Beruflich Dokumente

Kultur Dokumente

GX 600 Manual PDF

Hochgeladen von

KevinOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

GX 600 Manual PDF

Hochgeladen von

KevinCopyright:

Verfügbare Formate

GX 600 SERIES

(AUTOMATIC VOLTAGE REGULATOR)

Email Address: info@powersystems.com.au

Web Page: http://www.powersystems.com.au

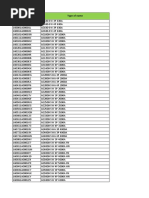

This AVR will replace the following Stamford Part Nos. And many more

Series 6 Stamford SX 460 E000 24600

E000 26000

450 13900

Power Drive Systems

GX 600 AUTOMATIC VOLTAGE REGULATOR

1.

INTRODUCTION

The GX600 is a solid state device, which is designed to give accurate and stable voltage

regulation of brushless alternators regardless of prime mover type and will replace most

Stamford series 6 regulators, Marathon SE350, Meccalte SR7, Braybon AVRs, and many

others.

The GX600 is suitable for one and three phase machines both 50 and 60Hz sensing. It is a one or

two phase sensing regulator with a voltage sensing range of 170 - 270 volts phase to

phase

and phase to neutral.

The GX600 regulator has several features:

Voltage adjustment + 10% over each range

Wide range of stability

Underspeed adjustment which will provide voltage droop with large motor starting loads

This feature will provide excellent starting characteristics and prevent unnecessary stalling of

the prime mover

Remote voltage adjustment available

Fuse protection

LED indication of underspeed operation

2.

OPERATION

The regulator senses the alternator output voltage and derives excitation power from the

centre tapped stator phase windings of the alternator.

Regulation and stability is maintained provided the prime mover speed is within governor

class A1 to ISO 3046, at any machine load or power factor by comparing the sensed voltage

with an internal reference.

The unit constantly adjusts the field excitation level to compensate for voltage difference

between the sensed voltage and reference.

Output voltage of the machine will be held to + 1.0% for steady state conditions including cold to

hot variations in ambient conditions of -10 deg. to +70 deg. and engine speed

changes of +

4% from preset nominal.

3.

CONSTRUCTION

The assembled PCB is designed to mount directly in the alternator terminal box using the

same mounting centres or in a separate control cubicle.

All components used are selected for stable operation in ambients ranging from -10 deg. to

+70 deg. and severely capacity derated for high reliability.

The printed circuit board is a 1.5mm reinforced fibreglass with double sided tracks and plated

through holes.

____________________________________________________________________________________

1

Power Drive Systems

GX 600 AUTOMATIC VOLTAGE REGULATOR

4.

CONTROLS

There are for standard controls on each regulator.

a.

STABILITY I R7

This potentiometer adjusts the stability and response of the alternator and should initially be set in

a counter clockwise position and rotate clockwise to give optimum stability and response

characteristics. Once set, no further adjustment should be necessary.

Full CCW position gives maximum response, minimum stability.

Full CW position gives minimum response, maximum stability.

b.

STABILITY II R12

This potentiometer widens range of stability and should always be normally fully anti-clockwise

and only adjusted slightly clockwise to provide further stability should STABILITY I run out of

range, particularly on single phase machines.

Set STABILITY II fully anti-clockwise for 1 phase or fully clockwise for 3 phase.

c.

VOLTAGE ADJUST R10

This potentiometer varies the reference voltage and hence the amount of excitation of the

alternator which adjusts the output voltage over a range of + 10%.

An external 5K potentiometer may be added to terminals P.P. for remote panel voltage

adjustment. When this is used the loop on P.P. is removed and the internal pot turned to

maximum.

d.

UNDERSPEED R22

This potentiometer sets the frequency at which voltage drooping with speed will occur.

For example, if set at 48Hz and a large motor is started, this temporarily overloads the prime

mover on starting. Once the speed falls to 48 Hz the alternator voltage will decrease and act as

an automatic reduced voltage the sensing range is 170 - 270 V.

5.

INITIAL SETTING UP

a.

VOLTAGE

The GX600 sensing voltage can be adjusted for the required sensing voltage by adjusting

potentiometer R10. For the required output voltage the sensing range is 170 - 270V.

Note:

If replacing other electric regulators for convenience use the same sensing connections if

possible.

b.

STABILITY I

Rotate clockwise to increase stability.

To check, if after sudden load change prolonged fluctuation occurs, turn stability slightly

clockwise, or if voltage is very slow to recover from load changes, then counter clockwise.

__________________________________________________________________________

2

Power Drive Systems

GX 600 AUTOMATIC VOLTAGE REGULATOR

c.

