Beruflich Dokumente

Kultur Dokumente

Transmission Losses in Reactive Muffler

Hochgeladen von

Vignesh PadmanabhanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Transmission Losses in Reactive Muffler

Hochgeladen von

Vignesh PadmanabhanCopyright:

Verfügbare Formate

Volume II, Issue VII, July 2015

IJRSI

ISSN 2321 - 2705

Transmission Losses in Reactive Muffler Analysis

by Boundary Element Method,Numerical Method &

Experimental Method

Akshay Gopal Doijode

Onkar Sharad Gadre

Dept. Of Mechanical Design Engineering

N.B.N Sinhgad College of Engineering

Ambegaon, Pune

Dept. Of Mechanical Design Engineering

N.B.N Sinhgad College Of Engineering,

Solapur, Pune

Abstract Combustion process in the I.C. engines and exhaust

process produces gaseous pollutants as well as acoustic

pollutants. The pulsating flow from each cylinder's exhaust

process of automobile engine sets up pressure waves in the

exhaust system having average pressure levels higher than the

atmospheric. The pressure waves propagate at speed of the

sound relative to the moving exhaust gas, which escapes with a

high velocity producing an objectionable exhaust noise. A

suitably designed exhaust muffler accomplishes the muffling of

this exhaust noise.

I.

INTRODUCTION

nternal combustion engines are typically equipped with an

exhaust muffler to suppress the acoustic pulse generated

by the combustion process. A high intensity pressure wave

generated by combustion in the engine cylinder propagates

along the exhaust pipe and radiates from the exhaust pipe

termination. The pulse repeats at the firing frequency of the

engine which is defined by f = (engine rpm x number of

cylinders)/120 for a four stroke engine. A pulse at the firing

frequency dominates the frequency content of exhaust noise,

but it also has a broadband component to its spectrum, which

extends to higher frequencies. Measurements of the exhaust

pipe pressure pulse on a Continental O-200cc engine show

that the majority of the pulse energy lies in the frequency

range of 0-1800 Hz. Exhaust mufflers are designed to reduce

sound levels at these frequencies.

In general, sound waves propagating along a pipe

can be attenuated using either a dissipative or a reactive

muffler. A dissipative muffler uses sound absorbing material

to take energy out of the acoustic motion in the wave, as it

propagates through the muffler.

Reactive silencers, which are commonly used in

automotive applications, reflect the sound waves back

towards the source and prevent sound from being transmitted

along the pipe. Reactive silencer design is based either on the

principle of a

Helmholtz resonator or an expansion chamber, and

requires the use of acoustic transmission line theory.

In a Helmholtz resonator design a cavity is attached

to the exhaust pipe. At a specific frequency the cavity will

resonate and the waves in the exhaust pipe are reflected back

towards the source[3]. However there are also pass band

www.rsisinternational.org/IJRSI.html

frequencies where the resonator has no effect and so

resonator muffler design is targeted to specific frequencies

where the majority of the attenuation is required. In some

designs, the muffler has several resonators of different sizes

to target a range of frequencies.

Expansion chamber mufflers reflect waves by

introducing a sudden change in cross sectional area in the

pipe. They do not have the high attenuation of the Helmholtz

resonator, but have a broadband frequency characteristic,

with pass bands when half the acoustic wavelength equals the

cavity length. Their performance also deteriorates at higher

frequencies when the cross axis dimension of the muffler is

82% of the acoustic Wavelength. Some expansion chamber

muffler systems are also packed with sound absorbing

material, which helps to improve the high frequency

attenuation.

In all muffler designs the tailpipe length can have an

important effect. The tailpipe itself acts as a resonant cavity

that couples with the muffler cavity. The attenuation

characteristics of a muffler are modified if the design tailpipe

is not used. Also, the effect of exhaust gas flow speed has a

detrimental effect on the muffler performance. In typical

industrial or diesel truck engine applications the exhaust flow

speed can be 164 ft/sec to390 ft/sec. The effect of flow is

related to the interaction of sound with turbulence and will be

dependent on the internal design of the muffler.

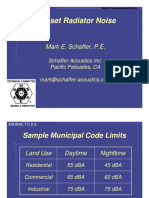

II. NOISE CONTRIBUTIONS FROM VARIOUS

AUTOMOTIVE SYSTEMS

The vehicle noise comprises three major sources,

viz., power unit, wind turbulence and tyre /road. The power

unit consists of engine, cooling fan, exhaust and

transmission. Main components of engine are injection

system, intake system and cylinder block, particularly the

sheet metal components. The best design practice is to design

as well as vehicle for quietness. This requires knowledge of

the mechanism of noise generation, propagation and

radiation. The principle of impedance mismatch needs to be

understood and made use of appropriately in design of

exhaust system. The contributions of noise by various

automotive systems are shown in fig.

