Beruflich Dokumente

Kultur Dokumente

Chemical Engineering Paper

Hochgeladen von

supermaqpOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chemical Engineering Paper

Hochgeladen von

supermaqpCopyright:

Verfügbare Formate

I NTERNATIONAL J OURNAL OF C HEMICAL

R EACTOR E NGINEERING

Volume 3

2005

Article A14

Hydrogenation of Acetylene: Kinetic

Studies and Reactor Modeling

Navid Mostoufi

Ali Ghoorchian

Rahmat Sotudeh-Gharebagh

University of Tehran, mostoufi@ut.ac.ir

University of Tehran, alighoorchian@yahoo.com

University of Tehran, sotudeh@ut.ac.ir

ISSN 1542-6580

c

Copyright

2005

by the authors.

All rights reserved.

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

Hydrogenation of Acetylene: Kinetic Studies and

Reactor Modeling

Navid Mostoufi, Ali Ghoorchian, and Rahmat Sotudeh-Gharebagh

Abstract

The kinetics of acetylene hydrogenation has been studied in a fixed bed reactor of a commercial Pd/Al2O3 catalyst. The experiments were carried out at 30,

50 and 70 o C with various feed compositions at atmospheric pressure. The experiments were repeated at 70 o C in the presence of the used catalyst to determine

the effect of the catalyst deactivation where the corresponding deactivation rate

constant was determined in order to predict the activity of the catalyst during each

run. Two well known kinetic models were used for a nearly similar catalyst to predict the experimental data of this work and none of them were found satisfactory.

A new model was then proposed to fit the experimental data. The hydrogenation

reactor was also simulated at industrial operating conditions with the proposed

kinetics for both plug and dispersion flows. The results of these simulations were

almost close to each other in most cases.

KEYWORDS: Acetylene hydrogenation, kinetics, modeling, plug and dispersion

flow, simulation, deactivation

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

Mostoufi et al.: Hydrogenation of Acetylene: Kinetic Studies and Reactor Modeling

1. INTRODUCTION

Polyethylene has been a key product for many industries since 1960s. The feed of the

polymerization reactor, which comes from the olefin plant, is a mixture of hydrocarbons mainly

consisting of ethylene. An undesired impurity in the ethylene stream is acetylene at approximately

0.3 to 2% of the effluent of the olefin plant. This small amount of impurity may lead to

undesirable polymer properties. The amount of acetylene in the feed of ethylene polymerization

reactor should not exceed 2-3 ppm (Bos et al., 1993). There are two possible ways for eliminating

acetylene from ethylene: hydrogenation of acetylene to ethylene and separation of acetylene from

the main stream (Haehn et al., 1997, Brodzinski and Cybulski, 2000). The most common

industrial method of eliminating acetylene is hydrogenation, as the separation method is both

expensive and dangerous (Vincent and Gonzales, 2001). Thus, in order to reach the desired

amount of acetylene for the polymerization step, it is selectively hydrogenated to ethylene in an

adiabatic fixed bed catalytic reactor. The reaction should be selective because many other chain

reactions can occur during hydrogenation if it is not controlled. Almost all these reactions are not

desirable and have to be prevented.

There are three major reactions considered in this system (Bos et al., 1993; Westerterp et al.,

2002):

C2 H 2 + H 2

C2 H 4 + H 2

C2 H 2 + 2H 2

C2 H 4

C2 H 6

C2 H 6

(1)

(2)

(3)

Reactions 1 and 2 are the main reactions occurring in such systems. However, there are also some

side reactions which inevitably occur during acetylene hydrogenation. The most important side

reaction is the reaction 3, i.e., the direct hydrogenation of acetylene to ethane. Acetylene can also

be hydrogenated to heavier products, called green oils, by oligomerization. However, according to

Leviness et al. (1984) and Sarkani et al. (1984) even direct hydrogenation of acetylene to ethane

can be neglected.

In the industrial plants, the hydrogenation process is controlled in a multi-bed adiabatic

reactor. There are two methods to achieve this goal (Weiss, 1996):

a) Hydrogen is separated from the feed before entering the hydrogenation reactor and then is

added to the feed at a desired amount. This method, called tail-end hydrogenation, uses

hydrogen concentration as a controlling parameter in the reactor in addition to the feed

temperature.

b) The feed, which may contain up to 20% hydrogen, directly enters the hydrogenation

reactor. This type of process is called front-end hydrogenation. In this type of systems, the

only controlling parameter would be the feed inlet temperature.

Many catalysts have been studied for hydrogenation of acetylene. Catalysts based on nickel

sulfide (Anderson et al., 1948), nickel or zinc based catalysts on alumina or silica (Muller et al.,

1987; Kummerow et al., 1983), cadmium, calcium, barium, strontium or magnesium on Cr2O3

(Weisang and Engelhard, 1970) as well as copper on alumina, magnesia or silica (Taghavi et al.,

1978) have been used in some cases. However, it was found that palladium is the most selective

metal for acetylene hydrogenation and the most common commercially used catalyst is

Pd/alumina (Brodzinski and Cybulski, 2000; Vincent and Gonzalez, 2001; Godinez et al., 1995;

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

International Journal of Chemical Reactor Engineering

Vol. 3 [2005], Article A14

Vincent and Gonzalez, 2002). This catalyst is usually prepared either by ion exchange or by

precipitation in order to produce a low dispersion, low metal content supported catalyst (Vincent

and Gonzalez, 2001).

In spite of many studies carried out by the researchers to describe the mechanism of

hydrogenation of acetylene and its corresponding kinetic rate, almost no attention has been paid to

the modeling of the industrial reactor of acetylene conversion. The aim of this work is, therefore,

to assess the existing kinetics in the literature and then provide a complete description of the

acetylene hydrogenation reactor based on a theoretical model.

