Beruflich Dokumente

Kultur Dokumente

Design and Stress Analysis of FRP Composite Pressure Vessel

Hochgeladen von

IJMTST-Online JournalOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design and Stress Analysis of FRP Composite Pressure Vessel

Hochgeladen von

IJMTST-Online JournalCopyright:

Verfügbare Formate

Volume: 2 | Issue: 05 | May 2016 | ISSN: 2455-3778

IJMTST

Design and Stress Analysis of FRP

Composite Pressure Vessel

M.A. Mujeeb Iqbal1 | Mohd.Hasham Ali2 | Mohammed Fareed3

1Assistant

Professor, Department of Mechanical Engineering, Muffakham Jah College of Engineering

& Technology, Hyderabad, Telanagana, India.

2Assistant Professor, Department of Mechanical Engineering, Muffakham Jah College of Engineering

& Technology, Hyderabad, Telanagana, India.

3Assistant Professor, Department of Mechanical Engineering, Vidya Jyothi Institute of Technology, Aziz

Nagar, Hyderabad, Telanagana, India.

ABSTRACT

Pressure vessels are containers that operate at pressures above atmospheric pressure. A pressure vessel

can be defined as a relatively high-volume pressure component ( such as a spherical or cylindrical container

) that has a cross section larger than the associated pipe or tubing .The composite materials have been widely

used for the manufacturing of pressure vessels from a very long time. These pressure vessels are

manufactured by filament winding process. The filament wound composite pressure vessels have special

characteristics of high strength to modulus ratio. The Filament wound composite pressure vessels have

become very popular in various industries and applications that include aerospace, sewage, chemical, oil

and gas industries. During operation these pressure vessels are subjected to very high internal pressures

and very high internal stresses are developed in them. The safety aspect is vital because of high working

pressure and build-up of high stresses in the pressure vessel. Therefore the stress and burst pressure

analysis are essential for the safe working and performance evaluation of such pressure vessels.

Finite element model of the multilayered filament wound composite pressure vessel is established by the

finite element software ANSYS 12. The pressure vessel is analyzed for maximum stress and its burst

pressure is predicted for hoop and helical windings of the fibers using a failure model such as the Tsai-Wu

failure criterion. The fibers are oriented helically for various orientations such as (+30/-30)s, (+35,-35)s

,(+40,-40)s ,(+45/-45)s, (+50,-50),(+55/-55)s,(+60,-60) and (+65/-65)s. Based on the maximum stress

criteria, burst pressure and optimum angle of fiber orientation were determined from the analysis. The aim of

this paper is to analyze stresses in a Glass filament wound FRP pressure vessel for different winding

orientations using Ansys 12 , and compute the burst pressure of the vessel by applying a suitable failure

criterion. This paper aims at developing composite pressure vessel using E-Glass , and this work will be

extremely useful for FRP-equipment manufacturers, designers, and consultants in the field of chemical

process industries .

KEYWORDS: Composite pressure vessels, filament winding, finite element analysis, internal pressure,

boundary conditions, fiber orientations

Copyright 2015 International Journal for Modern Trends in Science and Technology

All rights reserved.

I. INTRODUCTION

Pressure vessels have been manufactured by

filament winding for a long time. Although they

appear to be simple structures, pressure vessels

are among the most difficult

to

design.

Filament-wound composite pressure vessels

have found widespread use not only for military

use but also for civilian applications. This

technology originally developed for the militarys

internal use was adapted to civilian purpose and

later extended to the commercial market.

Applications include breathing device, such as

152

self-contained breathing apparatuses used by

fire-fighters and other emergency personnel, scuba

tanks for divers, oxygen cylinders for medical and

aviation cylinders for emergency slide inflation,

opening doors or lowering of landing gear,

mountaineering expedition equipment, paintball

gas cylinders, etc. A potential widespread

application for composite pressure vessels is the

automotive industry. Emphasis on reducing

emissions promotes the conversion to Compressed

Natural Gas (CNG) fuelled vehicles worldwide.

Engineers are seeking to replace fuel oils with

natural gas or hydrogen as the energy supply in

automobiles for air quality improvements and

International Journal for Modern Trends in Science and Technology

Design and Stress Analysis of FRP Composite Pressure Vessel

reduce global warning. Fuel cells in concert with

hydrogen gas storage technologies

are key

requirements for the successful application of

these fuels in vehicles. One of the limitations is

lack of vehicle range between refuelling stops.