Page 6

Volume II, Issue VII, July 2015

IJRSI

ISSN 2321 - 2705

The muffler performance must not deteriorate with time.

Flow-generated noise within muffler element and at the

tail pipe exit should be sufficiently low, particularly for

mufflers with large insertion loss.

Spark-arresting capability is also a requirement

occasionally (particularly for agricultural use).

Back pressure: It should be as minimum as possible.

Figure 2.1 - Noise Contributions by Various Automotive Systems

A. Need Of A Mufflers

Mufflers are used to reduce the combustion noise

present at the exit of the exhaust. As the noise norms

becoming more stringent, its necessary for the entire

automotive manufacturer to give more attention in the design

of mufflers. Designing mufflers have been a challenging task

for the designer for many years as it is not only reducing the

noise but it also creates backpressure, which reduces the

overall efficiency of the engine. Noise creates annoyance,

sleep disturbance and if it is too loud then it can damage our

hearing capability. Hence it is necessary to install muffler in

every automotive so that noise emission can be controlled

and remain within the noise norms.

B. Mufflers

Generally speaking, there is no technical distinction

between the silencer and muffler, and the terms are

frequently used are inter changeable. Silencer has been the

traditional name for the noise attenuating device, while a

muffler is smaller, mass produced device design to reduce

the engine exhaust noise.

A muffler is a device for reducing the amount of

noise emitted by a machine (I C engine). As the noise norms

becoming more stringent, its necessary for the entire

Automotive manufacturer to give more attention in the

design of mufflers. Designing mufflers have been a

challenging task for the designer for many years as it is not

only reducing the noise but it also creates backpressure,

which reduces the overall Efficiency of the engine. Noise

creates annoyance, sleep disturbance and if it is too loud then

it can damage our hearing capability. Hence it is necessary to

install muffler in every Automotive, so that noise emission

can be controlled and remain within the noise norms.

D. Types of mufflers

Despite the terms and myriad of configurations, the

silencer can be broken into three fundamental types:

1.Absorptive (dissipative), 2. Reactive or Reflective and

3.combination of Reactive and absorptive. In addition to the

three main silencer types, other functionality such as spark

arresting, emission control, heat recovery, etc., may also be

incorporated into the silencer design. Each type of silencer

has specific performance attributes that can be used

independently or in combination to produce the required IL

for a specific application.

III.

REACTIVE MUFFLER

Reactive silencers generally consist of several pipe

segments that interconnect with a number of larger chambers.

The noise reduction mechanism of reactive silencer is that

the area discontinuity provides an impedance mismatch for

the sound wave traveling along the pipe. This impedance

mismatch results in a reflection of part of the sound wave

back toward the source or back and forth among the

chambers. The reflective effect of the silencer chambers and

piping (typically referred to as resonators) essentially

prevents some sound wave elements from being transmitted

past the silencer. The reactive silencers are more effective at

lower frequencies than at high frequencies, and are most

widely used to attenuate the exhaust noise of internal

combustion engines. A generic reactive engine silencer

comprised of proportionally sized chambers with a pair of

interconnecting tubes is shown below.

C. Requirements of an engine exhaust muffler

Adequate insertion loss: The exhaust muffler is designed

so that muffled exhaust noise is at least 5 dB lower than the

combustion-induced engine body noise or other predominant

sources of noise like transmission noise in earth-moving

equipment. Frequency spectrum of unmuffled exhaust noise

is generally required for appreciation of the frequency range

of interest, although it is well known that most of the noise is

limited to the firing frequency and its few harmonics.

Size: A large muffler would cause problems of

accommodation, support (because of its weight) and of

course excessive cost price.

Breakout noise from your muffler shell must be

minimized.

www.rsisinternational.org/IJRSI.html

Figure 3.1 - Reactive muffler [9]

Many terms are used to define the working of any

reflective mufflers. These terms are very important to

completely understand the working of muffler.

Impedance:

The term impedance is used for the resistance of a

system to an energy source. For constant signal, it usually

Page 7

Volume II, Issue VII, July 2015

IJRSI

constant. For varying signal, its usually change with

frequency.

Acoustic impedance (z):

Its a frequency dependent parameter and is very useful.