UNDERSPEED

To adjust the underspeed characteristic the alternator must be running at 50Hz + no load 240Hz.

Connect an AC voltmeter across the output of the alternator and slowly turn the underspeed

potentiometer clockwise until the voltage just starts to fall, then turn slightly counterclockwise,

approx. 30 deg.

To check, apply full load if possible and voltage should not droop more than 1%, or alternatively

lower speed to 48Hz and voltage should droop.

When setting is completed return no load prime mover speed back to 52Hz (where a mechanical

governor is used).

6.

CONNECTIONS

a.

STANDARD 3 PHAASE 4 WIRE

_________________________________________________________________________________

3

Power Drive Systems

GX 600 AUTOMATIC VOLTAGE REGULATOR

b.

STANDARD 1 PHASE 2 WIRE

For parallel zig zag or double delta connection.

c.

CONNECTIONS

Some series 6 AVRs from Stamford have only 3 connections.

Connect Genaust GX600 as per figure 3.

7.

SPECIFICATIONS

1, 2 and 3 phase sensing

Voltage range 170 270 volts

Adjustment + 10% on each range

Maximum field current 10 amps

SCR rated at 25 amps 800 volts

Suitable for single and three phase alternators

Regulation + 1% (assuming class A1 governor ISO3046)

Size 100mm X 135mm

Mounting centres 115mm X81mm

Temperature -10 to 70

Reliable excitations 3 5 ohms

Minimum field resistance 3-5 ohms

Field voltage approx 50% of input sensing voltage

Replaces Stamford part numbers E000 24600, E000 26000, E450 13900 plus many more

_________________________________________________________________________________

4

Power Drive Systems

GX 600 AUTOMATIC VOLTAGE REGULATOR

STANDARD CONNECTION

_________________________________________________________________________________

5

Power Drive Systems

GX 600 AUTOMATIC VOLTAGE REGULATOR

SPECIAL CONNECTION

_________________________________________________________________________________

6

Power Drive Systems

GX 600 AUTOMATIC VOLTAGE REGULATOR

8.

COMPONENT LAYOUT

_________________________________________________________________________________

7

Power Drive Systems

GX 600 AUTOMATIC VOLTAGE REGULATOR

9.

BENCH TEST

a.

b.

The regulator can be bench tested as follows

REGULATOR TEST SET UP SELECTIONS

240v Sense

c.

TEST EQUIPMENT REQUIRED

A 240 Volt 40 Watt globe, complete with holder and wire.

3 pin 240 Volts mains plugs and leads.

Mains supply

d.

1.

PROCEDURE

Remove the regulator from generator.

2.

Connect as above and select 240 Volt position. (Note the original sensing voltage position)

3.

Mark position of voltage adjusting potentiometer with biro or pencil. ( This enables the

potentiometer to be returned to its original position)

4.

Turn voltage adjusting potentiometer fully clockwise.

5.

Turn on 240 Volt supply.

6.

240 Volt globe should illuminate.

7.

Turn 240 Volt supply off.

8.

Turn the voltage potentiometer full ant-clockwise.

9.

Turn 240 Volt supply on.

10.

240 Volts globe should just flash and then remain off immediately.

_________________________________________________________________________________

8

Power Drive Systems

GX 340 AUTOMATIC VOLTAGE REGULATOR

WARRANTY CLAIM PROCEDURE

(a)

On identifying a possible component fault advise the company in writing the model and serial

number of the component and major assembly it is part of as well as fault details.

(b)

Remove and return the faulty component to the company following any tests or checks

requested by the company.

BASIC WARRANTY CONDITIONS

(a)

The warranty is a 12 month back to base warranty where the customer is liable for the re

delivery costs.

(b)

Items modified without the companies knowledge or approval may not be warrantable.

(c)

If the company is required to inspect / remove or reinstall any part of the goods, the customer

will be liable for any out of pocket expenses.

(d)

Major third party items such as engines and alternators are subject to the original

manufacturers warranty only.

(e)

The warranty does not cover inter alias, loss of damage due to accident misuse or fair wear

and tear.

