Beruflich Dokumente

Kultur Dokumente

Tree Air

Hochgeladen von

gari_monsantoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tree Air

Hochgeladen von

gari_monsantoCopyright:

Verfügbare Formate

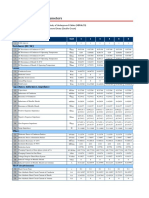

TECHNICAL DATA SHEET

AWG No 3/0 ACSR TREE WIRE (Item Code 002839)

BIDDER

MERALCO

REQUIRED

TENDERED

Phelps Dodge Philippines Energy

Products Corporation

Philippines

Manufacturer

Country of Origin

1. SCOPE

1. Cable type

2. Size

Concentric-lay-stranded ACSR

AWG No. 3/0

Concentric-lay-stranded ACSR

AWG No. 3/0

3. Application

For use as overhead electrical conductor in

34.5 kV system

For use as overhead electrical

conductor in 34.5 kV system

1. Complete Cable

as per ASTM B 232

as per ASTM B 232

2. Aluminum Conductor

as per ASTM B 230

as per ASTM B 230

ASTM B 498

ASTM B 498

2. STANDARDS

Steel Core

Jacket

ASTM D 1248

ASTM D 1248

Insulation

ASTM D 2656

ASTM D 2656

Thermoplastic-Insulated Wire and Cable

ICEA S-61-402, NEMA WC5

ICEA S-61-402, NEMA WC5

Aluminum 1350-H19 round wire for electrical

purposes

round zinc-coated

Class A per ASTM B 232

Aluminum 1350-H19 round wire for

electrical purposes

round zinc-coated

Class A per ASTM B 232

1. No joints of any kind shall be made in the finished

zinc- coated steel wire

Yes

Yes

2. Method of weld made, if ever, in the finished

individual aluminum wires composing the conductor

during stranding process shall be electric-butt

welds, cold- pressure welds, or cold-upset welds.

Yes

Yes

No weld made within 50 ft of a weld in the same

wire or in any other wire of the completed conductor

Yes

Yes

Concentric

Concentric

12

13

14.5

right hand

12

13

14.5

right hand

3. CONSTRUCTION

1. Conductor Material

1. Conductor

Steel Core

2. Conductor Classification

2. Joints

3. Lay

1. Conductor Lay

2. Lay Factor for aluminum wire layers

a. First Layer (Outside)

1) Minimum

2) Preferred

3) Maximum

3. Direction of Lay of the outside layer of aluminum

wire

BIDDER

MERALCO

REQUIRED

4. Physical Construction and Strength

a. Aluminum Conductor Area, mm

b. Aluminum conductor

1) No. of Strands

2) Strand Diameter, mm

c. Steel Core

1) No. of Strands

2) Strand Diameter, mm

d. Rated Strength, kN

5. Resistivity & Density

1. Aluminum Wire Resistivity, -mm/m (-cmil/ft)

2. Aluminum Wire Density, kg/m (lb/in)

6. Minimum Aluminum Cross-Sectional Area, mm

7. Covering

1. Insulation

TENDERED

85

85

6

4.25

6

4.25

1

4.25

29.4

1

4.25

29.4

0.028265 (17.002)

2705 (0.0975)

83.3

0.028265 (17.002)

2705 (0.0975)

83.3

Yes

Yes

3.175 (125)

2.858 (113)

3.175 (125)

2.858 (113)

Yes

Yes

3.175 (125)

2.858 (113)

3.175 (125)

2.858 (113)

Yes

Yes

1. Manufacturer's name and trademark

Yes

Yes

2. Year of manufacture

Yes

Yes

3. The words "MERALCO TREE WIRE"

Yes

Yes

4. Size of conductor

Yes

Yes

5. Voltage Application

Yes

Yes

1. XLPE with unaged and age physical properties

as per ASTM D 2656

2. Average insulation thickness, mm (mils)

Minimum insulation thickness, mm (mils)

2. Jacket

1. Jacket shall be high-density black polyethylene

(HDPE) Type III, Class C, Category 5, Grade

J5, track resistant, sunlight resistant, and

weather resistant as per ASTM D 1248

2. Average jacket thickness, mm (mils)

Minimum jacket thickness, mm (mils)

4. CABLE IDENTIFICATION

1. Jacket shall have identifying marking stamped legibly in

white indelible ink at approximately 60cm intervals along

oneline throughout the entire length of cable with

unmarked section not exceeding 15cm.

