Beruflich Dokumente

Kultur Dokumente

34sPACE WAGON

Hochgeladen von

rafaelcruzgjaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

34sPACE WAGON

Hochgeladen von

rafaelcruzgjaCopyright:

Verfügbare Formate

34-1

REAR

SUSPENSION

CONTENTS

34109000206

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . 2

SHOCK ABSORBER ASSEMBLY . . . . . . . . . . . 6

SERVICE SPECIFICATIONS . . . . . . . . . . . . . . . . . 2

REAR SPRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . 3

LOWER ARM ASSEMBLY . . . . . . . . . . . . . . . . 10

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . . . . . . . 4

SUSPENSION CROSSMEMBER . . . . . . . . . . . 15

Wheel Alignment Check and Adjustment . . . . . . . 4

Wheel Bearing Axial Play Check <4WD> . . . . . . 5

STABILIZER BAR . . . . . . . . . . . . . . . . . . . . . . . . 18

34-2

REAR SUSPENSION - General Information/Service Specifications

GENERAL INFORMATION

34100010277

The rear suspension is a semi-trailing arm type suspension.

COIL SPRING

Items

SPACE RUNNER

SPACE WAGON

Wire diameter average diameter free length mm

13 113 278

14 - 15 114 - 115 283 - 285

CONSTRUCTION DIAGRAM

Shock absorber

Coil spring

Suspension crossmember

Stabilizer bar

Lower arm assembly

SERVICE SPECIFICATIONS

Items

Toe-in

34100030235

Specifications

At the centre of tyre tread mm

32

Toe-angle (per wheel)

0_15 10

Camber

- 0_45 30

(difference between right and left wheel: less than 30)

Wheel bearing axial play mm

0.05

Wheel bearing rotation starting torque Nm

1.0 or less

Protruding length of stabilizer bar mounting bolt mm

15 - 17

34-3

REAR SUSPENSION - Special Tools

SPECIAL TOOLS

Tool

34100060180

Number

Name

Use

MB991004

Wheel alignment

gauge attachment

Wheel alignment measurement

cVehicles with aluminium type wheelsd

MB990241

A: MB990242

B: MB990244

Axle shaft puller

A: Puller shaft

B: Puller bar

Rear hub assembly removal <4WD>

MB991354

Puller body

MB990211

Slide hammer

MB990560

Bearing remover

Wheel bearing inner race removal <4WD>

MB990925

Bearing and oil

seal installer set

Wheel bearing removal <4WD>

For details of each installer, refer to GROUP

26 - Special Tools.

MB991400

Rear wheel

bearing and hub

installer

D

D

MB991401

Rear wheel

bearing and hub

installer base

MB991411

Rear wheel

bearing and hub

installer joint

Wheel bearing press-fitting <4WD>

Rear hub assembly press-fitting <4WD>

34-4

REAR SUSPENSION - Special Tools/On-vehicle Service

Tool

A

Number

Name

Use

A: MB991017

B: MB990998

C: MB991000

A, B: Front hub

remover and

installer

C: Spacer

Wheel bearing provisional holding

MB991000, which belongs to MB990998,

should be used as a spacer.

MB990326

Preload socket

Wheel bearing rotation starting torque

measurement

MB991318

Lower arm bushing

arbour

Driving out and press-fitting of suspension

crossmember

MB990840

Universal joint

remover and

installer

B

C

ON-VEHICLE SERVICE

33100100144

WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

Measure the wheel alignment with the vehicle parked on level

ground.

The rear suspension and wheels should be serviced to the

normal condition prior to measurement of wheel alignment.

TOE-IN

Standard value:

At the centre of tyre tread 3 2 mm

Toe angle (per wheel) 0_15 10

Carry out adjustment by turning the mounting bolts inside

the lower arm to the left and right by the same amounts.

LH: Turning clockwise toe-out direction

RH: Turning clockwise toe-in direction

Furthermore, toe adjustment can be mode at graduations

or approximately 2 mm.

REAR SUSPENSION - On - vehicle Service

34-5

CAMBER

MB991004

Standard value:

- 0_45 30 (difference between right and left wheels:

less than 30 )

NOTE

1. Camber is preset at the factory and can not be adjusted.

2. For vehicles equipped with aluminium wheels, measure

the camber after tightening the special tool (MB991004)

to the specified torque 226 Nm.