Weight, volume and cost of the containment vessel

are also considerations.

.

2.2.1.2 Nodes: The nodes associated with the

element are listed as I, J, K, etc. Elements are

connected to the nodes in the sequence and

orientation shown on the input figure for each

element type. This connectivity can be defined by

automatic meshing, or may be input directly by

the user with the E command.

II. FINITE ELEMENT ANALYSIS

2.1 Introduction to FE Analysis

Finite element analysis is a powerful numerical

technique for analysis. FEA is used for stress

analysis in that area of solid mechanics. The

basic concept of finite element method is that a

body / structure may be divided into smaller

elements called finite elements. The properties of

the element are formulated and combined to

obtain the solution for the entire body or

structure. For a given practical design problem

the engineer has to idealize the physical system

into a FE model with proper boundary conditions

and loads that are acting on the system. Then the

discretization of a given body or structure into

cells of finite elements is performed and the

mathematical model is analyzed for every

element and then for complete structure. The

various unknown parameters are computed by

using known parameters.

2.1.1 Steps involved in ANSYS Preprocessor :

Preprocessor Inputs are

(1) Element type

(2) Real constants

(3) Material properties (youngs modulus,

Poisons ratio, shear modulus)

(4) Meshing

Boundary conditions :

The boundary conditions like displacement and

pressure are applied.

Solution:

General post processor:

In the General post processor the results obtain

are deformation mechanical, and Stress

2.2 General Element Features

2.2.1 Element Input

2.2.1.1 Element Name

2. 2.1.2 Nodes

2.2.1.3 Degrees of Freedom

2.2.1.4 Real Constants

2.2.2.1.5 Material properties

2.2.1.6 Surface Loads

2.2.1.1 Element Name :An element type is

identified by a name (8 characters maximum),

such as PLANE82 consisting of a group label

(PLANE) and a unique, identifying number (82).

The element descriptions in Element Library are

arranged in order of these identification numbers.

The element is selected from the library for use in

the analysis by inputting its name on the element

type command

153

2.2.1.3 Degrees of Freedom: Each element type has

a degree of freedom set, which constitute the

primary nodal unknowns to be determined by the

analysis. They may be displacements, rotations,

temperatures, pressures, voltages, etc. Derived

results, such as stresses, heat flows, etc., are

computed from these degree of freedom results.

Degrees of freedom are not defined on the nodes

explicitly by the user, but rather are implied by the

element types attached to them. The choice of

element types is therefore, an important one in any

ANSYS analysis.

2.2.1.4 Real Constants: Data which are required for

the calculation of the element matrix, but which

cannot be determined from the node locations or

material properties, are input as "real constants."

Typical real constants include area, thickness,

inner diameter, outer diameter, etc.

Material properties: Various material

properties are used for each element type. Typical

material properties include Young's modulus (of

elasticity), density, coefficient of thermal

expansion, thermal conductivity, etc. Each

property is referenced by an ANSYS label - EX, EY,

and EZ for the directional components of Young's

modulus, DENS for density, and so on. All

material properties can be input as functions of

temperature.

2.2.1.5

2.2.1.6 Surface Loads:Various element types allow

surface loads. Surface loads are typically pressures

for structural element types, convections or heat

fluxes for thermal element types, etc.

2.3 Element type selection:Element : Structural

Solid Quad 8 node 82 ( Plane 82 )

Figure 2.1

Plane82 Geometry

2.3.1 PLANE82 Element Description: PLANE82 is a

higher order version of the 2-D, four-node element.

It provides more accurate results for mixed

International Journal for Modern Trends in Science and Technology

Volume: 2 | Issue: 05 | May 2016 | ISSN: 2455-3778

IJMTST

(quadrilateral-triangular) automatic meshes and

can tolerate irregular shapes without as much loss

of accuracy. The 8-node elements have compatible

displacement shapes and are well suited to model

curved boundaries.The 8-node element is defined

by eight nodes having two degrees of freedom at

each node: translations in the nodal x and y

directions. The element may be used as a plane

element or as an axisymmetric element. The

element has plasticity, creep, swelling, stress

stiffening, large deflection, and large strain

capabilities.

