Beruflich Dokumente

Kultur Dokumente

Method Statement For Mobilization Works Purpose

Hochgeladen von

Utku Can KılıçOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Method Statement For Mobilization Works Purpose

Hochgeladen von

Utku Can KılıçCopyright:

Verfügbare Formate

Method Statement for

Mobilization Works

TOTAL 9 PAGES

(Including Cover)

Purpose

PROJECT NAME

: Khabat Thermal Power Plant Units 1&2

DOCUMENT NO.

: KP-00+++-MQ758-V0002

TITLE

: Method Statement for Mobilization Works

For Approval

OWNER

: Ministry of Electricity (MOE) of

Kurdistan Regional Government

For Construction

17.09.2014

Rev.

No.

DATE

First Issue

DESCRIPTION

For Information

For Review

As-Built

MP

EO

AZ

TC

PREPARED

CHECKED

REVIEWED

APPROVED

GAMA POWER SYSTEMS ENG &CONTRACTING,INC.

Owner

Ministry of Electricity (MOE)

of Kurdistan Regional Government

Contractor

POSCO ENGINEERING

& CONSTRUCTION CO., LTD.

Main Subcontractor

GAMA POWER SYSTEMS

ENGINEERING & CONTRACTING,INC.

METHOD STATEMENT FOR MOBILIZATION WORKS

Page:

1/8

Doc.No:

KP-00+++-MQ758V0002

Date:

17.09.2014

Khabat Thermal Power Plant Units 1&2 Project

132kV Air Insulated Switchgear

METHOD STATEMENT FOR MOBILIZATION

WORKS

DOCUMENT NO: KP-00+++-MQ758-V0002

SUBCONTRACTOR: SIEMENS

GAMA REVIEW

Discipline

Superintendent

HSE Manager

QA/QC Manager

Site Manager

Name

Date

Sign

Remarks:

Any such review or consent by GAMA, shall not relieve the Subcontractor, in any case or for any reason whatsoever,

from any obligation, liability or responsibility arising out of or in connection with the Contract, including without being

limited thereto, to the responsibility for errors, omissions, discrepancies and non-compliances. Within this context, this

document shall not prevail over or amend the Contract, or relieve the Subcontractor from any of its duties, obligations,

responsibilities or liabilities under the Contract.

Anything presented herein by the Subcontractor shall in no event

i) excuse the Subcontractors non-performance under the Contract, or

ii) entitle him to a variation under the Contract or an adjustment to the Contract Price.

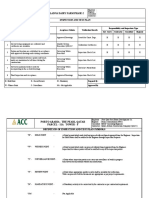

SUBCONTRACTOR

Rev.

No.

A

Date

Description*

Prepared

by

HSE

Manager

QA/QC

Manager

Site

Manager

Project

Manager

17.09.2014

Mobilization

Work

Mustafa

Peker

Eyyp zbay

Doc. No: KP-00+++-MQ758-V0002, Rev. No: A

METHOD STATEMENT FOR MOBILIZATION WORKS

Page:

2/8

Doc.No:

KP-00+++-MQ758V0002

Date:

17.09.2014

DOCUMENT HISTORY:

Rev.

No.

Date

17.09.2014

Remarks

(Reason for Revision)

First Issue

* Description:

Document issue purpose

-

First Issue

For Information

For Review

For Approval (or Issued for Construction)

Doc. No: KP-00+++-MQ758-V0002, Rev. No: A

METHOD STATEMENT FOR MOBILIZATION WORKS

Page:

3/8

Doc.No:

KP-00+++-MQ758V0002

Date:

17.09.2014

CONTENT

1.0

PURPOSE ........................................................................................................................................ 4

2.0

SCOPE OF WORK ........................................................................................................................... 4

3.0

RESPONSIBILITIES ........................................................................................................................ 4

4.0

DEFINITIONS / ABBREVIATIONS .................................................................................................. 4

5.0

PERSONNEL ................................................................................................................................... 4

