Beruflich Dokumente

Kultur Dokumente

The Optical Mouse Sensor As An Incremental Rotary Encoder

Hochgeladen von

Robert PetersonOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

The Optical Mouse Sensor As An Incremental Rotary Encoder

Hochgeladen von

Robert PetersonCopyright:

Verfügbare Formate

Sensors and Actuators A 155 (2009) 7381

Contents lists available at ScienceDirect

Sensors and Actuators A: Physical

journal homepage: www.elsevier.com/locate/sna

The optical mouse sensor as an incremental rotary encoder

M. Tresanchez, T. Pallej, M. Teixid, J. Palacn

Department of Computer Science and Industrial Engineering, Universitat de Lleida, Jaume II, 69, 25001 Lleida, Spain

a r t i c l e

i n f o

Article history:

Received 3 February 2009

Received in revised form 18 May 2009

Accepted 4 August 2009

Available online 8 August 2009

Keywords:

Optical mouse

Mouse sensor

Rotary encoder

Displacement sensor

a b s t r a c t

In this paper, a new application and capabilities of the sensor of the optical mouse are presented. An

inexpensive incremental rotary encoder is built based on a mechanical assembly where the sensor is at a

xed distance from a rotary white surface onto which a reference black line is drawn. The optical mouse

sensor measures changes in position by optically acquiring sequential surface images and mathematically

determining the direction and magnitude of movement. The optical sensor uses the information of the

images acquired and an attached light source in a closed control loop to keep an average illumination

level in the images. In this paper, the registers involved in this control loop are used to detect high

contrast marks without any dedicated image-processing procedure. The detection of this reference mark

in a rotary white surface allows the correction of long term cumulative errors originated in displacement

measurements performed by the optical sensor and enables the use of the rotary encoder in precision

measurements close to 1900 counts per revolution.

2009 Elsevier B.V. All rights reserved.

1. Introduction

The computer mouse, invented in 1964, has evolved from the

initial mechanical conguration based on wheels and a rotating

ball to the actual design based on optical sensors. The inexpensive

optical mouse sensor can be used specically as a displacement

sensor. In [1] the optical sensor is proposed and tested as a twodimensional displacement sensor over opaque objects when the

height offset does not exceed 1.25 mm. In [2] the optical sensor is

characterized as a motion sensor showing that limitations mainly

arise from the sensitivity of the device to the texture of the reference surface and the upper limit of the working speed. In [3],

the optical mouse sensor shows a very good coefcient of determination in a linear displacement over typical ground surfaces,

R2 = 0.9998, but a high dependence on the relative height of the

sensor with an error of 1% for an offset of 0.1 mm, and very bad

measurements in circular trajectories.

Despite these known problems, the optical mouse sensor has

been used in robotics to measure the displacement and trajectory of

a mobile robot [3,4]. In [59], several redundant optical sensors are

used to reduce the positioning error and eliminate measurement

outliers. In [9] an improvement of 26% in the measurement of the

speed is reported using two complementary sensors.

The optical mouse sensor can be used in other applications

where a kind of linear optical ow [10] is needed. In [11], the sensor is used to measure vibrations. In [12], it is used as a tracking

Corresponding author. Tel.: +34 973 702724; fax: +34 973 702702.

E-mail address: palacin@diei.udl.es (J. Palacn).

0924-4247/$ see front matter 2009 Elsevier B.V. All rights reserved.

doi:10.1016/j.sna.2009.08.003

device for surgical instruments in training setups. In [13], it is used

as a tracking device for small animals, in [14], to measure the solid

circulation rate in a circulating uidized bed and in [15] to classify

different types of materials and their surfaces as polished or milled.

Recently, in [16] the effects of illumination and acceleration on

the optical mouse sensor were analyzed using a laser-based sensor

(ADNS-6010). The results showed that acceleration and deceleration require a specic calibration when the sensor was used as

a precision measurement system. The results also showed a poor

correlation of the measurements of both axes and proved that this

correlation can be improved using additional light sources. We

agree with these results because the illumination obtained with a

standard LED is more diffuse and uniform than that obtained with

a laser-based LED (see Fig. 1).

In this paper, the optical mouse sensor is proposed as an inexpensive incremental rotary encoder. This application avoids the

most important problem associated with this optical sensor, its

strong sensitivity to height variations. In the encoder, the optical

sensor will be attached to the inner radial surface of a wheel to measure the displacement during a rotation with a known and xed

height, radius and measurement surface. Only one axis of the optical sensor is needed for the measurements while a reference mark

on the rotating surface will be used to count the number of revolutions, to correct cumulative errors in the displacement measured,

and for automatic internal calibration of the number of counts per

revolution (cpr) of the rotary encoder. The odometry in a low cost

mobile robot is the main design application of this device attached

or embedded in a caster or driving wheel although it could be used

in other inexpensive applications where a rotary measurement is

also needed.

74

M. Tresanchez et al. / Sensors and Actuators A 155 (2009) 7381

Fig. 1. Example of images obtained with two optical mouse sensors: LED-based

ADNS-3088 LED (left), laser-based ADNS-6010 (right).

bits data message. As an example, a low cost microprocessor such

as the PIC18F4550 working at 48 MHz requires 130 s to read one

register.

The ADNS-3088 provides read and write access to 31 internal

registers [17]. The relative displacement measured by the sensor

is obtained reading the MOTION, DELTA X, and DELTA Y registers.

The DELTA registers contain the accumulated relative displacement

since the last sensor reading (from 127 to 128). The MOTION register is 1 when any of the DELTA registers is different to zero and

can be used as a motion ag. The family of the ADNS-308X also

has other interesting registers, such as PIXEL BURST (values from

0 to 63) that allows sequential access (pixel by pixel) to the image

captured by the sensor, and SQUAL, SHUTTER, PIXELSUM that are

internal registers used to control the illumination of the area under

the sensor and will be explained later in the next section.

3. Detecting reference marks

Fig. 2. Sectional view of typical assembly of an optical mouse sensor (courtesy of

Avago).

The paper is structured as follows. Section 2 introduces the

working principle of the optical mouse sensor. Section 3 describes

the method proposed to detect reference marks. Section 4 describes

the implementation of the incremental rotary encoder. Section

5 shows the validation of the rotary encoder. Finally, Section 6

presents the nal conclusions.

2. Sensor description

The optical mouse sensor used in this paper is the ADNS-3088

[17] witch is an updated version of the versatile ADNS-3080 analyzed previously in [9]. The optical sensor includes a digital signal

processor (DSP) and a CMOS camera of 30 30 pixels on the same

chip. The optical mouse sensor is based on a very compact image

acquisition system with the following parts (Fig. 2): the main

sensor, an infrared light source (LED-based) that illuminates the

surface, and a convex lens that collects the reected light. All the

parts are mounted clipped in a base plane to keep the device very

close to the surface at a nominal distance of 2.4 mm.