________________________________________________________________________________

WARRANTY REGISTRATION

CUSTOMER NAME: _______________________________________________________________

ADDRESS: ______________________________________________________________________

________________________________________________________________________________

TELEPHONE No: ______________________________ FAX No: __________________________

ITEM MODEL No: ______________________________ SERIAL No: ______________________

SUPPLIER NAME: ________________________________________________________________

DATE PURCHASED: ______________________________________________________________

Das könnte Ihnen auch gefallen

- Sbi Afi 2012Dokument48 SeitenSbi Afi 2012Moneylife FoundationNoch keine Bewertungen

- AVR 380 ManualDokument14 SeitenAVR 380 Manualkazishah100% (1)

- GENUS Clock Gating Timing CheckDokument17 SeitenGENUS Clock Gating Timing Checkwasimhassan100% (1)

- The Impact of Social Networking Sites To The Academic Performance of The College Students of Lyceum of The Philippines - LagunaDokument15 SeitenThe Impact of Social Networking Sites To The Academic Performance of The College Students of Lyceum of The Philippines - LagunaAasvogel Felodese Carnivora64% (14)

- Preliminary Voters ListDokument86 SeitenPreliminary Voters Listمحمد منيب عبادNoch keine Bewertungen

- Power ElectronicsDokument16 SeitenPower ElectronicsPradeep AmmasaikuttiNoch keine Bewertungen

- Testing Maintenance Troubleshooting ACBDokument16 SeitenTesting Maintenance Troubleshooting ACB322399mk7086Noch keine Bewertungen

- Welding and Heat Treatment Requirements For Equipment and PipingDokument34 SeitenWelding and Heat Treatment Requirements For Equipment and Pipingonur gunesNoch keine Bewertungen

- Manual de Ligaçao SX 460Dokument6 SeitenManual de Ligaçao SX 460RobertoSoaresNoch keine Bewertungen

- HTDZ Catalogue 2019Dokument94 SeitenHTDZ Catalogue 2019Ioan TrifuNoch keine Bewertungen

- GX 600 ManualDokument10 SeitenGX 600 ManualKatherine Isahac Blue LaceNoch keine Bewertungen

- Ea15a Manual en PDFDokument6 SeitenEa15a Manual en PDFTimmyJuriNoch keine Bewertungen

- NDB Spares Kit Se125Dokument1 SeiteNDB Spares Kit Se125chienNoch keine Bewertungen

- QP Electrical Technology For The Candidate Joining As Electrical OfficerDokument7 SeitenQP Electrical Technology For The Candidate Joining As Electrical OfficerDevanshu SumanNoch keine Bewertungen

- ADR244ADokument36 SeitenADR244AVirender RanaNoch keine Bewertungen

- KSQ331x2: Sector Synchronising RelayDokument2 SeitenKSQ331x2: Sector Synchronising RelayDavid WebbNoch keine Bewertungen

- Generator TheoryDokument4 SeitenGenerator TheoryRachit KhannaNoch keine Bewertungen

- LAR100 Series Solar Pump Inverter User ManualDokument29 SeitenLAR100 Series Solar Pump Inverter User ManualfaitgpsNoch keine Bewertungen

- LXC701 V1.1 enDokument8 SeitenLXC701 V1.1 enAnonymous vqsuRy100% (1)

- Secure (Elite 440) MFM: Modbus Offset DescriptionDokument6 SeitenSecure (Elite 440) MFM: Modbus Offset DescriptionDhananjay SinghNoch keine Bewertungen

- ESD5500E Series Speed Control Unit: SpecificationsDokument5 SeitenESD5500E Series Speed Control Unit: SpecificationsMurilo FigueiredoNoch keine Bewertungen

- Sheet 3Dokument3 SeitenSheet 3geo_bi100% (1)

- Catalogues Au MyDokument28 SeitenCatalogues Au MyChu Hữu LạcNoch keine Bewertungen

- Experiment 2: Level Transmitter CalibrationDokument13 SeitenExperiment 2: Level Transmitter CalibrationMuhammad FawwazNoch keine Bewertungen

- DC6 - Two-Quadrant Chopper 200 HP DC DriveDokument3 SeitenDC6 - Two-Quadrant Chopper 200 HP DC Drivebryan eduardo villegas carrascoNoch keine Bewertungen

- ISF2 Catalog PDFDokument8 SeitenISF2 Catalog PDFbdikicNoch keine Bewertungen

- ABB Motor CatalogueDokument6 SeitenABB Motor CatalogueJeremy LandryNoch keine Bewertungen

- User's Manual: F Series Multi-Rate Multi-Function Watt-Hour MetersDokument16 SeitenUser's Manual: F Series Multi-Rate Multi-Function Watt-Hour MetersSlobodan SavicNoch keine Bewertungen

- (EPN (N401) :: A of atDokument2 Seiten(EPN (N401) :: A of atgeo_biNoch keine Bewertungen

- Type Irxm: Circulating Current RelayDokument7 SeitenType Irxm: Circulating Current RelayThejaswini ArNoch keine Bewertungen

