Beruflich Dokumente

Kultur Dokumente

Welding History - A Story of Harnessing Heat

Hochgeladen von

dxsszszOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Welding History - A Story of Harnessing Heat

Hochgeladen von

dxsszszCopyright:

Verfügbare Formate

THE HISTORY OF WELDING

Lead-in

Look at pictures A, B, C of welded constructions and define what

time period they refer to.

Picture A

Picture B

Picture C

Welding History - A Story of Harnessing Heat

Joining metal and welding history go

back several millennia starting in the

Bronze Age then Iron Age in Europe then

the Middle East. Welding was used in the

Iron pillar in Delhi, India, about 310 AD,

weighing 5.4 metric tons (picture at left).

The Middle Ages brought forge welding,

blacksmiths pounded hot metal until it

bonded. In 1540, Vannoccio Biringuccio

released De la pirotechnia, which

includes descriptions of the forging

operation. Renaissance craftsmen gained

skilled in the process, and the welding

continued to grow during the following

centuries.

Welding was transformed during the 19th century. In 1800,

Sir Humphrey Davy invented the electric arc, and advances in

welding continued with the metal electrode by a Russian, Nikolai

Slavyanov, and an American, C.L. Coffin late in the 1800s.

Acetylene was discovered in 1836 by Edmund Davy, but

was not practical in welding until about 1900, when a suitable

blowtorch was developed. At first, oxyfuel welding was the more

popular welding method due to its portability and relatively low

cost. As the 20th century progressed, it fell out of favor for

industrial applications. It was largely replaced with arc welding,

as metal coverings (known as flux) for the electrode that stabilize

the arc and shield the base material from impurities continued to

be developed.

In 1881 a Russian inventor, Benardos

demonstrated the carbon electrode welding

process. An arc was formed between a

moderately consumable carbon electrode and the

work. A rod was added to provide needed extra

metal.

Termite welding was invented in 1893,

another process, oxyfuel welding, became well

established.

Around 1900, A. P. Strohmenger brought a

coated metal electrode in Britain, which had a

more stable arc, and

in 1919, alternating current welding was invented by C.J. Holslag,

but did not become popular for another decade.

Resistance welding was developed during the end of the

19th century, with the first patents going to Elihu Thompson in

1885, and he produced advances over the next 15 years.

In 1904 Oscar Kjellberg in Sweden, who started ESAB,

invented and patented the covered electrode. This electric welding

process made strong welds of excellent quality.

World War I caused a major surge in the use of welding

processes, with the various military powers attempting to

determine which of the several new welding processes would be

best. The British primarily used arc welding, even constructing a

ship, the Fulagar, with an entirely welded hull. The Americans

were more hesitant, but began to recognize the benefits of arc

welding when the process allowed them to repair their ships

quickly after a German attack in the New York Harbor at the

beginning of the war. Arc welding was first applied to aircraft

during the war as well, as some German airplane fuselages were

constructed using the process.

During the 1920s, major advances were made in welding

technology, including the introduction of automatic welding in

1920, in which electrode wire was fed continuously.

Shielding gas became a subject receiving much attention,

as scientists attempted to protect welds from the effects of oxygen

and nitrogen in the atmosphere. Porosity and brittleness were the

primary problems, and the solutions that developed included the

use of hydrogen, argon, and helium as welding atmospheres.

During the following decade, further advances allowed for

the welding of reactive metals like aluminum and magnesium.

This, in conjunction with developments in automatic welding,

alternating current, and fluxes fed a major expansion of arc

welding during the 1930s and then during World War II.

A significant invention was defined in a patent by

Alexander, filed in December 1924, and became known as the

Atomic Hydrogen Welding Process. It looks like MIG welding

but hydrogen is used as the shielding gas which also provides

extra heat. A major innovation was described in a patent that

defines the Submerged Arc Process by Jones, Kennedy and

Rothermund. This patent was filed in October 1935 and assigned

to Union Carbide Corporation.

