Beruflich Dokumente

Kultur Dokumente

Jps R 07091516

Hochgeladen von

Ezza RiezaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Jps R 07091516

Hochgeladen von

Ezza RiezaCopyright:

Verfügbare Formate

Sanjay Madhavan et al /J. Pharm. Sci. & Res. Vol.

7(9), 2015, 704-707

A Review on Hydrocolloids-Agar and Alginate

Sanjay Madhavan, Dr. Abirami

Savitha Dental College and Hospitals, Chennai

Abstract

Aim:

To provide information on the hydrocolloids-agar and alginate used in dentistry.

Objective:

To know about the various uses, advantages, disadvantages and proper selection of the hydrocolloid impression materials.

Background:

A colloidal system consists of two phases; the dispersed phase and the dispersion phase. If the dispersion phase of the colloidal

system is water, it is called hydrocolloid. Hydrocolloid impression materials are based on the colloidal suspension of

polysaccharide in water. In sol form: there is random arrangement of polysaccharide chain. In gel form: the long

polysaccharide chains become aligned and material becomes viscous and develops elastic properties. Based on the mode of

gelation, they are classified as: reversible hydrocolloids e.g. agar, irreversible hydrocolloids e.g. alginate. Agar hydrocolloid

was the first successful elastic impression material to be used in dentistry. It is an organic hydrophilic colloid extracted from

certain types of seaweed. Alginates were first isolated by Stanford by alkaline extraction of brown algae a process used for

iodine extraction. Alginate impressions are taken to obtain diagnostic study models, which are the positive reproductions of the

teeth and surrounding structures. They are also used to fabricate bleaching trays and mouthguards.

Reason: To provide a detailed review on the composition, uses, manipulation, gelation process, properties of agar and alginate

impression materials.

Keywords: hydrocolloid, impression, setting time, composition.

INTRODUCTION

Impression materials are used to record intraoral structures

for the fabrication of definitive restorations. Accurate

impressions are necessary for construction of any dental

prosthesis. The accuracy of these final restorations depends

greatly on the impression materials and techniques.

Impression materials that are currently popular include

polyethers,

addition

silicones,

polysulfides

and

hydrocolloids (1). An ideal impression material should

have the following requirements: pleasant taste & odor, not

contain any toxic & irritating ingredients, adequate shelf

life, easy to disinfect without loss of accuracy, compatible

with die and cast material, dimensional stability, good

elastic properties, easy manipulation, adequate setting

characteristics, high degree of reproduction details,

adequate strength and economical. Impression materials

should reproduce hard and soft tissues accurately to obtain

biologically, mechanically, functionally, and aesthetically

acceptable restorations (2).Hydrocolloids have a high

hydrophilic nature that allows this material to capture

accurate impressions in the presence of some saliva or

blood. It has a low wetting angle so it easily captures full

arch impressions. It has moderate ability to reproduce detail

and costs relatively little compared with other impression

materials. It is not accurate enough for fixed partial

dentures but is used for partial framework impressions (3).

HYDROCOLLOID IMPRESSION MATERIALS

The two types of hydrocolloids used in dental impressions

are agar and alginate. Agar is a reversible hydrocolloid

because it can pass repeatedly between highly viscous gel

and low viscosity sol simply through heating and cooling.

However, alginate once converted to the gel form cannot be

converted back into the sol, and is therefore said to be

irreversible hydrocolloid material (4).

ALGINATE

Alginate, an elastic, irreversible hydrocolloid impression

material has been the staple of most dental practices for

many years. The general use of irreversible hydrocolloid

far exceeds that of any impression material, because of its

various advantages such as hydrophilicity, pleasant taste

and odor, non-staining, inexpensive, ease of mixing and

effective use in the presence of saliva. Alginate is used to

generate gypsum casts for numerous applications such as in

making diagnostic casts, provisional crowns and bridges,

orthodontic study models, sports mouth guards, bleaching

trays, and fabrication of removable prosthesis.(5,6,7)

Types

Type1 fast setting 1-2min

Type 2-normal setting 2-4mins

Composition

Potassium or sodium alginate 15%

Calcium sulphate 16%

Zinc oxide 4%

Diatomaceous earth 60%

Potassium titanium fluoride 3%

Sodium phosphate 2% (8)