Markings shall contain the following Information:

BIDDER

MERALCO

REQUIRED

TENDERED

5. TESTS

1. Mechanical and electrical properties of aluminum and

zinc coated steel wires before stranding

a. Aluminum wires as per ASTM B 230

Yes

Yes

Yes

Yes

Yes

Yes

3. A.C. withstand test as per Section 5.3 of Meralco EMDM-ST-DES-120.05

6. INSPECTION

Yes

Yes

Manufacturer to furnish MERALCO with two (2) certified

copies of test results.

7. PACKAGING AND PACKAGE MARKING

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

1430

Yes

1430

Yes

Yes

Yes

b. Zinc-coated steel wires as per ASTM B 498

2. All wires composing the conductors shall meet the

bending properties as per ASTM B 230 after stranding

1. Complete conductor shall be pack as follows:

1. Non-returnable treated wooden reels as per

MERALCO Drawing No. E-631-A

2. At least 0.5 meters of the inner end of wire shall

protude for the reel hub

3. A pointed arrow at the side of the reel shall indicate

the position of the outer end of the cable.

2. Both ends of the cable in each reel shall be sealed to

prevent enrty of moisture

3. Length per reel, m

4. Each reel shall be marked with at least 25.4mm (1") high

letters and/or numerals in red paint that pertains to the

serial number (if any) and MERALCO item code.

5. Net weight, length, size, kind of conductor, purchase

order number, and any other marks required shall be

made on a tag attached to the reel.

Remarks

Recommendation

Das könnte Ihnen auch gefallen

- The Chemistry of Polyethylene InsulationDokument11 SeitenThe Chemistry of Polyethylene Insulationgari_monsantoNoch keine Bewertungen

- TDEI v17 n10 p709 Xlpe Effects Water TRDokument7 SeitenTDEI v17 n10 p709 Xlpe Effects Water TRgari_monsantoNoch keine Bewertungen

- Aecd8 Ins Related Cable CompoDokument16 SeitenAecd8 Ins Related Cable Compogari_monsantoNoch keine Bewertungen

- Fault Current Cond Graph 4c Arm Cables PetronDokument1 SeiteFault Current Cond Graph 4c Arm Cables Petrongari_monsantoNoch keine Bewertungen

- TDS 3C+G (Bare) Cu-XLPE-BED-CTS-PVC 600V 90°C (ICEA)Dokument1 SeiteTDS 3C+G (Bare) Cu-XLPE-BED-CTS-PVC 600V 90°C (ICEA)gari_monsantoNoch keine Bewertungen

- What's The Difference Between EPR and TR-XLP Cable - Border StatesDokument6 SeitenWhat's The Difference Between EPR and TR-XLP Cable - Border Statesgari_monsantoNoch keine Bewertungen

- 000awg 35kv in Underground Ducts (1ckt)Dokument1 Seite000awg 35kv in Underground Ducts (1ckt)gari_monsantoNoch keine Bewertungen

- Fault Current Arm Graph 4c Arm Cable PetronDokument1 SeiteFault Current Arm Graph 4c Arm Cable Petrongari_monsantoNoch keine Bewertungen

- Get Started with Your CASIO WatchDokument4 SeitenGet Started with Your CASIO Watchgari_monsantoNoch keine Bewertungen

- Fault Current Cond Graph 3c Arm Cables PetronDokument1 SeiteFault Current Cond Graph 3c Arm Cables Petrongari_monsantoNoch keine Bewertungen

- TDS 240MM CU XLPE CTS PVC 8.7 - 15kVDokument1 SeiteTDS 240MM CU XLPE CTS PVC 8.7 - 15kVgari_monsantoNoch keine Bewertungen