Caution

To prevent the wheel bearing from damage, never subject

the wheel bearings to the full vehicle load when the flange

nuts are loosened.

WHEEL BEARING AXIAL PLAY CHECK <4WD>

34101140029

1. Remove the caliper assembly, and then hold it with a

wire to prevent it from falling . Then remove the brake

disc.

2. Check the bearings axial play.

Place a dial gauge against the hub surface; then move

the hub in the axial direction and check whether or not

there is axial play.

Limit: 0.05 mm

3. If the axial play exceeds the limit, replace the wheel

bearing.

34-6

REAR SUSPENSION - Shock Absorber Assembly

SHOCK ABSORBER ASSEMBLY

34100510197

REMOVAL AND INSTALLATION

Caution

*: To prevent a bushing from breakage, the part indicated by * should be temporarily tightened,

and then fully tightened with the vehicle on the ground in the unladen condition.

3

2

44 Nm

1

103 Nm*

AA"

Removal steps

1. Shock absorber mounting bolt

D Quarter armrest assembly

(Refer to GROUP 52A - Trims.)

2. Cap

3. Shock absorber mounting nuts

4. Shock absorber assembly

REMOVAL SERVICE POINT

AA" SHOCK ABSORBER MOUNTING BOLT

INSTALLATION

Support the lower arm assembly with a garage jack, and

after compressing the coil spring, remove the shock absorber

mounting bolt.

34-7

REAR SUSPENSION - Shock Absorber Assembly

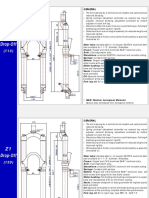

DISASSEMBLY AND REASSEMBLY

34100530155

25 Nm

1

2

3

4

5

6

10

7

8

11

Disassembly steps

AA" "AA 1. Self-locking nut

2. Washer

3. Collar

4. Upper bushing

5. Gasket

6. Bracket assembly

7.

8.

9.

10.

11.

Upper bushing

Cup assembly

Bump rubber

Dust cover

Shock absorber

DISASSEMBLY SERVICE POINT

Piston rod

AA" SELF-LOCKING NUT REMOVAL

Holding the piston rod, remove the self-locking nut.

Caution

Do not use an impact wrench as internal parts of the

strut assembly will be loosened.

REASSEMBLY SERVICE POINT

"AA SELF-LOCKING NUT INSTALLATION

Caution

Do not use an impact wrench as internal parts of the

strut assembly will be loosened.

INSPECTION

D

D

Check the rubber parts for damage.

Check the shock absorber for deformation.

34100540066

34-8

REAR SUSPENSION - Rear spring

REAR SPRING

34100610019

REMOVAL AND INSTALLATION

Caution

*: To prevent bushings from breakagethe parts indicated by * should be temporarily tightened,

and then fully tightened with the vehicle on the ground in the unladen condition.

Pre-removal Operation

D Main Muffler assembly Removal <4WD>

(Refer to GROUP 15.)

D Load Sensing Spring Removal <SPACE WAGON

- right side only> (Refer to GROUP 35A - Load

Sensing Proportioning Valve.)

Post-installation Operation

D Load Sensing Spring Installation <SPACE WAGON

- right side only> (Refer to GROUP 35A - Load

Sensing Proportioning Valve.)

D Main Muffler assembly Installation <4WD>

(Refer to GROUP 15.)

D Wheel Alignment Check and Adjustment

(Refer to P.34-4.)

11

9

7

10

54 - 64 Nm

8

103 Nm*

1

3

4

5

4

3

6

3

4

3

2

Removal steps

"BA 1. Self-locking nut

2. Bolt

3. Joint cup A

4. Stabilizer rubber

5. Joint cup B

6. Collar

AA"

AB"

7.

8.

"AA 9.

"AA 10.

11.

Bolt <4WD>

Shock absorber mounting bolt

Coil spring

Tube pad

Spring pad

REAR SUSPENSION - Rear spring

34-9

REMOVAL SERVICE POINTS

AA" BOLT REMOVAL <4WD>

Remove the bolt, and then hold the drive shaft to the vehicle

body with a wire.

AB" SHOCK ABSORBER MOUNTING BOLT REMOVAL

Support the lower arm assembly with a transmission jack,

and after compressing the coil spring, remove the shock

absorber mounting bolt.