The optical mouse sensor measures changes in position by

optically acquiring sequential surface images (frames) and mathematically determining the direction and magnitude of movement

at a very high rate (up to 6400 frames/s); the DSP detects small

variations in the roughness of the surface by means of the shadows created by the source light (see Fig. 1) that is also controlled

in a closed loop to maintain a constant illumination range in

the images acquired. According to the manufacturer specications, the maximum measurable speed is 40 in. per second (ips)

(1.016 m/s), the maximum acceleration during measurements is

15 g (147.15 m/s2 ) and the selectable resolutions are 400 and 800

counts per in. (cpi). The communication with the optical sensor is

performed by the standard SPI bus using an 8 bit address and 8

The optical sensor generates cumulative error in the measurements [1,4] even in the case of a placement at a xed height

and displacements parallel to its internal axis. This error can be

reduced by averaging a high number of sensors (10 or more) [3]

although this solution is not valid for a small and inexpensive rotary

encoder so, in this paper, we propose the inclusion of reference

marks on the rotary white surface screened by the optical sensor.

The detection of reference marks will enable the correction of the

displacement/rotation measured by the sensor although they will

require an initial calibration to establish the reference value of the

existing counts from mark to mark. In the case of a rotary encoder

the simplest mark is a radial black line (from the center to the outer

radius of the rotary surface). Once detected, the relative cumulated

value of the internal counters can be corrected with the reference

value corresponding to one revolution. The detection of the reference black line can be performed using two alternative methods:

reading the image acquired by the sensor and applying some imageprocessing algorithms or exploiting the information provided by

some additional internal registers involved in the control loop of

the illumination of the optical sensor.

The image acquired by the sensor can be read by repetitive

access to the PIXEL BURST register although this reading stops any

motion measurement and a long time is required to get the complete image using the SPI bus; 900 readings for a 30 30 image

(26 ms in SPI burst mode). The introduction of an internal image

buffer to allow complete image reading without stopping the sensor will enhance the development of unexpected new applications

of the optical mouse sensor [10]. As an alternative, some additional

internal registers as SQUAL, SHUTTER, and PIXELSUM offers average information of the internal status of the illumination control

loop and the image acquired by the sensor. These registers can be

read at any moment without disturbing the sensor and are candidates for indirect black-mark detection without reading the image

acquired by the sensor.

3.1. Detecting marks using SQUAL

The SQUAL register gives information about the changes (also

called features) detected in the image currently being analyzed.

This register is an indication of the roughness of the surface mea-

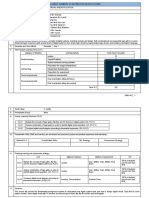

Table 1

Paper types analyzed.

Type

Size

Color

Manufacturer

Reference

Normal

Recycled

Adhesive

A4

A4

A4

White

White

White

International Paper

Evercopy Plus

Impega

70476

50048

00123

Weight

80 g/m2

80 g/m2

100 g/m2

SQUAL

Displacement

14 5

168 11

64 9

Bad (0)

OK

OK

M. Tresanchez et al. / Sensors and Actuators A 155 (2009) 7381

75

Fig. 3. Image of the experiment performed to evaluate the effect of one transversal

black line in some internal registers of the optical mouse sensor.

sured indirectly through the shadows enhanced by the lateral

illumination applied. The SQUAL register has values from 0 to 169;

a high value means that the image-processing algorithm used to

detect motion will have more points to compare and the motion

will be measured more accurately. As a reference, Table 1 shows

the value of the SQUAL register when placing the optical mouse

sensor over some standard paper for ofce use. The optical sensor does not work properly in the case of ne and reecting white

paper and, in general, SQUAL values greater than 30 ensure good

detection of the displacement.

Fig. 4 shows the dynamic evolution of the SQUAL register in a

forward displacement of the optical sensor (parallel to the y-axis)

over an adhesive white surface (see Table 1) with three transversal black lines, 1.2, 3.2 and 5.2 mm wide respectively, and elapsed

25.4 mm (1 in.) (Fig. 3); the lines where printed on a standard laser

printer. Fig. 4 shows that the SQUAL register has values from 50 to

68 for the white paper but has two positive peaks when the sensor

reaches the beginning and end of the lines and one or two negative

peaks depending on the width of the line. The number of features

detected varies very little in the white paper, increases suddenly in

the border of the lines, decreases suddenly when the line is completely under the sensor (the image becomes almost black and no

features are detected).

Fig. 4. Dynamic evolution of the SQUAL register when moving the optical mouse

sensor over white paper with three transversal black lines of width: 1.2, 3.2 and

5.2 mm, elapsed 25.4 mm.

Fig. 5. Dynamic evolution of the SHUTTER register when moving the optical mouse

sensor over white paper with three transversal black lines of width: 1.2, 3.2 and

5.2 mm, elapsed 25.4 mm.

3.2. Detecting marks using SHUTTER

The SHUTTER register is an indication of the intensity applied to

the LED, and then of the emitted light. When the image becomes

dark, an internal control loop increases the intensity applied to the

LED to keep an average illumination on the image. The SHUTTER has

16 bits of resolution and a high and a low register value; in each

step, the intensity applied to the LED changes 1/16. Fig. 5 shows

the dynamic evolution of the SHUTTER register when repeating the

displacement over the same surface and lines as in the previous

paragraph. Fig. 5 shows that the SHUTTER register has values from

20 to 25 for the white paper but increases to 40 for a width of

1.2 mm, 100 for a width of 3.2 mm and up to 270 for a width of

5.2 mm (see Fig. 3).

The results shown in Fig. 5 were obtained with a linear movement at a xed speed and the height of the peak is proportional

to the line width. Fig. 6 shows the minimum and maximum value

(peak) of the SHUTTER for a set of experiments with black lines of

different widths. The linear speed of the displacement was xed and

constant and lines were isolated with at least 20 mm of unmarked

white surface. The most interesting result is that the minimum

value is always the same (surface dependent) whereas the height

of the peak increases as the width of the line increases, although it

Fig. 6. Maximum and minimum value of the SHUTTER register for different line

widths.

76

M. Tresanchez et al. / Sensors and Actuators A 155 (2009) 7381

Fig. 7. Dynamic evolution of the PIXELSUM register when moving the optical mouse

sensor over white paper with three transversal black lines of width: 1.2, 3.2 and

5.2 mm, elapsed 25.4 mm.

saturates for widths greater than 7.6 mm. Therefore, an isolated line

wider than 2 mm can be easily detected by reading the SHUTTER

register and applying a threshold detection value of 60.

3.3. Detecting marks using PIXELSUM

The PIXELSUM register is the cumulative value of all the pixels of

the image currently analyzed by the sensor. The register has 8 bits

and its value must be multiplied by 256 to get the real value of the

cumulative addition of the 900 pixels in the image; its maximum

value is 221 (all pixels white). Fig. 7 shows the dynamic evolution

of the PIXELSUM register when repeating the displacement over

the same surface and lines as in the two previous paragraphs. Fig. 7

shows that the PIXELSUM register values range from 130 to 150 for

the white paper but decrease to 60 for a width of 1.2 mm, to 42 for

a width of 3.2 mm and 35 for a width of 5.2 mm (see Fig. 3). After

this initial negative peak, a positive peak up to 220 appears for the

width of 5.2 mm. This positive peak is originated by the internal

control loop of the camera that suddenly increases the intensity

of the LED to force the black line to appear almost white in the

image. Obviously, as the black line disappears from the image, the

PIXELSUM value also increases because the image is then too white.