Russell Meredith working at Northrop Aircraft Company

in 1939-1941 invented the TIG process. This new process was

called "Heliarc" as it used an electric arc to melt the base

material and helium to shield the molten puddle. Mr.Jack

Northrop's dream was to build a magnesium airframe for a

lighter, faster warplanes and his welding group invented the

process and developed the first TIG torches. The patents were

sold to Linde who developed a number of torches for different

applications. They also developed procedures for using Argon

which was more available and less expensive than Helium.

In 1957, the flux-cored arc welding process debuted, in

which the self-shielded wire electrode could be used with

automatic equipment, resulting in greatly increased welding

speeds, and that same year, plasma arc welding was invented.

Electroslag welding was released in 1958, and it was followed by

its cousin, electrogas welding, in 1961.

Other recent developments in welding include the 1958

breakthrough of electron beam welding, making deep and narrow

welding possible through the concentrated heat source.

Following the invention of the laser in 1960, laser beam welding

debuted several decades later, and has proved to be especially

useful in high-speed, automated welding. Both of these

processes, however, continue to be quite expensive due the high

cost of the necessary equipment, and this has limited their

applications.

Vocabulary

forge

oxyacetylene

porosity

brittleness

shielding gas

welding rod

MIG - metal

inert

torch

molten pool/puddle

impurities

gas

welding

1 Fill in the table with the scientists names and their

inventions from the lists below.

Scientists: Edmund Davy; A. P. Strohmenger; Jones, Kennedy

and Rothermund; Benardos; C.J. Holslag; Oscar Kjellberg;

Alexander; Nikolai Slavyanov and C.L. Coffin.

Inventions: discovered acetylene; invented the electric arc;

developed metal electrode; brought a coated metal electrode;

invented and patented the covered electrode; invented

alternating current; developed Submerged Arc Welding;

patented Atomic Hydrogen Welding process.

Date

1540

Scientist

Vannoccio Biringuccio

1800

1800s.

1836

1881

Sir Humphrey Davy;

1900

1904

1919

1935

1924

Invention

described forging operation

demonstrated the welding process

with carbon electrode

Say if the following is true or false. Correct the false

statements.

2

1. Arc welding was used to build the Iron pillar in Delhi, India.

2. The discovery of acetylene made it possible to

achieve higher heating temperatures.

3. The first electrode used in welding was a covered one.

4. Oxygen is used as shielding gas in TIG welding.

5. The TIG process made it possible to construct planes faster.

3

Answer the following question on the text.

1. Which process was developed earlier, MIG or TIG?

2. Why is rod added in carbon electrode welding?

3. What is the difference between the Atomic

Hydrogen Welding process and the MIG process?

4. What kind of gas was first used to shield the molten puddle?

5. Is tungsten electrode consumable?

Das könnte Ihnen auch gefallen

- Modern Developments in the Mechanics of ContinuaVon EverandModern Developments in the Mechanics of ContinuaSalamon EskinaziNoch keine Bewertungen

- History of WeldingDokument10 SeitenHistory of WeldingGracie O. ChingNoch keine Bewertungen

- Materials and Fluid Properties ChartDokument2 SeitenMaterials and Fluid Properties ChartBashu PoudelNoch keine Bewertungen

- Chandra 2014Dokument11 SeitenChandra 2014Usama Bin RaisNoch keine Bewertungen

- Bladeless Wind TurbineDokument4 SeitenBladeless Wind TurbineIJIERT-International Journal of Innovations in Engineering Research and TechnologyNoch keine Bewertungen

- 13 Full LineDokument104 Seiten13 Full LinewildfloNoch keine Bewertungen

- Materials Properties DatabaseDokument40 SeitenMaterials Properties DatabaseJuan Pablo ApazaNoch keine Bewertungen

- CD4mcu Data SheetDokument1 SeiteCD4mcu Data SheetAde Bagus SetiawanNoch keine Bewertungen