INSTALLATION SERVICE POINTS

Coil spring

Tube pad

"AA TUBE PAD/COIL SPRING INSTALLATION

Install the tube pad to the coil spring while aligning the end

of the pad with that of the spring. Then engage the bottom

of the coil spring in the spring seat groove of the lower arm

assembly properly.

Align each end

Lower arm assembly

"BASELF-LOCKING NUT INSTALLATION

Check that joint cups A and B face as shown, and then tighten

the self-locking nut so that the shown dimension (A) is at

the standard value.

Joint cup B

Joint cup A

Standard value (A): 15 - 17 mm

INSPECTION

D

D

34100630015

Check the coil springs for crack, damage or deterioration.

Check the spring seats for cracks and wear.

34-10

REAR SUSPENSION - Lower Arm Assembly

LOWER ARM ASSEMBLY

34100650011

REMOVAL AND INSTALLATION

<2WD>

Caution

*: To prevent bushings from breakagethe parts indicated by * should be temporarily tightened,

and then fully tightened with the vehicle on the ground in the unladen condition.

Pre-removal Operation

D Brake Fluid Draining

D Rear Hub Assembly Removal

(Refer to GROUP 27A.)

D Coil Spring Removal (Refer to P.34-8.)

Post-installation Operation

D Coil Spring Installation (Refer to P.34-8.)

D Rear Hub Assembly Installation

(Refer to GROUP 27A.)

D Brake Fluid Supplying

D Brake Line Bleeding

(Refer to GROUP 35A - On-vehicle Service.)

D Parking Brake Lever Stroke Check and Adjustment

(Refer to GROUP 36 - On-vehicle Service.)

D Wheel Alignment Check and Adjustment

(Refer to P.34-4.)

8

9

55 - 65 Nm

96 Nm*

2

7

4

6

103 Nm*

15 Nm

5

1

Removal steps

1. Shoe and lining assembly

(Refer to GROUP 36 - Parking

brake cable.)

2. Parking brake cable connection

3. Brake hose connection

4. Rear wheel speed sensor harness

connection <vehicles with ABS>

5.

AA" "CA 6.

7.

8.

9.

Rear brake assembly

Bolt assembly

Flange bolt

Stopper

Lower arm assembly

34-11

REAR SUSPENSION - Lower Arm Assembly

<4WD>

Caution

*: To prevent bushings from breakagethe parts indicated by * should be temporarily tightened,

and then fully tightened with the vehicle on the ground in the unladen condition.

Pre-removal Operation

D Brake Fluid Draining

D Drive Shaft Removal

(Refer to GROUP 27B.)

D Coil Spring Removal (Refer to P.34-8.)

Post-installation Operation

D Coil Spring Installation (Refer to P.34-8.)

D Drive Shaft Installation

(Refer to GROUP 27B.)

D Brake Fluid Supplying

D Brake Line Bleeding

(Refer to GROUP 35A - On-vehicle Service.)

D Parking Brake Lever Stroke Check and Adjustment

(Refer to GROUP 36 - On-vehicle Service.)

D Wheel Alignment Check and Adjustment

(Refer to P.34-4.)

14

13

12

55 - 65 Nm

5

15 Nm

11

96 Nm*

4

8

55 - 65 Nm

10

3

103 Nm*

Removal steps

1. Caliper assembly

2. Brake disc

3. Shoe and lining assembly

(Refer to GROUP 36 - Parking

brake cable.)

4. Parking brake cable connection

5. Brake hose connection

6. Rear wheel speed sensor harness

connection <vehicles with ABS>

AA" "CA 7.

8.

9.

AB" "BA 10.

11.

12.

AC" "AA 13.

14.

Bolt assembly

Flange bolt

Stopper

Rear hub assembly

Rear brake assembly

Snap ring

Wheel bearing

Lower arm assembly

34-12

REAR SUSPENSION - Lower Arm Assembly

REMOVAL SERVICE POINTS

Mating marks

AA" BOLT ASSEMBLY REMOVAL

Matchmark the lower arm bolt assembly and the crossmember,

and remove the bolt assembly.