Mathematically,

Z = p/(v*s)

Where,

P = sound-pressure,

V = particle velocity,

S = Surface area

Characteristic impedance (Zo):

Its a material property of a medium such as air, rock or

water. Mathematically,

ISSN 2321 - 2705

Insertion loss is defined as the difference between the

acoustic power radiated without the structure and that with

the structure. Symbolically,

IL= 10 log W1 dB

W2

where W1 and W2 denote the acoustic power without the

structure and with the structure.

Zo = *C

Where,

= Density of the medium

C = velocity of sound

A. Combination muffler

Some silencers combine both reactive and absorptive

elements to extend the noise attenuation performance over a

broader noise spectrum. Combination silencers are also

widely used to reduce engine exhaust noise.

Figure 3.3 Concept picture of Insertion Loss

2) Transmission loss (TL)

Transmission loss is defined as the ratio of the

incident power and transmitted powerfrom the structure.

Symbolically,

TL= 10 log Wi dB

Wt

Where Wi and Wtdenote the incident acoustic

power and transmitted acoustic power. TLis used in this

work to evaluate the performance of the muffler wall.

Figure 3.2 Combination Muffler Performance

B. Muffler performance parameters

As per the literature and statistical survey, the

required silencer volume for better performance is 8 10

times the engine capacity.The use of an exhaust silencer is

prompted by the need to reduce the engine exhaust noise. In

most applications the final selection of an exhaust silencer is

based on a compromise between the predicted acoustical,

aerodynamic, mechanical and structural performance in

conjunction with the cost of the resulting system.

Sound transmission characteristic of a structure can be

measured in terms of the one ofthe following parameters

1.

INSERTION LOSS, IL

2.

TRANSMISSION LOSS, TL

3.

LEVEL DIFFERENCE LD, OR NOISE REDUCTION, NR

Figure 3.4 Concept picture of Transmission Loss

3) Level difference (LD)

Level difference LD, or noise reduction, NR is the

difference in sound pressure levels attwo arbitrarily selected

points inside the structure and outside the structure.

Symbolically,

LD= 20 log Pi dB

Po

Where Pi and Po denote the pressure inside the structure and

outside the structure.

1) Insertion loss (IL)

Figure 3.5 Concept picture of Level difference

www.rsisinternational.org/IJRSI.html

Page 8

Volume II, Issue VII, July 2015

IJRSI

ISSN 2321 - 2705

4) Back Pressure:

The average pressure in the exhaust pipe during the

exhaust stroke is called the mean ambient pressure; and the

term back pressure is used to denote the difference

between this and the ambient pressure.

This back pressure is due to loss in stagnation

pressure in various tubular elements and across various

junctions. When this back pressure is low enough (less than

.1 bar), it simply represents a corresponding loss in the in

brake mean effective pressure (BMEP) of the engine.

Pressure drop across the complete muffler assembly:

The most important detrimental effect in a muffler

in a muffler with good insertionloss is the backpressure that

it would exert on the engine. This back pressure is due to loss

in stagnation pressure in various tubular elements and across

various junctions. When this backpressure is low enough

(less than 0.1 bar), it simply represents a corresponding loss

in the brake Mean Effective pressure (BMEP) of the engine.

The loss in BMEP owing to a sharp fall in the volumetric

efficiency of the engine. The loss in stagnation pressure

across various muffler elements is generally described in

terms of the dynamics head flow in the exhaust pipe:

Defining the area ratio n at any area discontinuity as:

The loss in stagnation pressure at various junctions has been

measured from the steady flow experiments to be as follows

Sudden Expansion and extended inlet:(1 n2)*H

( 1 )

Sudden contraction and extended outlet:

Flow Reversal cum expansion: H(n0.25)

Flow reversal cum contraction:0.5H (n < 0.25)

Free Expansion at the tail pipe: 0.4H

IV.

4.1.

pressure is the excess pressure from the mean

pressure.

Analysis is limited to relatively small acoustic

pressures so that the changes in density are small

compared with the mean density.

Muffler wall neither conduct nor transmit the sound

and viscosity effect at wall is neglected.

Analytical methods are good for calculating the TL of

SEC, complex geometry models are very difficult to

evaluate. The following formula is used to calculate TL in dB

of given model over a frequency range 0 to 3000 Hz. This

formula is valid for SEC with single chamber and derived

from logarithmic pressure difference of acoustic power of the

incident wave and the transmitted wave.

1

1

TL 10 log 10 1 M

M

4

4.2.

2

sin KL

Transfer Matrix Method(TMM)

Design of a complete muffler system is usually, a

very complex task because each ofits elements is selected by

considering its particular acoustic performance and its

interaction effects on the entire acoustic system performance.

For the frequency analysis of the muffler, it is very

convenient to use the transfer matrix method.