- Bitumastic 300 MDokument2 SeitenBitumastic 300 MANIBALLOPEZVEGA100% (1)

- Cryogenic SystemDokument1 SeiteCryogenic Systempap230% (1)

- ASWP Manual - Section 1 - IntroductionDokument17 SeitenASWP Manual - Section 1 - Introductionjmvm56Noch keine Bewertungen

- VVER Reactor Design Overview: Russian PWR with Horizontal Steam GeneratorsDokument5 SeitenVVER Reactor Design Overview: Russian PWR with Horizontal Steam GeneratorsAnbalagan GuruNoch keine Bewertungen

- Technology Development For Hardfacing ofDokument2 SeitenTechnology Development For Hardfacing ofabraham silva hernandezNoch keine Bewertungen

- ASME Code Cases for Nuclear ComponentsN-71-18N-71-18N-122-2N-131-1N-133-3N-154-1N-155-2N-160-1N-192-3N-201-5N-208-1N-213N-243N-249-14N-253-14N-254N-257N-258-2Dokument14 SeitenASME Code Cases for Nuclear ComponentsN-71-18N-71-18N-122-2N-131-1N-133-3N-154-1N-155-2N-160-1N-192-3N-201-5N-208-1N-213N-243N-249-14N-253-14N-254N-257N-258-2Biyong SantocildesNoch keine Bewertungen

- Engineering Fundamentals ThermodynamicsDokument133 SeitenEngineering Fundamentals ThermodynamicsDHASARAIAH SNEHANoch keine Bewertungen

- 5 - Section 14 - Arc Welding ConsumablesDokument11 Seiten5 - Section 14 - Arc Welding Consumablesrizkialia12Noch keine Bewertungen

- 10.1.1.144.9002 SW FatigueDokument13 Seiten10.1.1.144.9002 SW Fatigueb_wooNoch keine Bewertungen

- Team Pipe RepairDokument24 SeitenTeam Pipe RepairDavid Rios CruzNoch keine Bewertungen

- Fabricating Techniques: Welding Aluminum: Different But Not DifficultDokument5 SeitenFabricating Techniques: Welding Aluminum: Different But Not DifficultDee Dee0% (1)

- API Standard 1104 - Welding of Pipeline and Related FacilitiesDokument12 SeitenAPI Standard 1104 - Welding of Pipeline and Related Facilitiest.mohammed100% (1)

- Welders Hand BookDokument23 SeitenWelders Hand Booksamyqatar100% (2)

- Conference Fast Reactors and Related Fuel Cycles Challenges and Opportunities FR09Dokument410 SeitenConference Fast Reactors and Related Fuel Cycles Challenges and Opportunities FR09damp1r100% (1)

- Tefzel PDFDokument30 SeitenTefzel PDFFELIXENGIPLASCOMNoch keine Bewertungen

- Resistance WeldingDokument4 SeitenResistance WeldingAjith GanjiNoch keine Bewertungen

- FCI 70-2-2006 PreDokument1 SeiteFCI 70-2-2006 PreIkhsan LyNoch keine Bewertungen

- CWB Welder SOPDokument95 SeitenCWB Welder SOPHarminder KumarNoch keine Bewertungen

- The Boiler BookDokument1.140 SeitenThe Boiler BookJose Lorenzo ToralNoch keine Bewertungen

- Process Design of Cooling Towers StandardDokument11 SeitenProcess Design of Cooling Towers Standardravirawat15Noch keine Bewertungen

- Ped Asme ComparisionDokument31 SeitenPed Asme ComparisionJose A ManciniNoch keine Bewertungen

- Add02 1060.1Dokument14 SeitenAdd02 1060.1Diego Calderón AlvaradoNoch keine Bewertungen