Fig. 8 shows the maximum, average and minimum value of the

PIXELSUM register for a set of experiments with black lines of different widths. The linear speed of the displacement was xed and

constant (100 mm/s) and lines were isolated with at least 20 mm

Fig. 8. Maximum, average and minimum value of the PIXELSUM register for different line widths.

of unmarked white surface. Fig. 8 shows average values in a short

range, from 130 to 140. The maximum values correspond to the

height of the positive peak that saturates in its maximum allowable value (220) for lines wider than 5 mm. The minimum values

correspond to the height of the negative peak that saturates for

lines wider than 2 mm. Therefore, a threshold value of 120 applied

to the instantaneous value of PIXELSUM permits the detection of

lines up to 0.2 mm.

4. The incremental rotary encoder

The rotary encoder is based on a mechanical assembly (Fig. 9)

where the sensor is at a xed distance from a rotary surface covered

with an adhesive paper (see Table 1) onto which a reference black

line is drawn. In this implementation the y-axis of the optical sensor

is tangential to the center of the rotating surface.

The most important problem associated with the use of optical mouse sensors are the sensitivity to changes in the height and

the cumulative errors generated when measuring arbitrary motion

(displacements not parallel to any axis) [4]. The mechanical conguration of the rotary encoder solves the rst problem problems

because the optical sensor is placed at a xed height from the rotary

surface and minimizes the second because the orientation of the

y-axis is xed and tangential to the rotation of the surface.

A radial line printed on the white measurement surface analyzed by the optical sensor will be used as a reference to count

the number of turns and to correct cumulative error in the dis-

Fig. 9. Image (right) and drawing (left) of the parameters and parts of the rotary encoder.

M. Tresanchez et al. / Sensors and Actuators A 155 (2009) 7381

Fig. 10. Dynamic evolution of the SHUTTER, PIXELSUM and SQUAL registers when

moving the optical sensor linearly over white paper with three black lines of width:

1.2, 3.2 and 5.2 mm, elapsed 25.4 mm.

placement measured. From the design point of view, the design of

the rotary encoder has three different parameters that can be optimized (Fig. 9): the width of the reference line, w, the radius of the

placement of the sensor, r, and its relative height, h. However, other

parameters, such as the sensitivity to the orientation of the optical

sensor, , and the rotating speed, , need to be analyzed.

One of the most important parts of the proposed rotary encoder

is the procedure to detect the reference line. Fig. 10 compares the

evolution of the SHUTTER, PIXELSUM and SQUAL registers when

moving the optical sensor linearly over a white paper with three

black lines of width: 1.2, 3.3 and 5.2 mm (see Fig. 3). As can be

expected, the results in Fig. 10 indicate that PIXELSUM is an inputsensing variable in the internal camera control loop and SHUTTER is

an output reactive variable. The peak obtained with the SHUTTER

register is very clean but the peaks obtained with the PIXELSUM

register enable the detection of smaller lines and indicate more

clearly their beginning and ending location. Therefore, the PIXELSUM register will be used to detect the radial reference line on the

rotary white surface of the optical encoder.

The rst parameter analyzed is the radius of placement of the

sensor, r. The radius was measured with a precision of 0.05 mm

from the center of rotation of the wheel, established manually

with the images from the optical sensor (Fig. 11). Fig. 12 shows

the average counts per revolution (cpr) measured by the optical

sensor in 20 complete rotations (detected using the reference line

and the PIXELSUM register) in the y-axis (tangential to the rotation) and the x-axis (perpendicular) for both allowed resolutions of

the optical sensor, 400 and 800 cpi. The sensor was placed at the

recommended height (2.4 mm) and the angle of orientation of the

sensor, , was carefully adjusted to 0 (tangential to the rotation).

The angular speed was 15 revolutions per minute (rpm) throughout

the experiment.

Fig. 13 shows the standard deviation of the counts measured

in 20 turns over the y-axis for the different radii analyzed. The

standard deviation is slightly higher when doubling the resolution

of the optical sensor and is almost constant in a range from 8 to

77

Fig. 12. Average counts of both measurement axes in the allowed resolutions

depending on the placement radius of the sensor.

Fig. 13. Standard deviation of the counts measured in one complete turn over the

y-axis depending on the placement radius of the sensor.

12 mm, although the upper limit depends largely on the quality of

the mechanical device that holds the sensor over the surface of the

wheel, and which is more critical as size increases. Fig. 14 shows

the average relative error in the counts measured in one complete

turn compared with the analytical value obtained for both resolutions; 400 and 800 cpi. The relative error decreases as the radius of

curvature increases (the motion is focused on the y-axis) and can be

measured more easily by the optical sensor. According to the results

in Figs. 13 and 14, the placement radius of the optical mouse sensor must be in a range between 8 and 12 mm, with a coefcient of

determination in the counts measured, R2 , of 0.99991. These limits in the radius guarantee the development of small and compact

rotary encoders based on the optical mouse sensor.

Fig. 15 shows the histogram of the absolute error obtained in the

counts measured in one turn after 400 revolutions compared with

Fig. 11. Images from the ADNS-3088 used to locate the center of rotation of the wheel of the rotary encoder; the line has a width of 0.2 mm.

78

M. Tresanchez et al. / Sensors and Actuators A 155 (2009) 7381

Fig. 14. Relative error of the counts measured in one complete turn over the y-axis

depending on the placement radius of the sensor.

Fig. 15. Histograms of the absolute error obtained in the counts measured in one

turn at a xed angular speed of 15 rpm and the optical sensor placed at a radius of

10 mm for resolutions of 400 and 800 cpi.

the analytical value expected; the sensor was placed at a radius of

10 mm and the angular speed was 15 rpm. The standard deviation of

the measurements was 1.04 counts for 400 cpi and 1.70 counts for

800 cpi, that is the resolution nally chosen for the optical mouse

sensor of the rotary encoder because the resolution was improved

100% and the standard deviation of the measurements is only 62%

worse.

The second parameter analyzed is the sensitivity to the angular

speed, . Fig. 16 shows the counts measured in the y-axis for angu-

Fig. 16. Maximum, average and minimum counts measured in one complete turn

with the optical sensor placed at a radius of 10 mm.

Fig. 17. Standard deviation of the counts measured in one complete turn with the

optical sensor placed at a radius of 10 mm.

lar speeds from 5 to 100 rpm with the sensor placed at a radius of

10 mm, an angular orientation of 0 , and height of 2.4 mm. Fig. 16

shows that the average value measured decreases linearly with

speed, and the standard deviation of the measurements increases

linearly with speed (Fig. 17), although the average relative error in

the counts measured is always lower than 1.5%, which can be an

acceptable value in the context of inexpensive sensors.