The most popular traditional method for calculating

the transmission loss is Transfer Matrix Method. The

transmission loss of any acoustical filter is calculated by

determining the four poles parameters of a transfer matrix.

The 22 transfer matrix relates the pressure and the normal

particle velocity at inlet and outlet of the muffler. The

essence of the transfer matrix methods is its ability to break

the system into discrete elements, which can be modeled by

using basic acoustic principles. The boundary conditions of

pressure and volume flow continuity results into the

following equation in matrix form,

ACOUSTIC ANALYSIS OF MUFFLER

Calculation of TL by Analytical Method

i)

TL Calculation

Analytical approach is purely based upon the one dimension

wave equation and empirical formula of TL. The pressure

and particle velocity continuity equations are applied at the

junction where area discontinuity occurs. The following

assumptions are considered for the this analysis,

The sound is propagation is in free field and in one

direction only, plane wave theory.

There is no mean flow of the fluid. That is sound is

propagating while the fluid in the muffler is

stationary (zero Mach number).

The mean density and mean pressure are uniform

and steady throughout the fluid. The acoustic

www.rsisinternational.org/IJRSI.html

A11

A12

A21

A22

Pinlet

Poutlet

U outlet 0

Pinlet

U outlet

Poutlet 0

U inlet

Poutlet

U outlet 0

U inlet

U outlet

Poutlet 0

Page 9

Volume II, Issue VII, July 2015

IJRSI

Figure 4.1: Discretization of simple expansion chamber for TMM

For Transfer Matrix of Simple Expansion Chamber

ISSN 2321 - 2705

SYSNOISE

ABAQUS

ANSYS

NASTRAN

ABAQUS, ANSYS and NASTRAN are based on finite

element algorithm and they do not have the capability for

performing any kind of boundary element analysis.

SYSNOISE can do both boundary element and finite element

calculations. The maindis advantage of finite element

analysis is that the entire fluid medium surrounding the

object of study should be meshed and for a complex object

like an automotive muffler this could be quite tedious. For

the boundary element calculations, one need not mesh the

surrounding fluid medium and hence the meshing stage of

the analysis is quite simple. But boundary element analyses

are quite computationally intensive and could take much

longer solution time. For the geometry considered in this

study, the model size in terms of the number of nodes is

small and hence the boundary element analysis using

SYSNOISE as solver was deemed to be more appropriate.

4.3.1

A transfer matrix is calculated for a simple

expansion chamber with above dimension is calculated with

a simple MATLAB program. The TL of simple expansion

chamber model is calculated for 0 to 3000 Hz. The graph

shows the TL versus frequency for simple expansion

chamber with both empirical relation and TMM. The

MATLAB code [19] is included in appendix-A

4.2 Figure: Plot of TL Verses Frequency by Transfer Matrix Method for

Simple Expansion Chamber

Evaluate TL for Simple Expansion Chamber Muffler

In SYSNOISE By BEM:

SYSNOISE is an FEM/BEM based computational

acoustics program that allows users to input a geometry,

impose boundary conditions, select environmental

parameters, and solve the system of resulting equations in

one, two or three dimensions. Once the system has been

solved, a host of post-processing options are available to

determine the various performance characteristics. Using

command line code, it was possible to perform the

calculations for all three methods, utilizing both FEM and

BEM, and in both two and three dimensions.

4.3.2

A typical TL calculation using SYSNOISE has the

following steps

Model-1 Acoustic Harmonic BEM

Mesh on surface only

field-point mesh for other results

Direct BEM solver

closed geometry

fluid on one side: interior or exterior

Indirect BEM solver

no restriction on geometry

open

ribbed

fluid on both sides: interior and exterior

Surface absorbers

4.3.3

4.3. Numerical Approach to Evaluate TL for

Expansion Chamber Muffler)

(Simple

The radiated noise from a structure could be

numerically calculated using avariety of commercially

available codes. The four most popular codesused in the

industry are:

www.rsisinternational.org/IJRSI.html

Analysis in SYSNOISE by BEM:

Principle Steps of Boundary Element Application:Model Definition

Meshes

Model Type

Acoustic Properties

BC: source, vibrating panels

Advanced Boundary Conditions

Use of BEM solvers

Page 10

Volume II, Issue VII, July 2015

IJRSI

BEM applications

Post processing

Calculation of TL:

It is a reasonable speculation that the frequency at

which the TL would be maximum is at the acoustic modes of

muffler. The analysis is an integral step during the

calculation of TL using BEM. The acoustic modes of the

muffler could be obtained by performing a BEM analysis in

SYSNOISE. Acoustic finite element analysis is not a part the

boundary element analysis, which is used to calculate the TL.

