Beruflich Dokumente

Kultur Dokumente

Airgas

Hochgeladen von

tuna61Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Airgas

Hochgeladen von

tuna61Copyright:

Verfügbare Formate

ARC WELDING SAFELY

Welders shall follow safe welding practices

Employers shall provide safe working conditions and safety training.

FMES AN ASES

can be dangerous to

your health.

KEEP your head out of the fumes.

DONT get too close to the arc. se corrective

lenses if necessary to stay a reasonable

distance away from the arc.

READ and obey the warning label that

appears on all containers of welding materials.

ARC RAS can

inures eyes and

burn skin.

Above For iesel

USE ENOUGH VENTILATION or exhaust at the

arc, or both, to keep the fumes and gases from

your breathing one and the general area.

2.d.3. o not place your body between the electrode and

work cables. If the electrode cable is on your right

side, the work cable should also be on your right side.

USE NATURAL DRAFTS or fans to keep the

fumes away from your face.

If you develop unusual symptoms, see your

supervisor. Perhaps the welding atmosphere and

ventilation system should be checked.

SMOKE EXTRACTOR welding gun. For semiautomatic

welding processes, euipment exists for exhausting the

fumes at the arc.

USE NATURAL VENTILATION

wear correct eye, ear,

and body protection

PROTECT your eyes and face with welding helmet properly fitted

and with proper grade of filter plate See ANSI Z49.1.

PROTECT your body from welding spatter and arc flash with

protective clothing including woolen clothing, flame-proof apron and

gloves, leather leggings , and high boots.

O NO OC LIE ELECRICAL PARS

electric shock can kill

BE SURE you are insulated from live electrical parts.

BE SRE euipment is adeuate for the ob.

BE SRE euipment is installed according to prevailing codes.

BE SRE damaged parts are repaired or replaced.

BE SURE welding machine is properly grounded.

BE SURE gloves have no holes.

BE SURE to stay dry do not weld when you are wet.

BE SRE euipment is turned OFF when not in use.

O NO use cables that are too small, damaged, or poorly spliced.

O NO wrap cables around your body.

additional precautionary

measures

Insulated

PROTECT compressed gas cylinders from

excessive heat, mechanical shocks, and arcs

fasten cylinders so they cannot fall.

PROTECT other from spatter, flash, and glare with protective

screens or banners.

IN SOME AREAS protection from noise may be appropriate.

BE SURE cylinders are never grounded or

part of an electrical circuit.

BE SURE protective euipment is in good condition.

Also, wear safety glasses in work area AT ALL TIMES.

Insulated

REMOVE all potential fire haards from welding

area.

NO

1.a. urn the engine off before troubleshooting and maintenance

work unless the maintenance work reuires it to be running.

____________________________________________________

1.b. Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes

outdoors.

1.e. In some cases it may be necessary to remove safety

guards to perform reuired maintenance. Remove

guards only when necessary and replace them when the

maintenance reuiring their removal is complete.

Always use the greatest care when working near moving

parts.

___________________________________________________

1.f. o not put your hands near the engine fan. o

not attempt to override the governor or idler

by pushing on the throttle control rods while

the engine is running.

1.h.o avoid scalding, do not remove the

radiator pressure cap when the engine is

hot.

Insulated

SESE

WA

ALWAYS HAVE FIRE FIGHTING EQUIPMENT

READY FOR IMMEDIATE USE AND KNOW

HOW TO USE IT

cooperating for safety

special situations

DO NOT WELD OR CUT containers or materials which previously had been in contact with

haardous substances unless they are properly cleaned. his is extremely dangerous.

DO NOT WELD OR CUT painted or plated parts unless special precautions with ventilation have

been taken. hey can release highly toxic fumes or gases.

Cooperation between management

and employees is vital to the success

of every company. By working together

toward the common goal

SAFETY

IN WELDING

everyone wins

Welders and their supervisors should

have adeuate safely training.

Refer to the references shown below for directions on how to deal with such special situations.

For further information refer to American National Standard Z49.1, Safety in Welding and Cutting, available from

the American Welding Society, P.O. Box 351040, Miami FL 33135

Other details are given in itle 29. Code of Federal Regulations, Section 1910 Occupational Safety and ealth

Administration ocument 220, available from .S. epartment

of Labor, Washington, C 20210 and the booklet

Ls, hreshold Limit alues.