2. THEORY

2.1. Kinetics

The process of acetylene hydrogenation is consisted of adsorption of acetylene and hydrogen on

the catalyst surface, chemical reaction between the adsorbed species, and desorption of the

products from the surface (Vicent and Gonzalez, 2001). Bond (1962) proposed that since the

enthalpy of adsorption of acetylene is higher than that of ethylene, the surface coverage ratio of

acetylene to ethylene would be always high. Therefore, in this case it was expected that if a

mixture of acetylene and ethylene is used, hydrogenation of ethylene would not start until all the

acetylene in the mixture is consumed. However, the experiments conducted by Bos et al. (1993)

and Brodzinski and Cybulski (2000) indicated that this assumption is not realistic and

hydrogenation of ethylene cannot be completely prevented in any case. On the other hand, AlAmmar and Web (1978, 1979), Menshchikov et al. (1975) and Mc Gown et al. (1978) proposed

that the catalyst surface contains at least two different types of active sites. Furthermore,

Brodzinski and Cybulski (2000) proposed a model based on two active sites. They suggested that

these sites are created on the palladium surface by carbonaceous deposits. Some of these sites can

only take part in acetylene hydrogenation and others may be open to all the species in the gas

phase. Figure 1 show a simplified representation of active sites on the catalyst surface which is

proposed by Brodzinski and Cybulski (2000). As seen in this figure, different types of species are

adsorbed and react on different types of sites. According to Brodzinski and Cybulski (2000), a

type of site may exist which is too small for the species other than acetylene and hydrogen to be

adsorbed on. As compared to ethylene, acetylene is selectively hydrogenated on these sites by

hydrogen atoms which are also adsorbed on these sites.

Figure 1. Simplified representation of active sites on the catalyst surface (after Brodzineski and

Cybulski, 2000)

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

Mostoufi et al.: Hydrogenation of Acetylene: Kinetic Studies and Reactor Modeling

As mentioned above, researchers believe that different types of sites are formed on the surface of

the catalyst pellet due to the presence of carbonaceous deposits in the process of acetylene

hydrogenation. However, the exact source of these deposits is still in question. Based on the

assumption that the origin of formation of C4 oligomers (which are the precursors to carbon

deposits) is the acetylene adsorbed on the surface of catalyst, Al-Ammar and Webb (1978a,

1978b, 1979) suggested that these deposits are the source of deactivation and may contribute to

acetylene hydrogenation. Recently, Fasi et al. (2000) found that there are several types of surface

carbon and not all of them necessarily participate in the reaction. Larsson et al. (1998) showed

that it is the type of carbon not its amount that results in an increase in the selectivity to ethylene.

Therefore, carbon deposits can accept hydrogen at low temperatures and then release this

hydrogen at higher temperatures to participate in the hydrogenation procedure by a hydrogen

transfer mechanism (Vincent and Gonzalez, 2001). Based on this information, at least two

possible mechanisms may be suggested for this reaction system:

Mechanism 1: This mechanism is based on the reaction of acetylene in the form of vinylidene

with hydrogen molecules which are simultaneously adsorbed on the catalyst surface in a

competitive way. This is a Langmuir-Hinnshelwood mechanism and is the most common one

which has been proposed by almost all the researchers for such reaction system.

Mechanism 2: This mechanism involves the hydrogen transfer from carbonaceous deposits at

higher temperatures to the vinyl intermediate. This mechanism is called Al-Ammar mechanism.

These two proposed mechanisms are shown schematically in Figure 2. In addition to these

two main mechanisms, i.e., Langmuir-Hinshelwood and Al-Ammar mechanisms, other

mechanisms have been also considered for this system of reactions (Westerterp et al., 2002). Of

course, the temperature in industrial reactors of acetylene hydrogenation is les than 100 C in

which the only source of hydrogen comes from the dissociative adsorption of hydrogen followed

by direct hydrogenation over Pd sites. However, there is an alternative mechanism which starts to

happen at about 150 C which is much more selective towards ethylene formation than the low

temperature mechanism.

This mechanism involves hydride transfer from the growing

carbonaceous layer. This alternative mechanism becomes dominant at temperatures in excess of

175 C. Vincent and Gonzalez (2002) have addressed this point in considerable detail.

Figure 2. Representation of the two proposed mechanisms on catalyst surface (after Vincent and

Gonzalez, 2001)

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

International Journal of Chemical Reactor Engineering

Vol. 3 [2005], Article A14

Different kinetic models have been proposed based on each of the above described

mechanisms. Nevertheless, due to the complexity of the reactions in this system, none of the

proposed kinetics can be considered as the best, yet. Among them, the kinetic expressions

proposed by Boss et al. (1993), Brodzinski and Cybulski. (2000) and Menshchikov et al. (1975)

seem to be more acceptable and have been used by other researchers (Westerterp et al., 2002;

Vincent and Gonzalez, 2001). These kinetics expressions are given in Table 1.

Table 1. Kinetic models studied in this work

Kinetics Model

rC2 H 2 =

rC2 H 6 =

rC2 H 2 =

rC2 H 6 =

rC2 H 2 =

rC2 H 6 =

Reference

k1 PC2 H 2 PH 2

(1 + k 2 PC2 H 2 )(1 + k 3 PH 2 )

Bos et al. (1993)

k 4 PC2 H 4 PH 2

(1 + k 5 PC2 H 2 + k 6 PC2 H 4 ) 3

k1 PC2 H 2 PH 2

(1 + k 2 PC2 H 4 )(1 + k 3 PH 2 )

Menshchikov et al. (1975)

k 4 PC2 H 4 PH 2

(1 + k 5 PC2 H 4 )(1 + k 6 PH 2 )

k1 PC2 H 2 PH 2

(1 + k 2 PC2 H 4 )(1 + k3 PH 2 )

This work

k 4 PC2 H 4 PH 2

(1 + k5 PC2 H 4 )1.25 (1 + k 6 PH 2 )

2.2. Modeling

The acetylene hydrogenation system considered in this work consists of only Reaction (1) and (2).

All other side reactions are neglected. The industrial reactor of acetylene hydrogenation operates

at non-isothermal conditions. Therefore, in order to model such a reactor, the mass balance

equations have to be coupled with the energy balance equation and to be solved simultaneously.

Up to now most of the simulation studies in this field have been based on the plug flow

assumption for the reactor. Moreover, the few researchers, who have considered the dispersion

model, did not report temperature and concentration profiles in a large scale reactor or make a

comparison between these two models (Godinez et al., 1995; Szukiewicz et al., 1998). The

acetylene hydrogenation reactor has modeled by both models in this study.