2.3.2 PLANE82 Input Summary

Nodes

I, J, K, L, M, N, O, P

Degrees of Freedom

UX, UY

2.4 Material properties of E-glass fiber reinforced

polymer composite pressure vessel:

Table 2.1 Typical properties of filament wound pipes

(glass fibre reinforced)

Property

Density

Typical

Values

1.88-2.26

Tensile Strength, MPa

(Helical Windings)

344-1034

Compressive

Strength, MPa

(Helical Windings)

276-551

Shear Strength, MPa:

--Interlaminar

21-137

Resin Type,

Wind Pattern,

Glass/Resin

Ratio, Resin

Type

55-206

Material Properties

EX, EY, EZ, PRXY, PRYZ, PRXZ (or NUXY,

NUYZ, NUXZ),

Surface Loads

Pressures --

face 1 (J-I), face 2 (K-J), face 3 (I-K),

face 4 (I-L)

2.3.3

2.3.4

--Cross

Modulus of Elasticity

(Tension), GPa

21-41

Glass type, Wind

Pattern

Modulus of Rigidity

(Torsion), GPa

11-14

Flexural Strength

344-517

Wind Pattern

Wind Pattern,

Glass/Resin

Ratio

Element Behaviour:

\Option K3 = Axisymmetry

Problem description:

The Glass fiber reinforced polymer composite

pressure vessel is analyzed for two different cases

2.3.4.1 Case 1:

In the first case ,the pressure vessel is subjected

to working internal pressure of 35Mpa. The

pressure vessel is analyzed for hoop and various

helical fiber orientations (+30,-30)s ,(+35,-35)s

,(+40,-40)s , (+45,-45)s, (+50,-50)s, and (+55,-55)s

for symmetrical stacking sequence.

2.3.4.2 Case 2:

In the second case the pressure vessel is

subjected to high internal pressure values and the

burst pressure of the pressure vessel is predicted

for the same fiber orientations.The burst pressure

for the pressure vessel is predicted by

incrementally increasing the

Values of internal pressure from a working

pressure of 35Mpa.

Predominant

Process

Variables

Glass/Resin

Ratio

Glass Type,

Glass/Resin

Ratio, Wind

Pattern

Glass/Resin

Ratio, Resin

Type, Wind

Pattern

Table 2.2 Linear material properties of filament wound

pressure vessel (glass fibre reinforced)

MP,Value

EX

Value(Gpa)

29.0

EY

5.3

EZ

5.3

PRXY

0.44

PRYZ

0.20

PRXZ

0.44

GXY

5.11

GXZ

5.11

Description

Elastic modulus,

Element X-direction

Elastic modulus

,Element Y-direction

Elastic modulus,

Element Z-direction

Major poissons

ratio,XY Plane

Major poissons

ratio,YZ Plane

Major poissons

ratio,XZ Plane

Shear modulus, XY

Plane

Shear modulus, XZ

Plane

Fig 2.2 The above figure shows the finite element mode of

the glass fiber reinforced composite pressure vessel

154

International Journal for Modern Trends in Science and Technology

Design and Stress Analysis of FRP Composite Pressure Vessel

The geometry of GFPR composite pressure is free

meshed with Quad elements.All elements are

approximately of same size and the element edge

length is of 2.5mm.

2.6 Boundary conditions:

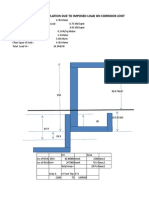

Figure 2.3 The above figure shows the geometric

2D-layout of GFRP composite pressure vessel

Figure 2.7 The above figure shows the boundary

conditions applied to the GFRP composite pressure vessel

and applied pressure of 35Mpa

Figure 2.4 The above figure shows the axisymmetric model

of GFRP composite pressure vessel

Figure 2.5 The above figure shows the stacking sequence

for hoop direction (90 degrees) of fibers orientation angle

of glass fiber reinforced composite pressure vessel

The above figure 2.5 shows the symmetrical

stacking sequence for hoop direction for the Glass

fiber reinforced composite vessel .Each layer

thickness is equal to 2.5mm and four layers are

selected for the analysis in symmetrical pattern

with angle equal to 90 degrees fiber orientation.