. ., American Conference of o vernmental Industrial ygeienists. P.O. box 1937,

Cincinnati, O 45201.

Special thanks to the

American Welding Society

and Lincoln Electric for the

information contained in this poster.

ELECTRIC AND

MAGNETIC FIELDS

may be dangerous

2.a. Electric current flowing through any conductor causes

localied Electric and Magnetic Fields EMF. Welding

current creates EMF fields around welding cables and

welding machines

2.b. EMF fields may interfere with some pacemakers, and

welders having a pacemaker should consult their physician

before welding.

2.c. Exposure to EMF fields in welding may have other health

effects which are now not known.

WELDING SPARKS can

cause fire or explosion.

2.d.5. o not work next to welding power source.

.a. Remove fire haards from the welding area.

If this is not possible, cover them to prevent

the welding sparks from starting a fire.

Remember that welding sparks and hot

materials from welding can easily go through small cracks

and openings to adace nt areas. Avoid welding near

hydraulic lines. ave a fire extinguisher readily available.

ELECTRIC SHOCK can kill.

3.a. he electrode and work or ground circuits

are electrically hot when the welder is on.

o not touch these hot parts with your bare

skin or wet clothing. Wear dry, hole-free

gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full

area of physical contact with work and ground.

In addition to the normal safety precautions, if welding

must be performed under electrically hazardous

conditions (in damp locations or while wearing wet

clothing; on metal structures such as floors, gratings or

scaffolds; when in cramped positions such as sitting,

kneeling or lying, if there is a high risk of unavoidable or

accidental contact with the workpiece or ground) use

the following equipment:

Semiautomatic DC Constant Voltage (Wire) Welder.

DC Manual (Stick) Welder.

AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nole or semiautomatic

welding gun are also electrically hot.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. he connection

should be as close as possible to the area being welded.

. b. Where compressed gases are to be used at the ob site,

special precautions should be used to prevent haardous

situations. Refer to Safety in Welding and Cutting ANSI

Standard Z49.1 and the operating information for the

euipment being used.

.c. When not welding, make certain no part of the electrode

circuit is touching the work or ground. Accidental contact can

cause overheating and create a fire haard.

.d.

Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically hot parts of

electrode holders connected to two welders because voltage

between the two can be the total of the open circuit voltage

of both welders.

3.i.

3..

o not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures

will not cause flammable or toxic vapors from substances

inside. hey can cause an explosion even though they have

been cleaned. For information, purchase Recommended

Safe Practices for the Preparation for Welding and Cutting of

Containers and Piping hat ave eld

aardous

Substances, AWS F4.1 from the American Welding Society

see address above.

.e. ent hollow castings or containers before heating, cutting or

welding. hey may explode.

.f.

Sparks and spatter are thrown from the welding arc. Wear oil

free protective garments such as leather gloves, heavy shirt,

cuffless trousers, high shoes and a cap over your hair. Wear

ear plugs when welding out of position or in confined places.

Always wear safety glasses with side shields when in a

welding area.

.g.

Connect the work cable to the work as close to the welding

area as practical. Work cables connected to the building

framework or other locations away from the welding area

increase the possibility of the welding current passing

through lifting chains, crane cables or other alternate circuits.

his can create fire haards or overheat lifting chains or

cables until they fail.

3.e. round the work or metal to be welded to a good electrical

earth ground.

.h. Also see item 1.c.

When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

CYLINDER may explode

if damaged.

Also see Items .c. and 8.

7.a. se only c ompressed gas cylinders

containing the correct shielding gas for the

process used and properly operating

regulators designed for the gas and

pressure used. All hoses, fittings, etc. should be suitable for

the application and maintained in good condition.

ARC RAYS can burn.

4.a. se a shield with the proper filter and cover

plates to protect your eyes from sparks and

the rays of the arc when welding or observing

open arc welding. eadshield and filter lens

should conform to ANSI Z87. I standards.

4.b. se suitable clothing made from durable flame-resistant

material to protect your skin and that of your helpers from

the arc rays.

___________________________________________________

1.g. o prevent accidentally starting gasoline engines while

turning the engine or welding generator during maintenance

work, disconnect the spark plug wires, distributor cap or

magneto wire as appropriate.

5.d. Read and understand the manufacturers instructions for this

euipment and the consumables to be used, including the

material safety data sheet MSS and follow your

employers safety practices. MSS forms are available from

your welding distributor or from the manufacturer.