There are no problems detecting the reference line in this speed

range. Fig. 18 shows the maximum, average and minimum values

of the register PIXELSUM, which are almost constant when using

a 0.2 mm wide line in a range of angular speed up to 100 rpm.

The results in Fig. 18 agree with the results also shown in Fig. 8,

therefore the detection of the reference line can be done at very

different angular speeds with a simple threshold in the values of

the PIXELSUM register. In theory, considering only the measurement limitations of the optical sensor, and the time spent reading

the PIXELSUM, DELTA X, and DELTA Y registers sequentially, the

maximum allowable speed when the sensor is placed at a radius

of 10 mm is 490 rpm, although the mechanical design of the rotary

encoder used in this paper did not allow this limit to be veried.

Fig. 19 repeats the previous experiment for line widths of 0.2,

1.2, and 2 mm (see Fig. 20) with the sensor placed at a radius of

Fig. 18. Maximum, average and minimum value of the PIXELSUM register for different angular speeds with the optical sensor placed at a radius of 10 mm.

M. Tresanchez et al. / Sensors and Actuators A 155 (2009) 7381

Fig. 19. Maximum, average and minimum counts measured in one complete turn

for different angular speeds with the optical sensor placed at a radius of 10 mm.

9.8, 10 and 10.2 mm. In all cases, the behavior is very similar; the

counts measured in one revolution slightly decreases as the speed

increases. The sensitivity to speed combined with the deviation of

the measurements precludes direct use of this rotary encoder in

applications where precision measurements are needed. However,

the reference line combined with an initial calibration of the rotary

encoder can be used to improve the precision of the measurements,

as stated in the validation section.

Another important factor in the design of the rotary encoder

is the sensitivity to errors in its angle of orientation, . Fig. 21

shows the average of the relative error in the counts measured in

one revolution depending on the angle of orientation of the sensor (0 corresponds to a perfect tangential orientation) obtained

with a 0.2 mm line, a radius of 10 mm and a xed angular speed

of 15 rpm. In general, the average relative error is below 1% for an

orientation in a range from 2.5 (to the center) to +1 . In his case,

this asymmetry is probably originated by the way that the optical ow algorithm implemented in the optical sensor averages the

displacement detected in the image. Fortunately, this error in the

orientation originates large displacement measurements in the xaxis and so can be automatically detected and corrected in an initial

mechanical calibration operation.

The last experiment of this section is used to conrm the sensitivity of the optical mouse sensor to changes in its relative height.

Starting at the height recommended by the manufacturer (2.4 mm),

Fig. 22 shows the average relative error in the counts measured in

one complete revolution depending on relative changes of height.

The experiment was performed with the optical sensor placed at a

radius of 10 mm and an angular speed of 15 rpm.

Fig. 22 shows that an offset of 0.3 mm in the height originates a

relative error in the measurements of 5.4%. Additionally, Fig. 23

shows the image of the reference line (0.2 mm) viewed by the opti-

79

Fig. 21. Average relative error in the counts measured in one complete turn for

different angles of orientation with the optical sensor placed at a radius of 10 mm.

Fig. 22. Average relative error in the counts measured in one complete turn for

different relative height offsets with the optical sensor placed at a radius of 10 mm.

cal sensor in the case of the recommended height and for an offset

of 1.2 mm where the sensor fails in the measurements.

5. Use and validation of the rotary encoder

The denitive design of the rotary encoder has a 100 mm-radius

wheel and the sensor placed at its recommended height at a radius

of 10 mm from the center of the wheel. The use of the rotary encoder

requires an initial calibration prior to any measurement operation.

As happens in the conventional mouse, it is supposed that the optical sensor will work with a dedicated microprocessor as a bridge to

Fig. 20. Lines of 0.2 (left), 1.2 (center) and 2 mm (right) viewed by the ADNS-3088.

80

M. Tresanchez et al. / Sensors and Actuators A 155 (2009) 7381

Fig. 23. Lines of 0.2 mm viewed by the ADNS-3088 at the nominal height (left) and

with a relative offset of 1.2 mm (right).

offer access to the internal registers and measurements provided

by the sensors using the RS232 or the USB buses available in most

computer and measurement equipment. This microprocessor can

be used to establish the initial calibration using dedicated selection

buttons (or bus commands) and to offer the results measured.

The initial calibration has two parts. The rst deals with the correction of the orientation of the sensor. This operation requires

the rotation of the wheel and is based on the distance measured

by the x-axis (or the axis radial to the center of the wheel). If the

orientation is correct then the values measured will have small positive and negative values and its cumulative value will be very low

in a complete turn (<100). Any sensor misalignment will produce

larger cumulative values as an indication that manual correction of

the orientation of the sensor is required. In normal operation, the

displacement measured along the x-axis can be checked to guarantee normal operation of the sensor and to remove measurement

outliers (none detected with the proposed measurement surface).

The second calibration deals with the automatic selection of the

counts per revolution of the sensor, which depends on its placement radius. This operation requires several rotations of the wheel

at a xed speed to obtain the average value of the counts per revolution. The average values obtained when the sensor is placed at a

radius of 10 mm are above 1900 cpr. This value is very large for an

encoder and, if desired, the microprocessor can be programmed to

offer always a xed proportional resolution, such as 100 cpr, with

a great reduction in the standard deviation of the counts offered

by the rotary encoder. In a mobile robot application where the

radius of the wheel is known, the internal microprocessor can be

programmed to convert the counts measured in relative or cumulative distance. Once calibrated, the rotary encoder will be ready

for normal operation. Then, the reference line can be used specifically as an index to count the rotations, but a more interesting

application is the correction of the cumulative counts measured by

the rotary encoder, that is, if an internal cumulative register says

that the counts measured in the last turn are 1932 but the calibration register is 1930; the cumulative displacement registers can be

corrected by subtracting 2 counts after detecting the reference line.

Fig. 24 shows the cumulative relative error in the counts measured by the rotary encoder in 200 revolutions at a xed angular

speed of 15 rpm. In this ideal case with xed speed, the relative

cumulative error computed by comparing the optical sensor raw

data with the corrected values (obtained by multiplying the number of turns by the number of counts obtained in the calibration)

rises very slowly (0.3% in 200 revolutions) and can be enough

in most inexpensive applications. This cumulative deviation will

be zero if the raw data are corrected with the calibration counts

every time the reference line is detected. Then, the error will only

appear in the raw data offered between two detections of the reference line. Additionally, the precision of the rotary encoder can be

improved signicantly just by adding more radial reference lines to

Fig. 24. Cumulative relative error in the counts measured by the rotary encoder

when compared with the expected value.

the adhesive surface used to detect the displacement, for example

8 lines instead of only one as used in this work.