- Fault Current Armor Graph 2c Arm Cable PetronDokument1 SeiteFault Current Armor Graph 2c Arm Cable Petrongari_monsantoNoch keine Bewertungen

- Nlupc 800mcm DBP 2ckts 05092014 SummaryDokument1 SeiteNlupc 800mcm DBP 2ckts 05092014 Summarygari_monsantoNoch keine Bewertungen

- 021Dokument4 Seiten021gari_monsantoNoch keine Bewertungen

- IEC (0.6/1kV) Vs ICEA (600V) Comparison XLPE Insulation Wall Thickness SizesDokument2 SeitenIEC (0.6/1kV) Vs ICEA (600V) Comparison XLPE Insulation Wall Thickness Sizesgari_monsantoNoch keine Bewertungen

- Bez 05 NewDokument8 SeitenBez 05 Newgari_monsantoNoch keine Bewertungen

- 15kv 133ilDokument1 Seite15kv 133ilgari_monsantoNoch keine Bewertungen

- 336.4mcm Acsr-AwDokument1 Seite336.4mcm Acsr-Awgari_monsantoNoch keine Bewertungen

- Results: Study: Execution: Date: Frequency: Conductor ResistancesDokument1 SeiteResults: Study: Execution: Date: Frequency: Conductor Resistancesgari_monsantoNoch keine Bewertungen

- Results: Installation Type: Buried DuctsDokument10 SeitenResults: Installation Type: Buried Ductsgari_monsantoNoch keine Bewertungen

- 500mcm 35kv in Underground Ducts (2ckt)Dokument1 Seite500mcm 35kv in Underground Ducts (2ckt)gari_monsantoNoch keine Bewertungen

- UV-stabilized PDX (Blk&Red)Dokument1 SeiteUV-stabilized PDX (Blk&Red)gari_monsantoNoch keine Bewertungen

- 500mcm 35kv in Underground Ducts (1ckt)Dokument1 Seite500mcm 35kv in Underground Ducts (1ckt)gari_monsantoNoch keine Bewertungen

- Get Started with Your CASIO WatchDokument4 SeitenGet Started with Your CASIO Watchgari_monsantoNoch keine Bewertungen

- 000awg 35kv in Underground Ducts (1ckt)Dokument1 Seite000awg 35kv in Underground Ducts (1ckt)gari_monsantoNoch keine Bewertungen

- Meralco: Single Core 35Kv Cu/Trxlpe/Cts/Llope It Power CableDokument2 SeitenMeralco: Single Core 35Kv Cu/Trxlpe/Cts/Llope It Power Cablegari_monsantoNoch keine Bewertungen

- 000awg 35kv in Underground Ducts (1ckt)Dokument1 Seite000awg 35kv in Underground Ducts (1ckt)gari_monsantoNoch keine Bewertungen

- Technical DataDokument1 SeiteTechnical Datagari_monsantoNoch keine Bewertungen

- 25KV Cable Technical Details UnarmoredDokument1 Seite25KV Cable Technical Details Unarmoredgari_monsantoNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Ubd Unitplan Elecmag Ky 2016Dokument4 SeitenUbd Unitplan Elecmag Ky 2016api-281562636Noch keine Bewertungen

- Cross-Reference - AWG To Metric Size (With Ampacity) of Insulated ConductorsDokument1 SeiteCross-Reference - AWG To Metric Size (With Ampacity) of Insulated ConductorsJoeDabid94% (16)

- Wire GaugeDokument10 SeitenWire GaugeSwaraj DhumalNoch keine Bewertungen

- ETS01-07-01 - Specs LV ABC & XLPE Cable Equipment & FittingsDokument61 SeitenETS01-07-01 - Specs LV ABC & XLPE Cable Equipment & FittingsTerex14253Noch keine Bewertungen

- RF Cable and Cable Accessories CatalogueDokument59 SeitenRF Cable and Cable Accessories Catalogueahm_shaabanNoch keine Bewertungen