This analysis is performed only to obtain a better

understanding of the system behavior. The acoustic FLUID

boundary element analysis consists of the following steps.

Mesh the acoustic cavity in HYPERMESH

Import the FE model to SYSNOISE

Assign the properties of air to the mesh

Mass density = 1.225 kg/m3

Sound velocity = 340 m/sec

Apply impedance boundary condition on the

open faces using the equation

2

= (0.24() + (0.56))

2

=

340

a= radius of pipe

Solve the model to obtain the results

.

ISSN 2321 - 2705

V.

REFERENCES

[1]. M. L. Munjal 1987Acoustics of Duct and Mufflers with application to

exhaust and ventilation system. New York: John Wiley and Sons.

[2]. Z. Tao and A. F. Seybert2003Society of Automotive Engineers, Inc.,A

Review of Current Techniques for Measuring Muffler Transmission

Loss.

[3]. Istvan L. Ver and Leo L. Beranek 2006 Noise and Vibration Control

Engineering principles and application. New Jersey: second edition

John Wiley & Sons, Inc.

[4]. T.W. Wu,, C.Y.R. Cheng, Z. Tao, 2003 Journal of Sound and

Vibration261 (2003) 115Boundary element analysis of packed

silencers with protectivecloth and embedded thin surfaces

[5]. Lawrence E. Kinsler, Austin R Frey, 1962 Fundamental of Acoustic

John Wiley & Sons Inc, New York London

[6]. A. K. M. Mohiuddin, AtaurRahman and Yazid Bin Gazali 2007

Journal of mechanical and material engineering Vol. 2 (No. 2. 118124). Simulation and Experimental Investigation of Muffler

Performance

[7]. www.wikibooks/EngineeringAcousticscarMufflersWikibooks,openboo

kforanorld.htm

[8]. O. Vasile, Reactive Silencer Modeling with Boundary Element Method

and Experimental Study, Proceedings of the 5th International Vilnius

Conference, Knowledge-Based Technologies and OR Methodologies

for Strategic Decisions of Sustainable Development (KORDS 2009),

September 30-October 3, 2009, Vilnius, Lithuania, pp. 544-549, ISBN

978-9955-28- 482-6.

[9]. C. Y. R. Cheng, T. W. Wu 1999 Society of Automotive Engineers, Inc.

Exhaust muffler Design and Analysis Using A Boundary Element

Method Based Computer Program

[10]. S. N. Y. Gerges, R. Jordan, F. A. Thieme, J. L. Bento Coelho, J. P.

Arenas 2005 ABCM Vol. XXVII, No. 2(132-140). Muffler Modeling

by Transfer Matrix Method and Experimental Verification.

[11]. Omid Z. Mehdizadeh and Marius Paraschivoiu 2005 Applied Acoustics

66 (2005) 902918. A three-dimensional finite element approach for

predicting the transmission loss in mufflers and silencers with no mean

flow.

[12]. A.D. Sahasrabudhe, M.L. Munjal and S. Anantha Ramu (1992),

Design of

expansion chamber mufflers incorporating 3-D effects,

Noise control engineering journal, Vol. 38(16), pp. 27-38.

[13]. I. J. Lee and A. Selamet, N. T. Huff 2003, Society of Automotive

Engineers, Inc, Acoustic Characteristics of Coupled Dissipativeand

Reactive Silencers

[14]. http://auto.howstuffworks.com/muffler3.htm

[15]. Don D. davis, Jr., George M. Stokes, Dewey moore, and George L.

Stevens, Jr. 1954 NACA, Report 1192. Theoretical and Experimental

Investigation of Mufflers with Comments on Engine Exhaust Muffler

Design.

[16]. O. Vasile, Contributions on modelling of noise and vibration control,

PhD,thesis, 2009.

[17]. Yoshihiro Isshiki, Yuzuru Shimamoto and Tomoyuki Wakisaka 1996

Society of automotive Engineers, Inc. 960637. Simulteneous prediction

of pressure losses and acoustic characteristics in silencers by numerical

simulation.

[18]. MATLAB 7.10.0 2010 users guide. The Mathworks Inc.

[19]. International Standard 1998 ISO 10534-2;1998(E). Acoustics Determination of sound

absorption coefficient and impedance in

impedance tubes Part 2: Transfer-Function Method.

[20]. http://www.silentor.com/filer/exhaust_silencer.pdf

[21]. OROS 3-Series/NVGate V7.10 2011 Users Manual. OROS, Inc.