6.0

MATERIALS ..................................................................................................................................... 4

7.0

EQUIPMENT .................................................................................................................................... 5

8.0

SUBCONTRACTORS SUB-TIER CONTRACTORS ...................................................................... 6

9.0

EXECUTION ..................................................................................................................................... 6

10.0

TIME LINE OF ACTIVITIES ............................................................................................................. 7

11.0

PROGRESS MEASUREMENT ........................................................................................................ 7

12.0

QUALITY REQUIREMENTS ............................................................................................................ 7

13.0

RISK ASSESSMENTS ..................................................................................................................... 8

Doc. No: KP-00+++-MQ758-V0002, Rev. No: A

METHOD STATEMENT FOR MOBILIZATION WORKS

Page:

1.0

4/8

Doc.No:

KP-00+++-MQ758V0002

Date:

17.09.2014

PURPOSE

PurposeofthissocumentistogivebriefdetailsaboutMobilizationActivitiesofKhabat

ThermalPowerPlant1&2132kVSubstationPart.

2.0

SCOPE OF WORK

ScopeofthisMethodofStatementisMobilizationActivitiesatKhabatThermalPower

Plant1&2132kVSubstationPart.

3.0

RESPONSIBILITIES

Allpersonnelassignedtothisprojectfrome.g.Engineering,QualityandPlanningOperations

etc.;arefunctionallyresponsibletotheProjectManager,workingasateamtoachievethe

objectiveofcompletingtheprojecttothecustomerssatisfaction.

TheProjectManageristheprimarycontactregardingcommunicationbetweenthecustomer

andSIEMENS

4.0

DEFINITIONS / ABBREVIATIONS

QEHS

QA

QC

LV

ITP

AIS

5.0

:Quality,Environmental,Health&Safety

:QualityAssurance

:QualityControl

:LowVoltage

:InspectionandTestPlan

:AirIsolatedSwitchyard

PERSONNEL

SiteManager1

SiteForemen1

Workers2

Operators1

6.0

MATERIALS

RebarsS420(TSE500,fyk=420N/mm)

Concrete(Type:C25forFoundations,C20forLeanConcretes)

Formworks(timberandplywood/wood)

Gravelorcrushedstone

Perforateddrainagepipes

Doc. No: KP-00+++-MQ758-V0002, Rev. No: A

METHOD STATEMENT FOR MOBILIZATION WORKS

Page:

5/8

Doc.No:

KP-00+++-MQ758V0002

Bricks

Plasteringmaterials(roughcast,gypsumplaster)

Paints

Marble

CeramicTiles

DoorsandWindows

7.0

Date:

17.09.2014

EQUIPMENT

1.MandatoryPersonalProtectiveEquipment,

SafetyHelmet

SafetyShoes

SafetyVest

SafetyGloves

SafetyGlassess/Goggles

2.PersonalProtectiveEquipmentRequiredDuetoSpecificRisks,

SafetyHarness,

Dustand/orChemicalMasks

WeldingShield

3.SafetyBarricadingFence/NetlonFence

4.RelatedSafety/WarningSigns.

5.Machines

Crane1(10ton)

Manlift

Excavator

HandTools

Backhoeloader

Loader

Trucks

Scaffold

Concretevibrator

Concretemixer

Doc. No: KP-00+++-MQ758-V0002, Rev. No: A

METHOD STATEMENT FOR MOBILIZATION WORKS

Page:

8.0

6/8

Doc.No:

KP-00+++-MQ758V0002

Date:

17.09.2014

SUBCONTRACTORS SUB-TIER CONTRACTORS

CompanyName

:SilopiAypanaatSan.Tic.Ltd.ti.

Address

:YesiltepeMah.2.Cad.iekApt.No:41Kat:1Silopi/SIRNAK

Tel

:04865186900

Fax

:04865186900

:mesut.aydin@silopiaypa.com

9.0

EXECUTION

9.1 Site Preparation

All materials, which will be used for installation of the prefabricated office building, will be stored

properly near installation area. The concrete platform, which will be used for installing on, will be

cleanedandpreparedforinstallation.