Chemistry and setting

Retardation of the setting reaction: 2Na3PO4+3CaSO4

Ca3(PO4)2+3Na2SO4

Setting reaction of alginate: Na alginate+CaSO4-mixed

with H2O Ca alginate+Na2SO4

On mixing the powder with water, a sol is formed, a

chemical reaction takes place, and a gel is formed. Sodium

alginate reacts with calcium sulfate, resulting in sodium

sulfate and calcium alginate. This reaction occurs too

quickly often during mixing or loading of the impression

tray. Hence it is slowed down by the addition of trisodium

phosphate to the powder. Trisodium phosphate reacts with

calcium sulfate to produce calcium phosphate, preventing

704

Sanjay Madhavan et al /J. Pharm. Sci. & Res. Vol. 7(9), 2015, 704-707

calcium sulfate from reacting with sodium alginate to form

a gel. This second reaction occurs in preference to the first

reaction until the trisodium phosphate is used up, and then

alginate sets as a gel (9).

Dispensing

Alginate powder is supplied in packages for single

impressions or in bulk. Paste type of alginate is also

available. Paste form is available in two viscosities, tray

and syringe viscosities. The paste-type material has a

shorter gelation time than the powder-type material. The

best surface quality can be obtained with the paste-type

material (10). It has been recommended to dispense the

powder by fluffing it by rotating and tumbling the can,

dipping the scoop, tapping the scoop gently with the

spatula, and levelling the powder in the scoop with a

spatula (11).

Mixing and loading the tray

Mixing is initiated by adding measured quantity of water to

clean flexible rubber bowl. This is followed by sifting the

measured quantity of powder into the water. This technique

of adding powder to the water is known as sifting and it

ensures that the powder particles are wet evenly. Colder

water can be used if longer working time is desired. Mixing

should be rapid with a wide-bladed spatula. A vigorous

figure of eight motion by swiping or stroping the mixture

against the sides of the bowl is recommended. The resultant

mix should be creamy in consistency but must not drip off

the spatula when lifted from the bowl. Mixing time is 60

seconds for hand spatulation and 15 seconds for

mechanical. The required amount of material is loaded onto

the tray. The tray must be filled with the impression

material up to the tray borders and any excess unsupported

material at the periphery must be removed with the mixing

spatula. The surface of the alginate is smoothed with a wet

gloved finger (12).

Impression making

Impression tray is positioned in the mouth by retracting the

patient's lips on one side with a mouth mirror/gloved

finger; and on the other side, by rotating the tray into the

mouth. The tray has to be centered in position in the mouth;

and with light pressure, impression is held in place. The

soft tissues, especially labial flange, should be relieved and

manipulated for the alginate to flow into the sulci and

record the details. When tray is seated, pressure should be

released immediately and the tray should be held lightly in

place to prevent unseating. Alginate materials start setting

from the tooth surface to the impression tray. Pressure will

cause impression to set under strain. Once set, the

impression has to be removed with a firm, quick snap. The

impression should not be rocked or twisted before or during

removal of the impression. This is to minimize the time for

which the set material is distorted as it moves over the

teeth. (13)

Storage and disinfection

Set alginate undergoes imbibition and syneresis if left in a

normal clinical environment. After being removed from the

mouth, alginate impressions should be washed with a water

spray and dried until the shine just disappears. The

impression has to be covered with damp gauze and left in a

zip-lock plastic bag until the cast is poured. Distortion can

be a problem if disinfection guidelines are not strictly

adhered to. Hydrocolloids are hydrophilic in nature; hence

they swell if immersed in water or disinfectant. Immersion

disinfectants like 1% sodium hypochlorite or 2%

glutaraldehyde can result in changes of 0.1%, and hence the

quality of the impression surface may not be impaired if the

recommended period of time(10mins) is strictly

followed.(14)

Advantages

1. Non toxic and non irritant

2. Good surface detail

3. Ease of use

4. Cheap and good shelf life

5.hydrophilicity

Disadvantages

1. Poor dimensional stability

2. Low tear strength

3. Messy to work with

4. Porosities on the surface of the poured models (15).

Recent developments

Dust-free alginate impression material

Antiseptic alginate impression material

Chromatic colour changing alginate

AGAR

Agar-agar is an organic colloid derived from the cell wall

of red seaweed (16). It is essentially a hydrophilic,

emulsoid polysaccharide (17). Reversible hydrocolloid was

introduced to the dental profession in 1925 by Alphons

Poller, an Austrian as impression material (18).Agar was

first introduced into dentistry for recording crown

impressions in 1937 by Sears (19) and was the first elastic

impression material available.

