81Noch keine Bewertungen

- Data Science Master60 Englisch Studienablaufplan MyStudies NEU 1Dokument1 SeiteData Science Master60 Englisch Studienablaufplan MyStudies NEU 1Kyaw Si ThuNoch keine Bewertungen

- Czech-Medical-Equipment - Innovation and TrendsDokument52 SeitenCzech-Medical-Equipment - Innovation and TrendsDavid ArgentinNoch keine Bewertungen

- Inspection Report: Vaccum Test RecordDokument21 SeitenInspection Report: Vaccum Test RecordWahyudi MetrizaNoch keine Bewertungen

- Sciencedirect: Green Architecture: A Concept of SustainabilityDokument10 SeitenSciencedirect: Green Architecture: A Concept of SustainabilityRoma Bianca Tan BisdaNoch keine Bewertungen

- HP LaserJet - Install An HP Universal Print Driver (UPD) Using A USB ConnectionDokument7 SeitenHP LaserJet - Install An HP Universal Print Driver (UPD) Using A USB Connectionaleksandar71Noch keine Bewertungen

- SV-DX 2-0-1 Release Notes Man-00327 - 001 - 01Dokument8 SeitenSV-DX 2-0-1 Release Notes Man-00327 - 001 - 01aytaç yiğiterNoch keine Bewertungen

- Amazon EC2 Lab2Dokument25 SeitenAmazon EC2 Lab2biswajitmohanty8260Noch keine Bewertungen

- 2020 - IDIBO - EAST - 0007 - Schneider Make PLC Spares - ISS Inc. - Rev0Dokument9 Seiten2020 - IDIBO - EAST - 0007 - Schneider Make PLC Spares - ISS Inc. - Rev0amit kumarNoch keine Bewertungen

- 1.3 Basic Hydraulic Symbols and Major ComponentsDokument31 Seiten1.3 Basic Hydraulic Symbols and Major ComponentsX800XLNoch keine Bewertungen

- Erporting Ov5645 To Android4.2.2Dokument7 SeitenErporting Ov5645 To Android4.2.2saradhidvNoch keine Bewertungen

- QO D 8 1 7 Ver 1 2 Relaxation of Vendor Registration RequirementsDokument3 SeitenQO D 8 1 7 Ver 1 2 Relaxation of Vendor Registration RequirementsMohit SinghNoch keine Bewertungen

- Electric Traction - ReferenceDokument19 SeitenElectric Traction - ReferenceShrestha SanjuNoch keine Bewertungen

- Nasa STD 5005dDokument76 SeitenNasa STD 5005dvominhthaiNoch keine Bewertungen

- Cpu 260 PDFDokument70 SeitenCpu 260 PDFFernandoCamargoNoch keine Bewertungen

- MC 0069-01 SYS Analysis and DesignDokument14 SeitenMC 0069-01 SYS Analysis and DesignshrikrushNoch keine Bewertungen

- Manual ZonkoDokument22 SeitenManual ZonkoJesus CasasNoch keine Bewertungen

- Maryland Teacher Technology Standards and ArtifactsDokument4 SeitenMaryland Teacher Technology Standards and ArtifactsLauren ZizwarekNoch keine Bewertungen

- CompressorDokument27 SeitenCompressorhidayat rachmatNoch keine Bewertungen

- Power SupplyDokument3 SeitenPower SupplytejisainiNoch keine Bewertungen

- Canteen Credit System Automates Manual ProcessDokument24 SeitenCanteen Credit System Automates Manual ProcessCRYPTO GAMINGNoch keine Bewertungen

- Detecting Conficker Worm With NMapDokument2 SeitenDetecting Conficker Worm With NMapsricommercialNoch keine Bewertungen

- MIDTERMRESEARCHMETHODSDokument2 SeitenMIDTERMRESEARCHMETHODSJL YaranonNoch keine Bewertungen

- Fundamentals of Information Systems - FinalDokument12 SeitenFundamentals of Information Systems - Finalzeosgw100% (2)

- Impulse Valve Operator (Ivo) Kit: DescriptionDokument6 SeitenImpulse Valve Operator (Ivo) Kit: DescriptionRami goNoch keine Bewertungen

- E80XN, E90XN, E100XN, E100XNS, E120XN (A099) : 4051566 ©2013 Hyster Company 12/2013Dokument496 SeitenE80XN, E90XN, E100XN, E100XNS, E120XN (A099) : 4051566 ©2013 Hyster Company 12/2013Miguel OrgueiraNoch keine Bewertungen