Crossmember

Bolt assembly

AB" REAR HUB ASSEMBLY REMOVAL <4WD>

MB991354

MB990211

Caution

The ball bearing will be damaged when the rear hub is

removed. If the rear hub has been removed, always

replace the ball bearing.

MB990244 (three)

AC" WHEEL BEARING REMOVAL <4WD>

1. Use the special tool to drive out the wheel bearing inner

race.

Piece of

metal

MB990560

MB990938

MB990934

Lower arm

assembly

2. Use the special tools to remove the wheel bearing from

the lower arm assembly.

REAR SUSPENSION - Lower Arm Assembly

MB991400

34-13

INSTALLATION SERVICE POINTS

"AA WHEEL BEARING INSTALLATION <4WD>

Wheel bearing

Lower arm

assembly

MB991401

"BA REAR HUB ASSEMBLY INSTALLATION <4WD>

MB991400

Rear hub

assembly

Lower arm

assembly

MB991411

"CABOLT ASSEMBLY INSTALLATION

Align the marks on the lower arm bolt assembly and the

crossmember, and tighten the nut.

34-14

REAR SUSPENSION - Lower Arm Assembly

INSPECTION

D

D

D

34100660014

Check the lower arm for deformation and deterioration.

Check all bolts for condition and straightness.

Check the spring seats for cracks and wear.

WHEEL BEARING ROTATION STARTING TORQUE

CHECK <4WD>

1. Install the special tool to the rear hub assembly and tighten

the nut to the specified torque 196 - 255 Nm.

MB991017

MB991000

(MB990998)

Wheel bearing

2. Use the special tool to measure the wheel bearing rotation

starting torque.

Limit: 1.0 Nm or less

3. The wheel bearing rotation starting torque should be within

the limit value range, and there should be no engagement

or feeling of roughness.

MB990326

REAR SUSPENSION - Suspension Crossmember

SUSPENSION CROSSMEMBER

34-15

34100680010

REMOVAL AND INSTALLATION

Caution

*: To prevent bushings from breakagethe parts indicated by * should be temporarily tightened,

and then fully tightened with the vehicle on the ground in the unladen condition.

Pre-removal Operation

Brake Fluid Draining

Post-installation Operation

D Brake Fluid Supplying

D Brake Line Bleeding

(Refer to GROUP 35A - On-vehicle Service.)

D Parking Brake Lever Stroke Check and Adjustment

(Refer to GROUP 36 - On-vehicle Service.)

D Wheel Alignment Check and Adjustment

(Refer to P.34-4.)

4

15 Nm

12

11

55 - 65 Nm

96 Nm*

7

10

103 Nm*

78 - 93 Nm

98 - 118 Nm

44 Nm

98 - 118 Nm

AA"

Removal steps

D Lift supporting point

D Coil spring (Refer to P.34-8.)

D Center exhaust pipe

(Refer to GROUP 15.)

D Differential carrier assembly <4WD>

(Refer to GROUP 27.)

D Bracket assembly <4WD> (Refer to

GROUP 27 - Differential mount.)

1. Caliper assembly

2. Brake disc

3. Shoe and lining assembly

(Refer to GROUP 36 - Parking

brake cable.)

4. Parking brake cable connection

5. Brake hose connection

6. Rear wheel speed sensor harness

connection <vehicles with ABS>

AB" "BA 7. Bolt assembly

8. Flange bolt

9. Crossmember bracket

"AA 10. Lower stopper

11. Suspension crossmember assembly

12. Upper stopper

34-16

REAR SUSPENSION - Suspension Crossmember

REMOVAL SERVICE POINTS

AA" LIFT SUPPORTING POINT

When the suspension crossmember is lowered from the

vehicle, slide a lift arm to the front side of the vehicle slightly

to make sure that the crossmember does not interfere with

nearby parts.

AB" BOLT ASSEMBLY REMOVAL

Matchmark the lower arm bolt assembly and the crossmember,

and then remove the bolt assembly.

Mating marks

Crossmember

Bolt assembly

INSTALLATION SERVICE POINTS

"AA LOWER STOPPER INSTALLATION

For the lower stopper bolts, first install the short (front) bolt

loosely while no load is applied to it, and then tighten the

long (rear) bolt to the specified torque. Finally, tighten the

short bolt to the specified torque.

"BA BOLT ASSEMBLY INSTALLATION

Align the marks on the lower arm bolt assembly and the

crossmember, and then tighten the nut.