Composition

Borates 0.2 0.5%

Water 85.5%

Agar 13-17%

Sulfates 1 2%

Fillers (diatomaceous earth, silica, wax rubber) 0.5 -1%

Bactericide; thymol & glycerin are used

Color & flavour (20)

Chemistry and setting

Agar provides a thermoreversible gel and the sol-gel

formation is reversible and depends on temperature. This

material forms a colloid after absorbing water, which

liquefies between 71C and 100C and sets to a gel again

between 30C and 50C, depending on concentration of the

agar (21). The setting of the reversible hydrocolloid is

called gelation.

Manipulation

At first reverse the hydrocolloid gel to the sol stage.

Boiling water is a convenient way of liquefying the

705

Sanjay Madhavan et al /J. Pharm. Sci. & Res. Vol. 7(9), 2015, 704-707

material. The material must be held at this temperature for

a minimum of 10mins. Propylene glycol can be added to

the water to obtain 100 degrees. There are three

compartments in the conditioning unit, making it possible

to liquefy, store and temper the material. The hydrocolloid

is usually supplied in two forms: syringe and tray materials.

After it has been liquefied, the material must be stored in

the tray. The impression trays are rim locked with water

circulating device. This type of tray allows a space of 3mm

occlusally and laterally and extends distally to cover all the

teeth (22).

Impression making

The syringe material is taken directly from the storage

compartment and applied to the prepared cavities. It is first

applied to the base of the preparation and then the reminder

of the tooth is covered. By the time the cavity preparation

and adjoining teeth have been covered, the tray material has

been properly tempered and is now ready to be placed

immediately in the mouth to form the bulk of impression.

Gelation is accelerated by circulating cool water,

approximately, 18 21 degrees through the tray for 3 5

minutes.

Disinfection

For disinfecting the impression, iodophor, bleach or

gluteraldehyde can be used. The hydrocolloid may be

disinfected by 10 minute immersion in/or spraying with the

antimicrobial agent such as sodium hypochlorite and

glutaraldehyde without sufficient dimensional change (23).

Recent techniques

Wet field technique

The oral tissues are flooded with warm water. The syringe

material is then injected in to the surface to be recorded.

Before syringe material gels tray material is seated. The

hydraulic pressure of the viscous tray material forces the

fluid syringe material down in to the areas to be recorded.

The motion displaces the syringe material as well as blood

and debris throughout the sulcus.

Laminate technique

The general procedure is to heat the agar to be placed into

re-usable syringes for about six min in boiling water. The

agar is stored for at least 10 min at 65C before being

syringed around the preparations. A mix of alginate

containing 10% more water than normally recommended is

placed in a tray and it is immediately seated over the agar

syringe material. The cool mix of alginate helps gel the

agar, and when the alginate has set, the combined

impression is removed. The technique simplifies the use of

agar and provides an impression surface that allows for

preparation of stone casts acceptable for crown and bridge

applications (24).

Advantages

Inexpensive

No odors

Nontoxic

Nonstaining

Disadvantages

Complexity of the technique

Lower-than desirable tear strength.

PROPERTIES

Dimensional stability

Irreversible hydrocolloid impression material has

dimensional changes as a result of synergists or evaporation

of water when exposed to air(25).Storage medium such as

2% potassium sulphate solution or 100% relative humidity

in a storage chamber, is suggested to reduce the

dimensional change of agar impressions.

Strength

Alginate; Compressive strength- 5000-8000gm/cm2

Tear strength

- 350-700gm/cm2 (26).

Agar;

Compressive strength- 8000gm/cm2

Tear strength- 7000gm/cm2 (27).