9.2 Carrier System Installation with External walls

Special shaped steel profiles will be fixed by using steel dowels on the concrete platform. After that

specialshapedprofiles,whichisusedasverticalcarrier,willbeinstalledbystartingfromonecornerto

another corner. At this time extarnal walls will be installed between two vertical profiles. Doors and

windowswillbeinstalledwhereisnecessary.

9.3 Interior wall Installation

Specialshapedprofileswillbeinstalledontheconcreteplatformbysteeldowelsforbuildingdesigned

rooms.Afterthatspecialshapedprofiles,whichisusedasverticalcarrier,willbeinstalledbystarting

from one corner to another corner. At this time internal walls will be installed between two vertical

profiles.Doorswillbeinstalledwhereisnecessary.

9.4 Roof Installation

Rooftrusswillbeliftedbyusingcraneandinstalledontheverticalprofiles.Afterthetrussinstallation

purlinswillbeinstalled.Afterthattheroofpanelswillbeinstalled.

9.5 Electrical wiring works

Electricalwiringswillbeinstalledbyusingsurfacemountedcablechannels.Andwiringswillbe

connectedtotheelectricboard.

9.6 Sanitary system installation

Necessarypipingwillbedonetoprovidefreshwaterandremovethesewagewateratthewet

areas.Aftertheinstallationiscompleteleakagetestwillbedonevisually.

Doc. No: KP-00+++-MQ758-V0002, Rev. No: A

METHOD STATEMENT FOR MOBILIZATION WORKS

Page:

10.0

7/8

Doc.No:

KP-00+++-MQ758V0002

Date:

17.09.2014

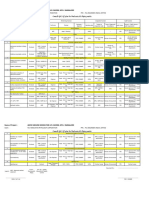

TIME LINE OF ACTIVITIES

Approximate durations will be shown below for each section. Also each step of the work will

repeated and performed together for accelerate the work. Also working Schedule will be

followed.

ForecastedStart&FinishDatesofMobilization:01/09/201407/09/2014

11.0

PROGRESS MEASUREMENT

All Mobilization Activities will be completed in one week period. The missing Items will be

followedduringcontractperiod.

12.0

QUALITY REQUIREMENTS

Toolbox talk will be done with the team who is involved in the foundation works. Job Safety

Analysis(JSA)willbepreparedanddistributedtoSiteSupervisor(s).UsingrelatedJSA,

MethodStatementandRisk

Assessmentwillbediscussedduringthetoolboxtalk.

Whileexcavationworks,barricadewillbeinstalledtothearoundthepitandwarningsignswill

beputtowarnotherpeopletokeepaway.

MandatoryPersonalProtectiveEquipmentwillbeusedbythepersoninvolvedintheoperation.

ThereisnorequirementforadditionalPPE.

RiskAssessmentwillbetakenintoconsiderationandrequiredprecautionswillbetaken.

Doc. No: KP-00+++-MQ758-V0002, Rev. No: A

METHOD STATEMENT FOR MOBILIZATION WORKS

Page:

13.0

8/8

Doc.No:

KP-00+++-MQ758V0002

Date:

17.09.2014

RISK ASSESSMENTS

WorkRiskassessmentaboutallworksandpossiblerisksatthesite,islistedasfollow.

Guidance

Doc. No: KP-00+++-MQ758-V0002, Rev. No: A

Das könnte Ihnen auch gefallen

- Nursing School Necessities Cheat SheetDokument3 SeitenNursing School Necessities Cheat SheetRevNoch keine Bewertungen

- Chemical Handling ProcedureDokument15 SeitenChemical Handling ProcedureGHULAM MOHYUDDINNoch keine Bewertungen

- Staples Worklife Magazine - Winter 2019Dokument68 SeitenStaples Worklife Magazine - Winter 2019Anonymous fq268KsS100% (1)