Finally the last experiment was an extreme manual manipulation of the rotation of the rotary encoder; the orientation and

acceleration of the rotations were changed randomly and suddenly

to simulate the worst operational conditions (that do not correspond to a typical measurement application). The worst relative

error measured during one arbitrary partial rotation was below 1%

and this cumulative error was corrected after detecting the reference line.

6. Conclusions

In this paper, a new application for the optical mouse sensor as an incremental rotary encoder was presented. The main

sensitivity problems of these kind of inexpensive optical sensors

are: sensitivity to changes in height and cumulative error in the

motion measured in arbitrary trajectories. The use as part of a

rotary encoder minimizes these problems because the optical sensor is always at the same height, pointing to the same surface with

the same relative orientation (the measurement axis is always the

same). In such conditions, the coefcient of determination of the

displacement measured is very good, R2 = 0.99991.

The use of such additional available internal registers as SHUTTER, SQUAL, and PIXELSUM permits the detection of reference

marks in the rotating surface and then the correction of cumulative

errors in the displacement measured by the optical mouse sensor. A

radial line of 0.2 mm is detected at angular speeds up to 100 rpm by

applying a threshold values to the PIXELSUM register of the optical

sensor.

The sensitivity of the mechanical placement of the optical sensor

inside the rotary encoder was analyzed: the acceptable values for

an error of orientation of the sensor were from 2.5 to 1 , and

0.3 mm for the error in height of the sensor. The counts measured

by the rotary encoder were tested for different angular speeds with

an error lower than 1% in one revolution; this cumulative error is

reset to zero when detecting the radial line labelled in the rotating

surface.

A rotary encoder built using a rotary surface covered with a

granulated white adhesive paper and an optical mouse sensor

(ADNS-3088 at 800 cpi) placed at a xed radius of 10 mm and a

xed height of 2.4 mm enables the measurement of the angular

displacement with a resolution close to 1900 counts per revolution and the implementation of a procedure to correct cumulative

measurement errors originated by the optical sensor. This inexpen-

M. Tresanchez et al. / Sensors and Actuators A 155 (2009) 7381

sive rotary encoder was primarily designed for odometry in low

cost mobile robot applications but can be used in a wide range of

applications to measure rotation or displacement.

Acknowledgements

With the support of the Government of Catalonia (Comissionat

per a Universitats i Recerca, Departament dInnovaci, Universitats

i Empresa) and the European Social Fund.

References

[1] T.W. Ng, The optical mouse as a two-dimensional displacement sensor, Sens.

Actuators A SA107 (2003) 2125.

[2] U. Minoni, A. Signorini, Low-cost optical motion sensor: an experimental characterization, Sens. Actuators A SA128 (2006) 402408.

[3] J. Palacin, I. Valganon, R. Pernia, The optical mouse for indoor mobile robot

odometry measurement, Sens. Actuators A SA126 (2006) 141147.

[4] J.A. Cooney, W.L. Xu, G. Bright, Visual dead-reckoning for motion control of a mecanum-wheeled mobile robot, Mechatronics M14 (2004) 623

637.

[5] S. Lee, Mobile robot localization using optical mice, in: IEEE Int. Conf. Robotics,

Automation and Mechatronics, Singapore, December 13, vol. 2, 2004, pp.

11921197.

[6] D. Sekimori, F. Miyazaki, Self-localization for indoor mobile robots based on

optical mouse sensor values and simple global camera information, in: IEEE

Int. Conf. Robotics and Biomimetics, Hong Kong and Macau, June 29July 3,

2005, pp. 605610.

[7] A. Bonarini, M. Matteucci, M. Restelli, Automatic error detection and reduction

for an odometric sensor based on two optical mice, in: IEEE Int. Conf. Robotics

and Automation, Barcelona, Spain, April 1822, 2005, pp. 16751680.

[8] J. Hu, Y. Chang, Y. Hsu, Calibration and on-line data selection of multiple optical

ow sensors for mobile robot localization, in: IEEE Int. Conf. Intelligent Robots

and Systems, Nice, France, September 2226, 2008, pp. 987992.

[9] S. Kim, S. Lee, Robust mobile robot velocity estimation using redundant number of optical mice, in: IEEE Int. Conf. Information and Automation, Zhangjiaje,

China, June 2023, 2008, pp. 107112.

[10] S. Hengstler, H. Aghajan, MeshEye: a hybrid-resolution smart camera mote for

applications in distributed intelligent surveillance, in: 6th Int. Symp. Information Processing in Sensor Networks, Cambridge, MA, April 2527, 2007, pp.

360369.

81

[11] T.W. Ng, K.T. Ang, The optical mouse for vibratory motion sensing, Sens. Actuators A SA-116 (2004) 205208.

[12] M.K. Chmarra, N.H. Bakker, C.A. Grimbergen, J. Dankelman, TrEndo, a device

for tracking minimally invasive surgical instruments in training setups, Sens.

Actuators A SA126 (2006) 328334.

[13] G.K. Lott, M.J. Rosen, R.R. Hoy, An inexpensive sub-millisecond system for

walking measurements of small animals based on optical computer mouse

technology, J. Neurosci. Methods JNM-161 (2007) 5561.

[14] S. Matsuda, Measurement of solid circulation rate in a circulating uidized bed,

Powder Technol. PT-187 (2008) 200204.

[15] N.N.A. Charniya, S.V. Dudul, Sensor for classication of material type and its

surface properties using radial basis networks, IEEE Sens. J. SJ-8 (2008) 1981

1991.

[16] N.N.A. Charniya, S.V. Dudul, Investigations into the effects of illumination and

acceleration on optical mouse sensors as contact-free 2D measurement devices,

Sens. Actuators A SA-149 (2009) 8792.

[17] Avago, ADNS-3080 and ADNS-3088 High Performance Optical Mouse Sensor,

http://www.avagotech.com (2008).

Biographies

Marcel Tresanchez received the BSc and MSc degrees in engineering from the University of Lleida (UdL), Spain in 2005 and 2007, respectively. He is currently a Ph.D.

student in the robotics laboratory of the UdL and his research interests include

mobile robots, precision agriculture and the educational application of robotics.

Tomas Palleja received the BSc and MSc degrees in engineering from the University of Lleida (UdL), Spain in 2004 and 2006, respectively. He is currently a Ph.D.

student in the robotics laboratory of the UdL and his research interests include precision agriculture, mobile robots, human system interaction and the educational

application of robotics.

Merce Teixido received the BSc and MSc degrees in engineering from the University

of Lleida (UdL), Spain in 2006 and 2008, respectively. She is currently a Ph.D. student in the robotics laboratory of the UdL and her research interests include human

computer interaction, avatar modeling and the educational application of robotics.

Jordi Palacin received the BSc and MSc degrees in electronics from the Polytechnic

University of Catalonia in 1990 and University of Barcelona (UB), Spain in 1997. He

received the Ph.D. degree in electronics from the UB in 2005. In 1992, he joined the

Department of Computer Science and Industrial Engineering at the University of

Lleida (UdL), Spain leading the robotics group. His research area involves compact

modeling, data fusion and signal processing applications in robotics.

