Beruflich Dokumente

Kultur Dokumente

Design of Machine Members-2

Hochgeladen von

Vibin KrishnaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design of Machine Members-2

Hochgeladen von

Vibin KrishnaCopyright:

Verfügbare Formate

www.jntuworld.com || www.android.jntuworld.com || www.jwjobs.net || www.android.jwjobs.

net

R09

R

Code No: 09A60304

(Mechanical Engineering)

Time: 3 hours

.IN

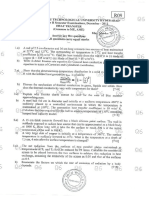

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY, HYDERABAD

B. Tech III Year II Semester Examinations, May 2013

Design of Machine Members-II

Max. Marks: 75

LD

Answer any five questions

All questions carry equal marks

---

The following data is given for a full hydrodynamic bearing used for electric

motor:

Radial load = 1200 N; Journal Speed = 1440 rpm; Journal diameter = 50 mm;

Static load on the bearing = 350 N; Operating temperature = 65 0C;

journal and the bearing are 2 and 1 micron

The values of surface roughness of the journal

respectively. The minimum film thickness is five times the surface roughness.

Determine

a) length of the bearing,

b) select a suitable lubricant based on viscosity of the lubricant,

c) flow of the lubricant.

[15]

2.a)

Compare the variation of coefficient of friction versus speed for rolling contact

bearing and sliding contact bearing.

A ball bearing is operating on a work cycle

cy

consisting of three parts a radial

load of 3000 N at 1440 rpm for one quarter cycle, a radial load of 5000 N at 720

rpm for one half cycles and radial lo

ad of 2500 N at 1440 rpm for the remaining

load

cycle. The expected life of the bearing is 10000 Hrs. Calculate the dynamic load

carrying capacity of the bearing.

[5+10]

TU

Derive the conditions for the maximum pow

er transmission in the flat belt drives.

power

Design an open type flat belt drive for a compressor running at 720 rpm which is

driven by a 25 kW, 1440 rpm motor. Centre distance is 3 m.

[3+12]

LJ

3.a)

b)

b)

W

O

1.

Design a side crankshaft for 500 mm 600 mm gas engine. The weight of the

flywheel is 80 kN and the explosion pressure

pressure is 2.5 MPa. The gas pressure at the

maximum torque is 0.9 MPa, when the crank is 300 from the Inner Dead Centre.

[15]

The connecting rod is 4.5 times the crank radius.

AL

4.

5.

Design a pair of spur pinion and gear made of cast steel and cast iron respectively.

The diameter of pinion is 140 mm and transmits 30 kW at 1250 rpm. The gear

ratio is 3:1 and teeth are 200 full depth involute system. Check the design for wear

strength and dynamic load assuming BHN 250 for pinion material.

[15]

6.

Two parallel shafts are connected by helical gears with 200 full depth teeth and

helix angle of 150. The material for both gears is forged steel with safe static

stress of 140 MPa. The power to be transmitted is 40 kW at 1400 rpm of the

pinion. Design the gears with Lewis equation and check for the wear strength.

Use BHN = 250, gear ratio = 4.5.

[15]

www.jntuworld.com || www.jwjobs.net

www.jntuworld.com || www.android.jntuworld.com || www.jwjobs.net || www.android.jwjobs.net

A pair of worm gear is designated by as 1/40/10/4. The input speed of the worm

shaft is 1000 rpm. The worm wheel is made of phosphor bronze while the worm

is made of hardened steel. Determine the power transmitting capacity based on

beam strength and on wear strength.

[15]

8.

force

A screw press is required to exert a fo

rce of 50 kN when applied torque is 560

Nm. The unsupported length of the screw is 450 mm and a thrust bearing of

provided

hardened steel on cast iron is provide

d at the power end. Determine the

dimensions of screw and nut, and efficiency using the data given below.

The permissible stresses in steel screw:

Tension and compression 85 MPa, Shear 55 MPa,

The permissible bearing pressure is 13.5 MPa for steel screw and C.I nut

The permissible shearing stress in the CI is 20 MPa

The yield strength of steel of screw = 260 MPa

The coefficient of friction in screw and nut is 0.15.

[15]

W

O

LD

.IN

7.