- Project Management Aspects During Mobilization StageDokument3 SeitenProject Management Aspects During Mobilization StageNazee 122333Noch keine Bewertungen

- Psycho Dynamic Psychotherapy For Personality DisordersDokument40 SeitenPsycho Dynamic Psychotherapy For Personality DisorderslhasniaNoch keine Bewertungen

- Field Inspection - Test PlanDokument59 SeitenField Inspection - Test PlansswahyudiNoch keine Bewertungen

- MOS - Fire FightingDokument23 SeitenMOS - Fire FightingMohammad Hadoumi SaldanNoch keine Bewertungen

- Larsen and Toubro's Substructure Waterproofing MethodDokument6 SeitenLarsen and Toubro's Substructure Waterproofing MethodGaneshNoch keine Bewertungen

- Installation of Fire Detection SystemDokument8 SeitenInstallation of Fire Detection SystemUtku Can KılıçNoch keine Bewertungen

- RAMS For Temporary ServicesDokument22 SeitenRAMS For Temporary ServicesAnandu AshokanNoch keine Bewertungen

- Erection ProtocolsDokument17 SeitenErection ProtocolsSam50% (2)

- Rsae-Frm-216 Rev 00 Inspection Check List LV Bus DuctDokument1 SeiteRsae-Frm-216 Rev 00 Inspection Check List LV Bus DuctUtku Can Kılıç50% (2)

- Method Statement for Electro Mechanical Works InstallationDokument17 SeitenMethod Statement for Electro Mechanical Works Installationsushanta chowdhuryNoch keine Bewertungen

- VT Test ProsedureDokument7 SeitenVT Test ProsedureUtku Can KılıçNoch keine Bewertungen

- VT Test ProsedureDokument7 SeitenVT Test ProsedureUtku Can KılıçNoch keine Bewertungen

- Site Camp Establishment NWTGC (Rev)Dokument20 SeitenSite Camp Establishment NWTGC (Rev)Avinash LalNoch keine Bewertungen

- Instrumentation Work Procedure For Kokori - Uzere Surge Vessel Installation BidDokument10 SeitenInstrumentation Work Procedure For Kokori - Uzere Surge Vessel Installation BiddejiNoch keine Bewertungen

- SOP16 Testing of Fire Alarm SystemDokument1 SeiteSOP16 Testing of Fire Alarm Systemanil kumarNoch keine Bewertungen

- ITP For Batteries, Chargers and UPSDokument7 SeitenITP For Batteries, Chargers and UPSUtku Can Kılıç100% (1)

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDokument3 SeitenProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNoch keine Bewertungen

- MHI Electrical 1st Comment RSAE-ITP-QA-EL-012 ITP For LV Bus DuctDokument5 SeitenMHI Electrical 1st Comment RSAE-ITP-QA-EL-012 ITP For LV Bus DuctUtku Can KılıçNoch keine Bewertungen

- 00-Site InstructionDokument7 Seiten00-Site InstructionSyed Munawar AliNoch keine Bewertungen

- AL UDEID AIR BASE RACEWAY MODIFICATION PROJECTDokument12 SeitenAL UDEID AIR BASE RACEWAY MODIFICATION PROJECTgangadharan000Noch keine Bewertungen

- PP13 00 Bat Enl Gam 001 PDFDokument16 SeitenPP13 00 Bat Enl Gam 001 PDFUtku Can Kılıç100% (1)

- Inspection Test Plan For Civil Works: Rev - A 28.05.2022Dokument17 SeitenInspection Test Plan For Civil Works: Rev - A 28.05.2022Suraj ShettyNoch keine Bewertungen

- Field Installation, Inspection & Test PlanDokument2 SeitenField Installation, Inspection & Test PlanSaiful Ahda100% (1)

- Excavation and BackfillingDokument2 SeitenExcavation and BackfillingyasserNoch keine Bewertungen

- Khabat Power Plant Auto Transformer Test ReportsDokument11 SeitenKhabat Power Plant Auto Transformer Test ReportsUtku Can KılıçNoch keine Bewertungen