Das könnte Ihnen auch gefallen

- A Study of An Optical Mouse To Customize Ii For Implementation of Wireless Draw PenDokument3 SeitenA Study of An Optical Mouse To Customize Ii For Implementation of Wireless Draw PenEditor IJRITCCNoch keine Bewertungen

- K5-Nota Kuliah OSHADokument9 SeitenK5-Nota Kuliah OSHAMuhamad Ismail Mohd JamilNoch keine Bewertungen

- JKR 4.4 TABC - Air Cooled Package SystemDokument22 SeitenJKR 4.4 TABC - Air Cooled Package SystemAniq AimanNoch keine Bewertungen

- Engineering Metrology & Measurements NotesDokument48 SeitenEngineering Metrology & Measurements NotesJeevanandam Shanmuga100% (1)

- SolutionChap32 PDFDokument25 SeitenSolutionChap32 PDFChai Usajai Usajai100% (1)

- Kertas Penerangan FullDokument50 SeitenKertas Penerangan FullPAUL KENNY TSHONGNoch keine Bewertungen

- Course Outline - DEA 2313Dokument11 SeitenCourse Outline - DEA 2313Roger JohnNoch keine Bewertungen

- Course Outline: Perancangan KursusDokument8 SeitenCourse Outline: Perancangan KursusAnonymous V76nXvDAGNoch keine Bewertungen

- KSKV SVM 2017: SMAW 1 Course InformationDokument20 SeitenKSKV SVM 2017: SMAW 1 Course InformationNurun NazirahNoch keine Bewertungen

- Nota Kuliah (4) PREPARE PRODUCT REPORTDokument26 SeitenNota Kuliah (4) PREPARE PRODUCT REPORTAdrian SamuelNoch keine Bewertungen

- Nota Praktikal 5 (Inspect - Testing) - EditDokument11 SeitenNota Praktikal 5 (Inspect - Testing) - EditMuhammad Ilyasak Abdul HalimNoch keine Bewertungen

- Choosing the Correct SensorDokument11 SeitenChoosing the Correct Sensorkarim mohamedNoch keine Bewertungen

- Smart Helmet Alcohol Detection and Sleep AlertDokument4 SeitenSmart Helmet Alcohol Detection and Sleep AlertEditor IJTSRDNoch keine Bewertungen

- Perform basic robot control (40/40Dokument5 SeitenPerform basic robot control (40/40Walid FarHanNoch keine Bewertungen

- Lab Sheet Teknologi Elektrik No 1-Rev1Dokument11 SeitenLab Sheet Teknologi Elektrik No 1-Rev1semi2542Noch keine Bewertungen

- MC-091 L3 KK 1 6Dokument6 SeitenMC-091 L3 KK 1 6bmrajahNoch keine Bewertungen

- Soalan Ujian HidraulikDokument9 SeitenSoalan Ujian HidraulikDilla AfzanNoch keine Bewertungen

- Mobile Air Conditioner ManualDokument18 SeitenMobile Air Conditioner Manualmalaikat maut100% (1)

- ElbaDokument17 SeitenElbacathytingNoch keine Bewertungen

- RSL Etn 2023Dokument3 SeitenRSL Etn 2023Masila IsmailNoch keine Bewertungen

- Tajuk PSM Sem1 1011Dokument28 SeitenTajuk PSM Sem1 1011khairul_husniNoch keine Bewertungen

- Kertas Penerangan C01Dokument14 SeitenKertas Penerangan C01AngelinaNoch keine Bewertungen

- Skills Competition (Mechatronics)Dokument13 SeitenSkills Competition (Mechatronics)Putri Chairany100% (1)

- Practical Test 1 k4Dokument5 SeitenPractical Test 1 k4Vicea NurrNoch keine Bewertungen

- A) Discuss How Student Can Plan For A Successful Laboratory Assignment SubmissionDokument2 SeitenA) Discuss How Student Can Plan For A Successful Laboratory Assignment SubmissionNazhan HakeemNoch keine Bewertungen

- K1-Nota Kuliah OSHADokument8 SeitenK1-Nota Kuliah OSHAMuhamad Ismail Mohd JamilNoch keine Bewertungen

- Cara Import Meteo Data From Different SourceDokument4 SeitenCara Import Meteo Data From Different SourceKania ZahrawatiNoch keine Bewertungen

- PMMC & Moving IronDokument51 SeitenPMMC & Moving IronNiladri DeyNoch keine Bewertungen

- Lukisan Kejuruteraan ReportDokument18 SeitenLukisan Kejuruteraan Reportaq laparNoch keine Bewertungen

- Jadual Peratusan Masa C02 6.8Dokument6 SeitenJadual Peratusan Masa C02 6.8Cucu MaAtok MeseiryNoch keine Bewertungen

- Industrial AC MotorsDokument86 SeitenIndustrial AC Motorsandry wibowoNoch keine Bewertungen

- Pseudocode Methods for Parking Charges, Exponentiation, Temperature Conversion and MoreDokument1 SeitePseudocode Methods for Parking Charges, Exponentiation, Temperature Conversion and MoreALan d'ToDz CRewNoch keine Bewertungen

- Sistem PenggeraDokument35 SeitenSistem PenggeraThinesNoch keine Bewertungen

- Electronics Programme Structure Vocational College MalaysiaDokument2 SeitenElectronics Programme Structure Vocational College MalaysiaNoradawiyah AzmanNoch keine Bewertungen

- Latihan JedaDokument9 SeitenLatihan JedaRizal MaslahNoch keine Bewertungen

- Tensile Test AnalysisDokument8 SeitenTensile Test AnalysisNazmul HasanNoch keine Bewertungen

- 3.syllabus Deb 1133Dokument7 Seiten3.syllabus Deb 1133AngelinaNoch keine Bewertungen

- Cover Page - PHY094 Entrepreneurial Mindset Assignment - StudentDokument2 SeitenCover Page - PHY094 Entrepreneurial Mindset Assignment - StudentApik YaaNoch keine Bewertungen

- KSKV Etn1013 - Electronic Schematic DrawingDokument12 SeitenKSKV Etn1013 - Electronic Schematic DrawingNur Hafizah RazaliNoch keine Bewertungen

- Mechanical Engineering Department: Djj3053 - Engineering Mechanics Lab: Velocity and AccelerationDokument8 SeitenMechanical Engineering Department: Djj3053 - Engineering Mechanics Lab: Velocity and AccelerationMuhd AriffNoch keine Bewertungen

- Chapter 1 - Aircond & VentilationDokument54 SeitenChapter 1 - Aircond & Ventilationepy87Noch keine Bewertungen

- Trolley Turning and Lifting Mechanism: Ayneendra B, Mohd Salman, Jimmy Thaddeus Ojyok Attari, Marvan EDokument8 SeitenTrolley Turning and Lifting Mechanism: Ayneendra B, Mohd Salman, Jimmy Thaddeus Ojyok Attari, Marvan ERahul PrasadNoch keine Bewertungen

