Beruflich Dokumente

Kultur Dokumente

Estacion de Rebombeo Ptar-Opcion

Hochgeladen von

Raul CabanillasOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Estacion de Rebombeo Ptar-Opcion

Hochgeladen von

Raul CabanillasCopyright:

Verfügbare Formate

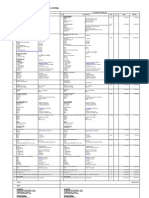

3756 M&L Bronze Fitted

End Suction Cast Iron Pumps

MODEL : 19BFFRMR0(1)

Submittal Data

Hydraulic Data

Maximum Flow

Motor Data

3656/3756 M L Group

Flow at Duty Point Maximum TDH TDH at Duty Point NPSHR Voltage / Phase / Enclosure

Model

9m

19BFFRMR0(1)

129 l/s

84 l/s

Submittal Prepared for:

Engineer:

Submittal Prepared by:

Submittal Date: 24.03.2014

11 m

3m

Job:

Contractor:

Company:

Approved by:

Qty.

Date:

Engineering Data

Standard Equipment / Capability:

Pump Code: 19BFFRMR0(1)

Pump Size: 8 x 10 - 13 L FRM

Pump Max Horsepow er: 15,828 hp

Pump Horsepow er at Rating Point: 15,60 hp

Pump Shut Off Head: 36 ft

Motor Speed:

Max. Temperature: 100 C

Liquid: Water, pure

Motor Code:

System Input Pow er:

Motor Rated Horsepow er:

Max. Frequency:

Electrical Enclosures:

Motor Standard:

Suction Flange Standard:ANSI

Suction Flange Rating: Class 125

Suction Size: 10"

Discharge Flange Standard:ANSI

Discharge Flange Rating: Class 125

Discharge:8"

Approximate Net Weight: Consultar kg

Impeller Size: 249,24 mm

Impeller Construction: Cerrado

Impeller Type: Rodete radial

Impeller Material:

ASTM B584, Modified C87500-Lead Free

Sense of Rotation: en el sentido del reloj

Shaft Seal: Carbon/Ceramic/BUNA

The 3656 and 3756 M & L-Group pumps from Goulds have been

designed with technical benefits to meet the needs of users in a variety

of water supply, recirculation, and cooling applications.

The model 3656 offers close coupled design for space saving and simplified maintenance.

The model 3756 offers a bearing frame mounted design for

flexibility of installation and drive arrangements.

SAE drive sizes 1 through 5 available on all pumps.

Back pull-out to reduce maintenance down time.

Standard Type 21 mechanical seal for both reliability and availability.

Carbon/ceramic/ BUNA standard, with other faces and elastomers available.

Available in packed stuffing box design with TeflonTM impregnated

packing, split Teflon lantern ring, tapped flush

connection and 2 piece investment cast interlocking gland, all standard.

Available in all iron or bronze fitted construction for application versatility.

Replaceable wearing components include stainless steel shaft

sleeve and casing and hub wear rings to maintain peak efficiency.

Enclosed impeller design, dynamic balancing and

renewable wear rings reduce losses affecting performance and pump life.

125 Class ANSI flange suction/ discharge connections and casing

rotation for piping connection versatility.

NPT threaded connections are supplied on 1 1/2 x 2 10 and 2 1/2 x 3 8 models.

Optional rigid carbon steel bedplate, sheet metal coupling

guard and T. B. Woods spacer coupling for 3756 models.

Standard NEMA motor frame, JM shaft extension (mechanical seal)

JP shaft extension (packed box), C face mounting, single phase or

three phase, 3500 or 1750 RPM for 60 Hz, 2900 or 1450 RPM for 50 Hz.

Open drip-proof and totally enclosed fan cooled.

Optional explosion proof and high efficiency motors are available.

Printed f rom data f ile

24.03.2014

3756 M&L Bronze Fitted

End Suction Cast Iron Pumps

MODEL : 19BFFRMR0(1)

Performance Data

Hydraulic Data

Maximum Flow

Motor Data

3656/3756 M L Group

Flow at Duty Point Maximum TDH TDH at Duty Point NPSHR Voltage / Phase / Enclosure

Model

9m

19BFFRMR0(1)

129 l/s

84 l/s

11 m

Submittal Prepared for:

Engineer:

Submittal Prepared by:

Submittal Date: 24.03.2014

3m

Job:

Contractor:

Company:

Approved by:

Fluid: Water, pure

[m] Altura de impulsin

25

24

330,2

23

22

21

20

19

18

17

16

15

14

13

12

249,2

11

10

9

8

7

6

5

4

3

2

1

0

[%] Eficiencia

80

70

60

50

40

30

20

10

Qty.