- Att-2 Grounding & Lightning Protection - Tech - Specs.Dokument34 SeitenAtt-2 Grounding & Lightning Protection - Tech - Specs.Utku Can Kılıç100% (1)

- FHC Installation Method StatementDokument9 SeitenFHC Installation Method StatementMeriam DacunesNoch keine Bewertungen

- Dr. LakshmayyaDokument5 SeitenDr. LakshmayyanikhilbNoch keine Bewertungen

- MV&LV Switchgear Test ReportDokument4 SeitenMV&LV Switchgear Test ReportUtku Can Kılıç100% (1)

- MV&LV Switchgear Test ReportDokument4 SeitenMV&LV Switchgear Test ReportUtku Can Kılıç100% (1)

- Resource Deployment Plan - HehDokument2 SeitenResource Deployment Plan - HehMyjaz Jaz100% (1)

- Visual and Technical Checking of I&C SystemsDokument13 SeitenVisual and Technical Checking of I&C SystemszhangyiliNoch keine Bewertungen

- Method Statement For Installation of AHU-FAHU PDFDokument19 SeitenMethod Statement For Installation of AHU-FAHU PDFbryanNoch keine Bewertungen

- Method Statement For UPSDokument12 SeitenMethod Statement For UPSelbaraniNoch keine Bewertungen

- Method Statement For Stone WorksDokument10 SeitenMethod Statement For Stone WorksvisanuNoch keine Bewertungen

- KP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Dokument1 SeiteKP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Utku Can KılıçNoch keine Bewertungen

- Inspection and Test Plan For Lightning Protection InstallationDokument1 SeiteInspection and Test Plan For Lightning Protection InstallationUtku Can Kılıç100% (1)

- Project Earthwork ProcedureDokument6 SeitenProject Earthwork ProcedureJitesh SahiNoch keine Bewertungen

- Rsae ITP QA: Document Review and Cover Sheet Company: Construction ContractorDokument5 SeitenRsae ITP QA: Document Review and Cover Sheet Company: Construction ContractorUtku Can KılıçNoch keine Bewertungen

- Petroleum Test Questions Answers English Issue6 2016 08Dokument124 SeitenPetroleum Test Questions Answers English Issue6 2016 08Utku Can KılıçNoch keine Bewertungen

- 250600DBQRD0008 - Exde00 - 22 - Procedure For Handling, Transport and Storage of Pipes From The Stock Pile To TrenchDokument22 Seiten250600DBQRD0008 - Exde00 - 22 - Procedure For Handling, Transport and Storage of Pipes From The Stock Pile To TrenchAbdullah AbdullahNoch keine Bewertungen

- O&M Mobilisation PlanDokument3 SeitenO&M Mobilisation PlanKL Wong100% (1)

- m1439-Ghd-mcl-mss-005 Existing Dry Type Transformer ReconditioningDokument27 Seitenm1439-Ghd-mcl-mss-005 Existing Dry Type Transformer ReconditioningAnandu AshokanNoch keine Bewertungen

- Method Statement For Execution of WorkDokument10 SeitenMethod Statement For Execution of WorkSharat SahaNoch keine Bewertungen

- QAP For Overall Mechanical ActivitiesDokument2 SeitenQAP For Overall Mechanical ActivitiesMaheshwar polepallyNoch keine Bewertungen

- Lightning Protection ITPDokument3 SeitenLightning Protection ITPUtku Can KılıçNoch keine Bewertungen

- KP-00+++-MQ758-V0008-Rev 1-METHOD OF STATEMENT FOR HV SUBSTATION BUSBAR INSTALLATION WORKSDokument21 SeitenKP-00+++-MQ758-V0008-Rev 1-METHOD OF STATEMENT FOR HV SUBSTATION BUSBAR INSTALLATION WORKSUtku Can KılıçNoch keine Bewertungen