The mass and energy balance equations, assuming the plug flow pattern for the gas, are as

follows:

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

Mostoufi et al.: Hydrogenation of Acetylene: Kinetic Studies and Reactor Modeling

dC A

=

dz

(1 )

rA

u

F

dT

CP

=

A

dz

(4)

H i ri

(5)

The second method of simulating this system is to take dispersion of the gas into

consideration. In this case, the mass balance equation should be rewritten as follows:

DA d 2C A

u dz 2

dC A

+

dz

(1 )

rA = 0

u

(6)

Thermal dispersion may be neglected in this case as the ratio of thermal dispersion coefficient to

mass dispersion coefficient is very low and the energy balance equation would be the same as the

previous case (Equation 5) in the modeling. Therefore, mass balance equations (Equation 6)

should be solved for all species together with the energy balance equation (Equation 5),

simultaneously. In order to solve the mass balance equation (Equation 6), two boundary

conditions are needed for each species. In this case, Dankwerts boundary conditions may be used

(Fogler, 1999) as given bellow:

at

at

z = 0; C A0 =

z = L;

Da

u

CA

z

z =0

+ C A (0 + , t )

CA

=0

z

(7)

(8)

Equations (5), (6), (7) and (8) form a set of boundary-value differential equations and could be

solved by the finite difference method (Constantinides and Mostoufi, 1999).

3. EXPERIMENTAL

3.1. Catalyst and Gases

The catalyst was Pd/Al2O3 with commercial name of G58-B from Sud-Chemie which is currently

used in many petrochemical complexes. Both new and used catalysts were employed in the

experiments. The used catalyst was acquired from an industrial reactor being in service for six

months before getting deactivated and taken out from the reactor.

The gases used in this work were 99.65% pure C2H2, 99.99% pure C2H4 and 99.99% H2 along

with 99.95% nitrogen. The latter was used as the diluting gas to prevent high conversion of

acetylene during the experiments. In order to obtain the desired concentration of hydrogen in the

mixture, hydrogen gas was premixed with nitrogen at a 1:9 ratio. To make such a premixed gas,

the container was first vacuumed and then filled by a calculated amount of hydrogen and then

slowly pressurized with nitrogen up to 6 barg.

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

International Journal of Chemical Reactor Engineering

Vol. 3 [2005], Article A14

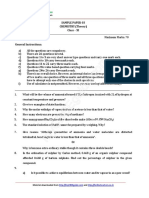

3.2. Apparatus and Procedure

The experimental set-up for measuring the reaction rates of acetylene hydrogenation reactions is

shown in Figure 3. The 3 mm ID U-shaped micro reactor filled with 0.3 grams of finely

pulverized catalyst with a mesh of 180 to 300 m. Such size of the catalyst ensures the absence of

the effect of inter-particle heat and mass transfer resistances during the experiments in the

operating conditions of this work. Flow rates of the inlet streams were measured by three

rotameters. The reactor was placed in a warm water bath equipped with temperature controller

and heater. Compositions of both inlet and outlet streams of the reactor were analyzed by a gas

chromatograph (GC) equipped with a FID analyzer. At the beginning of each run, the feed was

analyzed by the GC before entering the reactor. During the experiments, the product gas from the

reactor was also conducted to the same GC for determining its composition after the reaction. The

feed flow rate varied between 30 to 110 mL/min and its composition was changed from high about

25% to less than 1% of acetylene content. The experiments were carried out at three different

temperatures, i.e., 30, 50 and 70 C.

Figure 3. Simplified schematic diagram of the experimental set up of this study. 1-C2H2 container

2-C2H4 container 3- H2+N2 container 4-Pressure regulator 5-Rotameter 6-Reactor 7Thermocouple and temperature indicator 8-Heater 9-Gas chromatograph.

In addition to the new catalyst, the experiments were repeated with the deactivated catalyst to

obtain a deactivation coefficient for this catalyst. The experiments for the old catalyst were

carried out only at 70C because as the catalyst becomes deactivated in the reactor, the feed

temperature is increased to counter this effect. The feed temperature used at industrial reactors at

such conditions is usually between 70 to 80C.

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

Mostoufi et al.: Hydrogenation of Acetylene: Kinetic Studies and Reactor Modeling

4. RESULTS AND DISCUSSION

4.1. Kinetics

Using the data of these experiments, the reaction rates of acetylene consumption and ethane

formation in each case were found to be as follows:

rC2 H 2 =

rC2 H 6 =

FC2 H 2 (in )

FC2 H 2 ( out )

m

FC2 H 6 ( out )

FC2 H 6 (in )

m

(9)

(10)

The calculations and discussions done below are based on these reaction rates.

Initially, the two well known kinetic models of Bos et al. (1993) and Menshchikov et al.

(1975) were considered as the base models and fitted the experimental data of this work to these

models to obtain new kinetic parameters for the catalyst employed in this study. It is worth

mentioning that in both models of Bos et al. (1993) and Menshchikov et al. (1975), the parameters

have been provided for a different type of catalysts than that studied in this work and as the

different types of catalysts may have different metal content and different porosities which

certainly affect the kinetic studies. Therefore, new kinetic parameters have to be obtained to fit

the new catalyst behavior. New reaction rate constants, evaluated from fitting the experimental

data of this work to the above mentioned kinetic models, are given in Table 2. An Arrhenius type

of temperature dependency is considered for the reaction rate constants as follows:

k i = ki , 0 exp

E a ,i

(11)

RT

The parity plot of the calculated reaction rates based on the kinetic model of Bos et al. (1993)

against the experimental reaction rates of this work are shown in Figures 4a and 4b for acetylene

consumption rate and ethane formation rate, respectively. The constants of the Bos et al. (1993)

model used in this figure are those reported in Table 2. It can be seen in Figure 4a that the model

of Bos et al. (1993) over-predicts the acetylene consumption rates obtained in this work.

According to this figure, the higher the temperature, the higher is the deviation of the model from

the reality. Figure 4b is the same comparison for ethane formation rate. It is evident in this figure

that data scattering is less than what was observed for acetylene consumption rate (Figure 4a).

Nevertheless, at lower temperatures the model of Bos et al. (1993) underestimates while at high

temperatures the model overestimates the reaction rate and the difference between calculated and

observed data is quit high.