INSPECTION

D

34100690013

Check the crossmember for cracks or deformation.

REAR SUSPENSION - Suspension Crossmember

REAR

FRONT

MB991318

MB991318

Slit

34-17

SUSPENSION CROSSMEMBER BUSHING

34101420017

REPLACEMENT

1. Make a mark on the crossmember bracket to match the

slits on the old bushing, and use these marks to position

the new bushing.

2. Insert a flat-tipped screwdriver between the old bushing

and the crossmember bracket, and lever around the

bushing to break the seal.

3. Use the special tool to tap out the bushing from the

crossmember bracket.

4. Align the slits on the new bushing with the mating marks

on the crossmember bracket.

Mating marks

5. Use the special tool to reduce the size of the rear end

of the bushing.

MB990840

MB991318

Bushing

outer

case

Crossmember

flange

6. Use the special tool to press-fit the bushing until the

outside case of the bushing is fitting securely in the

crossmember flange.

34-18

REAR SUSPENSION - Stabilizer Bar

STABILIZER BAR

34100710016

REMOVAL AND INSTALLATION

29 - 34 Nm

1

3

4

5

9

4

3

6

3

10

4

3

8

2

7

23 Nm

Removal steps

"CA 1. Self-locking nut

2. Bolt

3. Joint cap A

4. Stabilizer rubber

5. Joint cap B

"AA

"AA

AA" "BA

"AA

6.

7.

8.

9.

10.

Collar

Fixture

Bushing

Propeller shaft connection <4WD>

Stabilizer bar

REMOVAL SERVICE POINT

AA" PROPELLER SHAFT DISCONNECTION

1. Make mating marks on the differential companion flange

and flange yoke, and then separate the differential carrier

assembly and the propeller shaft.

2. Suspend the propeller shaft from the body with wire, etc,

so that there are no sharp bends.

Mating marks

REAR SUSPENSION - Stabilizer Bar

Inside of the

vehicle

Approx. 10 mm

34-19

INSTALLATION SERVICE POINTS

"AA STABILIZER BAR/BUSHING/FIXTURE

INSTALLATION

Position the stabilizer bar at the left side of the vehicle so

that its identification mark is as shown, and then tighten the

fixture mounting nut assembly.

"BA PROPELLER SHAFT INSTALLATION

Align the marks on the propeller shaft and the companion

flange, and then install the propeller shaft.

"CA SELF-LOCKING NUT INSTALLATION

Check that joint cups A and B face as shown, and then tighten

the self-locking nut so that the shown dimension (A) is at

the standard value.

Joint cap B

Joint cap A

Standard value (A): 15 - 17 mm

INSPECTION

D

D

D

34100720019

Check the bushing for wear and deterioration.

Check the stabilizer bar for deterioration or damage.

Check all bolts for condition and straightness.

NOTES

Das könnte Ihnen auch gefallen

- 26 PDFDokument22 Seiten26 PDFrafaelcruzgjaNoch keine Bewertungen

- Manual Pajero 4x4 Rear AxleDokument32 SeitenManual Pajero 4x4 Rear AxleGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Manual Pajero 4x4 Front SuspentionDokument16 SeitenManual Pajero 4x4 Front SuspentionGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- Service Brakes Mitsubishi GalantDokument0 SeitenService Brakes Mitsubishi GalantIsraelxcNoch keine Bewertungen

- Mitsubishi l200 26 Front AxleDokument71 SeitenMitsubishi l200 26 Front Axlenikirafferty5453Noch keine Bewertungen

- 36sPACE WAGONDokument10 Seiten36sPACE WAGONrafaelcruzgjaNoch keine Bewertungen

- Suspension: General Procedures Wheel AlignmentDokument18 SeitenSuspension: General Procedures Wheel Alignmentpavel35Noch keine Bewertungen

- 27 Rear Axle 123Dokument35 Seiten27 Rear Axle 123Pafuncio de AlecrimNoch keine Bewertungen

- Manual Pajero4x4steereingDokument42 SeitenManual Pajero4x4steereingGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- 37a SteeringDokument35 Seiten37a SteeringPedro IpanemaNoch keine Bewertungen

- Steering System Service ManualDokument36 SeitenSteering System Service Manualmybdt1691Noch keine Bewertungen