- Khabat Power Plant Test ReportDokument11 SeitenKhabat Power Plant Test ReportUtku Can Kılıç100% (2)

- Method Statement of ExcavationDokument9 SeitenMethod Statement of ExcavationAmit kumar thakurNoch keine Bewertungen

- Check List of Lightning Protection ErectionDokument1 SeiteCheck List of Lightning Protection ErectionUtku Can KılıçNoch keine Bewertungen

- Installation of Fire Alarm System Method StatementDokument9 SeitenInstallation of Fire Alarm System Method StatementiamajumalNoch keine Bewertungen

- Method Statement of Installation of SS Puddle FlangesDokument7 SeitenMethod Statement of Installation of SS Puddle Flangessarmad spectrumNoch keine Bewertungen

- Method Statement for Excavation WorksDokument12 SeitenMethod Statement for Excavation WorksBasem DoniaNoch keine Bewertungen

- NS1 Work Plan Procedure For Circulating Water Piping Installation Rev.2 Part 1 of 5Dokument46 SeitenNS1 Work Plan Procedure For Circulating Water Piping Installation Rev.2 Part 1 of 5namdq-10% (1)

- Conduit BKM 7102Dokument9 SeitenConduit BKM 7102Utku Can Kılıç100% (1)

- Electrical Works Grounding ITPDokument3 SeitenElectrical Works Grounding ITPUtku Can KılıçNoch keine Bewertungen

- Khabat TPP Electrical Panels InstallationDokument6 SeitenKhabat TPP Electrical Panels InstallationUtku Can KılıçNoch keine Bewertungen

- For Information For Review For Approval For Construction As-BuiltDokument21 SeitenFor Information For Review For Approval For Construction As-BuiltUtku Can KılıçNoch keine Bewertungen

- INSPECTION & TEST PLAN FOR CLEANING/FLUSHING CHEMICAL DOSING SYSTEMDokument1 SeiteINSPECTION & TEST PLAN FOR CLEANING/FLUSHING CHEMICAL DOSING SYSTEMDong Vanra100% (1)

- For Information For Review For Approval For Construction As-BuiltDokument20 SeitenFor Information For Review For Approval For Construction As-BuiltUtku Can KılıçNoch keine Bewertungen

- Demolition & Debris Removal Plan for Qayyarah Power PlantDokument17 SeitenDemolition & Debris Removal Plan for Qayyarah Power Plantsamer8saifNoch keine Bewertungen

- Method Statement for Water ChlorinationDokument7 SeitenMethod Statement for Water Chlorinationarshad iqbal100% (1)

- ITP Plan - FF PDFDokument7 SeitenITP Plan - FF PDFAltaf KhanNoch keine Bewertungen

- Irrigation ChecklistDokument12 SeitenIrrigation ChecklistZeeshan Hasan100% (1)

- 3.1method Statment For Installation of Fire Protection System FinalDokument31 Seiten3.1method Statment For Installation of Fire Protection System Finalمقاول تكييف كهرباء وصحيNoch keine Bewertungen

- ITP-FW For Civil & Building WorksDokument17 SeitenITP-FW For Civil & Building WorksRizki KresnaNoch keine Bewertungen

- Installation Method StatementDokument6 SeitenInstallation Method StatementgururajNoch keine Bewertungen

- Procedure Installation of Grounding & Lightning System - LABUAN BAJO PDFDokument9 SeitenProcedure Installation of Grounding & Lightning System - LABUAN BAJO PDFWika Djoko ONoch keine Bewertungen

- 7104 - PW - TRC001-D Inspection & Test PlanDokument6 Seiten7104 - PW - TRC001-D Inspection & Test PlanPaul KwongNoch keine Bewertungen

- Inspection and Test Plan for Mars CS PackageDokument17 SeitenInspection and Test Plan for Mars CS PackageMariah PearsonNoch keine Bewertungen

- Hip Plan - Hvac WorkDokument30 SeitenHip Plan - Hvac WorksrisetNoch keine Bewertungen