- SEO Optimized Product Data Sheet for OK Tigrod 316L TIG Welding RodDokument2 SeitenSEO Optimized Product Data Sheet for OK Tigrod 316L TIG Welding Rodsoft4gsmNoch keine Bewertungen

- NTC ThermistorsDokument17 SeitenNTC ThermistorssumivrindavanNoch keine Bewertungen

- Hot & Cold WorkingDokument18 SeitenHot & Cold WorkingMadushan MadushaNoch keine Bewertungen

- Diesel Engine Indicator Valves and AccessoriesDokument1 SeiteDiesel Engine Indicator Valves and AccessoriesJose Luis RattiaNoch keine Bewertungen

- 2015 - 07094934Dokument9 Seiten2015 - 07094934mjimenezgNoch keine Bewertungen

- BS 4504 Slip On Flanges PDFDokument7 SeitenBS 4504 Slip On Flanges PDFMaclean ArthurNoch keine Bewertungen

- Fcaw Welding Guide PDFDokument2 SeitenFcaw Welding Guide PDFElizabethNoch keine Bewertungen

- Welding Metallurgy Part 2Dokument28 SeitenWelding Metallurgy Part 2Anonymous UM7Bt6bNoch keine Bewertungen

- Ador BookletDokument22 SeitenAdor Bookletgssrraju0% (1)

- API 653 Tank Inspection, Repair, and Maintenance StandardDokument3 SeitenAPI 653 Tank Inspection, Repair, and Maintenance StandardRuben AranaNoch keine Bewertungen

- Teknologi Las Kapal: How Do Shielded Metal Arc Welding On PipingDokument42 SeitenTeknologi Las Kapal: How Do Shielded Metal Arc Welding On Pipingardin0506Noch keine Bewertungen

- Filler Wires PDFDokument7 SeitenFiller Wires PDFJayaram MVNoch keine Bewertungen

- Welding AluminumDokument4 SeitenWelding AluminumHeryanda OnDaudNoch keine Bewertungen

- Alloy CuAg0,04 ofDokument13 SeitenAlloy CuAg0,04 ofnetzaalvaradoNoch keine Bewertungen

- Mott 4e Applied Strength of Materials Solutions Chapter 1Dokument12 SeitenMott 4e Applied Strength of Materials Solutions Chapter 1kmantillaNoch keine Bewertungen

- Astm b68 1995Dokument12 SeitenAstm b68 1995leonardoportocNoch keine Bewertungen

- C. K. Smoley-Principles of Structural EngineeringDokument393 SeitenC. K. Smoley-Principles of Structural Engineeringraahul_nNoch keine Bewertungen

- Difference ASME B31.1 and B31Dokument2 SeitenDifference ASME B31.1 and B31masmarkun4444Noch keine Bewertungen

- Aws WJ 201705Dokument165 SeitenAws WJ 201705Fabricio TarulloNoch keine Bewertungen

- 11 Refractory Weld Studs Sunbelt Stud Welding CatalogDokument14 Seiten11 Refractory Weld Studs Sunbelt Stud Welding CatalogKotenguNoch keine Bewertungen

- Glen Allan Shocking Truths About WeldingDokument33 SeitenGlen Allan Shocking Truths About Weldingashlyjon1Noch keine Bewertungen

- Prophets, Pastors and Public Choices: Canadian Churches and the Mackenzie Valley Pipeline DebateVon EverandProphets, Pastors and Public Choices: Canadian Churches and the Mackenzie Valley Pipeline DebateNoch keine Bewertungen

- Fatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965Von EverandFatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965E. GassnerNoch keine Bewertungen

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceVon EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNoch keine Bewertungen

- Advances in Nuclear Science and Technology: Volume 2Von EverandAdvances in Nuclear Science and Technology: Volume 2Noch keine Bewertungen

- Advances in Research on the Strength and Fracture of Materials: An OverviewVon EverandAdvances in Research on the Strength and Fracture of Materials: An OverviewD M R TaplinNoch keine Bewertungen