The same comparison for the kinetic model of Menshchikov et al. (1975) is shown in Figures

5a and 5b. The constants of the Menshchikov et al. (1975) model used in this figure are those

reported in Table 2. Figure 5a compares the calculated and observed rates of acetylene

consumption. Although the data points in this figure are scattered, these points are also evenly

distributed around the unity line. This fact indicates that the kinetic model of Menshchikov et al.

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

International Journal of Chemical Reactor Engineering

0.7

0.9

(a)

(b)

0.8

0.6

Calculated Reaction Rates (mmol/kg cat.s)

Calculated Reaction Rates (mmol/kg cat.s)

Vol. 3 [2005], Article A14

30 C

50 C

70 C

0.7

0.6

0.5

0.4

0.3

0.2

30C

50C

70C

0.5

0.4

0.3

0.2

0.1

0.1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.1

0.2

0.9

0.3

0.4

0.5

0.6

0.7

Experimental ReactionRates (mmol/kg cat.s)

Experimental Reaction Rates (mmol/kg cat.s)

Figure 4. Parity plot of experimental reaction rates vs those calculated by the model of Bos et al.

(1993) (a) acetylene consumption rate (b) ethane formation rate

0.45

0.50

(b)

(a)

0.35

0.45

Calculated Reaction Rates (mmol/kg cat.s)

Calculated Reaction Rates (mmol/kg cat.s)

0.40

30 C

50 C

70 C

0.30

0.25

0.20

0.15

0.10

0.05

0.00

0.00

0.40

30 C

50 C

70 C

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0.05

0.10

0.15

0.20

0.25

0.30

Experimental Reaction Rates (mmol/kg cat.s)

0.35

0.40

0.45

0.00

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

Experimental Reaction Rates (mmol/kg cat.s)

Figure 5. Parity plot of experimental reaction rates vs those calculated by the model of

Menshchikov et al. (1975) (a) acetylene consumption rate (b) ethane formation rate

(1975) for acetylene consumption rate is adequate, even though the experimental error has caused

the data points to be scattered. This point could be more clearly understood if one compares

Figure 5a with Figure 4a (corresponding to the same reaction rate with a different equation). In

fact, in Figure 4a the data points are scattered as well as biased toward higher values. Thus, even

if scattering of the data is contributed to the experimental error in Figure 4a, the kinetic model of

Bos et al. (1993) is inadequate to estimate the acetylene consumption rate properly. Therefore, it

can be concluded that the kinetic model of Menshchikov et al. (1975) with the newly calculated

parameters is an appropriate model for evaluating the acetylene consumption rate for the catalyst

employed in this work. Figure 5b is the same comparison for ethane formation rate. Although the

agreement between this model and the experimental ethane formation rates is considerably better

than that of the model of Bos et al. (1993) (compare Figure 4b with Figure 5b), however, still there

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

Mostoufi et al.: Hydrogenation of Acetylene: Kinetic Studies and Reactor Modeling

are some points where the agreement is not satisfactory. It should be noted that the agreement

between both Bos et al. (1993) model and Menshchikov et al. (1975) model is considerably better

for the points with lower acetylene content in terms of acetylene consumption rate than those

obtained with high acetylene content in the feed. Therefore, acetylene concentration of more than

20% in the feed, in both models would result in an unacceptable difference between calculated and

observed rates.

By considering all the above mentioned parity plots presented in Figures 4a, 4b, 5a and 5b, it

can be concluded that the model of Bos et al. (1993) cannot predict the reaction rates of the

catalyst employed in this study in the range and operating conditions of this study for either

acetylene consumption rate or ethane formation rate. However, the model of Menshchikov et al.

(1975) is able to predict the rate of acetylene consumption satisfactorily for the catalyst and

conditions of this study while its rate of ethane formation still needs to be improved. Therefore, a

new kinetic model is proposed here which consists of the acetylene consumption rate of the model

of Menshchikov et al. (1975), for with new parameters which have been obtained in this study,

and a new rate expression for ethane formation which better fits the experimental data. After

simplifying, this new model is given as follows:

48.01exp

rC2 H 2 =

668.6

404.3

1 + 584.59 exp

PC2 H 4 1 + 2.855 exp

PH 2

T

T

202.67 exp

rC2 H 6 =

146.8

PC2 H 2 PH 2

T

4784

PC2 H 4 PH 2

T

1502.7

1 + 0.0742 exp

PC2 H 4

T

1.25

400

1 + 2.89 exp

PH 2

T

(12)

(13)

This model is presented in its general from in Table 1 and its parameters are also given in Table 2.

It is worth noting that the power 1.25 in the denominator of Equation (13) is only a fitting

parameter and does not correspond to mechanism of the reaction.

A comparison between the calculated ethane formation rate and the experimental results of

this work is shown in Figure 6. It can be seen in this figure that there is a good agreement

between the model prediction and real reaction rates. The performance of the new rate equation,

presented in Equation (13), is considerably improved as compared to those proposed by Bos et al.

(1993) and Menshchikov et al. (1975). It seems that the reason that the new kinetic expressions

[Equations (12) and (13)] fit the experimental data of this work better than the previous data in the

literature is that the catalyst employed in this work (which is an industrial catalyst) slightly differs

from those employed by other researchers.

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

International Journal of Chemical Reactor Engineering

10

Vol. 3 [2005], Article A14

Calculated Reaction Rates (mmol/kg cat.s)

0.5

30 C

50 C

70 C

0.4

0.3

0.2

0.1

0

0

0.1

0.2

0.3

0.4

0.5

Experimental Reaction Rates (mmol/kg cat.s)

Figure 6. Parity plot of experimental ethane formation rates vs those calculated by the model of

this work.

4.2. Reactor Modeling

The two flow models coupled with each of the three kinetic models described in the Theory

section were solved for an industrial-scale reactor. The operating conditions considered for the

simulation are listed in Table 3. It is worth mentioning that in the industrial acetylene

hydrogenation units, two reactors in series are employed for complete conversion of acetylene in

the feed (Weiss, 1996). The values given in Table 3 are typical for the first hydrogenation reactor.

Results of this simulation are shown in Figures 7a-d in terms of profiles of temperature, acetylene

conversion, ethylene formation, and ethane formation along the reactor, respectively. In these

figures, the results of simulation of the reactor by the two flow models, i.e., plug flow and

dispersion flow, which are coupled with the three kinetic models, i.e., Bos et al. (1993),

Menshchikov et al. (1975) and the proposed model in this study are shown.