- PPR Method StatementDokument53 SeitenPPR Method StatementDiaa Gobran100% (1)

- Fire Hose Rack & Reel Testing ProcedureDokument2 SeitenFire Hose Rack & Reel Testing ProcedureDong VanraNoch keine Bewertungen

- Systems Punch List 90709Dokument57 SeitenSystems Punch List 90709calwatchNoch keine Bewertungen

- LVFR Sprinkler System RequirementsDokument4 SeitenLVFR Sprinkler System RequirementsridwanNoch keine Bewertungen

- Anand Engineering Products Private Limited: Before Welding Inspection Check ListDokument1 SeiteAnand Engineering Products Private Limited: Before Welding Inspection Check ListAnilkumarGopinathanNairNoch keine Bewertungen

- SWMS 1 Loading, Unloading & ShiftingDokument8 SeitenSWMS 1 Loading, Unloading & ShiftingJ.j.JijoNoch keine Bewertungen

- PLTU KALTIM TELUK BALIKPAPAN 2X100 MW PROJECT HSE PLANDokument16 SeitenPLTU KALTIM TELUK BALIKPAPAN 2X100 MW PROJECT HSE PLANmorgojoyoNoch keine Bewertungen

- 26076-110-GPP-GCX-00094 Work Method Statement For Loading Unloading GeneratorDokument10 Seiten26076-110-GPP-GCX-00094 Work Method Statement For Loading Unloading Generatorbangun0% (1)

- BRT-Peshawer-Package-I-Reach-I - METHOD STATEMENTDokument66 SeitenBRT-Peshawer-Package-I-Reach-I - METHOD STATEMENTRizwanNoch keine Bewertungen

- RT Mod MS 001Dokument10 SeitenRT Mod MS 001Kelly BatesNoch keine Bewertungen

- Annex II - A - Design ReportDokument281 SeitenAnnex II - A - Design ReportAlejandro MartinezNoch keine Bewertungen

- FRN MST PPL Pl1 011 p4 C c1Dokument18 SeitenFRN MST PPL Pl1 011 p4 C c1Utku Can Kılıç100% (1)

- Khabat Power Plant Auto Transformer Test ReportDokument3 SeitenKhabat Power Plant Auto Transformer Test ReportUtku Can Kılıç100% (1)

- IQ347 300 EL CHL 00036 Lightning ProtectionDokument1 SeiteIQ347 300 EL CHL 00036 Lightning ProtectionUtku Can KılıçNoch keine Bewertungen

- Post Insulator Installation ChecklistDokument1 SeitePost Insulator Installation ChecklistUtku Can KılıçNoch keine Bewertungen

- KP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Dokument2 SeitenKP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Utku Can KılıçNoch keine Bewertungen

- PP13 15 Ac Enl Gam 002Dokument31 SeitenPP13 15 Ac Enl Gam 002Utku Can KılıçNoch keine Bewertungen

- KP-00+++-CQ712-B7907 - Rev.B - ITP For MV Switchgear Installation Cover PageDokument1 SeiteKP-00+++-CQ712-B7907 - Rev.B - ITP For MV Switchgear Installation Cover PageUtku Can KılıçNoch keine Bewertungen

- KP-00+++-CQ712-B7368-Rev 0-ITP Lightning Protection PDFDokument3 SeitenKP-00+++-CQ712-B7368-Rev 0-ITP Lightning Protection PDFUtku Can KılıçNoch keine Bewertungen

- KP-00+++-CQ712-B7907 - F01 - Rev.B - MV Switchgear Installation Inspection Checklist1Dokument2 SeitenKP-00+++-CQ712-B7907 - F01 - Rev.B - MV Switchgear Installation Inspection Checklist1Utku Can KılıçNoch keine Bewertungen

- Manage WHS Operations - Assessment 2 - v8.2Dokument5 SeitenManage WHS Operations - Assessment 2 - v8.2Daniela SanchezNoch keine Bewertungen

