Beruflich Dokumente

Kultur Dokumente

F 670 - 87 R94 - Rjy3mc1sruq - PDF

Hochgeladen von

RománBarciaVazquezOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

F 670 - 87 R94 - Rjy3mc1sruq - PDF

Hochgeladen von

RománBarciaVazquezCopyright:

Verfügbare Formate

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what

changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F 670 87 (Reapproved 1994)e1 670 02

An American National Standard

Standard Specification for

Tanks, 5 and 10-Gal (20 and 40-L) Lube Oil Dispensing1

This standard is issued under the fixed designation F 670; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e1 NOTESection 9 was added editorially in December 1994.

1. Scope

1.1 This specification covers the material, dimensions, and construction of 5 and 10-gal (20 and 40-L) tanks purchased to store

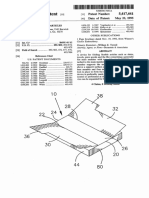

and dispense lubricating oils. The tanks are industrial safety cans mounted on a T-bar bracket, complete with drip tray. Fig. 1. They

1

This specification is under the jurisdiction of ASTM Committee F-25 on Shipbuilding Ships and Marine Technology and is the direct responsibility of Subcommittee

F25.03 on Outfitting.

Current edition approved March 27, 1987. Dec. 10, 2002. Published August 1987. January 2003. Originally published as F 670 80. approved in 1980. Last previous

edition approved F 670 807 (19894)e1.

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 670 87 (1994)e1 670 02

meet or exceed current marine safety regulations.2

1.2 This equipment design has been shock tested in accordance with MIL-S-901 as follows:

1.2.1 Grade B,

1.2.2 Light weight,

1.2.3 Mounting fixture (4A),

1.2.4 Class I, and

1.2.5 Test Report No. (Letter N-2027/9936 SER 200-4622, dated Sept. 24, 19853).

1.3 The .

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

F 670 87 (1994)e1 670 02

Dimensions

Size

5-gal

10-gal

A

Height, in.

B

Bolt Hole Spacing, in.

C

Tank Height, in.

D

Number of Bolt Holes

22

3334

10

1012

9

2078

3

4

12

12

78

Note 1Dimensions and construction for guidance only.

Note 21 in. = 25.4 mm.

Note 31 lb = 0.4536 Kg.

FIG. 1 Dimension of Tank

Weight, lb

Dry

Wet (Water)

39

49

81

132

F 670 87 (1994)e1 670 02

A 36/A36M Specification for Carbon Structural Steel2

A 108 Specification for Steel Bars, Carbon, Cold Finished, Standard Quality3

A 164 Specification for Electrodeposited Coatings of Zinc on Steel4

A 167 Specification for Stainless and Heat-Resisting Chromium-Nickel Steel Plate, Sheet, and Strip5

A 308 Specification for Steel Sheet, Cold-Rolled, Long Terne (Lead-Tin Alloy) Coated by the Hot-Dip Process6

A 569/A569M Specification for Steel, Carbon (0.15 Maximum, Percent), Hot-Rolled Sheet and Strip Commercial Quality

2.2 Military Standard:

MIL-S-901 Requirements for Shock Test, High-Impact; Shipboard Machinery, Equipment and Systems78

3. Ordering Information

3.1 Orders for tanks under this specification shall include the following:

3.1.1 Quantity (number),

3.1.2 Size, either 5 or 10 gal (20 or 40 L),

3.1.3 Purchase option for finished tank materials: Terne plate (4.1.23), and

3.1.4 ASTM designation and year of issue.

3.2 If only size, quantity, and ASTM designation are specified and no purchase options are specified, then suppliers shall furnish

all stainless steel tanks, brass faucets with flame flash arrestors, and painted steel mounting columns with bolt-on drip tray

assemblies, which include perforated steel tray liners, drain plugs, drilled mounting holes, and mounting bolts.

3.3 Optional packaging/shipping.

3.3.1 If required for shipping, tanks shall be packaged individually in cartons suitable for freight handling.

4. Materials and Manufacture

4.1 Materials:

4.1.1 316 Stainless Steel Sheet (Specification A 167), minimum thickness 24 gage (0.6 mm) on tank body, 22 gage (0.8 mm)

on tank top and bottom; body bracket, filler spout, flash arrestor, vacuum breaker valve and linkage.

4.1.2 316 Stainless Steel [mathit]Cast, Cast, Wrought, or Forged Flanges, (for faucet and drain).

4.1.3 Terne Plate Sheet (purchase option), minimum thickness 22 gage (0.8 mm) on tank body, top and bottom: body bracket,

filler spout (Specification A 308).