Parameter

C2H2

C2H4

C2H6

H2

Reactor length

Inlet temperature

Pressure

Table 3. Modeling conditions

Unit

%

%

%

%

m

K

bar(g)

Value

4

93

1

2

3

293

25

Figure 7a illustrates the temperature profiles of the reactor for the three kinetic models as

coupled with the two flow models. It can be seen in this figure that all these models predict

almost the same final temperatures for the reactor. In addition, the results of dispersion and plug

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

Mostoufi et al.: Hydrogenation of Acetylene: Kinetic Studies and Reactor Modeling

11

models are actually close to each other. The exit temperature of the reactor is about 360 to 365 K

according to all models which are close to the exit temperature of the product from the first

hydrogenation reactor in the industrial acetylene converting units.

50

370

(a)

Despersion

Plug

360

This Work

350

Acetylene Conversion (%)

Bos et al.

This Work

Temperature (K)

Menshchikov et al.

40

This Work

340

330

Bos et al.

320

310

This Work

30

20

10

Bos et al.

300

Bos et al.

0

290

0

0.5

1.5

2.5

0.5

1.5

2.5

Reactor Length (m)

Reactor Length (m)

25

(d)

(c)

Dispersion

Plug

Dispersion

Plug

2.5

20

Menshchikov et al.

Menshchikov et al.

Ethane Formation (%)

Ethylene Formation (%)

Menshchikov et al.

(b)

Plug

Dispersion

Menshchikov et al.

1.5

This Work

15

Bos et al.

10

This Work

5

This Work

Bos et al.

0.5

Menshchikov et al.

Bos et al.

0

0

0.5

1.5

2.5

0.5

Reactor Length (m)

1.5

2.5

Reactor Length(m)

Figure 7. Simulation results for different flow patterns combined with kinetic models investigated

in this work (a) temperature profiles (b) acetylene conversion profiles (c) ethylene

formation profiles (d) ethane formation profiles.

The corresponding acetylene conversion profiles are shown in Figure 7b. This conversion is

calculated from the following formula:

X C2 H 2 =

FC2 H 2 ( in )

FC 2 H 2

FC 2 H 2 ( in )

(14)

It is also seen in Figure 7b that the profiles are close to each other and so do the exit conversions.

This is an expected trend since all three kinetic models considered in this study provide quite the

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

International Journal of Chemical Reactor Engineering

12

Vol. 3 [2005], Article A14

same acetylene hydrogenation rates (see Table 1). This figure illustrates that only about half of

the acetylene is eliminated in the first hydrogenation reactor and the rest of this task remains to be

accomplished in the second reactor. The reason for not completing the conversion of acetylene in

a single reactor is controlling the temperature, as discussed in the introduction section and shown

in Figure 7a.

Ethylene formation can be calculated from:

X C2 H 4 =

FC2 H 4

FC2 H 4 (in )

FC 2 H 4 ( in )

(15)

The profiles of ethylene formation along the reactor are shown in Figure 7c. It can be seen in this

figure that the kinetic model of Menshchikov et al. (1975) predicts the highest ethylene formation

among the three models and the model developed in this work predicts the lowest. The difference

between the predictions of the three models observed in Figure 7c is due to the fact that in the

process of ethylene formation, two reaction rates (i.e., acetylene conversion and ethane formation)

are involved. Although all three kinetic models considered in this study provide almost the same

acetylene conversion rates, they are dissimilar in the rate of ethane formation (see Table 1).

Therefore, different profiles are obtained from each kinetic model for ethylene formation. This

figure also reveals that regardless of the kinetic model used in the simulation, the plug model

provides lower ethylene formations compared to the dispersion flow model. This is some thing

that can be expected because in dispersion flow the back mixing phenomena helps the conversion

of acetylene to be higher than that of plug flow. Consequently, the ethylene formation would be

also higher in this case.

Ethane formation is calculated from:

X C2 H 6 =

FC2 H 6

FC2 H 6 (in )

FC2 H 6 ( in )

(16)

Figure 7d shows the profiles of ethane formation along the reactor length for the models

considered in this work. It is clear in this figure that each kinetic model predicts a different ethane

formation rate as compared to another one. The discussions made for Figure 7c regarding the

difference of the three kinetic models in terms of ethane formation rate are also valid here. In fact,

the difference between these models, which is mainly originated from the difference in ethane

formation rate, shows up noticeably in this figure. Since the reaction rates proposed in this work

fits the experimental data better than the other two models (see Figures 4b, 5b and 6), the results

of simulation with the new model can be more trusted for the employed catalyst and operating

conditions of this simulation.

When the hydrogenation catalyst is used in an industrial reactor, it is gradually deactivated

until it reaches the point of inefficiency. At this point, it should be replaced with fresh catalyst.

However, up to this point the feed temperature is gradually being increased during the usage of the

catalyst to counter the effect of deactivation. This increase in the temperature can raise the

activity of the catalyst to some extent. Figure 8 demonstrates the effect of increasing the feed

temperature on exit acetylene concentration with catalysts of different activities for the simulation

parameters given in Table 3. The operating point of the fresh catalyst (acetylene concentration at

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

Mostoufi et al.: Hydrogenation of Acetylene: Kinetic Studies and Reactor Modeling

13

the reactor exit for the catalyst of the activity equal to unity) is also illustrated in the same figure.

It is obvious from this figure that in neither case, increasing the temperature can lead to an exit

acetylene concentration equal to that with a new catalyst being employed. In fact, the effect of

increasing the feed temperature on the performance of a reactor containing deactivated catalyst is

to decrease the acetylene concentration at the beginning, although such a concentration would not

reach the concentration equivalent to the fresh catalyst. Nevertheless, further increase in the feed

temperature even overturns this trend and results in decreasing the acetylene conversion in the

reactor. This is because of the reverse effect of temperature on the concentration of feed

components and the reaction rate. The higher the temperature, the higher will be the reaction rate

but at the same time the feed concentration would become lower as the temperature increases. It is

for this reason that increasing the feed temperature cannot be used as the only way of dealing with

deactivation of the catalyst during each run. Therefore, in practice, two reactors are used in series

in order to help the catalyst in the second reactor of the process to reach the desired concentration

of acetylene in the final product, in addition to increasing the feed temperature of the first reactor.