- Measuring and Monitoring Relays - ABBDokument76 SeitenMeasuring and Monitoring Relays - ABBpevareNoch keine Bewertungen

- NSP783 Motor Manual English VersionDokument55 SeitenNSP783 Motor Manual English VersionOctavianus HarahapNoch keine Bewertungen

- Drawing PDFDokument18 SeitenDrawing PDFJeremiah LangoeyNoch keine Bewertungen

- DC-DC Converter DrivesDokument37 SeitenDC-DC Converter DrivesShivachandra ChavanNoch keine Bewertungen

- Assignment Induction MotorsDokument3 SeitenAssignment Induction MotorsMallikarjunBhiradeNoch keine Bewertungen

- Inv 2nd FLR CabinetDokument2 SeitenInv 2nd FLR CabinetJack HarrisonNoch keine Bewertungen

- Generator Excitation Control Systems & MethodsDokument5 SeitenGenerator Excitation Control Systems & MethodsJohan GantivaNoch keine Bewertungen

- MK150SDokument3 SeitenMK150Stk1958Noch keine Bewertungen

- Technical Data: Monitoring Relays - VOX SeriesDokument2 SeitenTechnical Data: Monitoring Relays - VOX SeriesVasuPatelNoch keine Bewertungen

- Single Phase AlternatorDokument7 SeitenSingle Phase AlternatorMahmood AhmedNoch keine Bewertungen

- Lowara Elp Windings Resistance ValueDokument111 SeitenLowara Elp Windings Resistance ValueKostasNoch keine Bewertungen

- AVR sps-101Dokument1 SeiteAVR sps-101Sunil SangaNoch keine Bewertungen

- UPS Prolink PRO-SeriesDokument2 SeitenUPS Prolink PRO-SeriesJon TimanNoch keine Bewertungen

- Joventa DMDokument2 SeitenJoventa DMsandiatru88Noch keine Bewertungen

- FS9721-LP1 4000 Counts Digital Multimeter: FortuneDokument31 SeitenFS9721-LP1 4000 Counts Digital Multimeter: FortunealejandroNoch keine Bewertungen

- TCGEN2.0: Automati C & Manual Mains FailureDokument2 SeitenTCGEN2.0: Automati C & Manual Mains FailureRic Rio0% (1)

- KRLDokument4 SeitenKRLShehroz MinhasNoch keine Bewertungen

- Bang Gia Thiet Bi Dien Mitsubishi 01-04-2020Dokument422 SeitenBang Gia Thiet Bi Dien Mitsubishi 01-04-2020Kien Nguyen TrungNoch keine Bewertungen

- Sensor de TierraDokument3 SeitenSensor de TierraAnonymous FXM2q3hM2Noch keine Bewertungen

- Development of Electric Drives in Light Rail Transit (LRT) SystemDokument31 SeitenDevelopment of Electric Drives in Light Rail Transit (LRT) SystemArjun Pratap Singh100% (1)

- Danfoss Mbs 3000Dokument2 SeitenDanfoss Mbs 3000zethramNoch keine Bewertungen

- Manual PA150Dokument18 SeitenManual PA150ricardoNoch keine Bewertungen

- Easy Weld MIG NB-500D ManualDokument20 SeitenEasy Weld MIG NB-500D ManualDavy R.K.Noch keine Bewertungen

- FDK Multi-2700 Instruction ManualDokument23 SeitenFDK Multi-2700 Instruction ManualpieguzNoch keine Bewertungen

- Chapter 2 Op AmpDokument148 SeitenChapter 2 Op AmpMuhammad Ummair100% (1)

- HCI634H - Winding 311 and 312: Technical Data SheetDokument9 SeitenHCI634H - Winding 311 and 312: Technical Data Sheet3efooNoch keine Bewertungen

- AC&M Power TransducersDokument2 SeitenAC&M Power TransducersLare LenangNoch keine Bewertungen

- MPR50 User Manual Eng v1.78Dokument19 SeitenMPR50 User Manual Eng v1.78nebiyou100% (2)

- Catalogue-DC Shunt MotorDokument2 SeitenCatalogue-DC Shunt MotorVikash Kumar SinghNoch keine Bewertungen

- KUVAG Indicating System CPI VI-3P R (10-52kV)Dokument3 SeitenKUVAG Indicating System CPI VI-3P R (10-52kV)registracijus100% (1)

- GX - 340 - Manual STAMFORD SERIE 3 PART 450-11700Dokument11 SeitenGX - 340 - Manual STAMFORD SERIE 3 PART 450-11700Manuel Otero100% (2)