Date:

Duty Chart: 1180 RPM

Area de aplicacin

60%

70%

80%

85%

Rendimiento

86%

9,49 m

72,5%

330,2

249,2

[hp] Potencia en el eje motor P2

40

69,3 %

330,2 (P2)

35

30

25

20

249,2 (P2)

15

10

15,6 hp

86,25 l/s

0

10

20

Printed f rom data f ile

24.03.2014

30

40

50

60

70

80

90

100 110 120 130 140 150 160 170 180 190 200

[l/s]

Unit Dimensions

3756 M&L Bronze Fitted

End Suction Cast Iron Pumps

MODEL : 19BFFRMR0(1)

Hydraulic Data

Maximum Flow

129 l/s

Motor Data

3656/3756 M L Group

Flow at Duty Point Maximum TDH TDH at Duty Point NPSHR Voltage / Phase / Enclosure

84 l/s

11 m

Submittal Prepared for:

Engineer:

Submittal Prepared by:

Submittal Date: 24.03.2014

9m

3m

Model

19BFFRMR0(1)

Job:

Contractor:

Company:

Approved by:

Date:

Dimension

Value

Dimension

Value

CP m ax

DC max

DD

Discharge

Flange

J

K

M

N

R

Suction

673,1

374,65

330,2

8" ANSI

ANSI class 150

60,325

190,5

165,1

139,7

171,45

10" ANSI

W

X

Y

Z

219,08

323,85

101,6

254

Printed f rom data f ile

24.03.2014

Qty.

Das könnte Ihnen auch gefallen

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Bombas Goulds 4NS Aguas ResidualesDokument6 SeitenBombas Goulds 4NS Aguas ResidualescamatuteNoch keine Bewertungen

- 9bf1l5c0 Bomba Goulds 3656s Bronze FittedDokument3 Seiten9bf1l5c0 Bomba Goulds 3656s Bronze FittedElmer RafaelNoch keine Bewertungen

- Submittal Data: End Suction Stainless Steel PumpsDokument3 SeitenSubmittal Data: End Suction Stainless Steel PumpsGustavo Farelo SuarezNoch keine Bewertungen

- Submittal Data: End SuctionDokument3 SeitenSubmittal Data: End Suctionrodriguez.gaytanNoch keine Bewertungen

- W13018-YT01-GDF-457110 Rev 5-APVDokument8 SeitenW13018-YT01-GDF-457110 Rev 5-APVJosé santanaNoch keine Bewertungen

- GA DrawingDokument4 SeitenGA DrawingGalih PrianggodoNoch keine Bewertungen

- BQ STP RBC Carrefour Lebakbulus PT Dwimitra 17.11.11Dokument1 SeiteBQ STP RBC Carrefour Lebakbulus PT Dwimitra 17.11.11boim1234Noch keine Bewertungen

- Grundfosliterature 3081235Dokument156 SeitenGrundfosliterature 3081235Uhudhu AhmedNoch keine Bewertungen

- L Series TUthill PumpsDokument32 SeitenL Series TUthill PumpsFarazAduck100% (1)

- PLL 1374Dokument52 SeitenPLL 1374Vinod Yb100% (1)

- Datasheet BombaDokument4 SeitenDatasheet BombasaculNoch keine Bewertungen

- FHRDokument5 SeitenFHRJavier Melendez RomanNoch keine Bewertungen

- VPC (Flowserve)Dokument5 SeitenVPC (Flowserve)Wissam JarmakNoch keine Bewertungen

- Centrifugal PUMP SPECIFICATIONDokument6 SeitenCentrifugal PUMP SPECIFICATIONAlvin Smith100% (1)

- Further Product Details: Position Qty. Description CRE 64-2-2 A-F-A-E-HQQEDokument10 SeitenFurther Product Details: Position Qty. Description CRE 64-2-2 A-F-A-E-HQQEitsirc67Noch keine Bewertungen