4.1.4 Mild Steel:

4.1.4.1 Bolt-On Column Stand, T-section, hot-rolled (Specification A 36/A 36M); minimum thickness 0.160 in. (4 mm).

4.1.4.2 Drip Tray Bracket, round edge, hot-rolled (Specification A 569/A569M).

4.1.4.3 Drip Tray Assembly, hot or cold-rolled (Specification A 108).

4.1.4.4 Drip Tray Liner, 11-gage (3 mm), zinc-plated (Specification A 164).

4.1.4.5 Filler Spout Cover, zinc-plated steel (Specification A 164).

4.1.4.6 Drip Tray Drain, 34-in. (20 mm) NPS drain.

4.1.5 Cast Brass:

4.1.5.1 Faucet, lever-lock, self-closing, 34-in. (20 mm) outside diameter, male threaded.9

4.1.5.2 Drip Tray Drain Plug and Tank Bottom Drain Plug, 34-in. (20 mm) NPS.

4.1.6 Cast Aluminum, self-closing, spring-action type, one-piece, filler spout cover lever.

4.2 ManufactureAll sheet metal seams shall be welded.

5. Dimensions and Weight

5.1 The dimensions in Fig. 1 are recommended nominal dimensions. Weights are estimated and are not critical. Volume of tanks

shall be 5 and 10 gal (20 and 40 L), respectively.

6. Workmanship, Finish, and Appearance

6.1 Workmanship on tank, stand, and drip pan shall be of sufficient quality to prevent dirt accumulation. Welding shall have

small, even beading, free of slag and spatter. Surface of all castings shall be of uniform texture, without cracks, pitting, or flashing.

2

Regulations Governing Use

Annual Book of Dangerous Articles as Ships Stores and Supplies on Board Vessels, available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. ASTM Standards, Vol 01.04.

3

Available from Supervisor

3

Annual Book of Shipbuilding, New Orleans, LA. ASTM Standards, Vol 01.05.

4

Discontinued 1981Replaced by B 633, Annual Book of ASTM Standards, Vol 01.04. 02.05.

5

Annual Book of ASTM Standards, Vol 01.053.

6

DiscontinuedReplaced by B 633,

6

Annual Book of ASTM Standards, Vol 02.05. 01.06.

8

Discontinued 2000Replaced by A 1011/A 1011M, Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 01.06.

9

Protectoseal 531G, available from The Protectoseal Co., 225 Foster Ave., Bensenville, IL 60106, or equivalent, has been found suitable for this purpose.

2

F 670 87 (1994)e1 670 02

Stand and drip tray shall have corners broken and all burrs removed.

6.2 Tank, column, bracket, and tray shall be covered with one coat 1.5 mils (0.05 mm) thick of a zinc rich primer. The stainless

steel tank shall have no paint.

7. Testing Methods

7.1 Test each tank and subject by subjecting to an internal air pressure of 5 psi (35 kPa) with no visible seam leakage when

subjected to underwater or soap bubble test.

8. Packaging

8.1 If required for shipping, tanks shall be packaged individually in cartons suitable for freight handling.

9. Keywords

98.1 lubricating oil tanks; marine; marine storage tanks; marine technology; oil dispensers; ships; tanks

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- F 1068 - 90 R98 - Rjewnjgtotbsothfmq - PDFDokument4 SeitenF 1068 - 90 R98 - Rjewnjgtotbsothfmq - PDFRománBarciaVazquezNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- F 1030 - 86 R98 - Rjewmza - PDFDokument3 SeitenF 1030 - 86 R98 - Rjewmza - PDFRománBarciaVazquezNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- F 1069 - 87 R99 - Rjewnjk - PDFDokument6 SeitenF 1069 - 87 R99 - Rjewnjk - PDFRománBarciaVazquezNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- F 1070 - 87 R99 - Rjewnza - PDFDokument4 SeitenF 1070 - 87 R99 - Rjewnza - PDFRománBarciaVazquezNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- F 1019M - 95 - Rjewmtlnlvjfra - PDFDokument11 SeitenF 1019M - 95 - Rjewmtlnlvjfra - PDFRománBarciaVazquezNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- F 1019M - 95 - Rjewmtlnltk1qq - PDFDokument7 SeitenF 1019M - 95 - Rjewmtlnltk1qq - PDFRománBarciaVazquezNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- F 1019M - 00 - Rjewmtln PDFDokument7 SeitenF 1019M - 00 - Rjewmtln PDFRománBarciaVazquezNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- F 987 - 04 - RJK4NW - PDFDokument4 SeitenF 987 - 04 - RJK4NW - PDFRománBarciaVazquez0% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- F 1068 - 90 R03 - Rjewnjg - PDFDokument4 SeitenF 1068 - 90 R03 - Rjewnjg - PDFRománBarciaVazquezNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- F 1007 - 86 R02 - Rjewmdc - PDFDokument4 SeitenF 1007 - 86 R02 - Rjewmdc - PDFRománBarciaVazquezNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- F 1018 - 87a R99 - RJEWMTG - PDFDokument12 SeitenF 1018 - 87a R99 - RJEWMTG - PDFRománBarciaVazquezNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- F 1006 - 86 R04 - Rjewmdy - PDFDokument3 SeitenF 1006 - 86 R04 - Rjewmdy - PDFRománBarciaVazquezNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Flashlights On Vessels: Standard Specification ForDokument4 SeitenFlashlights On Vessels: Standard Specification ForRománBarciaVazquezNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Searchlights On Motor Lifeboats: Standard Specification ForDokument3 SeitenSearchlights On Motor Lifeboats: Standard Specification ForRománBarciaVazquezNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- F 1006 - 86 R97 - Rjewmdytodzsotc - PDFDokument3 SeitenF 1006 - 86 R97 - Rjewmdytodzsotc - PDFRománBarciaVazquezNoch keine Bewertungen