- 4.syllabus - Deb1143 - Digital Electronic and ApplicationDokument7 Seiten4.syllabus - Deb1143 - Digital Electronic and ApplicationadibNoch keine Bewertungen

- PT326-Round2 Expt3 Batch19Dokument6 SeitenPT326-Round2 Expt3 Batch19Radhey MeenaNoch keine Bewertungen

- P.praktikal - Kertas Untuk Jawapan Amali (Power Supply)Dokument15 SeitenP.praktikal - Kertas Untuk Jawapan Amali (Power Supply)Angelina100% (1)

- Introducing Science Daily Lesson PlansDokument27 SeitenIntroducing Science Daily Lesson PlansaldruzzNoch keine Bewertungen

- Silibus Sem 1 - Sem 3 A17Dokument139 SeitenSilibus Sem 1 - Sem 3 A17Hariq Hann0% (1)

- Mechatronic Course OutlineDokument8 SeitenMechatronic Course OutlineAnonymous V76nXvDAGNoch keine Bewertungen

- Lab Sheet Dea 2342 - 1Dokument6 SeitenLab Sheet Dea 2342 - 1Kero Malek100% (1)

- Lab Sheet 5 - Lukisan Mesin Elektrik - 2Dokument8 SeitenLab Sheet 5 - Lukisan Mesin Elektrik - 2Amirul WanNoch keine Bewertungen

- Solar Electric Fencing System Protects CropsDokument18 SeitenSolar Electric Fencing System Protects Cropsshivani jadhavNoch keine Bewertungen

- Pelan Mengajar (Amali) : Institut Wawasan, 50 & 50A, Lorong Semarak 1, Taman Semarak, 09000 KULIM, Kedah Darul AmanDokument5 SeitenPelan Mengajar (Amali) : Institut Wawasan, 50 & 50A, Lorong Semarak 1, Taman Semarak, 09000 KULIM, Kedah Darul AmanEllyYanaNoch keine Bewertungen

- Tudung Saji InovasiDokument4 SeitenTudung Saji InovasiAly Rajaie Anna RusliNoch keine Bewertungen

- Kertas Penerangan 2Dokument35 SeitenKertas Penerangan 2zamreeharunNoch keine Bewertungen

- TJJWDokument57 SeitenTJJWAdam MusavvirNoch keine Bewertungen

- Rancangan Pengajaran Kolej VokasionalDokument22 SeitenRancangan Pengajaran Kolej VokasionalAizi ElegantNoch keine Bewertungen

- Stick Blind ManDokument4 SeitenStick Blind ManجعفرالشموسيNoch keine Bewertungen

- Accurate Real Time Altitude Estimation PDFDokument5 SeitenAccurate Real Time Altitude Estimation PDFMartin Manullang100% (1)

- Cavallo 2014Dokument7 SeitenCavallo 2014Trần Hoàng LâmNoch keine Bewertungen

- Intelligent Active Range Sensor for Vehicle GuidanceDokument8 SeitenIntelligent Active Range Sensor for Vehicle GuidanceUtsav V ByndoorNoch keine Bewertungen

- Introduction and Overview - Probabilistic Graphical ModelsDokument15 SeitenIntroduction and Overview - Probabilistic Graphical ModelsRobert PetersonNoch keine Bewertungen

- Characterization of A Low-Cost Optical Flow Sensor When Using An External Laser As A Direct Illumination SourceDokument15 SeitenCharacterization of A Low-Cost Optical Flow Sensor When Using An External Laser As A Direct Illumination SourceRobert PetersonNoch keine Bewertungen

- Statistical Shape Modeling of The Left Ventricle: Myocardial Infarct Classification ChallengeDokument13 SeitenStatistical Shape Modeling of The Left Ventricle: Myocardial Infarct Classification ChallengeRobert PetersonNoch keine Bewertungen

- Optimizing Neural Networks That Generate ImagesDokument120 SeitenOptimizing Neural Networks That Generate ImagesRobert PetersonNoch keine Bewertungen

- Optimizing Neural Networks That Generate ImagesDokument120 SeitenOptimizing Neural Networks That Generate ImagesRobert PetersonNoch keine Bewertungen

- Infarct Localization From Myocardial DeformationDokument13 SeitenInfarct Localization From Myocardial DeformationRobert PetersonNoch keine Bewertungen

- 1511 06434 PDFDokument16 Seiten1511 06434 PDFTote123456789Noch keine Bewertungen

- Bimodal Assessment of Laparoscopic Suturing SkillsDokument5 SeitenBimodal Assessment of Laparoscopic Suturing SkillsRobert PetersonNoch keine Bewertungen

- Using Cine MR Images To Evaluate Myocardial Infarct Trasnmurality On Delayed Enhancement ImagesDokument4 SeitenUsing Cine MR Images To Evaluate Myocardial Infarct Trasnmurality On Delayed Enhancement ImagesRobert PetersonNoch keine Bewertungen

- A Study of Psychomotor Skills in Minimally Invasive Surgery - What Differentiates Expert and Nonexpert PerformanceDokument10 SeitenA Study of Psychomotor Skills in Minimally Invasive Surgery - What Differentiates Expert and Nonexpert PerformanceRobert PetersonNoch keine Bewertungen

- Assessment of Laparoscopic Suturing Skills of Urology Residents - A Pan-European StudyDokument9 SeitenAssessment of Laparoscopic Suturing Skills of Urology Residents - A Pan-European StudyRobert PetersonNoch keine Bewertungen

- LR1V Linear Regression with One VariableDokument3 SeitenLR1V Linear Regression with One VariableRobert PetersonNoch keine Bewertungen

- Objective Classification of Residents Based On Their Psychomotor Laparoscopic SkillsDokument9 SeitenObjective Classification of Residents Based On Their Psychomotor Laparoscopic SkillsRobert PetersonNoch keine Bewertungen

- Relevance of Motion-Related Assessment Metrics in Laparoscopic SurgeryDokument16 SeitenRelevance of Motion-Related Assessment Metrics in Laparoscopic SurgeryRobert PetersonNoch keine Bewertungen

- How To Objectively Classify Residents Based On Their Psychomotor Laparoscopic SkillsDokument11 SeitenHow To Objectively Classify Residents Based On Their Psychomotor Laparoscopic SkillsRobert PetersonNoch keine Bewertungen

- EU-rapport 'On Ageing 2015'Dokument436 SeitenEU-rapport 'On Ageing 2015'pensiontalkNoch keine Bewertungen

- Robust Statistics For Outlier Detection (Peter J. Rousseeuw and Mia Hubert)Dokument8 SeitenRobust Statistics For Outlier Detection (Peter J. Rousseeuw and Mia Hubert)Robert PetersonNoch keine Bewertungen