- Grundfos LiteratureDokument36 SeitenGrundfos Literaturebenjiy80Noch keine Bewertungen

- Amacan PDokument52 SeitenAmacan PGogyNoch keine Bewertungen

- BAGFLODokument68 SeitenBAGFLOAlicia ViridianaNoch keine Bewertungen

- EngineerDokument11 SeitenEngineerphaindikaNoch keine Bewertungen

- Bombas Goulds 3656-3756 ML PDFDokument40 SeitenBombas Goulds 3656-3756 ML PDFCesar Sialer DiazNoch keine Bewertungen

- 6 Konitzer2Dokument32 Seiten6 Konitzer2mchramziNoch keine Bewertungen

- Comparision Sheet-Ccoling TowersDokument16 SeitenComparision Sheet-Ccoling TowersKenny RuizNoch keine Bewertungen

- Instalasi POMPADokument106 SeitenInstalasi POMPAMeliaGrinaNoch keine Bewertungen

- Aurora Pump 6-491-12aDokument28 SeitenAurora Pump 6-491-12ajuan yenqueNoch keine Bewertungen

- Slurry Pumps WH Agitator - Models - HSD, KTV, KRS, NKZ, GPN, Gsz-6Dokument5 SeitenSlurry Pumps WH Agitator - Models - HSD, KTV, KRS, NKZ, GPN, Gsz-6Guilherme CamposNoch keine Bewertungen

- EP04 & EP05 Series: Model 3871Dokument4 SeitenEP04 & EP05 Series: Model 3871JOSE INESNoch keine Bewertungen

- 2009 02 M HD 319 0Dokument5 Seiten2009 02 M HD 319 0ZoebairNoch keine Bewertungen

- WH2009 WaterHorseCatalogDokument132 SeitenWH2009 WaterHorseCatalogAiko FeroNoch keine Bewertungen

- Electric Motor - Iron Horse PDFDokument68 SeitenElectric Motor - Iron Horse PDFAriesFranandaPanjaitanNoch keine Bewertungen

- SUBMERSIBLE PUMP Selection: Data Required For SelectionDokument7 SeitenSUBMERSIBLE PUMP Selection: Data Required For SelectionmadyandiNoch keine Bewertungen

- Grundfos MTS Screw Spindle PumpDokument68 SeitenGrundfos MTS Screw Spindle PumpAnonymous lswzqlo100% (1)

- Rexroth PumpsDokument24 SeitenRexroth PumpsAmanda SmithNoch keine Bewertungen

- Bomba Hidraulica Sp25Dokument5 SeitenBomba Hidraulica Sp25Javier SumozaNoch keine Bewertungen

- WaterWolf Data Sheet PDFDokument2 SeitenWaterWolf Data Sheet PDFcarlosfariasfakeNoch keine Bewertungen

- Technical Specifications For Centrifugal Pumps PDFDokument12 SeitenTechnical Specifications For Centrifugal Pumps PDFVicky GautamNoch keine Bewertungen

- KSB Centrifugal PumpsDokument12 SeitenKSB Centrifugal Pumpswoodywheel100% (1)

- Catalogodp Pumps PDFDokument32 SeitenCatalogodp Pumps PDFmanuelarranoNoch keine Bewertungen

- Innomag BrochureDokument8 SeitenInnomag BrochureHENDRIK2011Noch keine Bewertungen

- Grundfos Submersible Pumps Data BookDokument100 SeitenGrundfos Submersible Pumps Data BookonspsnonsNoch keine Bewertungen

- Motor PDFDokument81 SeitenMotor PDFmaungNoch keine Bewertungen

- Hydraulic PressDokument5 SeitenHydraulic PressMuhammad Iqbal ZahidNoch keine Bewertungen

- Combined Ad218103 Bcaf 4790 8e97 Fcbac43bdc61Dokument4 SeitenCombined Ad218103 Bcaf 4790 8e97 Fcbac43bdc61Wissam JarmakNoch keine Bewertungen

- G2DT-21 2HP-230V-60HZ-1FDokument8 SeitenG2DT-21 2HP-230V-60HZ-1FDaniel AbantoNoch keine Bewertungen

- KP KPV Internet 74005Dokument60 SeitenKP KPV Internet 74005Udomsin WutigulpakdeeNoch keine Bewertungen