AL

LJ

TU

********

www.jntuworld.com || www.jwjobs.net

Das könnte Ihnen auch gefallen

- 05-04 Machine Design & Cad-II (Me)Dokument2 Seiten05-04 Machine Design & Cad-II (Me)Abdul AhadNoch keine Bewertungen

- MD II Machine Design AssignmentsDokument5 SeitenMD II Machine Design Assignmentsrishabhk28995Noch keine Bewertungen

- PMD ModelDokument8 SeitenPMD ModelDamodara SatyaDeva MadhukarNoch keine Bewertungen

- Dme Model Key 2019Dokument25 SeitenDme Model Key 2019Siva RamanNoch keine Bewertungen

- Supp Nov 2009Dokument10 SeitenSupp Nov 2009prk74Noch keine Bewertungen

- Machine Design-II Question BankDokument32 SeitenMachine Design-II Question BankAbhishek SakatNoch keine Bewertungen

- WWW - Manaresults.co - In: (Mechanical Engineering)Dokument2 SeitenWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailNoch keine Bewertungen

- 12 Me 5dcdm2Dokument3 Seiten12 Me 5dcdm2Abhyudaya SinghNoch keine Bewertungen

- DMM Ii (2015)Dokument35 SeitenDMM Ii (2015)gorijalaNoch keine Bewertungen

- 13 ME AssignmentDokument2 Seiten13 ME AssignmentMuhammad Sharif JamaliNoch keine Bewertungen

- DME Model QuesDokument3 SeitenDME Model QuesSiva RamanNoch keine Bewertungen

- ME 331 - DESIGN OF MACHINE ELEMENTS EXAMDokument5 SeitenME 331 - DESIGN OF MACHINE ELEMENTS EXAMarumugam_rNoch keine Bewertungen

- WWW - Manaresults.Co - In: (Common To Ame, Me)Dokument3 SeitenWWW - Manaresults.Co - In: (Common To Ame, Me)Vikranth DeepakNoch keine Bewertungen

- Machine Design Answer KeyDokument16 SeitenMachine Design Answer KeyK.KESAVARAJ HICET STAFF MCTSNoch keine Bewertungen

- 07a6ec05 Designofmachinemembers IIDokument11 Seiten07a6ec05 Designofmachinemembers IIzahid_polyNoch keine Bewertungen

- Design of Machine Elements - IIDokument8 SeitenDesign of Machine Elements - IIprasaad26Noch keine Bewertungen

- MD2 Model QuestionsDokument2 SeitenMD2 Model Questionsmanish sharmaNoch keine Bewertungen

- Me1302 Dme 2Dokument4 SeitenMe1302 Dme 2sumikannu100% (1)

- Projects For Lab BDokument91 SeitenProjects For Lab BPeter AshrafNoch keine Bewertungen

- Assignment 1 (Unit 1 and 2)Dokument5 SeitenAssignment 1 (Unit 1 and 2)Atharva ChoudhariNoch keine Bewertungen

- Design of Transmission Systems 3Dokument2 SeitenDesign of Transmission Systems 3srajapratyNoch keine Bewertungen

- Design of Transmission SystemsDokument3 SeitenDesign of Transmission SystemsSaravanan KumarNoch keine Bewertungen

- Design of Machine Elements 2 Jan 2014Dokument2 SeitenDesign of Machine Elements 2 Jan 2014Prasad C M100% (1)

- Dmm2 Mar2006Dokument8 SeitenDmm2 Mar2006Abdul Saleem MohammedNoch keine Bewertungen

- TUTORIAL 3 Design of Shaft Key and CouplingDokument2 SeitenTUTORIAL 3 Design of Shaft Key and Couplingrip111176100% (1)

- ME6601 Transmission Design QuestionsDokument11 SeitenME6601 Transmission Design QuestionsMURUGANNoch keine Bewertungen

- Dme 2Dokument6 SeitenDme 2NITHISH KUMAR M SNoch keine Bewertungen

- 2020-11-10SupplementaryME402ME402-E - Ktu QbankDokument2 Seiten2020-11-10SupplementaryME402ME402-E - Ktu QbankbilalfocusNoch keine Bewertungen

- Dme Quest Ut-2Dokument9 SeitenDme Quest Ut-2aadhithyarajasekaranNoch keine Bewertungen

- 4363 111 Machine Design IDokument6 Seiten4363 111 Machine Design Iyogesh_b_k100% (2)

- Final Design Work SheetDokument7 SeitenFinal Design Work SheetKINDUNoch keine Bewertungen