4.3. Catalyst Deactivation

As mentioned in the Experimental section, both active and deactivated catalysts were employed in

this study. The new catalyst was used to find the proper kinetic for the system and the deactivated

one was used to study the effect of using the catalyst for a long time and determine the

deactivation coefficient for the catalyst. This deactivation coefficient can be used for analyzing

the long term dynamic behavior of the acetylene hydrogenation unit and estimates the temperature

evolution of the feed to the reactor during the catalyst useful life.

0.04

0.038

a = 0.1

Exit Acetylene (kmole/s)

0.036

0.034

0.032

a = 0.3

0.03

a = 1.0

0.028

a = 0.5

0.026

a = 0.7

0.024

0.022

0.02

290

300

310

320

330

340

350

360

370

380

390

Feed Temperature (K)

Figure 8. Effect of temperature on altering the activity of deactivated catalyst.

The rate of reaction incorporating catalyst deactivation can be obtained as follows:

ri ,d = ri a (t )

(17)

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

International Journal of Chemical Reactor Engineering

14

Vol. 3 [2005], Article A14

from which the deactivation coefficient could be evaluated by using the experimental data of this

work. There is no explicit expression for the deactivation rate of this catalyst in the literature.

Therefore, although the future works might suggest a nonlinear relationship between the catalyst

deactivation rate and the fraction of active catalyst, a first-order deactivation rate is assumed in

this case:

da

= kd a

dt

(18)

or

a(t ) = e

kd t

(19)

The deactivated catalyst used in this study had been used in the corresponding industrial

process for six months for which the deactivation coefficient was found to be 0.25. Based on this

value, the deactivation rate constant is estimated to be

k d = 2.772 (0.067)

month

(20)

The figure in the parenthesis in Equation (20) is the standard deviation of the calculated

deactivation constant.

5. CONCLUSIONS

Selective hydrogenation of acetylene was studied in a fixed bed reactor of a commercial Pd/Al2O3.

Using the experimental data of this work and existing kinetic models from the literature, a new

kinetic expression for hydrogenation of acetylene was developed. The acetylene hydrogenation

reactor was simulated with different flow models (i.e., plug flow and dispersion flow models)

coupled with three different kinetic models (i.e., Bos et al., 1993; Menshchikov et al., 1975) and

the new model developed in this study). It has been shown that although the profiles along the

reactor length could be different, in most cases the differences between plug and dispersion flow

models are small in terms of reactor outlet quantities. The effect of deactivation of the catalyst

was studied experimentally with a used catalyst and the deactivation rate constant of the catalyst

was evaluated. It was demonstrated by simulation that it is necessary to employ two

hydrogenation reactors in series due to the following reasons:

(a) Practical temperature control of the reactor: Hydrogenation of the whole acetylene in the

feed would result in an unacceptable increase in the temperature of the outlet of the reactor if a

single reactor is to be employed.

(b) Reaching the desired exit concentration of acetylene: While the catalyst gets deactivated

over the time, it is not possible to overcome the deactivation of the catalyst only by increasing the

feed temperature, thus, a second reactor is needed to complete the process of acetylene

hydrogenation up to the desired exit acetylene concentration.

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

Mostoufi et al.: Hydrogenation of Acetylene: Kinetic Studies and Reactor Modeling

NOTATION

a

A

CA

Cp

DA

Ea

F

Fi

Hj

k

k0

kd

L

m

P

R

ri

ri,d

t

T

u

X

z

fraction of active catalyst

cross section area (m2)

concentration of component A (kmole/m3)

specific heat (J/kmole.K)

dispersion coefficient of component A (m2/s)

activation energy (J/kmole)

total molar flow rate of feed (kmole/s)

molar flow rate of species i (kmole/s)

heat of reaction of reaction j (J/kmole)

reaction rate constant

frequency factor

deactivation rate constant (s-1)

reactor length (m)

mass of catalyst (kg)

pressure (Pa)

gas consntant (J/kmole.K)

reaction rate of species i (kmole/kg cat.s)

reaction rate of species i for a deactivated catalyst (kmole/kg cat.s)

time (sec)

temperature (K)

superficial velocity (m/s)

conversion

distance along the reactor (m)

Greek Letters

bed voidage

catalyst density (kg/m3)

c

Subscripts

A

component A

d

deactivation

in

inlet

out

outlet

REFERENCES

Al-Ammar, A.S., Webb, G., Hydrogenation of acetylene over supported metal catalyst, Part I:

Adsorption of [14C] acetylene and [14C] ethylene on silica supported rhodium, iridium and

palladium and aluminum supported palladium, J. Chem. Soc. Faraday Trans. I, Vol. 74, 195-205

(1978).

Al-Ammar, A.S., Webb, G., Hydrogenation of acetylene over supported metal catalyst, Part II:

[14C] Tracer deactivation phenomena:, J. Chem. Soc. Faraday Trans. I, Vol. 74, 657-664 (1978).

Al-Ammar, A.S., Webb, G., Hydrogenation of acetylene over supported metal catalyst, Part III:

[14C] Tracer studied of the effects of the added ethylene and carbon monoxide on the reaction

catalyzed by silica-supported palladium, rhodium and indium, J. Chem. Soc. Faraday Trans. I,

Vol. 75, 1900-1911 (1979).

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

15

16

International Journal of Chemical Reactor Engineering

Vol. 3 [2005], Article A14

Anderson, J., Mc Alister, S.H., Derr, E.L., Peterson, W.H., Diolefines in alkylation feed stocks

conversion to monolefines by selective hydrogenation, Ind. Eng. Chem., Vol. 40, 2295-2301

(1948).

Bos, A.N., Bootsma, E.S, Foeth, F., Sleyster, H.W., Westertrep, K.R., A kinetic study of the

hydrogenation of ethyne and ethene on a commercial Pd/Al2O3 catalyst, Chem. Eng. Proc., Vol.

32, 53-63 (1993).

Brodzinski, A., Cybulski, A., The kinetic model of hydrogenation of acetylene-ethylene mixtures

over palladium surface covered by carbonaceous deposits, Appl. Catal. A, Vol. 198, 51-66

(2000).

Constantinides, A., Mostoufi, N., Applied Numerical Methods for Chemical Engineers with

MATLAB Applications, Prentice Hall PTR, Upper Saddle River, NJ (1999).