- Reorganizing Barangay Council for Child ProtectionDokument3 SeitenReorganizing Barangay Council for Child ProtectionCasim Bailan JrNoch keine Bewertungen

- 9 Facebook BmiDokument29 Seiten9 Facebook BmiDin Flores MacawiliNoch keine Bewertungen

- PE 11 Cardio Endurance Workout ReflectionsDokument2 SeitenPE 11 Cardio Endurance Workout ReflectionsFranky MendozaNoch keine Bewertungen

- Work Authorization Permit.Dokument1 SeiteWork Authorization Permit.Gabriel TanNoch keine Bewertungen

- CH 09Dokument16 SeitenCH 09KittiesNoch keine Bewertungen

- Sir 2014 SouthamericaDokument33 SeitenSir 2014 SouthamericahusseinNoch keine Bewertungen

- Endocervical PolypDokument2 SeitenEndocervical PolypRez007Noch keine Bewertungen

- Low Back Pain Dr. Hardhi PRanataDokument57 SeitenLow Back Pain Dr. Hardhi PRanataPerwita ArumingtyasNoch keine Bewertungen

- PM - IntelliVue MP2 Patient MonitorDokument30 SeitenPM - IntelliVue MP2 Patient MonitorpilarNoch keine Bewertungen

- Mixed Connective Tissue DZ (SLE + Scleroderma)Dokument7 SeitenMixed Connective Tissue DZ (SLE + Scleroderma)AshbirZammeriNoch keine Bewertungen

- Ekstrak Kulit Buah Naga Super Merah Sebagai Anti-Kanker PayudaraDokument5 SeitenEkstrak Kulit Buah Naga Super Merah Sebagai Anti-Kanker PayudaraWildatul Latifah IINoch keine Bewertungen

- Assessmen Ttool - Student AssessmentDokument5 SeitenAssessmen Ttool - Student AssessmentsachiNoch keine Bewertungen

- Nutrition Care Plan - DysphagiaDokument1 SeiteNutrition Care Plan - DysphagiaElaine ArsagaNoch keine Bewertungen

- Allergen ControlDokument20 SeitenAllergen Controlmedtaher missaoui100% (1)

- Progress Test 04Dokument6 SeitenProgress Test 04Lemmy the GamerNoch keine Bewertungen

- Secrets of AntimonyDokument9 SeitenSecrets of AntimonyNCSASTRONoch keine Bewertungen

- AFP Hemoptysis - 2022Dokument9 SeitenAFP Hemoptysis - 2022Joshua DiaoNoch keine Bewertungen

- Drug in PregnancyDokument5 SeitenDrug in PregnancyjokosudibyoNoch keine Bewertungen

- Specialist Declaration of Psychiatrist Alex Kørner On Stig DragholmDokument9 SeitenSpecialist Declaration of Psychiatrist Alex Kørner On Stig DragholmStig DragholmNoch keine Bewertungen

- Diabetes and Hearing Loss (Pamela Parker MD)Dokument2 SeitenDiabetes and Hearing Loss (Pamela Parker MD)Sartika Rizky HapsariNoch keine Bewertungen

- MSDS Material Safety Data Sheet Decon 90 CleanerDokument4 SeitenMSDS Material Safety Data Sheet Decon 90 CleanerNorman LeungNoch keine Bewertungen

- 2022-03-15 Board of Supervisors - Full Agenda-2940Dokument546 Seiten2022-03-15 Board of Supervisors - Full Agenda-2940ShannanAdamsNoch keine Bewertungen

- Ulrich Merzenich2007Dokument13 SeitenUlrich Merzenich2007oka samiranaNoch keine Bewertungen

- Anand - 1994 - Fluorouracil CardiotoxicityDokument5 SeitenAnand - 1994 - Fluorouracil Cardiotoxicityaly alyNoch keine Bewertungen

- Jakarta Cardiovascular Care Unit Network System OverviewDokument52 SeitenJakarta Cardiovascular Care Unit Network System OverviewekaNoch keine Bewertungen