- Cluch MonteroDokument16 SeitenCluch MonteroGonzalez RubenNoch keine Bewertungen

- GR00005400 27 PDFDokument6 SeitenGR00005400 27 PDFNicu PascalutaNoch keine Bewertungen

- GR00006300 35a PDFDokument26 SeitenGR00006300 35a PDFNicu PascalutaNoch keine Bewertungen

- D Transmission2010Dokument37 SeitenD Transmission2010Akrae AcrNoch keine Bewertungen

- Parking Brake System: SectionDokument8 SeitenParking Brake System: Sectiontipo3331Noch keine Bewertungen

- 2003 Nissan Altima 2.5 Serivce Manual PBDokument8 Seiten2003 Nissan Altima 2.5 Serivce Manual PBAndy DellingerNoch keine Bewertungen

- 2D Задняя подвескаDokument10 Seiten2D Задняя подвескаtankg1000Noch keine Bewertungen

- HF35Dokument64 SeitenHF35Alexandre Da Silva PintoNoch keine Bewertungen

- GR00000700 11C PDFDokument52 SeitenGR00000700 11C PDFNicu PascalutaNoch keine Bewertungen

- zxr400 H 04Dokument23 Seitenzxr400 H 04hugo_bikerNoch keine Bewertungen

- Front AxleDokument63 SeitenFront AxleGreg HannaNoch keine Bewertungen

- Lancer FRONT AXLEDokument48 SeitenLancer FRONT AXLEziko23Noch keine Bewertungen

- Manual - Motor Série 4D5Dokument45 SeitenManual - Motor Série 4D5FcoElmoNoch keine Bewertungen

- Marzocchi 01 Z1 - Dropoff ManualDokument18 SeitenMarzocchi 01 Z1 - Dropoff ManualHarry James BoundenNoch keine Bewertungen

- Manual Pajero 4x4 Service BrakesDokument70 SeitenManual Pajero 4x4 Service BrakesGIAN CARLO MAMANI GILES.Noch keine Bewertungen

- zxr400 H 10Dokument7 Seitenzxr400 H 10hugo_bikerNoch keine Bewertungen

- TP31201-1 700 Multi-Link Rear SuspensionDokument42 SeitenTP31201-1 700 Multi-Link Rear Suspensionvanapeer100% (1)

- RAXDokument12 SeitenRAXRafaelCazalesFuentesNoch keine Bewertungen

- A32 MTDokument47 SeitenA32 MTLevin Tan HtNoch keine Bewertungen

- Front & Rear AxleDokument26 SeitenFront & Rear AxleSteve BelangerNoch keine Bewertungen

- 32sPACE WAGONDokument8 Seiten32sPACE WAGONrafaelcruzgjaNoch keine Bewertungen

- Hyundai HD78 D4GA Manual Transmission (M035S5)Dokument20 SeitenHyundai HD78 D4GA Manual Transmission (M035S5)Bigfair HD78Noch keine Bewertungen

- Volvo F9Q EngineDokument42 SeitenVolvo F9Q EngineAoife Fitzgerald100% (2)

- Honda Monkey z50j Workshop ManualDokument276 SeitenHonda Monkey z50j Workshop ManualKeith Romanowski100% (3)

- Removing EngineDokument11 SeitenRemoving EngineValuableManualsNoch keine Bewertungen

- Clutch Master Cylinder 7 - . - . - . - . - . - . - . - . - . - . - .Dokument8 SeitenClutch Master Cylinder 7 - . - . - . - . - . - . - . - . - . - . - .rafaelcruzgjaNoch keine Bewertungen

- Suspension and Axle PDFDokument57 SeitenSuspension and Axle PDFJohn SimmondsNoch keine Bewertungen

- Suspension AxleDokument97 SeitenSuspension AxleLoc TruongNoch keine Bewertungen

- Toyota Corolla+c52 Shift ManualDokument221 SeitenToyota Corolla+c52 Shift Manualdaswine100% (4)

- Pajero Timing BeltDokument44 SeitenPajero Timing Beltguzzi1100100% (2)

- Kawasaki KLX110 & KLX110L Service Repair Manual - Chapter 4 - Engine Top EndDokument41 SeitenKawasaki KLX110 & KLX110L Service Repair Manual - Chapter 4 - Engine Top EndbarackkNoch keine Bewertungen