Flow & distortion

This material does not readily flow into areas in which the

tray does not extend. If distortion occurs, it cannot be

corrected (28).

Agar is sufficiently fluid to allow detailed reproduction of

hard & soft tissue. If the material is held rigidly to the tray,

then the impression material shrinks toward the center of its

mass. Rapid cooling may cause a concentration of stress

near the tray where gelation first takes place.

Compatibility with gypsum

The sodium sulphate that was formed as a by-product of the

setting reaction of the alginate is a gypsum setting retarder

at high concentrations and thereby produce poor surfaces

(29). Agar impression material contains borax, which is a

retarder for setting of gypsum. This can be overcome by

immersing the agar impression in a solution containing a

gypsum accelerator or by incorporating a gypsum surface

hardener.

Accuracy

Most alginate impressions are not capable of producing

finer details as much as obtained with other elastomeric

impression materials (30).

Agar produces an accurate impression. The combination of

agar and alginate appears to produce excellent results and

detailed accuracy.

CONCLUSION

Making impressions is an important part of indirect

restorations that is often overlooked. The increased use of

agar impression material as a result of the development of

the agar alginate combination technique should level off

and continue at a modest level. Increased development of

dustless and higher tear strength alginates should be

expected as well as increased efforts to re-formulate

alginates to produce products with better reproduction of

detail and compatibility with gypsum products. With the

selection of an appropriate impression material and

impression technique, impression taking is reliable and

reproducible, with consistent successful results.

706

Sanjay Madhavan et al /J. Pharm. Sci. & Res. Vol. 7(9), 2015, 704-707

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

11)

12)

13)

14)

15)

REFERENCES

Self Disinfecting Reversible Hydrocolloid Impression Gels: Effect of

Composition and Nanosilver on Characteristic Properties and

Gelation Temperature S. Azemat Miri1 , G. Mir Mohamad

Sadeghi2,* and M. Rabiee1. Journal of Research Updates in Polymer

Science, 2012 Vol. 1, No. 1.

Faria AC, Rodrigues RC, Macedo AP, Mattos Mda G, Ribeiro RF.

Accuracy of stone casts obtained by different impression

materials. Braz Oral Res. 2008;22:2938.

Barry S. Rubel DMD. Dent Clin N Am 2007; 51: 629-42.

Crowns and other extra-coronal restorations: Impression materials

and technique R W Wassell, D Barker & A W G WallsBritish Dental

Journal 192, 679 - 690 (2002) Published online: 29 June 2002

doi:10.1038/sj.bdj.4801456

Carr AB, McGivney GP, Brown DT. McCracken's Removable

partialprosthodontics. 11th ed. St. Louis: Mosby; 2008. Impression

materials and procedures for removable partial dentures; pp. 2734.

Nandini VV, Venkatesh KV, Nair KC. Alginate impressions: A

practical perspective. J Conserv Dent.2008;11:3741. [PMC free

article] [PubMed].

Sedda M, Casarotto A, Rausita A, Borracchini A. Effect of storage

time on the accuracy of casts made from different irreversible

hydrocolloids. J Contemp Dent Pract. 2008;9:5966.

http://indiandentalacademy.blogspot.in/2013/08/hydrocolloids.html

Anusavice KJ, Kenneth J. Phillips' science of dental materials. 11th

ed. Elsevier; 2003. pp. 21030.

Murata H, Kawamura M, Hamada T, Chimori H, Nikawa H.

Physical properties and compatibility with dental stones of current

alginate impression materials. J Oral Rehabil. 2004;31:111522

CASWELL, C.W.; VON GOTEN, A.S.; and MENG, T.R. (1986):

Volumetric Proportioning Techniques for Irreversible Hydrocolloids:

A Comparative Study, J Am Dent Assoc 112:859-861

Ashley M. Making a good impression: A How to' Paper on dental

alginate. Dent Update. 2005;32:16975.

Alginate impressions: A practical perspective V Vidyashree Nandini,

K Vijay Venkatesh,1 and K Chandrasekharan Nair. J Conserv Dent.