Figure 4.3: Simulation results of Simple Expansion Chamber

4.3.1

Model of simple expansion chamber

www.rsisinternational.org/IJRSI.html

Page 11

Das könnte Ihnen auch gefallen

- Silencer PRINTDokument2 SeitenSilencer PRINTChandima WijesekeraNoch keine Bewertungen

- Louvres Bro enDokument84 SeitenLouvres Bro entagiriNoch keine Bewertungen

- Ashrae 48Dokument63 SeitenAshrae 48Mohamed Aboobucker Mohamed IrfanNoch keine Bewertungen

- Fractal ForestsDokument50 SeitenFractal ForestsWell Fournier0% (1)

- Sound Attenuators LeafletDokument7 SeitenSound Attenuators LeafletBalanSelvamNoch keine Bewertungen

- Kinetics Silencer SpecificationDokument4 SeitenKinetics Silencer Specificationswapnil.upgadeNoch keine Bewertungen

- Air Master SilencersDokument17 SeitenAir Master SilencersZainul Abedin SayedNoch keine Bewertungen

- TW Ycm01265958803Dokument62 SeitenTW Ycm0126595880313239563Noch keine Bewertungen

- Updated Silencers Bro PDFDokument20 SeitenUpdated Silencers Bro PDFdimchienNoch keine Bewertungen

- Smoke Fans CatalogueDokument54 SeitenSmoke Fans CataloguejayanthahhyNoch keine Bewertungen

- Request 15 NoiseDokument28 SeitenRequest 15 NoiseHannibal1969Noch keine Bewertungen

- MufflerDokument6 SeitenMufflerDhurai Raj100% (2)

- Acoustic Optimisation of A Fan Test RigDokument17 SeitenAcoustic Optimisation of A Fan Test Rigspotty81Noch keine Bewertungen

- Noise Reduction in Centrifugal Fans: A Literature SurveyDokument29 SeitenNoise Reduction in Centrifugal Fans: A Literature SurveyPooria1989Noch keine Bewertungen

- Active Noise Control in Luxury VehiclesDokument247 SeitenActive Noise Control in Luxury VehiclesMizioNoch keine Bewertungen

- Transformers Are Never SilentDokument4 SeitenTransformers Are Never SilentEngr. AbdullahNoch keine Bewertungen

- AcousticInsulation enDokument97 SeitenAcousticInsulation enBernardo ArevalilloNoch keine Bewertungen

- Diesel Engines and the Environment - Noise SourcesDokument8 SeitenDiesel Engines and the Environment - Noise SourcespawanNoch keine Bewertungen

- Final Acoustic Enclosure PresentationDokument48 SeitenFinal Acoustic Enclosure PresentationsartajyadNoch keine Bewertungen

- Noise Measurement Analysis and Sound Propagation FundamentalsDokument2 SeitenNoise Measurement Analysis and Sound Propagation FundamentalsSohJiaJieNoch keine Bewertungen

- Sheet Steel Facts 16Dokument4 SeitenSheet Steel Facts 16Giordano VieiraNoch keine Bewertungen

- Acoustic CatalogDokument12 SeitenAcoustic CatalogrohizatNoch keine Bewertungen

- Price Noise Control OverviewDokument62 SeitenPrice Noise Control OverviewJulián PassardiNoch keine Bewertungen

- Design and Comparison of Mufflers Having Different Arrangements For Diesel EngineDokument8 SeitenDesign and Comparison of Mufflers Having Different Arrangements For Diesel EngineWaruna PasanNoch keine Bewertungen

- 12 New Trends in ManagementDokument18 Seiten12 New Trends in ManagementSaqib IqbalNoch keine Bewertungen

- Noise Reduction in Hvac Duct SystemsDokument27 SeitenNoise Reduction in Hvac Duct SystemsQOBITNoch keine Bewertungen

- Rectangular Duct AtteDokument4 SeitenRectangular Duct AtteShahrukh AnsariNoch keine Bewertungen

- 1 ISTIQ Acoustic DoorDokument6 Seiten1 ISTIQ Acoustic DoorjaladimudaNoch keine Bewertungen

- Genset Noise Outdoor Environment Sound SilencerDokument18 SeitenGenset Noise Outdoor Environment Sound SilencerTrần Quang ToánNoch keine Bewertungen

- Fan Sound Sound Ratings Fe 300Dokument8 SeitenFan Sound Sound Ratings Fe 300hardik033Noch keine Bewertungen

- Uaet Industrial Noise Series Viii Absorptive Silencer DesignDokument9 SeitenUaet Industrial Noise Series Viii Absorptive Silencer DesignSérgio AmorimNoch keine Bewertungen