Fasi, A., Kiss, J.T., Torok, B., Palinco, I., The selectivity and activity determining role of

carbonaceous species and metal-metal oxide interface in metal-catalyzed hydrogenation and

isomerization reactions, Appl. Catal. A, Vol. 200, 189-200 (2000).

Fogler, H.S., Elements of Chemical Reaction Engineering, 3rd ed. Prentice Hall PTR, Upper

Saddle River, NJ (1999).

Godinez, C., Cabanes, A.L., Villora, G., Experimental study of the front-end selective

hydrogenation of steam-cracking C2-C3 mixture, Chem. Eng. Proc., Vol. 34, 459-468 (1995).

Haehn, P.C., Haidengger, E., Schdel, N., Revival of acetylenes within the petrochemical

industry, Hydrocarbon Eng., Vol. 1, 41-48 (1997).

Kummerow, I., Trimm, D.L., Wainwright, M.S., Studies of the catalytic hydrogenation of

acetylene impurities in a butadiene stream. Chemeca 83, Chem. Eng. Today, 103-109 (1983).

Larsson, M., Janson, J., Asplund, S., The role of coke in acetylene hydrogenation on Pd/PAl2O3, J. Catal., Vol. 178, 49-57 (1998).

Leviness, S., Nair, V., Weiss, A. H., Schay, Z. Guczi, L., Acetylene hydrogenation selectivity

control on PdCu/ Al2O3 catalysts, J. Molecular Catal., Vol. 25, 131-140 (1984).

Mc Gown, W.T., Kemball, C., Whan, D., Hydrogenation of acetylene in excess of ethylene on an

alumina supported palladium catalyst at atmospheric pressure in a spinning basket-reactor, J.

Catal., Vol. 51, 173-184 (1978).

Menshchikov, V.A., Falkovich, Y.G., Aerov, M.E., Hydrogenation kinetics of acetylene on a

palladium catalyst in the presence of ethylene, Kinet. Catal., Vol. 16, 1338-1355 (1975).

Muller, M., Deller, K., Volheim, G, Kuhn, W., Selective hydrogenation of acetylene in the

manufacturing of vinylchloride, Chem. Eng. Tech., Vol. 59, 645-647 (1987).

Srkny, A., Guczi, L., Weiss, A. H., On the aging phenomenon in palladium catalyzed acetylene

hydrogenation, Appl. Catal., Vol. 10, 369-388 (1984).

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

Mostoufi et al.: Hydrogenation of Acetylene: Kinetic Studies and Reactor Modeling

Szukiewicz, M., Kaczmarski, K., Petrus, R., Modeling of fixed-bed reactor: two models of

industrial reactor for selective hydrogenation of acetylene, Chem. Eng. Sci., Vol. 53, 149-155

(1998).

Taghavi, M.B., Pajonk, G., Teicher, S.J., Hydrognation slective en phase gazeuse de

lactylene en thylne en prsence de catalyseures au cuivre, dpos sur lalmine, de magnsie

et la silica, Bull. Soc. Chim. France, Vol. 7, 1302-1308 (1978).

Vincent, M.J., Gonzalez, R.D., A LangmuirHinshelwood model for a hydrogen transfer

mechanism in the selective hydrogenation of acetylene over a Pd/W-Al2O3 catalyst prepared by the

solgel method, Appl. Catal. A, Vol. 217, 143-156 (2001).

Vincent M.J., Gonzalez, R.D., Selective hydrogenation of acetylene through a short contact time

reactor, AIChE J., Vol. 48, 1257-1267 (2002).

Weisang, E., Engelhard, P.A., Nouveaux catalyseures dhydrogenation selective. Chim. Ind.

Genie. Chim., Vol. 103, 287-296 (1970).

Weiss, G., Modeling and control of an acetylene converter, J. Proc. Cont., Vol. 6, 7-15 (1996).

Westerterp, R., Bos, R., Wijngaarden, R., Kusters, W., Selective hydrogenation of acetylene in an

ethylene stream in an adiabatic reactor, Chem. Eng. Tech., Vol. 25, 529-539 (2002).

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

17

18

International Journal of Chemical Reactor Engineering

Brought to you by | University of Saskatchewan

Authenticated | 128.233.210.97

Download Date | 10/4/13 4:08 PM

Table 2. Parameters of the kinetic models studied in this work

Parameter

Unit

Bos et al. (1993)

Menshchikov et al. (1975)

k1,0

kmole. kgcat -1.s -1. bar -2

33.39

77.09

k2,0

bar -1

5.1089

5052.8

k3,0

bar -1

3379.0

10.512

k4,0

kmole. kg cat -1.s -1. bar -2

10.1710-3

12.0310-5

k5,0

bar -1

44.635

11.509

k6,0

bar -1

0.0446

11.075

Ea,1

kJ/kmole

14638

-1220.46

Ea,2

kJ/kmole

-107.67

-5558.8

Ea,3

kJ/kmole

-3379.0

-3362.0

Ea,4

kJ/kmole

40354.0

28652.0

Ea,5

kJ/kmole

-33806.0

18425.0

Ea,6

kJ/kmole

-29400.0

4923.0

* The figures in the parentheses are standard deviation of calculated parameters.

Vol. 3 [2005], Article A14

This work*

77.09 (0.000353)

5052.8 (0.484)

10.512 (0.434)

4.0210-5 (5.1910-6)

9.4561 (0.0711)

10.5045 (0.0648)

-1220.46 (0.518)

-5558.8 (178.09)

-3362.0 (141.7)

39774.0 (0.076)

-12494.0 (261.5)

3326.6 (208.09)

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- History of Singing PDFDokument92 SeitenHistory of Singing PDFRuf M100% (2)

- IMSLP03271-Franck - Eighteen Short PiecesDokument20 SeitenIMSLP03271-Franck - Eighteen Short PiecesArinze AnozieNoch keine Bewertungen

- Ave María HoffmannDokument3 SeitenAve María HoffmannsupermaqpNoch keine Bewertungen

- Aint Got Time To Die Hall Johnson PDFDokument14 SeitenAint Got Time To Die Hall Johnson PDFsupermaqp100% (1)

- All in The April EveningDokument4 SeitenAll in The April Eveningsupermaqp100% (1)