- F 993 - 86 R01 - RJK5MW - PDFDokument6 SeitenF 993 - 86 R01 - RJK5MW - PDFRománBarciaVazquezNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- F 1005 - 91 R02 - Rjewmdu - PDFDokument20 SeitenF 1005 - 91 R02 - Rjewmdu - PDFRománBarciaVazquez100% (1)

- F 986 - 86 R97 - Rjk4ni04nli5nw - PDFDokument5 SeitenF 986 - 86 R97 - Rjk4ni04nli5nw - PDFRománBarciaVazquezNoch keine Bewertungen

- F 906 - 85 R98 - Rjkwni04nvi5oa - PDFDokument5 SeitenF 906 - 85 R98 - Rjkwni04nvi5oa - PDFRománBarciaVazquezNoch keine Bewertungen

- F 987 - 93 - Rjk4ny05mw - PDFDokument4 SeitenF 987 - 93 - Rjk4ny05mw - PDFRománBarciaVazquezNoch keine Bewertungen

- F 906 - 85 R03 - RJKWNG - PDFDokument5 SeitenF 906 - 85 R03 - RJKWNG - PDFRománBarciaVazquezNoch keine Bewertungen

- F 856 - 97 R04 - RJG1NG - PDFDokument7 SeitenF 856 - 97 R04 - RJG1NG - PDFRománBarciaVazquezNoch keine Bewertungen

- F 957 - 91 R01 - RJK1NW - PDFDokument5 SeitenF 957 - 91 R01 - RJK1NW - PDFRománBarciaVazquezNoch keine Bewertungen

- F 986 - 86 R04 - RJK4NG - PDFDokument5 SeitenF 986 - 86 R04 - RJK4NG - PDFRománBarciaVazquezNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- F 987 - 93 - Rjk4ny1sruq - PDFDokument6 SeitenF 987 - 93 - Rjk4ny1sruq - PDFRománBarciaVazquezNoch keine Bewertungen

- F 941 - 99 - RJK0MQ - PDFDokument3 SeitenF 941 - 99 - RJK0MQ - PDFRománBarciaVazquezNoch keine Bewertungen

- F 940 - 99 - Rjk0ma - PDFDokument4 SeitenF 940 - 99 - Rjk0ma - PDFRománBarciaVazquezNoch keine Bewertungen

- F 956 - 91 R96 - Rjk1ni05mvi5ng - PDFDokument5 SeitenF 956 - 91 R96 - Rjk1ni05mvi5ng - PDFRománBarciaVazquezNoch keine Bewertungen

- F 957 - 91 R96 - Rjk1ny05mvi5ng - PDFDokument5 SeitenF 957 - 91 R96 - Rjk1ny05mvi5ng - PDFRománBarciaVazquezNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- F 856 - 97 - Rjg1ni05nw - PDFDokument7 SeitenF 856 - 97 - Rjg1ni05nw - PDFRománBarciaVazquezNoch keine Bewertungen

- GBL20D×57 型刮板捞渣机: Installation and Operation InstructionDokument19 SeitenGBL20D×57 型刮板捞渣机: Installation and Operation Instructiondawn moonNoch keine Bewertungen

- US5417641Dokument13 SeitenUS5417641Trung Hieu NguyenNoch keine Bewertungen

- Oilfield ProductsDokument12 SeitenOilfield ProductsHAMSKULLNoch keine Bewertungen

- ASB-912-060UL - ASB-914-043UL - Checking of The Oil Pump Fixing Bolts For Correct Torque For ROTAX Engine Type 912 and 914 (Series)Dokument10 SeitenASB-912-060UL - ASB-914-043UL - Checking of The Oil Pump Fixing Bolts For Correct Torque For ROTAX Engine Type 912 and 914 (Series)Dennis HNoch keine Bewertungen