- Usha Martin: Global Wire Rope Company ProfileDokument18 SeitenUsha Martin: Global Wire Rope Company Profilejose klareNoch keine Bewertungen

- 19 PDFDokument6 Seiten19 PDFSugianto BarusNoch keine Bewertungen

- MCC Panel BOM ComponentsDokument6 SeitenMCC Panel BOM Componentssunil halvadiyaNoch keine Bewertungen

- 01 BuyLog2013 LoadCtrCircBreak PDFDokument42 Seiten01 BuyLog2013 LoadCtrCircBreak PDFMasood AlamNoch keine Bewertungen

- HV Cable Joints and TerminationsDokument117 SeitenHV Cable Joints and Terminationscubur.abur4794100% (7)

- EIM 7 Quarter 3 FinalDokument2 SeitenEIM 7 Quarter 3 FinalJenelyn RusianaNoch keine Bewertungen

- Basic Electricity Questions IGCSEDokument11 SeitenBasic Electricity Questions IGCSEFan Xin Foo100% (1)

- Method Statement: Corrosion Control Using Sika® Ferrogard®-300S Duo Hybrid Galvanic AnodesDokument13 SeitenMethod Statement: Corrosion Control Using Sika® Ferrogard®-300S Duo Hybrid Galvanic AnodesArturo lopez abucharNoch keine Bewertungen

- Eskom Park Witbank Fence Earthing Installation GuideDokument2 SeitenEskom Park Witbank Fence Earthing Installation GuideAndile Cele100% (1)

- Pec PDFDokument22 SeitenPec PDFIvan-Jeff Alcantara75% (4)

- SL No Description Supplier Purchase Date Miscellaneous I Connectors/Clamps Rate /unit (RS)Dokument72 SeitenSL No Description Supplier Purchase Date Miscellaneous I Connectors/Clamps Rate /unit (RS)api-25885200100% (1)

- Wfti Spring 2015Dokument84 SeitenWfti Spring 2015Darko MiladinovicNoch keine Bewertungen

- Radiographic Testing Device Evaluates Image QualityDokument19 SeitenRadiographic Testing Device Evaluates Image QualityVaisakVenugopalNoch keine Bewertungen

- Chapter 7 - Electrical UtilizationDokument21 SeitenChapter 7 - Electrical UtilizationKamaruz DanialNoch keine Bewertungen

- Factory Acceptance Test for Medium Voltage CablesDokument4 SeitenFactory Acceptance Test for Medium Voltage CablesMohammed AL-HejeriNoch keine Bewertungen

- Anixter High Temperature Wire Wire Wisdom enDokument2 SeitenAnixter High Temperature Wire Wire Wisdom enFelipe GustavoNoch keine Bewertungen

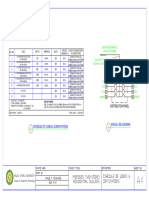

- Schedule of Loads and ComputationsDokument1 SeiteSchedule of Loads and ComputationskimberlyjoyregaladoNoch keine Bewertungen

- KEI Cable List Price Oct 2021Dokument5 SeitenKEI Cable List Price Oct 2021Nagi ReddyNoch keine Bewertungen

- Railway FI - 180118 - WebDokument90 SeitenRailway FI - 180118 - Webamitvaishnav1Noch keine Bewertungen

- RMIL General-BrochureDokument17 SeitenRMIL General-Brochurechinkal miglaniNoch keine Bewertungen

- LEEA New Rigging ManualDokument106 SeitenLEEA New Rigging ManualAkramKassisNoch keine Bewertungen

- Electric Fence Installation and SpecificationsDokument4 SeitenElectric Fence Installation and SpecificationsAb CNoch keine Bewertungen

- 501-380 Fieldbus Physical Layer Troubleshooting Guide PDFDokument29 Seiten501-380 Fieldbus Physical Layer Troubleshooting Guide PDFdiosjirehNoch keine Bewertungen

- Medidores SQDDokument20 SeitenMedidores SQDYusep DiegoNoch keine Bewertungen