2008 Jan-Mar; 11(1): 3741. doi: 10.4103/0972-0707.43416

Rubel BS. Impression materials: A comparative review of

impression materials mostly used in restorative dentistry. Dent Clin

North Am. 2007;51:62942.

The Selection, Use and Accuracy of Alginate Impression Materials

DENTAL LEARNING A PEER REVIEWED PUBLICATION

Stan Presley,DDS and Jaimee Morgan,DDS.

16) Mantell, C . L.. The Water Soluble Gums, New York: Reinhold

Publishing Corp., 1947.

17) Alexander, Jerome, Colloid Chemistry, New York: Reinhold

Publishing Corp., vol. V I, 1946.

18) Agar K. Elastic impression materials. Dent Clin N Amer 1971;15(1):

81-98.

19) Sears AW. Hydrocolloid impression technique for inlays and fixed

bridges.Dent Digest 1937; 43: 23023.

20) Anusavice Skinners science of dental materials. Tenth Edition.

Restorative dental materials-craig

21) Self Disinfecting Reversible Hydrocolloid Impression Gels: Effect of

Composition and Nanosilver on Characteristic Properties and

Gelation Temperature S. Azemat Miri1 , G. Mir Mohamad

Sadeghi2,* and M. Rabiee1.

22) Anusavice Skinners science of dental materials. Tenth Edition,

Dental materials and their selection-willian .j.o brien

23) Restorative dental materials-craig, Removable prosthodintics- stewar

24) REVIEW OF DENTAL IMPRESSION MATERIALS Department

of Biomaterials, School of Dentistry, University of Michigan, Ann

Arbor, Michigan 48109 Adv Dent Res 2(l):51-64, August, 1988.

25) Jamani KD. The effect of pouring time and storage condition on the

accuracy of irreversible hydrocolloid impressions. Saudi Dent

J. 2002;14(3):12630.

26) Mechanical Properties of Hydrocolloid and Rubber Impression

Materials G. W. MAC PHERSON,' R. G. CRAIG, and F. A.

PEYTON University of Michigan, School of Dentistry, Ann Arbor,

Michigan.

27) Self Disinfecting Reversible Hydrocolloid Impression Gels: Effect of

Composition and Nanosilver on Characteristic Properties and

Gelation Temperature S. Azemat Miri1 , G. Mir Mohamad

Sadeghi2,* and M. Rabiee1 Journal of Research Updates in Polymer

Science, 2012 Vol. 1, No. 1.

28) Rubel BS (2007), Impression materials: a comparative review of

impression materials most commonly used in restorative dentistry.

Dent Clin North Am. vol. 51:pp. 629-642.

29) JARVIS, R.G. and EARNSHAW, R. (1981): The Effect of Alginate

Impressions on the Surface of Cast Gypsum. II. The Role of Sodium

Sulphate in Incompatibility, Aust Dent / 26:12-17.

30) A Comparative Study on Accuracy and Reproducibility of Alginate

and Addition Reaction Silicone as an Impression Materials. Updat

Dent. Coll .j 2013; 3(2):28-33.

707

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Minute Math 2Dokument112 SeitenMinute Math 2Lidia Dicu100% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Diagnosing Borderline Personality DisorderDokument12 SeitenDiagnosing Borderline Personality DisorderAnonymous 0uCHZz72vwNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Power BI For Data ModellingDokument25 SeitenPower BI For Data ModellingJunior Leite100% (1)

- Marana Karaka SthanaDokument20 SeitenMarana Karaka SthanaKamal RanathungaNoch keine Bewertungen

- Model Curriculum Vitae and Resume For Law Student GraduatesDokument2 SeitenModel Curriculum Vitae and Resume For Law Student GraduatesSnehal SinghNoch keine Bewertungen

- Testing MechanicalDokument42 SeitenTesting MechanicalSadique ChakoleNoch keine Bewertungen

- University of The CordillerasDokument2 SeitenUniversity of The Cordillerasmj Canilang100% (1)

- ISO 30401 MandateDokument4 SeitenISO 30401 MandateTheerapan CNoch keine Bewertungen

- Frequencies: StatisticsDokument5 SeitenFrequencies: StatisticsEzza RiezaNoch keine Bewertungen