- 12ME5DCDM2Dokument3 Seiten12ME5DCDM2Abhyudaya SinghNoch keine Bewertungen

- Design of Transmission Systems 10Dokument2 SeitenDesign of Transmission Systems 10srajapratyNoch keine Bewertungen

- Diploma Board Examination - December 2020Dokument2 SeitenDiploma Board Examination - December 2020Pradeep AppuNoch keine Bewertungen

- nr321401 Principles of Machine DesignDokument2 Seitennr321401 Principles of Machine DesignSRINIVASA RAO GANTANoch keine Bewertungen

- ME2352 Design of Transmission Question BankDokument4 SeitenME2352 Design of Transmission Question BankKarthik SubramaniNoch keine Bewertungen

- Machine Design - II Question Bank and Bearing CalculationsDokument2 SeitenMachine Design - II Question Bank and Bearing CalculationsmaheshNoch keine Bewertungen

- MODEL QUESTION PAPER Mechanical VibrationsDokument3 SeitenMODEL QUESTION PAPER Mechanical VibrationsDarani PriyaNoch keine Bewertungen

- Design of Machine Elements-II Exam QuestionsDokument9 SeitenDesign of Machine Elements-II Exam QuestionsPrasinNoch keine Bewertungen

- Dts Model Que Type B 2018-19Dokument2 SeitenDts Model Que Type B 2018-19rammit2007Noch keine Bewertungen

- DMM-III Assignment TestDokument2 SeitenDMM-III Assignment TestSaibabu SoloNoch keine Bewertungen

- Dme Model 2Dokument6 SeitenDme Model 2YashwanthI-StyleKuttiNoch keine Bewertungen

- Tutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentDokument12 SeitenTutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentSURYA S96Noch keine Bewertungen

- Sathyabama University: Register NumberDokument3 SeitenSathyabama University: Register NumberSecret SecretNoch keine Bewertungen

- WWW - Manaresults.Co - In: (Common To ME, AME)Dokument3 SeitenWWW - Manaresults.Co - In: (Common To ME, AME)Your ChoiceNoch keine Bewertungen

- Me 7 Sem Subject Design of Mechanical Drives Jun 2017Dokument2 SeitenMe 7 Sem Subject Design of Mechanical Drives Jun 2017djniksthehearteditorNoch keine Bewertungen

- 1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringDokument3 Seiten1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringChadaram JagadishNoch keine Bewertungen

- Design of Transmission Systems Question BankDokument10 SeitenDesign of Transmission Systems Question BankDesejo SozinandoNoch keine Bewertungen

- rr320305 Design of Machine Members IIDokument8 Seitenrr320305 Design of Machine Members IISrinivasa Rao GNoch keine Bewertungen

- Mech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsDokument5 SeitenMech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsARIGARAN SNoch keine Bewertungen

- Design of Transmission Systems - Important QuestonsDokument5 SeitenDesign of Transmission Systems - Important QuestonsPost BoxNoch keine Bewertungen

- Machine Design - LDokument2 SeitenMachine Design - LNilesh Mistry (Nilesh Sharma)Noch keine Bewertungen

- Imp Qoestions MDDokument3 SeitenImp Qoestions MDvenuedNoch keine Bewertungen

- 07a60304 - Dynamics of MachineryDokument8 Seiten07a60304 - Dynamics of MachineryRajaganapathy GanaNoch keine Bewertungen

- Design of Transmission System QuestionsDokument4 SeitenDesign of Transmission System QuestionsMangesh SNoch keine Bewertungen

- Machine Design Elements and AssembliesVon EverandMachine Design Elements and AssembliesBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkVon EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNoch keine Bewertungen

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsVon EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNoch keine Bewertungen

- HEAT TRANSFER Jntu-H PaperDokument2 SeitenHEAT TRANSFER Jntu-H PaperVibin KrishnaNoch keine Bewertungen

- HEAT TRANSFER Previous PaperDokument8 SeitenHEAT TRANSFER Previous PaperVibin KrishnaNoch keine Bewertungen

- 07a60302 Refrigerationandairconditioning PDFDokument8 Seiten07a60302 Refrigerationandairconditioning PDFVibin KrishnaNoch keine Bewertungen

- Finite Element Methods Exam QuestionsDokument8 SeitenFinite Element Methods Exam QuestionsVibin KrishnaNoch keine Bewertungen