- Segmentation and Tracking The Left Ventricle by Learning The Dynamics in Cardiac ImagesDokument16 SeitenSegmentation and Tracking The Left Ventricle by Learning The Dynamics in Cardiac ImagesRobert PetersonNoch keine Bewertungen

- A Home Sleep Apnea Screening DeviceDokument9 SeitenA Home Sleep Apnea Screening DeviceRobert PetersonNoch keine Bewertungen

- Scale-Invariant Isotropy of An Optical Mouse Array For Mobile Robot Velocity EstimationDokument5 SeitenScale-Invariant Isotropy of An Optical Mouse Array For Mobile Robot Velocity EstimationRobert PetersonNoch keine Bewertungen

- Tracking DevicesDokument23 SeitenTracking DevicesRobert PetersonNoch keine Bewertungen

- The Gamer's Soul Never DiesDokument6 SeitenThe Gamer's Soul Never DiesRobert PetersonNoch keine Bewertungen

- Long Range Measurements Using A Contactless Low Cost Optical SensorDokument6 SeitenLong Range Measurements Using A Contactless Low Cost Optical SensorRobert PetersonNoch keine Bewertungen

- A Laparoscopic Surgery Training InterfaceDokument7 SeitenA Laparoscopic Surgery Training InterfaceRobert PetersonNoch keine Bewertungen

- SoM A Smart Sensor For Human Activity Monitoring and Assisted Healthy AgeingDokument8 SeitenSoM A Smart Sensor For Human Activity Monitoring and Assisted Healthy AgeingRobert PetersonNoch keine Bewertungen

- Bioelectrical Impedance Analysis-Part I Review of Principle and MethodsDokument18 SeitenBioelectrical Impedance Analysis-Part I Review of Principle and MethodslayzarleskaNoch keine Bewertungen

- Using The Image Acquisition Capabilities of The Optical Mouse Sensor To Build An Absolute Rotary EncoderDokument7 SeitenUsing The Image Acquisition Capabilities of The Optical Mouse Sensor To Build An Absolute Rotary EncoderRobert Peterson100% (1)

- Collaborative Networks Approach To Active AgeingDokument8 SeitenCollaborative Networks Approach To Active AgeingRobert PetersonNoch keine Bewertungen

- INDIAMART 25012022003631 Investor Presentation Q3FY2021-22Dokument84 SeitenINDIAMART 25012022003631 Investor Presentation Q3FY2021-22geethvazNoch keine Bewertungen

- CH06 Binding MaterialsDokument114 SeitenCH06 Binding MaterialsAbass AwalehNoch keine Bewertungen

- ZetaPlus EXT SP Series CDokument5 SeitenZetaPlus EXT SP Series Cgeorgadam1983Noch keine Bewertungen

- Batangas State University - Testing and Admission OfficeDokument2 SeitenBatangas State University - Testing and Admission OfficeDolly Manalo100% (1)

- Blasting 001 Abb WarehouseDokument2 SeitenBlasting 001 Abb WarehouseferielvpkNoch keine Bewertungen

- Oracle Fusion Middleware: CloningDokument25 SeitenOracle Fusion Middleware: CloningSwathiPatluriNoch keine Bewertungen

- VR 2200 CatalogueDokument4 SeitenVR 2200 Catalogueh.torabyNoch keine Bewertungen

- An Evaluation of Maglev Technology and Its Comparison With High Speed Rail PDFDokument20 SeitenAn Evaluation of Maglev Technology and Its Comparison With High Speed Rail PDFJohanFaqar ZainNoch keine Bewertungen

- ASTM 3950 Testing Methods For Strapping Versie 2007 211007 PDFDokument7 SeitenASTM 3950 Testing Methods For Strapping Versie 2007 211007 PDFNestor CzerwackiNoch keine Bewertungen

- Installation and Operating Instructions Gen-Key: Energy DivisionDokument22 SeitenInstallation and Operating Instructions Gen-Key: Energy DivisionAnonymous RcxX0FcNoch keine Bewertungen

- Tectonics, Vol. 8, NO. 5, PAGES 1015-1036, October 1989Dokument22 SeitenTectonics, Vol. 8, NO. 5, PAGES 1015-1036, October 1989atoinsepeNoch keine Bewertungen

- Pressure Vessel Components and MaterialsDokument30 SeitenPressure Vessel Components and MaterialsFirst UserNoch keine Bewertungen

- The Remains of The Day-Excerpts-1Dokument2 SeitenThe Remains of The Day-Excerpts-1DajanaNoch keine Bewertungen

- Sample Format PDFDokument5 SeitenSample Format PDFRhod R. AvisoNoch keine Bewertungen

- Filipino Catholic Wedding Ceremony LiturgyDokument8 SeitenFilipino Catholic Wedding Ceremony LiturgyHoney Joy ChuaNoch keine Bewertungen

- Checking battery control unitDokument3 SeitenChecking battery control unitjuanNoch keine Bewertungen

- IT Department - JdsDokument2 SeitenIT Department - JdsShahid NadeemNoch keine Bewertungen

- Odoo Video Conference User GuidesDokument12 SeitenOdoo Video Conference User GuidesZeus TitanNoch keine Bewertungen

- Hunch or Reason?: Reading File 11Dokument2 SeitenHunch or Reason?: Reading File 11georgiana dinuNoch keine Bewertungen

- ADJECTIVES ENDING IN Ing and EdDokument1 SeiteADJECTIVES ENDING IN Ing and EdRafael FloresNoch keine Bewertungen

- Vaiana Et Al (2021)Dokument11 SeitenVaiana Et Al (2021)Raffaele CapuanoNoch keine Bewertungen

- Guide To Program EVK1100 With AVR32studioDokument2 SeitenGuide To Program EVK1100 With AVR32studioRobert T. WursterNoch keine Bewertungen

- Manual Lift Release System: Parts List and DiagramsDokument4 SeitenManual Lift Release System: Parts List and DiagramsPartagon PowNoch keine Bewertungen

- MTH101 Practice Qs Solutions Lectures 1 To 22 PDFDokument50 SeitenMTH101 Practice Qs Solutions Lectures 1 To 22 PDFRubab Babar75% (4)

- SPXDokument6 SeitenSPXapi-3700460Noch keine Bewertungen

- Communication Thesis PDFDokument2 SeitenCommunication Thesis PDFBarbara0% (2)

- Baroque MusicDokument15 SeitenBaroque Musicthot777100% (2)

- Special Functions of Signal ProcessingDokument7 SeitenSpecial Functions of Signal ProcessingSaddat ShamsuddinNoch keine Bewertungen

- Symbolic Calculus Sage ReferenceDokument25 SeitenSymbolic Calculus Sage ReferenceLn Amitav BiswasNoch keine Bewertungen

- Deepali Bhartiya: TCI Express Limited Gurgaon Assistant Manager Prateek Group Noida Senior ExecutiveDokument3 SeitenDeepali Bhartiya: TCI Express Limited Gurgaon Assistant Manager Prateek Group Noida Senior ExecutiveThe Cultural CommitteeNoch keine Bewertungen