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionVon EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNoch keine Bewertungen

- D8a3 D8a8 d983 D983d8aad8a7d8a8d98aDokument32 SeitenD8a3 D8a8 d983 D983d8aad8a7d8a8d98adxsszszNoch keine Bewertungen

- Determine Your Finality Arabe PDFDokument88 SeitenDetermine Your Finality Arabe PDFdxsszszNoch keine Bewertungen

- Anglais LV1 BTN 2013 PDFDokument3 SeitenAnglais LV1 BTN 2013 PDFdxsszszNoch keine Bewertungen

- Presentations EBSDDokument73 SeitenPresentations EBSDdxsszszNoch keine Bewertungen

- Exercice KarnaughDokument4 SeitenExercice KarnaughdxsszszNoch keine Bewertungen

- CIT Livre Act CompetitiviteDokument8 SeitenCIT Livre Act CompetitivitedxsszszNoch keine Bewertungen

- Jobs and How To Get OneDokument4 SeitenJobs and How To Get OnedxsszszNoch keine Bewertungen

- CIT Livre InnovationDokument4 SeitenCIT Livre InnovationdxsszszNoch keine Bewertungen

- Macro-Micro Aspects of Fatigue of MetalsDokument50 SeitenMacro-Micro Aspects of Fatigue of MetalsdxsszszNoch keine Bewertungen

- Lycée St Louis à Gignac: Classe 2CITDokument4 SeitenLycée St Louis à Gignac: Classe 2CITdxsszszNoch keine Bewertungen

- Diodes ExercicesDokument21 SeitenDiodes ExercicesMaxence KouessiNoch keine Bewertungen

- Fatigue FracrtographyDokument40 SeitenFatigue FracrtographydxsszszNoch keine Bewertungen

- SEM Appearance Fatigue StriationsDokument10 SeitenSEM Appearance Fatigue StriationsdxsszszNoch keine Bewertungen

- Fabrication and Welding Engineering Curriculum GuideDokument107 SeitenFabrication and Welding Engineering Curriculum GuidePurnawanNoch keine Bewertungen

- Fatigue Cracking and FractographyDokument9 SeitenFatigue Cracking and FractographydxsszszNoch keine Bewertungen

- Matlab FemDokument45 SeitenMatlab Femsohailrao100% (3)

- Mickey MouseDokument31 SeitenMickey Mousedxsszsz88% (8)

- FEA TheoryDokument49 SeitenFEA Theoryof_switzerlandNoch keine Bewertungen

- CXC Physics 1994 - Paper1Dokument10 SeitenCXC Physics 1994 - Paper1Jotham OmoregieNoch keine Bewertungen

- Advanced Application of Micropasma WeldingDokument12 SeitenAdvanced Application of Micropasma WeldingKonstantin MarjanuczNoch keine Bewertungen

- Understanding States of Matter: Solids, Liquids and GasesDokument3 SeitenUnderstanding States of Matter: Solids, Liquids and GasesRussel Valentine OliverosNoch keine Bewertungen

- Calculation of Dew Point of Flue Gas 4x135 MW Jindal, AngulDokument2 SeitenCalculation of Dew Point of Flue Gas 4x135 MW Jindal, AngulAshitava SenNoch keine Bewertungen

- Phase Rule Class 2ND Sem NotesDokument6 SeitenPhase Rule Class 2ND Sem NotesAmartya PraharajNoch keine Bewertungen

- Projet Proposal For The Construction of A Marcet BoilerDokument5 SeitenProjet Proposal For The Construction of A Marcet BoilerOjiSofttouchCharlesNoch keine Bewertungen

- PSV Calculation SampleDokument2 SeitenPSV Calculation SampleNaveen RaoNoch keine Bewertungen

- Ensuring Reliability of Compressor Gas Seals During Long Periods of Pressurized HoldDokument10 SeitenEnsuring Reliability of Compressor Gas Seals During Long Periods of Pressurized HoldKader BenNoch keine Bewertungen