- Sound insulation fundamentals ventilation planningDokument23 SeitenSound insulation fundamentals ventilation planningblindjaxx100% (1)

- Architectural Acoustics SolutionsDokument56 SeitenArchitectural Acoustics Solutionsshyma_97Noch keine Bewertungen

- Top 10 Noise Control Solutions 2015 EmailDokument12 SeitenTop 10 Noise Control Solutions 2015 EmailRodrigo MottaNoch keine Bewertungen

- Noise Control EngineeringDokument12 SeitenNoise Control EngineeringArindam BhowmickNoch keine Bewertungen

- C008 - Quiet Revolution Noise Statement 20100803v1Dokument15 SeitenC008 - Quiet Revolution Noise Statement 20100803v1Roland PetersNoch keine Bewertungen

- (IISc Lecture Notes 3) M.L. Munjal - Noise and Vibration Control (2013, World Scientific)Dokument260 Seiten(IISc Lecture Notes 3) M.L. Munjal - Noise and Vibration Control (2013, World Scientific)สาธิต ปริ นทร์ทอง100% (2)

- Sound Attenuators LeafletDokument7 SeitenSound Attenuators LeafletSundar Ramasamy0% (1)

- Muffler Design For Automotive Exhaust Noise Attenuation - A ReviewDokument4 SeitenMuffler Design For Automotive Exhaust Noise Attenuation - A ReviewStylishrockerPradeepNoch keine Bewertungen

- 615 Fullpaper 1238981371122068 PDFDokument15 Seiten615 Fullpaper 1238981371122068 PDFlucaNoch keine Bewertungen

- Acoustic GuideDokument17 SeitenAcoustic GuideMohamad ShabeerNoch keine Bewertungen

- Design and Optimization of Exhaust MufflerDokument7 SeitenDesign and Optimization of Exhaust MufflerBenjamín AlainNoch keine Bewertungen

- Engineering Controls Reduce Hydro Powerplant NoiseDokument33 SeitenEngineering Controls Reduce Hydro Powerplant Noisepradip panthaNoch keine Bewertungen

- A Review Paper On Design of Muffler Toward Reduce Sound in Exhaust System of IC EngineDokument6 SeitenA Review Paper On Design of Muffler Toward Reduce Sound in Exhaust System of IC EngineJose PradoNoch keine Bewertungen

- HVAC Noise and Vibration Control SummaryDokument37 SeitenHVAC Noise and Vibration Control SummaryYel DG100% (1)

- Detailed Scheduling Planning Board Technical HelpDokument6 SeitenDetailed Scheduling Planning Board Technical Helpmanojnarain100% (1)

- Designing and Calculation of MufflerDokument7 SeitenDesigning and Calculation of MufflerPravin Patil100% (1)

- Kenneth Kaliski Slides 6.7.11Dokument21 SeitenKenneth Kaliski Slides 6.7.11Northeast Wind Resource Center (NWRC)Noch keine Bewertungen

- Cooling Tower Noise Control Silencers Reduce SoundDokument37 SeitenCooling Tower Noise Control Silencers Reduce SoundUllas EK100% (1)

- Acoustics GuidelinesDokument20 SeitenAcoustics Guidelinesrommel duran100% (1)

- Active Noise Reduction in Ventilation DuctsDokument9 SeitenActive Noise Reduction in Ventilation DuctsRobson Queiroz DamascenoNoch keine Bewertungen

- Product Design of MufflerDokument16 SeitenProduct Design of MufflernaniNoch keine Bewertungen

- Design Principles and Optimization of Exaust Reactive MufflerDokument6 SeitenDesign Principles and Optimization of Exaust Reactive MufflerBenjamín Alain100% (1)

- 7th Sem ProjectDokument68 Seiten7th Sem ProjectKumar SiddhanthNoch keine Bewertungen

- Noise Control: Determining The Best OptionDokument5 SeitenNoise Control: Determining The Best OptionCarlos SantosNoch keine Bewertungen

- Simulation of BJT Amplifier: Course - Section: ECE20L-E06 Group NumberDokument10 SeitenSimulation of BJT Amplifier: Course - Section: ECE20L-E06 Group NumberLuch ÜNoch keine Bewertungen

- Design and Analysis of Muffler for Two-wheelerDokument9 SeitenDesign and Analysis of Muffler for Two-wheelerDeepak ChaurasiaNoch keine Bewertungen

- Engineering Acoustics Lecture 11Dokument27 SeitenEngineering Acoustics Lecture 11Isuru Kasthurirathne100% (1)

- Designing Quiet Structures: A Sound Power Minimization ApproachVon EverandDesigning Quiet Structures: A Sound Power Minimization ApproachNoch keine Bewertungen