5.e. Also see item 1.b.

3.f.

____________________________________________________

1.c. o not add the fuel near an open flame weld ing arc or when the engine is running. Stop

the engine and allow it to cool before refueling to prevent spilled fuel from vaporiing on

contact with hot engine parts and igniting. o

not spill fuel when filling tank. If fuel is spilled,

wipe it up and do not start engine until fumes

have been eliminated.

____________________________________________________

1.d. eep all euipment safety guards, covers and devices in position and in good repair.eep hands, hair, clothing and tools

away from -belts, gears, fans and all other moving parts

when starting, operating or repairing euipment.

____________________________________________________

5.c. Shielding gases used for arc welding can displace air and

cause inury or death. Always use enough ventilation,

especially in confined areas, to insure breathing air is safe.

2.d.4. Connect the work cable to the workpiece as close as

possible to the area being welded.

BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

FOR ENGINE

powered equipment.

IN A LARGE ROOM OR OUTDOORS, natural

ventilation may be adeuate if you keep your

head out of the fumes See below.

PROTECT adeuate ventilation is available when welding

in confined areas or where there are barriers to air movement.

MCM-14 2007

2.d.2. Never coil the electrode lead around your body.

Engines

Read and understand the following safety highlights.

For additional safety information, it is strongly recommended that you purchase a copy of Safety in

Welding & Cutting - ANSI Standard Z49.1 from the

American Welding Society, P.O. Box 351040, Miami,

Florida 33135 or CSA Standard W117.2-1974. A Free

copy of Arc Welding Safety booklet E205 is available

from the Lincoln Electric Company, 22801 St. Clair

Avenue, Cleveland, Ohio 44117-1199.

ELECRIC SOC

can kill.

YES

some ventilation

suggestions

USE EXHAUST AT THE ARC

iesel engine exhaust and some of its constituents

are known to the State of California to cause cancer, birth defects, and other reproductive harm.

ARC WELDING CAN BE HAZARDOUS. PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR

DEATH. KEEP CHILDREN AWAY. PACEMAKER WEARERS

SHOULD CONSULT WITH THEIR DOCTOR BEFORE OPERATING.

fumes and

gases can be

dangerous to

your health

NO

2.d.1. Route the electrode and work cables together - Secure

them with tape when possible.

he engine e xhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

he Above For asoline Engines

WARNING:

YES

2.d. All welders should use the following procedures in order to

minimie exposure to EMF fields from the welding circuit:

CALIFORNIA PROPOSITION 65 WARNINGS

he

As in most trades, welders are exposed to certain haards. aards exist with all arc welding processes. Welding is safe when

safe practices are followed.

his information is a brief outline of precautionary measures that will help avoid the haards of arc welding.

Read and understand the manufacturers instructions and your employers safe practices.

our Safety irector or Supervisor should be consulted when specific uestions arise.

PROTECT YOURSELF AND OTHERS.

READ AND UNDERSTAND THIS

INFORMATION.

WARNING

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

can be dangerous.

5.a. Welding may produce fumes and gases

haardous to health. Avoid breathing these

fumes and gases.When welding, keep

your head out of the fume. se enough

ventilation and/or exhaust at the arc to keep

fumes and gases away from the breathing one. When

welding with electrodes which require special

ventilation such as stainless or hard facing (see

instructions on container or MSDS) or on lead or

cadmium plated steel and other metals or coatings

which produce highly toxic fumes, keep exposure as

low as possible and below Threshold Limit Values (TLV)

using local exhaust or mechanical ventilation. In

confined spaces or in some circumstances, outdoors, a

respirator may be required. Additional precautions are

also required when welding on galvanized steel.

5.b. o not weld in locations near chlorinated hydrocarbon vapors

coming from degreasing, cleaning or spraying operations.

he heat and rays of the arc can react with solvent vapors to

form phosgene, a highly toxic gas, and other irritating products.

7.b. Always keep cylinders in an upright position securely

chained to an undercarriage or fixed support.

7.c. Cylinders should be located:

Away from areas where they may be struck or subected to

physical damage.

A safe distance from arc welding or cutting operations and

any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically hot parts to touch a cylinder.

7.e. eep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. alve protection caps should always be in place and hand

tight except when the cylinder is in use or connected for

use.