- M60es54 P549yb Man 001Dokument21 SeitenM60es54 P549yb Man 001Riski KurniawanNoch keine Bewertungen

- Navy M BronzeDokument1 SeiteNavy M BronzeDeepak KumarNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Instalacion y Mantenimiento FT FTI OKDokument4 SeitenInstalacion y Mantenimiento FT FTI OKAura RamirezNoch keine Bewertungen

- ST25 Parts CatalogDokument38 SeitenST25 Parts Catalogdesechable100% (1)

- Torque Hub 147023Dokument144 SeitenTorque Hub 147023Hidraumak Nordeste HidraumakNoch keine Bewertungen

- 1LE1503-1DB23-4AC4 Datasheet enDokument1 Seite1LE1503-1DB23-4AC4 Datasheet enMo MosadNoch keine Bewertungen

- Technical Data Torque: High Performance Butterfly Valve HP 114 High Performance Butterfly Valve HP 114 Quality FeaturesDokument6 SeitenTechnical Data Torque: High Performance Butterfly Valve HP 114 High Performance Butterfly Valve HP 114 Quality FeaturesRosa PonceNoch keine Bewertungen

- 19d Impeller SpacingDokument9 Seiten19d Impeller Spacingbtgottlieb100% (1)

- 3 Day Vertical Blind Corded Prior To 07-09-14Dokument2 Seiten3 Day Vertical Blind Corded Prior To 07-09-14aloha138Noch keine Bewertungen

- Bolted ConnectionsDokument3 SeitenBolted ConnectionsandreiroscaNoch keine Bewertungen

- 03) PIPE193.7x8 V-BRACE - GUSSET PLT.Dokument114 Seiten03) PIPE193.7x8 V-BRACE - GUSSET PLT.Civil StructureNoch keine Bewertungen

- Irb 340Dokument25 SeitenIrb 340testeNoch keine Bewertungen

- BS MA 47-1977 Ships' Cargo BlocksDokument19 SeitenBS MA 47-1977 Ships' Cargo Blocksvagabond_ldNoch keine Bewertungen

- LA6 Series - Web Manual (En)Dokument42 SeitenLA6 Series - Web Manual (En)anandbhanushali1541991Noch keine Bewertungen

- Chapter 3Dokument25 SeitenChapter 3Fadhiran YahyaNoch keine Bewertungen

- Thomson BSA Lead Screws CatalogDokument16 SeitenThomson BSA Lead Screws CatalogElectromateNoch keine Bewertungen

- Kumho Gas Meter Catalogue PDFDokument8 SeitenKumho Gas Meter Catalogue PDFAlejandro CocaNoch keine Bewertungen

- A Single Cylinder Vertical Steam EngineDokument3 SeitenA Single Cylinder Vertical Steam EngineAxel DominiqueNoch keine Bewertungen

- 350 SX-F Cairoli Replica 2012: Spare Parts Manual: ChassisDokument36 Seiten350 SX-F Cairoli Replica 2012: Spare Parts Manual: ChassischarlesNoch keine Bewertungen

- Mbe35 - 50 Operation Manual CompletoDokument58 SeitenMbe35 - 50 Operation Manual CompletoFlavio MeloNoch keine Bewertungen

- 1" Rotary Hammer V.S. Sds-Plus Model Hr2450Dokument5 Seiten1" Rotary Hammer V.S. Sds-Plus Model Hr2450Jos1Noch keine Bewertungen

- FBB150 Installation Manual 2014Dokument88 SeitenFBB150 Installation Manual 2014Yanko150Noch keine Bewertungen

- Test Report Astm F1427Dokument28 SeitenTest Report Astm F1427Pham UtNoch keine Bewertungen

- Welcome To JB SteelDokument5 SeitenWelcome To JB SteelMohit BansalNoch keine Bewertungen

- Catalogues$Ci Tata Superace 1ton RHD b3Dokument200 SeitenCatalogues$Ci Tata Superace 1ton RHD b3Diane Owen100% (5)

- Manual Desarmado y Armado - Bomba Cat 3406Dokument39 SeitenManual Desarmado y Armado - Bomba Cat 3406Gallego Carlos100% (1)

- Real Life: Construction Management Guide from A-ZVon EverandReal Life: Construction Management Guide from A-ZBewertung: 4.5 von 5 Sternen4.5/5 (4)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- A Place of My Own: The Architecture of DaydreamsVon EverandA Place of My Own: The Architecture of DaydreamsBewertung: 4 von 5 Sternen4/5 (242)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Von EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Noch keine Bewertungen

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesVon EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNoch keine Bewertungen

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsVon EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNoch keine Bewertungen

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationVon EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettBewertung: 4 von 5 Sternen4/5 (1)