- Trane Split System 23-55 TonsDokument4 SeitenTrane Split System 23-55 Tonsyadi_baeNoch keine Bewertungen

- Pleuger Electrical Submersible Pumps and Water-Filled MotorsDokument12 SeitenPleuger Electrical Submersible Pumps and Water-Filled MotorsGabrielMachado100% (1)

- SUBMERSIBLE PUMP SelectionDokument6 SeitenSUBMERSIBLE PUMP SelectionSyed Muztuza AliNoch keine Bewertungen

- 4030 / 4280 Series: End Suction PumpsDokument8 Seiten4030 / 4280 Series: End Suction PumpsShrikant WalseNoch keine Bewertungen

- DLU TechDokument20 SeitenDLU Techqwerty_conanNoch keine Bewertungen

- 6-Doosan CigrePrep - 1222MVA GEN Development - FontRevID31VER89Dokument23 Seiten6-Doosan CigrePrep - 1222MVA GEN Development - FontRevID31VER89Yogananda Madhava SettyNoch keine Bewertungen

- Position Qty. Description SP 30-16: Further Product DetailsDokument9 SeitenPosition Qty. Description SP 30-16: Further Product DetailsJulio César Elías RiveraNoch keine Bewertungen

- Submersible Propeller Pump Type ABS VUPXDokument8 SeitenSubmersible Propeller Pump Type ABS VUPXAgus SalmanNoch keine Bewertungen

- Bom Grundfox Pump HSDokument80 SeitenBom Grundfox Pump HSHai DoNoch keine Bewertungen

- Bombas Centrífugas BlackmerDokument180 SeitenBombas Centrífugas BlackmerGustavo Restrepo100% (1)

- Non Clogging PumpsDokument15 SeitenNon Clogging PumpsSouvik SingharoyNoch keine Bewertungen

- CP Range: Redefining Flow ControlDokument8 SeitenCP Range: Redefining Flow ControlSmootherNoch keine Bewertungen

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Von EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Bewertung: 3.5 von 5 Sternen3.5/5 (3)

- All-in-One Manual of Industrial Piping Practice and MaintenanceVon EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceBewertung: 5 von 5 Sternen5/5 (1)

- FUP OSCE v9 L-1 PDFDokument8 SeitenFUP OSCE v9 L-1 PDFRamos Llanos VladimirNoch keine Bewertungen

- ASTM (Hammer Test)Dokument3 SeitenASTM (Hammer Test)Efri Dwiyanto100% (1)

- Tuberia Novafort PavcoWavin PeruDokument2 SeitenTuberia Novafort PavcoWavin PeruRaul CabanillasNoch keine Bewertungen

- ELE Soil Moisture Catalogue - EnGDokument4 SeitenELE Soil Moisture Catalogue - EnGCarlos CuyunNoch keine Bewertungen

- 9 - 1 - Beam - Deflection - 2 - Method de Superposition OkDokument10 Seiten9 - 1 - Beam - Deflection - 2 - Method de Superposition OkRaul CabanillasNoch keine Bewertungen

- 9 - 1 - Beam - Deflection - 2 - Method de Superposition OkDokument10 Seiten9 - 1 - Beam - Deflection - 2 - Method de Superposition OkRaul CabanillasNoch keine Bewertungen

- Astm A563Dokument4 SeitenAstm A563Raul CabanillasNoch keine Bewertungen

- Astm F436Dokument1 SeiteAstm F436Raul CabanillasNoch keine Bewertungen

- Portland Bolt A563 Nut Compatibility ChartDokument1 SeitePortland Bolt A563 Nut Compatibility ChartsdsessenNoch keine Bewertungen

- CentrifugalandAxialCompressorControlInstructorsGuide 1Dokument133 SeitenCentrifugalandAxialCompressorControlInstructorsGuide 1Abelio TavaresNoch keine Bewertungen

- Pompe KSB CPKN ManuelleDokument60 SeitenPompe KSB CPKN ManuelleAbeka KaderNoch keine Bewertungen

- Centrifugal Pump PDFDokument20 SeitenCentrifugal Pump PDFSumedh Singh100% (1)

- 4 X 5 and 5 X 6 Parts & Service Manual TUL-C-600 - A PDFDokument47 Seiten4 X 5 and 5 X 6 Parts & Service Manual TUL-C-600 - A PDFzachNoch keine Bewertungen