7.g. Read and follow the instructions on compressed gas

cylinders, associated euipment, and CA publication P-l,

Precautions for Safe andling of Compressed ases in

Cylinders, available from the Compressed as Association

1235 Jefferson avis ighway, Arlington, A 22202.

FOR ELECTRICALLY

powered equipment.

8.a. urn off input power using the disconnect

switch at the fuse box before working on

the euipment.

8.b. Install euipment in accordance with the .S. National

Electrical Code, all local codes and the manufacturers

recommendations.

8.c. round the euipment in accordance with the .S. National

Electrical Code and the manufacturers recommendations.

Mar 95

Das könnte Ihnen auch gefallen

- Welding SymbolsDokument21 SeitenWelding Symbolstuna61Noch keine Bewertungen

- Using Welding Inspection ToolsDokument9 SeitenUsing Welding Inspection Toolstuna61Noch keine Bewertungen

- Screw ChartDokument1 SeiteScrew Chartintoyou2007Noch keine Bewertungen

- 5-Plywoodplans Trestle TableDokument6 Seiten5-Plywoodplans Trestle Tabletuna61Noch keine Bewertungen

- Ana White - Entryway Bench and Storage Shelf With Hooks - 2017-12-08 PDFDokument10 SeitenAna White - Entryway Bench and Storage Shelf With Hooks - 2017-12-08 PDFtuna61Noch keine Bewertungen

- Understanding Cup WalkingDokument2 SeitenUnderstanding Cup Walkingtuna61Noch keine Bewertungen

- Nuance Power PDF Trial: Corner CupboardDokument26 SeitenNuance Power PDF Trial: Corner Cupboardtuna61Noch keine Bewertungen

- Lincoln GMAW Welding GuideDokument96 SeitenLincoln GMAW Welding GuideМич БјукенонNoch keine Bewertungen

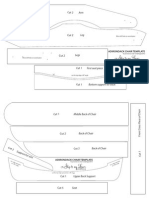

- Pushstick Template PDFDokument2 SeitenPushstick Template PDFtuna61Noch keine Bewertungen

- Adriondack Chair Template 2012Dokument2 SeitenAdriondack Chair Template 2012pocetnikNoch keine Bewertungen

- 3-Building A Picnic TableDokument9 Seiten3-Building A Picnic Tabletuna61Noch keine Bewertungen

- American RobinDokument1 SeiteAmerican Robintuna61Noch keine Bewertungen

- How To Read Welding GaugesDokument6 SeitenHow To Read Welding GaugesSaira ShahNoch keine Bewertungen

- PW3Dokument49 SeitenPW3Mujaffar ShaikhNoch keine Bewertungen

- Sample Continuity Report PDFDokument1 SeiteSample Continuity Report PDFtuna61Noch keine Bewertungen

- Pnumbers PDFDokument16 SeitenPnumbers PDFtuna61Noch keine Bewertungen

- P NumbersDokument16 SeitenP Numberstuna61Noch keine Bewertungen

- Tig Welding BookletDokument26 SeitenTig Welding Booklettuna610% (1)

- Best Welder PDFDokument6 SeitenBest Welder PDFtuna61100% (1)

- Miller TIG HandbookDokument20 SeitenMiller TIG Handbookquiron2010Noch keine Bewertungen

- R 4Dokument106 SeitenR 4tuna61Noch keine Bewertungen

- ALC 10029C AlcoTec Technical GuideDokument20 SeitenALC 10029C AlcoTec Technical Guidetuna61Noch keine Bewertungen

- Top Tips For Passing STDokument1 SeiteTop Tips For Passing STtuna61Noch keine Bewertungen

- Common GMAW Shielding Gases and Transfer Modes ChartDokument3 SeitenCommon GMAW Shielding Gases and Transfer Modes Charttuna61Noch keine Bewertungen

- User Inputs Cost Outputs: Fillet Weld Cost Analysis ToolDokument2 SeitenUser Inputs Cost Outputs: Fillet Weld Cost Analysis Tooltuna61Noch keine Bewertungen

- VT 1Dokument2 SeitenVT 1tuna61Noch keine Bewertungen

- Hastelloy C-2000 Welding Data: General InformationDokument1 SeiteHastelloy C-2000 Welding Data: General Informationtuna61Noch keine Bewertungen

- Test PlateDokument1 SeiteTest Platetuna61Noch keine Bewertungen

- Tig Welding BookletDokument26 SeitenTig Welding Booklettuna61Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- D-5 Track Maintenance Activities - Part 4Dokument35 SeitenD-5 Track Maintenance Activities - Part 4rajeshengasst89Noch keine Bewertungen