- Perbandingan Mutu Dan Harga Tablet Amoksisilin 500 MG Generik Dengan Non Generik Yang Beredar Di PasaranDokument16 SeitenPerbandingan Mutu Dan Harga Tablet Amoksisilin 500 MG Generik Dengan Non Generik Yang Beredar Di Pasarantzennopharma7828Noch keine Bewertungen

- Australian Dental Journal: The Contemporary Management of Third MolarsDokument8 SeitenAustralian Dental Journal: The Contemporary Management of Third MolarsEzza RiezaNoch keine Bewertungen

- The Effect of Various Classes of Malocclusions On The Maxillary Arch Forms and Dimensions in Jordanian PopulationDokument7 SeitenThe Effect of Various Classes of Malocclusions On The Maxillary Arch Forms and Dimensions in Jordanian PopulationEzza RiezaNoch keine Bewertungen

- Daftar PustakaDokument2 SeitenDaftar PustakaEzza RiezaNoch keine Bewertungen

- Nasakah PublikasiDokument11 SeitenNasakah PublikasiEzza RiezaNoch keine Bewertungen

- Dog Training Book Rex in The CityDokument56 SeitenDog Training Book Rex in The CitybebekbuluhNoch keine Bewertungen

- InTech-Diagnostic Imaging in Oral and Maxillofacial PathologyDokument25 SeitenInTech-Diagnostic Imaging in Oral and Maxillofacial PathologyDian Primadia PutriNoch keine Bewertungen

- Test KtiDokument1 SeiteTest KtiEzza RiezaNoch keine Bewertungen

- Lembaran Rekap PedodonsiaDokument1 SeiteLembaran Rekap PedodonsiaEzza RiezaNoch keine Bewertungen

- 167Dokument9 Seiten167real_septiady_madrid3532Noch keine Bewertungen

- Maybelline Co - IdDokument2 SeitenMaybelline Co - IdEzza RiezaNoch keine Bewertungen

- Pyogenic Granuloma of Gingiva: A MisnomerDokument4 SeitenPyogenic Granuloma of Gingiva: A MisnomerInternational Organization of Scientific Research (IOSR)Noch keine Bewertungen

- KUISIONERDokument9 SeitenKUISIONERRini Ajah RNoch keine Bewertungen

- Oral and Maxillofacial Surgery and Procedures 003Dokument4 SeitenOral and Maxillofacial Surgery and Procedures 003Ezza RiezaNoch keine Bewertungen

- Oral and Maxillofacial Surgery and Procedures 003Dokument4 SeitenOral and Maxillofacial Surgery and Procedures 003Ezza RiezaNoch keine Bewertungen

- 07 PDFDokument7 Seiten07 PDFEzza RiezaNoch keine Bewertungen

- 7 130p D PDFDokument108 Seiten7 130p D PDFEzza RiezaNoch keine Bewertungen

- Gingival Epulis CaseDokument5 SeitenGingival Epulis Casejinny1_0Noch keine Bewertungen

- Oral and Maxillofacial Surgery Syllabus 01.PDF 30538196Dokument117 SeitenOral and Maxillofacial Surgery Syllabus 01.PDF 30538196Ezza RiezaNoch keine Bewertungen

- Gingival Epulis CaseDokument5 SeitenGingival Epulis Casejinny1_0Noch keine Bewertungen

- 2212 4403Dokument18 Seiten2212 4403Ezza RiezaNoch keine Bewertungen

- 1-The Etiology of Orthodontic ProblemsDokument47 Seiten1-The Etiology of Orthodontic ProblemsEzza RiezaNoch keine Bewertungen

- Gingival Epulis CaseDokument5 SeitenGingival Epulis Casejinny1_0Noch keine Bewertungen

- Research Article: Effectiveness of Mouth Washes On Streptococci in Plaque Around Orthodontic AppliancesDokument5 SeitenResearch Article: Effectiveness of Mouth Washes On Streptococci in Plaque Around Orthodontic AppliancesEzza RiezaNoch keine Bewertungen

- Ameloblastoma: A Clinical Review and Trends in ManagementDokument13 SeitenAmeloblastoma: A Clinical Review and Trends in ManagementEzza RiezaNoch keine Bewertungen