- Front Axle & Front Suspension: Go To Table of Contents Go To Quick Reference IndexDokument28 SeitenFront Axle & Front Suspension: Go To Table of Contents Go To Quick Reference IndexLevin Tan HtNoch keine Bewertungen

- Brake SystemDokument11 SeitenBrake SystemSaima ZaibNoch keine Bewertungen

- 14.1. Suspension Delantera Elantra 94Dokument22 Seiten14.1. Suspension Delantera Elantra 94Richard QuiguangoNoch keine Bewertungen

- Engine PDFDokument19 SeitenEngine PDFRojascometNoch keine Bewertungen

- Parking Brake System: SectionDokument9 SeitenParking Brake System: SectionRafaelCazalesFuentesNoch keine Bewertungen

- 42 - ClutchDokument24 Seiten42 - ClutchArif WidayuniNoch keine Bewertungen

- 07 Clutch SystemDokument18 Seiten07 Clutch SystemJuanNoch keine Bewertungen

- Manual Transmission 5 SpeedDokument12 SeitenManual Transmission 5 Speedav1135100% (1)

- Rear AxleDokument108 SeitenRear AxleGreg HannaNoch keine Bewertungen

- 2003 Nissan Altima 2.5 Serivce Manual RSUDokument12 Seiten2003 Nissan Altima 2.5 Serivce Manual RSUAndy Dellinger100% (1)

- 4.2. Brake SystemDokument34 Seiten4.2. Brake SystemChristian Icaza SamaniegoNoch keine Bewertungen

- 03 DR-Z125-03-EngineDokument60 Seiten03 DR-Z125-03-EngineVincent RoyNoch keine Bewertungen

- Drive Axle Rear Non IntegralDokument17 SeitenDrive Axle Rear Non IntegralAnimemanuel MuñozNoch keine Bewertungen

- Motorcycle, Solo (Harley-Davidson Model WLA)Von EverandMotorcycle, Solo (Harley-Davidson Model WLA)Noch keine Bewertungen

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- 52sPACE WAGONDokument100 Seiten52sPACE WAGONrafaelcruzgjaNoch keine Bewertungen

- Heater, Air Conditioner and VentilationDokument38 SeitenHeater, Air Conditioner and VentilationrafaelcruzgjaNoch keine Bewertungen

- Chassis ElectricalDokument114 SeitenChassis ElectricalrafaelcruzgjaNoch keine Bewertungen

- 36sPACE WAGONDokument10 Seiten36sPACE WAGONrafaelcruzgjaNoch keine Bewertungen

- 23 PDFDokument72 Seiten23 PDFrafaelcruzgjaNoch keine Bewertungen

- 32sPACE WAGONDokument8 Seiten32sPACE WAGONrafaelcruzgjaNoch keine Bewertungen

- Engine and Emission ControlDokument18 SeitenEngine and Emission ControlrafaelcruzgjaNoch keine Bewertungen

- 31sPACE WAGONDokument4 Seiten31sPACE WAGONrafaelcruzgjaNoch keine Bewertungen

- 25 PDFDokument12 Seiten25 PDFrafaelcruzgjaNoch keine Bewertungen

- 22sPACE WAGONDokument16 Seiten22sPACE WAGONrafaelcruzgjaNoch keine Bewertungen

- 16sPACE WAGONDokument32 Seiten16sPACE WAGONrafaelcruzgjaNoch keine Bewertungen

- Clutch Master Cylinder 7 - . - . - . - . - . - . - . - . - . - . - .Dokument8 SeitenClutch Master Cylinder 7 - . - . - . - . - . - . - . - . - . - . - .rafaelcruzgjaNoch keine Bewertungen

- 14sPACE WAGONDokument20 Seiten14sPACE WAGONrafaelcruzgjaNoch keine Bewertungen

- 15sPACE WAGONDokument8 Seiten15sPACE WAGONrafaelcruzgjaNoch keine Bewertungen

- 12sPACE WAGONDokument8 Seiten12sPACE WAGONrafaelcruzgjaNoch keine Bewertungen

- Maruti Suzuki ALTO K10: 3.52 Max. 49.00 Child 21.67 Max. 34.00 AdultDokument4 SeitenMaruti Suzuki ALTO K10: 3.52 Max. 49.00 Child 21.67 Max. 34.00 AdultTanmay Gupta 83Noch keine Bewertungen