- 2.11.1 Introduction - Simple Recombination Model: Fig.2.11.1 Carrier Recombination Mechanisms in SemiconductorsDokument7 Seiten2.11.1 Introduction - Simple Recombination Model: Fig.2.11.1 Carrier Recombination Mechanisms in SemiconductorsWahyu SipahutarNoch keine Bewertungen

- Quick Quiz: Copymaster File 9Dokument2 SeitenQuick Quiz: Copymaster File 9ReenuNoch keine Bewertungen

- Fluid Flow (Laminar) Practice Sheet - SolutionsDokument2 SeitenFluid Flow (Laminar) Practice Sheet - SolutionsHercules ArgyNoch keine Bewertungen

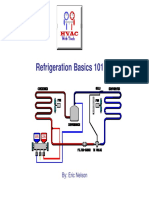

- Ref BasicsDokument15 SeitenRef BasicsManasvini KarthihaNoch keine Bewertungen

- Steam Jet Refrigeration SystemDokument6 SeitenSteam Jet Refrigeration Systembbaytl100% (1)

- Macolla 11, Fase I: Vialidad de Acceso, Plataforma Y Definición de Equipos Mayores de La Macolla 11 en El Centro Operativo Petromonagas (Copem)Dokument2 SeitenMacolla 11, Fase I: Vialidad de Acceso, Plataforma Y Definición de Equipos Mayores de La Macolla 11 en El Centro Operativo Petromonagas (Copem)vacarrizaNoch keine Bewertungen

- Cryogenics EngineeringDokument174 SeitenCryogenics EngineeringGomathi Sankar100% (1)

- Unit-1 Solids: Questions Carrying One MarkDokument159 SeitenUnit-1 Solids: Questions Carrying One MarkGahan Gowda SNoch keine Bewertungen

- L1 NCERT P BLOCK GP 13Dokument48 SeitenL1 NCERT P BLOCK GP 13bansalharshvardhan0Noch keine Bewertungen

- Soal Termodinamika 1Dokument7 SeitenSoal Termodinamika 1Tiara Andini0% (1)

- (2-2-1) NPTEL - Properties of Cryogenic FluidsDokument28 Seiten(2-2-1) NPTEL - Properties of Cryogenic FluidsNirmal JayanthNoch keine Bewertungen

- Slide 15 - 3. Physical Vapor DepositionDokument33 SeitenSlide 15 - 3. Physical Vapor DepositionMuhammad RezaNoch keine Bewertungen

- REVIEWDokument14 SeitenREVIEWerlifieNoch keine Bewertungen

- Chapter 3 - Conservation of EnergyDokument79 SeitenChapter 3 - Conservation of EnergyBananaliksNoch keine Bewertungen

- 07 Chapter 10 (Compiled)Dokument86 Seiten07 Chapter 10 (Compiled)Haziq KhairiNoch keine Bewertungen

- LPG PracticeDokument91 SeitenLPG PracticeКирилл Винокуров100% (14)

- R23 LinkDokument2 SeitenR23 LinkQurban Ali RindNoch keine Bewertungen

- Plasma DrillingDokument31 SeitenPlasma DrillingSaurav SenguptaNoch keine Bewertungen

- 7G Particle Theory: 3 0 Stage DDokument3 Seiten7G Particle Theory: 3 0 Stage DBen PassmoreNoch keine Bewertungen

- Production Logging Tools - Total Company PDFDokument36 SeitenProduction Logging Tools - Total Company PDFبوشناق بوشناقNoch keine Bewertungen

- Resato Check ValveDokument4 SeitenResato Check ValveSam LarismaNoch keine Bewertungen

- Q1, Gen Chem 2 Sy 2022-2023Dokument4 SeitenQ1, Gen Chem 2 Sy 2022-2023Jenny Vhie S. VinagreraNoch keine Bewertungen