- Choral Singing and Psychological WellbeingDokument7 SeitenChoral Singing and Psychological WellbeingsupermaqpNoch keine Bewertungen

- Coconut and Banana ErnstschererDokument6 SeitenCoconut and Banana ErnstscherersupermaqpNoch keine Bewertungen

- Childrens Choir Ave VerumDokument2 SeitenChildrens Choir Ave VerumsupermaqpNoch keine Bewertungen

- Chironomy PDFDokument101 SeitenChironomy PDFsupermaqp100% (1)

- Ghana SongsDokument7 SeitenGhana SongssupermaqpNoch keine Bewertungen

- Haskell Julie PDFDokument17 SeitenHaskell Julie PDFsupermaqp100% (1)

- PIC16F84A DataSheetDokument88 SeitenPIC16F84A DataSheetEmanueleNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Kimia T4 2023 - DLPDokument10 SeitenKimia T4 2023 - DLPbrendan chee junNoch keine Bewertungen

- Csir Net Dec 14Dokument24 SeitenCsir Net Dec 14Aamer100% (1)

- Unit II - Lecture NotesDokument5 SeitenUnit II - Lecture NotesSteve Sullivan100% (1)

- Different Methods of Food PreservationDokument22 SeitenDifferent Methods of Food Preservationanand jeughaleNoch keine Bewertungen

- Geoffrey Pass B.SC., PH.D., Haydn Sutcliffe B.SC., PH.D., F.R.I.C. (Auth.) - Practical Inorganic Chemistry - Preparations, Reactions and Instrumental Methods-Springer Netherlands (1974)Dokument254 SeitenGeoffrey Pass B.SC., PH.D., Haydn Sutcliffe B.SC., PH.D., F.R.I.C. (Auth.) - Practical Inorganic Chemistry - Preparations, Reactions and Instrumental Methods-Springer Netherlands (1974)BrunoRamosdeLima100% (2)

- Soal latihanNMR PDFDokument20 SeitenSoal latihanNMR PDFDamar Nurwahyu BimaNoch keine Bewertungen

- Part XI - CHEMISTRY OF CARBON COMPOUNDS (Part 1)Dokument67 SeitenPart XI - CHEMISTRY OF CARBON COMPOUNDS (Part 1)yana LAUNoch keine Bewertungen

- Amination: Amination Is The Process of Introducing The Amino Group (Dokument9 SeitenAmination: Amination Is The Process of Introducing The Amino Group (Riva Nur ArofahNoch keine Bewertungen

- Astm D 3176 89 R02 PDFDokument3 SeitenAstm D 3176 89 R02 PDFHidan WL100% (1)

- Guidelines Part IIDokument162 SeitenGuidelines Part IICristina StancaNoch keine Bewertungen

- Practice Test 11Dokument63 SeitenPractice Test 11The LightNoch keine Bewertungen

- Heat and Mass Transfer Unit OperationsDokument5 SeitenHeat and Mass Transfer Unit OperationsFran LeeNoch keine Bewertungen

- Costs of Storing and Transporting HydrogenDokument216 SeitenCosts of Storing and Transporting Hydrogenknoxd77Noch keine Bewertungen

- 30 Years of PSA Technology For HydrogenDokument25 Seiten30 Years of PSA Technology For Hydrogengrpalem100% (4)

- Sample Paper-03 CHEMISTRY (Theory) Class - XI: Material Downloaded From andDokument4 SeitenSample Paper-03 CHEMISTRY (Theory) Class - XI: Material Downloaded From andSarthakNoch keine Bewertungen

- 9701 s11 QP 41 PDFDokument20 Seiten9701 s11 QP 41 PDFNeural Spark Physics CieNoch keine Bewertungen

- Alkanes Worksheet and Key02 25 09 PDFDokument8 SeitenAlkanes Worksheet and Key02 25 09 PDFCarl Kenneth ReyesNoch keine Bewertungen

- AAPG - 1986 - Guidelines For Evaluating Petroleum Source Rock - Peters PDFDokument12 SeitenAAPG - 1986 - Guidelines For Evaluating Petroleum Source Rock - Peters PDFIntan ParamitaNoch keine Bewertungen

- College of Allied Medical ProfessionsDokument4 SeitenCollege of Allied Medical ProfessionsCyrus De LeonNoch keine Bewertungen

- A Brief Summary of The Haber ProcessDokument4 SeitenA Brief Summary of The Haber ProcessKarez Marto100% (1)

- tp11 c7Dokument12 Seitentp11 c7Aditya SrinivasNoch keine Bewertungen

- PMR v26 I4 158 166 PDFDokument9 SeitenPMR v26 I4 158 166 PDFemzzNoch keine Bewertungen

- Fun Nemonics in ChemDokument3 SeitenFun Nemonics in ChemSuresh BabuNoch keine Bewertungen

- SP 1190 Desing - For - Sour - Service - SpecificationDokument15 SeitenSP 1190 Desing - For - Sour - Service - Specificationhappale2002100% (1)

- 1 DR K Srilatha CV - K SRILATHADokument19 Seiten1 DR K Srilatha CV - K SRILATHAKiran ModiNoch keine Bewertungen

- 11th Chemistry Unit Wise Important Questions English MediumDokument3 Seiten11th Chemistry Unit Wise Important Questions English MediumSathya Sree100% (1)

- Oerlikon Fluxofil and Fluxocord Tubular Cored Welding Wires For Fcaw and SawDokument55 SeitenOerlikon Fluxofil and Fluxocord Tubular Cored Welding Wires For Fcaw and SawdannNoch keine Bewertungen

- Journal of Cleaner Production: Di Zhang, Peng Hang, Guilian LiuDokument11 SeitenJournal of Cleaner Production: Di Zhang, Peng Hang, Guilian Liufrank2593Noch keine Bewertungen

- Chap 1 Mole Concept TheoryDokument22 SeitenChap 1 Mole Concept TheoryshriNoch keine Bewertungen

- United States Patent (19) : Im, Naperville, Both of Ill. Attorney, Agent, or Firm-William C. Clarke Arthur GDokument9 SeitenUnited States Patent (19) : Im, Naperville, Both of Ill. Attorney, Agent, or Firm-William C. Clarke Arthur GFebrian Dimas Adi NugrahaNoch keine Bewertungen