- Combichem: Centrifugal PumpsDokument8 SeitenCombichem: Centrifugal PumpsrizkyNoch keine Bewertungen

- Rikt71 Produkt e A4 Web Final PDFDokument6 SeitenRikt71 Produkt e A4 Web Final PDFJaswindersingh BhatiaNoch keine Bewertungen

- OPITODokument56 SeitenOPITOSultan SerikNoch keine Bewertungen

- Centifugal+Chiller+ (1000+ +10000+kW) MideaDokument35 SeitenCentifugal+Chiller+ (1000+ +10000+kW) MideaevrimkNoch keine Bewertungen

- QL Series: Vertical, Double-Suction Twin-Volute Turbine PumpsDokument8 SeitenQL Series: Vertical, Double-Suction Twin-Volute Turbine PumpsCarlos RiveraNoch keine Bewertungen

- Liquid Ring Compressor and Vac Pumps SIHIDokument11 SeitenLiquid Ring Compressor and Vac Pumps SIHImdtaheri100% (2)

- Pedrollo Close Coupled Centrifugal Pump - Semi Open Impeller - NGA PDFDokument5 SeitenPedrollo Close Coupled Centrifugal Pump - Semi Open Impeller - NGA PDFSartika Nur AisyahNoch keine Bewertungen

- KSB Borehole LiteratureDokument24 SeitenKSB Borehole LiteratureSudip LamsalNoch keine Bewertungen

- Standard: IPS-I-PM-305Dokument21 SeitenStandard: IPS-I-PM-305Arash AbbasiNoch keine Bewertungen

- RUH Umpen: Ruhrpumpen GMBHDokument40 SeitenRUH Umpen: Ruhrpumpen GMBHjacobo nasimbaNoch keine Bewertungen

- Chapter 8-Design of The Rotor of A TurbomachineDokument18 SeitenChapter 8-Design of The Rotor of A TurbomachineSiraj Mohammed100% (2)

- Blue Eco Marine 240/320/500 900/1500/2200: User ManualDokument14 SeitenBlue Eco Marine 240/320/500 900/1500/2200: User ManualBolohan AurelNoch keine Bewertungen

- Design Features: Goulds Model CWXDokument8 SeitenDesign Features: Goulds Model CWXIsrael ColinaNoch keine Bewertungen

- KREBS slurryMAX Pump BrochureDokument12 SeitenKREBS slurryMAX Pump Brochuredavidgaro12Noch keine Bewertungen

- Ebara - Cryogenic Pump and ExpandersDokument20 SeitenEbara - Cryogenic Pump and ExpandersXue Feng Du0% (1)

- Blower Design ImpDokument7 SeitenBlower Design Impinstrutech100% (2)

- Boiler Feed PumpDokument46 SeitenBoiler Feed Pumppratapsingh12100% (1)

- GSP160, GSP300 Sub-Prime® Electric Submersible Dewatering PumpsDokument2 SeitenGSP160, GSP300 Sub-Prime® Electric Submersible Dewatering PumpsAbcehmu EgiNoch keine Bewertungen

- Design and Optimization of Lily ImpellerDokument5 SeitenDesign and Optimization of Lily ImpellerVIVA-TECH IJRINoch keine Bewertungen

- LUTZ - Pump PP (2019)Dokument4 SeitenLUTZ - Pump PP (2019)Gissette Ivonne Cortés AlarcónNoch keine Bewertungen

- CBD-03 - 4ls@17,5m - TP50M38H-2-3Dokument4 SeitenCBD-03 - 4ls@17,5m - TP50M38H-2-3FMTNoch keine Bewertungen

- Module 5: Centrifugal PumpsDokument24 SeitenModule 5: Centrifugal PumpsJoy CharlesNoch keine Bewertungen

- Krovni VentilatoriDokument6 SeitenKrovni VentilatoridrbaneNoch keine Bewertungen

- Sistemas Hidromecánicos 1 - ENGLISHDokument12 SeitenSistemas Hidromecánicos 1 - ENGLISHerick aguilarNoch keine Bewertungen

- OutlineDokument11 SeitenOutlinemichsantosNoch keine Bewertungen

- Rotating EquipmentDokument202 SeitenRotating EquipmentJithin Rajan Joseph100% (1)