- AVC63-7F Voltage Regulator - Instructions - 9302800994-D - March 2012 - BASLER ELECTRIC PDFDokument4 SeitenAVC63-7F Voltage Regulator - Instructions - 9302800994-D - March 2012 - BASLER ELECTRIC PDFpevareNoch keine Bewertungen

- Model 460 ManualDokument6 SeitenModel 460 ManualCommunications ShipyardNoch keine Bewertungen

- EA05AF ManualDokument4 SeitenEA05AF Manualabuzer1981Noch keine Bewertungen

- Ea460 Manual enDokument5 SeitenEa460 Manual enabuzer1981Noch keine Bewertungen

- General Arrangement, Isometric Views and B.O.M. A Midget Steam Car Using A Double Acting Oscillating EngineDokument3 SeitenGeneral Arrangement, Isometric Views and B.O.M. A Midget Steam Car Using A Double Acting Oscillating EngineRobson Carlos0% (1)

- Impeller Velocity TrianglesDokument2 SeitenImpeller Velocity TrianglesLorettaMayNoch keine Bewertungen

- Englis 123Dokument39 SeitenEnglis 123Cindy EysiaNoch keine Bewertungen

- Bubble Deck SlabDokument29 SeitenBubble Deck SlabJhimy Rusbel Gutierrez YanapaNoch keine Bewertungen

- Et200sp Im 155 6 PN ST Manual en-US en-USDokument47 SeitenEt200sp Im 155 6 PN ST Manual en-US en-USayaz officeNoch keine Bewertungen

- Paper Format IJRDTDokument3 SeitenPaper Format IJRDTrock starNoch keine Bewertungen

- SmoothWall Express 2.0 Quick-Start GuideDokument6 SeitenSmoothWall Express 2.0 Quick-Start Guideinfobits100% (1)

- Basic: M1736N Model: MW73VR Model Code: Mw73Vr/BwtDokument42 SeitenBasic: M1736N Model: MW73VR Model Code: Mw73Vr/Bwtsantiago962Noch keine Bewertungen

- Edug 899 - Grade 2 Forces and Motion Unit - CompletedDokument37 SeitenEdug 899 - Grade 2 Forces and Motion Unit - Completedapi-241358660Noch keine Bewertungen

- Accounting For A Service CompanyDokument9 SeitenAccounting For A Service CompanyAnnie RapanutNoch keine Bewertungen

- Game On Series BibleDokument28 SeitenGame On Series Bibleapi-513832615Noch keine Bewertungen

- Catphan®604 ManualDokument34 SeitenCatphan®604 ManualTold Told LeungNoch keine Bewertungen

- p1632 eDokument4 Seitenp1632 ejohn saenzNoch keine Bewertungen

- BF254 BF255Dokument3 SeitenBF254 BF255rrr2013Noch keine Bewertungen

- Auburn Bsci ThesisDokument5 SeitenAuburn Bsci Thesisafksaplhfowdff100% (1)

- FL Switch 2000Dokument124 SeitenFL Switch 2000marcosNoch keine Bewertungen

- 1.6 FSI Inlet Manifold Removal Guide - Audi A2 Owners' ClubDokument3 Seiten1.6 FSI Inlet Manifold Removal Guide - Audi A2 Owners' Clubdusan jovanovicNoch keine Bewertungen

- Permutation, Combination & ProbabilityDokument9 SeitenPermutation, Combination & ProbabilityVicky RatheeNoch keine Bewertungen

- Professional Development Objectives Related To Modalities Specific TopicsDokument3 SeitenProfessional Development Objectives Related To Modalities Specific TopicsCris100% (1)

- Expansions Meet Health Care Needs: Economists Question Trump Plan FiguresDokument10 SeitenExpansions Meet Health Care Needs: Economists Question Trump Plan FiguresThe Daily Tar HeelNoch keine Bewertungen

- MetLife CaseDokument4 SeitenMetLife Casekatee3847Noch keine Bewertungen

- CE Laws L8 L15Dokument470 SeitenCE Laws L8 L15Edwin BernatNoch keine Bewertungen

- Gel Electrophoresis Worksheet Teacher AnswersDokument3 SeitenGel Electrophoresis Worksheet Teacher AnswersChris FalokunNoch keine Bewertungen

- Introduction To Physiotherapy PracticeDokument22 SeitenIntroduction To Physiotherapy PracticejNoch keine Bewertungen

- 3rd Quarter SUMMATIVE TEST in MAPEHDokument3 Seiten3rd Quarter SUMMATIVE TEST in MAPEHzaile felineNoch keine Bewertungen