- Rolling vs Sliding Bearings: Advantages & TypesDokument8 SeitenRolling vs Sliding Bearings: Advantages & TypesDebabrat SaikiaNoch keine Bewertungen

- 1 141227035156 Conversion Gate02 PDFDokument52 Seiten1 141227035156 Conversion Gate02 PDFPhasin ChitutsahaNoch keine Bewertungen

- Ceramic Rolling Element Damage Sensitivity and Gearbox System ResponseDokument9 SeitenCeramic Rolling Element Damage Sensitivity and Gearbox System ResponseAnonymous lEX5U51wOANoch keine Bewertungen

- Scheerer Bearing Oil IndustryDokument8 SeitenScheerer Bearing Oil IndustryJosé Del Orbe García100% (1)

- Norma ISO 12240-4 Horquillas Articuladas PDFDokument39 SeitenNorma ISO 12240-4 Horquillas Articuladas PDFNemoz ZrNoch keine Bewertungen

- HCH BearingDokument2 SeitenHCH BearingSh.nasirpurNoch keine Bewertungen

- BSDDokument18 SeitenBSDdenisNoch keine Bewertungen

- NSK Bro Agriculture A4 GB v10Dokument17 SeitenNSK Bro Agriculture A4 GB v10Maxi452Noch keine Bewertungen

- Crossed Roller Paper WebDokument5 SeitenCrossed Roller Paper WebMohamed Salah-EldinNoch keine Bewertungen

- VMKV Engineering College Question Bank on Machine Design ElementsDokument14 SeitenVMKV Engineering College Question Bank on Machine Design ElementsSatwik PriyadarshiNoch keine Bewertungen

- Axial AngularDokument9 SeitenAxial AngularAlejandroInostrozaNoch keine Bewertungen

- Unit 1 Shaft, Key, Splines, Couplings, Bearings, Clutch and BrakeDokument200 SeitenUnit 1 Shaft, Key, Splines, Couplings, Bearings, Clutch and BrakeAbhijeet somawarNoch keine Bewertungen

- Bearing Load CalculationDokument9 SeitenBearing Load CalculationwahyoesoemantriNoch keine Bewertungen

- American Woodworker No 114 May 2005Dokument65 SeitenAmerican Woodworker No 114 May 2005sibaldeNoch keine Bewertungen

- NBC Training Report - Ball Bearing DivisionDokument51 SeitenNBC Training Report - Ball Bearing DivisionBrandon Johnson100% (6)

- Softening PointDokument12 SeitenSoftening PointFaeez Zain50% (2)

- E1221Dokument20 SeitenE1221LLNoch keine Bewertungen

- Datasheet qc11Dokument58 SeitenDatasheet qc11Saúl Alejandro Peréz RamírezNoch keine Bewertungen

- Engineering Vol 56 1893-11-03Dokument33 SeitenEngineering Vol 56 1893-11-03ian_newNoch keine Bewertungen

- Flygt Repair Kits InfoDokument32 SeitenFlygt Repair Kits Infokztro066Noch keine Bewertungen

- Design of Bearings Chapter 4: Selection of Taper Roller BearingsDokument5 SeitenDesign of Bearings Chapter 4: Selection of Taper Roller BearingsJai SharmaNoch keine Bewertungen

- NSK Cat E1102m b206-233Dokument14 SeitenNSK Cat E1102m b206-233Bibek DevNoch keine Bewertungen

- Lubricant TestingDokument68 SeitenLubricant TestingSamsudin Ahmad100% (2)

- RulmanKatalogu 2018 05 18 15 - 24 - 59Dokument336 SeitenRulmanKatalogu 2018 05 18 15 - 24 - 59Alvaro Felipe CharlinNoch keine Bewertungen

- Bearing and Linear Replacement Guide WebDokument300 SeitenBearing and Linear Replacement Guide WebAdam StroufNoch keine Bewertungen

- Technical OfferDokument50 SeitenTechnical OfferHisham ElsayedNoch keine Bewertungen

- Baumueller DS2 100 200 - 2022 - enDokument88 SeitenBaumueller DS2 100 200 - 2022 - enDikr ElhakimNoch keine Bewertungen

- The Main Types of Bearings PDFDokument9 SeitenThe Main Types of Bearings PDFThomas KamongNoch keine Bewertungen