- Gingival Epulis CaseDokument5 SeitenGingival Epulis Casejinny1_0Noch keine Bewertungen

- Kista Odontogenik Di Rumah Sakit Dr. Wahidin Sudirohusodo MakassarDokument8 SeitenKista Odontogenik Di Rumah Sakit Dr. Wahidin Sudirohusodo MakassarEzza RiezaNoch keine Bewertungen

- 15 Angle ClassificationDokument33 Seiten15 Angle ClassificationEzza RiezaNoch keine Bewertungen

- Ich GuidelinesDokument5 SeitenIch GuidelinesdrdeeptisharmaNoch keine Bewertungen

- ExampleApp Functional SpecificationDokument119 SeitenExampleApp Functional SpecificationmilosvarakNoch keine Bewertungen

- Final SPKDokument9 SeitenFinal SPKAinul qalbiNoch keine Bewertungen

- Knowledge Intensive Business Services (KIBS) : Don Scott-Kemmis July 2006Dokument8 SeitenKnowledge Intensive Business Services (KIBS) : Don Scott-Kemmis July 2006KALAWANoch keine Bewertungen

- An Introduction To Genre Theory: January 1997Dokument16 SeitenAn Introduction To Genre Theory: January 1997pratolectusNoch keine Bewertungen

- IT MANAGER Job Description - Minconsult SDN BHDDokument4 SeitenIT MANAGER Job Description - Minconsult SDN BHDSivasakti MarimuthuNoch keine Bewertungen

- Basic ConceptsDokument96 SeitenBasic ConceptsMuthu KumarNoch keine Bewertungen

- Liverpool University Campus MapDokument2 SeitenLiverpool University Campus MapJohn LukNoch keine Bewertungen

- HIRARC - Yawar Hassan KhanDokument11 SeitenHIRARC - Yawar Hassan KhanCyberMissio StudiosNoch keine Bewertungen

- Recovering The Essence in Language - EssayDokument3 SeitenRecovering The Essence in Language - EssayOnel1Noch keine Bewertungen

- Castellated Beam: Cell Form: Ds 0.25 DsDokument2 SeitenCastellated Beam: Cell Form: Ds 0.25 DsعلياسماعيلNoch keine Bewertungen

- Studio D A1 WorkbookDokument4 SeitenStudio D A1 WorkbookZubyr Bhatty0% (1)

- 9990 Y18-20 Sy PDFDokument40 Seiten9990 Y18-20 Sy PDFmashalNoch keine Bewertungen

- Science Documentary 2016: The Math Mystery Mathematics in Nature and Universe. (A Reaction Paper)Dokument3 SeitenScience Documentary 2016: The Math Mystery Mathematics in Nature and Universe. (A Reaction Paper)Ms Tuesday WattpadNoch keine Bewertungen

- Art Intg Proj CL 6-10Dokument5 SeitenArt Intg Proj CL 6-10Sarthak JoshiNoch keine Bewertungen

- Empirical and Tchebysheff's TheoremDokument7 SeitenEmpirical and Tchebysheff's TheoremLee Yee RunNoch keine Bewertungen

- Many Worlds InterpretationDokument26 SeitenMany Worlds InterpretationahsbonNoch keine Bewertungen

- Oracle Linux 7 Update 5-E93593Dokument68 SeitenOracle Linux 7 Update 5-E93593Saad Ullah KhanNoch keine Bewertungen

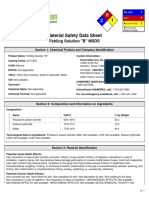

- Fehling Solution "B" MSDS: Section 1: Chemical Product and Company IdentificationDokument6 SeitenFehling Solution "B" MSDS: Section 1: Chemical Product and Company IdentificationAnnisaNoch keine Bewertungen

- 2023 Occ 1ST ExamDokument3 Seiten2023 Occ 1ST ExamSamantha LaboNoch keine Bewertungen

- Beyond GrammarDokument184 SeitenBeyond Grammaryazadn100% (2)

- The Historical & Evolutionary Theory of The Origin of StateDokument5 SeitenThe Historical & Evolutionary Theory of The Origin of StateMateen Ali100% (1)