- Muffler CFDDokument11 SeitenMuffler CFDfarhath78Noch keine Bewertungen

- MEC 115 Noise Vibration&ControlDokument150 SeitenMEC 115 Noise Vibration&ControlMauriceNoch keine Bewertungen

- Analysis and Design of MufflersDokument9 SeitenAnalysis and Design of MufflersDavid PriceNoch keine Bewertungen

- Lining DuctworkDokument4 SeitenLining Ductworkthanh_79Noch keine Bewertungen

- Acoustics Course NotesDokument162 SeitenAcoustics Course NotesBelaliaNoch keine Bewertungen

- Noise Pollution - Prevention and Control - Rules 2000 & Laws & Noise Limits - IndiaDokument32 SeitenNoise Pollution - Prevention and Control - Rules 2000 & Laws & Noise Limits - IndiaIastra50% (2)

- Frequently Asked Questions (Faq) FOR New Unifi Mobile Prepaid #BebasDokument1 SeiteFrequently Asked Questions (Faq) FOR New Unifi Mobile Prepaid #BebasNgHanSeongNoch keine Bewertungen

- Vspa 50Dokument5 SeitenVspa 50elfo111Noch keine Bewertungen

- Nervous System Reaction PaperDokument3 SeitenNervous System Reaction PaperJohn Ruel Sanchez IINoch keine Bewertungen

- Sheet No. 1: Roop LalDokument6 SeitenSheet No. 1: Roop LalzzzNoch keine Bewertungen

- Teaching Load FinalDokument12 SeitenTeaching Load FinalEdward BarberNoch keine Bewertungen

- INCaDokument47 SeitenINCaMehdi SoltaniNoch keine Bewertungen

- X English QPDokument29 SeitenX English QPbadasserytechNoch keine Bewertungen

- DSP Lab - ScilabDokument17 SeitenDSP Lab - ScilabSai Nikshipth MaddhugaruNoch keine Bewertungen

- Boyut AnaliziDokument65 SeitenBoyut AnaliziHasan Kayhan KayadelenNoch keine Bewertungen

- TCXD 46-1984 / Lightning Protection For Buildings - Standard For Design and ConstructionDokument30 SeitenTCXD 46-1984 / Lightning Protection For Buildings - Standard For Design and ConstructiontrungjindoNoch keine Bewertungen

- Exercise 7 - The Avian EggDokument5 SeitenExercise 7 - The Avian EggSebastian SmytheNoch keine Bewertungen

- Standards List July2019Dokument8 SeitenStandards List July2019Richard PNoch keine Bewertungen

- Upto 62rd BPSC Mechanical Question BankDokument140 SeitenUpto 62rd BPSC Mechanical Question BankASHISH KUMAR SINGHNoch keine Bewertungen

- DLT - Ate 2022Dokument28 SeitenDLT - Ate 2022chellep.uniNoch keine Bewertungen

- ARHITECTURA Si FOCULDokument282 SeitenARHITECTURA Si FOCULTheodor DinuNoch keine Bewertungen

- Order Details for Order #10105Dokument2 SeitenOrder Details for Order #10105Mohamed HarbNoch keine Bewertungen

- Western Preços - SPDokument28 SeitenWestern Preços - SPRobertaoJasperNoch keine Bewertungen

- 3D Model Files Presentation 1Dokument9 Seiten3D Model Files Presentation 1SolidSpy24Noch keine Bewertungen

- Department of Mechanical Engineering Polytechnic Sultan Haji Ahmad Shah Kuantan, Pahang DJJ 30122-CADDokument2 SeitenDepartment of Mechanical Engineering Polytechnic Sultan Haji Ahmad Shah Kuantan, Pahang DJJ 30122-CADAbdul MalikNoch keine Bewertungen

- Daniel Kipkirong Tarus C.VDokument19 SeitenDaniel Kipkirong Tarus C.VPeter Osundwa KitekiNoch keine Bewertungen

- PVG 32 BobinasDokument64 SeitenPVG 32 BobinasSaul CastañedaNoch keine Bewertungen

- Electric Current and Ohm's LawDokument2 SeitenElectric Current and Ohm's LawSheldon MillerNoch keine Bewertungen

- Phase 2 (57 Selectee)Dokument4 SeitenPhase 2 (57 Selectee)AmarNoch keine Bewertungen

- Floor Heating Controls Wiring Instructions for FS and BA Master Weather CompensationDokument12 SeitenFloor Heating Controls Wiring Instructions for FS and BA Master Weather Compensationjamppajoo2Noch keine Bewertungen