- GES Equipment Report MT6020 Parts Package GuideDokument10 SeitenGES Equipment Report MT6020 Parts Package GuideporometalNoch keine Bewertungen

- WiringDokument67 SeitenWiringKhépLạiNoch keine Bewertungen

- Disco1 Comb MPL 090508 Add DelDokument6 SeitenDisco1 Comb MPL 090508 Add DelBalachandar SathananthanNoch keine Bewertungen

- Ampera Control Module U Code ListDokument27 SeitenAmpera Control Module U Code ListGaby VasileNoch keine Bewertungen

- Cross JointDokument10 SeitenCross JointWesley Gao100% (1)

- A8 Brochure FinalDokument23 SeitenA8 Brochure Finalkatoyev852Noch keine Bewertungen

- Traction Control SystemDokument24 SeitenTraction Control SystemRakeshSaini100% (1)

- Buses in MoldovaDokument2 SeitenBuses in MoldovaMihai CheibasNoch keine Bewertungen

- Carrera Katalog 2015 US DS Ansicht Final PDFDokument74 SeitenCarrera Katalog 2015 US DS Ansicht Final PDFlauraNoch keine Bewertungen

- AY0001900RdDokument7 SeitenAY0001900RdRamesh arumugamNoch keine Bewertungen

- Electronic Control System ToyotaDokument11 SeitenElectronic Control System ToyotagabotoyoNoch keine Bewertungen

- Honda Motorcycle Parts 2006 CBR1000RR A BATTERY (2) DiagramDokument3 SeitenHonda Motorcycle Parts 2006 CBR1000RR A BATTERY (2) DiagramMark AbNoch keine Bewertungen

- TeslaDokument18 SeitenTeslaTanika GargNoch keine Bewertungen

- Maintenance KitsDokument6 SeitenMaintenance Kitssebastian BugueñoNoch keine Bewertungen

- Catalogo IronmanDokument212 SeitenCatalogo IronmanDiego PinedaNoch keine Bewertungen

- Chapter 2 1Dokument15 SeitenChapter 2 1Nurhazimah RahmatNoch keine Bewertungen

- Tesla Innovation ProjectDokument13 SeitenTesla Innovation ProjectManish GangadkarNoch keine Bewertungen

- Special License Plate AppDokument2 SeitenSpecial License Plate AppFernando HarklessNoch keine Bewertungen

- Mazda CX 7 p1Dokument8 SeitenMazda CX 7 p1raisviranNoch keine Bewertungen

- Rider'S Manual: BMW MotorradDokument316 SeitenRider'S Manual: BMW MotorradThanasis XigisNoch keine Bewertungen

- Team Bicol Endo For The Month of Dec.2019 With Col IdDokument37 SeitenTeam Bicol Endo For The Month of Dec.2019 With Col IdJohn Albert AlejandrinoNoch keine Bewertungen

- Mercedes Benz Cars at A Glance Edition 2014Dokument43 SeitenMercedes Benz Cars at A Glance Edition 2014ExtratenorNoch keine Bewertungen

- Parte CatalogueDokument1 SeiteParte CatalogueErnesto ChristianNoch keine Bewertungen

- Honda ByfaDokument3 SeitenHonda Byfaarckangel53Noch keine Bewertungen

- 250 1836 2009 2013tacomaDokument12 Seiten250 1836 2009 2013tacomaedgargtzNoch keine Bewertungen

- n800-ELECTRICAL DIAGRAMDokument190 Seitenn800-ELECTRICAL DIAGRAMLucía jandigNoch keine Bewertungen

- Tabelle ACI 2023 Auto Termiche Bifuel Benzina GPL e Metano Fuori ProduzioneDokument3 SeitenTabelle ACI 2023 Auto Termiche Bifuel Benzina GPL e Metano Fuori ProduzioneIl DanielNoch keine Bewertungen

- Terex Tr45 Off Highway Truck Parts BookDokument20 SeitenTerex Tr45 Off Highway Truck Parts Bookdavid100% (25)

- MQB - Skoda Octavia A7 - v1.110.7Dokument41 SeitenMQB - Skoda Octavia A7 - v1.110.7hall100% (2)