- Chapter 18Dokument12 SeitenChapter 18Dr. Firoze KhanNoch keine Bewertungen

- Healthcare Supply Chain in Novel Coronavirus (COVID-19) CrisisDokument31 SeitenHealthcare Supply Chain in Novel Coronavirus (COVID-19) CrisisMohd Yousuf MasoodNoch keine Bewertungen

- Mushoku Tensei 4,5,6Dokument634 SeitenMushoku Tensei 4,5,6duc thangNoch keine Bewertungen

- Indian Apparel Industry FundamentalsDokument101 SeitenIndian Apparel Industry FundamentalsRitika SharmaNoch keine Bewertungen

- 2.5 - Basics of Fabric Production (Knitting)Dokument8 Seiten2.5 - Basics of Fabric Production (Knitting)R G Panneerselvam100% (1)

- Truck and TrailerDokument1 SeiteTruck and TrailerAviects Avie JaroNoch keine Bewertungen

- Chapter 7Dokument15 SeitenChapter 7api-294209774Noch keine Bewertungen

- US English VocabularyDokument2 SeitenUS English VocabularyСеня Peach100% (1)

- Reinforcing MaterialsDokument114 SeitenReinforcing MaterialsSıdıka Sertkol KavuşNoch keine Bewertungen

- ITC Gardenia LavendreriaDokument6 SeitenITC Gardenia LavendreriaMuskan AgarwalNoch keine Bewertungen

- Background of The Industrial RevolutionDokument4 SeitenBackground of The Industrial RevolutionchetanashetyeNoch keine Bewertungen

- Operating TheatreDokument26 SeitenOperating TheatreStephen Pilar PortilloNoch keine Bewertungen

- Janome Memory Craft 200E Sewing Machine Instruction ManualDokument54 SeitenJanome Memory Craft 200E Sewing Machine Instruction ManualiliiexpugnansNoch keine Bewertungen

- The Mummy 1999Dokument239 SeitenThe Mummy 1999jvaloreNoch keine Bewertungen

- HVZ Award SubmissionDokument13 SeitenHVZ Award Submissionpresident4122Noch keine Bewertungen

- Crash (Film Script)Dokument52 SeitenCrash (Film Script)Maite GuelermanNoch keine Bewertungen

- The Bachelor, by Tilly Bagshawe - ExtractDokument22 SeitenThe Bachelor, by Tilly Bagshawe - ExtractAnonymous ikUR753amNoch keine Bewertungen

- ICDC Student GuideDokument45 SeitenICDC Student GuideBhavya HoodaNoch keine Bewertungen

- Gul Ahmed Summer Volume 2 2016Dokument99 SeitenGul Ahmed Summer Volume 2 2016Naeem Abbas BhattiNoch keine Bewertungen

- Đề Tiếng Anh 3 Smart Start - TEST Ck2Dokument5 SeitenĐề Tiếng Anh 3 Smart Start - TEST Ck2Huyền NgọcNoch keine Bewertungen

- Foam Latex Prosthetic Application GuideDokument16 SeitenFoam Latex Prosthetic Application GuidebaranovschiNoch keine Bewertungen

- Assisted Gowning & GlovingDokument12 SeitenAssisted Gowning & GlovingCarmina GurreaNoch keine Bewertungen

- 6,75 Over Easy - ENDokument3 Seiten6,75 Over Easy - ENsofia3015Noch keine Bewertungen

- Inferences Worksheet 5Dokument2 SeitenInferences Worksheet 5Alyssa LNoch keine Bewertungen

- Harry Potter - Poster DeconstructionDokument6 SeitenHarry Potter - Poster Deconstructiontina1238Noch keine Bewertungen

- Basketball England - National Basketball League Regulations 2014-15Dokument40 SeitenBasketball England - National Basketball League Regulations 2014-15JayNoch keine Bewertungen

- FeedbackDokument274 SeitenFeedbackDergosNoch keine Bewertungen

- Texas Roadhouse Menu GuideDokument39 SeitenTexas Roadhouse Menu GuideMark ViauNoch keine Bewertungen

- Jisung Hydrahulic Breaker Operation & Maintenance ManualDokument56 SeitenJisung Hydrahulic Breaker Operation & Maintenance ManualMilton Hernandez Pérez100% (4)