The Boundary Conditions and Loads are now

applied. ANSYS will automatically apply the

Axisymmetric Boundary Conditions along the

Y-axis.However, we must apply the Symmetry

Boundary Conditions along the upper edge of the

model. Finally, the Pressure equal to 35Mpa is

applied on all lines that make up the inner surface

of the vessel.

Figure 2.8 The above figure shows the maximum stress

equal to 132.489 , for the GFRP composite pressure vessel

for hoop ( 90 degree fiber orientation angle) at working

pressure of 35Mpa

2.5 Meshing:

Figure 2.9 The above figure shows the stacking sequence of

(+30,-30, -30,and +30 ) fiber orientation angles

Figure: 2.6 The above figure shows a zoomed section of

the meshed geometry of the Glass fiber reinforced

composite pressure vessel along the thickness of the

walls of the vessel.

155

International Journal for Modern Trends in Science and Technology

Volume: 2 | Issue: 05 | May 2016 | ISSN: 2455-3778

IJMTST

Figure 2.14 The above figure shows the burst pressure

equal to 110.415Mpa , for the GFRP composite pressure

Figure 2.10 The above figure shows the maximum stress vessel for (+35,-35, -35,and +35 ) fiber orientation angle

equal to 62.937Mpa, for the GFRP composite pressure vessel

for (+30,-30, -30,and +30 ) fiber orientation angle at working

pressure of 35Mpa

Figure 2.15 The figure shows the stacking sequence of

(+40,-40, -40 ,and +40 ) fiber orientation angles

Figure 2.11 The above figure shows the burst pressure equal

to 110.415Mpa ,for the GFRP composite pressure vessel for

(+30,-30, -30,and +30 ) fiber orientation angle

Figure 2.16 The above figure shows the maximum stress

equal to 36.437Mpa, at pressure of 35Mpa for (+40,-40,

-40 ,and +40 ) fiber orientation angle

Figure 2.12 The figure shows the stacking sequence of

(+35,-35, -35 ,and +35 ) fiber orientation angles

Figure 2.17 The above figure shows the burst pressure

equal to 185.497Mpa , for the GFRP composite pressure

vessel for (+40, -40, -40,and +40 ) fiber orientation

Figure 2.13 The above figure shows the maximum stress

equal to 61.832Mpa, at working pressure of 35Mpa for

(+35,-35, -35,and +35 ) fiber orientation angle

Figure 2.18 The figure shows the stacking sequence of

(+45 ,-45, -45 ,and +45 ) fiber orientation angle

156

International Journal for Modern Trends in Science and Technology

Design and Stress Analysis of FRP Composite Pressure Vessel

Figure 2.19 The above figure shows the maximum stress

equal to 38.645Mpa, at pressure of 35Mpa for (+45, -45,

-45,and +45 ) fiber orientation

Figure 2.20 The above figure shows the burst pressure

equal to 181.081Mpa , for the GFRP composite pressure

vessel for (+45,-45, -45,and +45 ) fiber orientation angle

Figure 2.23 The above figure shows the burst pressure

equal to 114.832Mpa , for the GFRP composite pressure

vessel for (+50, -50, -50, and +50 ) fiber orientation

angle

Figure 2.24 The figure shows the stacking sequence of

(+55, -55, -55 ,and +55 ) fiber orientation angle

Figure 2.21 The figure shows the stacking sequence of

(+50 , -50, -50 ,and +50 ) fiber orientation angle

Figure 2.25 The above figure shows the maximum stress

equal to 60.728Mpa, for the GFRP composite pressure

vessel for (+55 ,-55 ,-55 ,and +55 ) fiber orientation angle

at working pressure of 35Mpa

Figure 2.22 The above figure shows the maximum stress

equal to 41.958Mpa, for the GFRP composite pressure

vessel for (+50, -50 , -50 ,and +50 ) fiber orientation at

working pressure of 35Mpa.

Figure 2.26 The above figure shows the burst pressure

equal to 103.79, for the GFRP composite pressure vessel

for (+55, -55, -55, and +55 ) fiber orientation angle

157

International Journal for Modern Trends in Science and Technology

Volume: 2 | Issue: 05 | May 2016 | ISSN: 2455-3778

IJMTST

Figure 2.27 The above figure shows the stacking sequence

of (+60, -60, -60 ,and +60 ) fiber orientation angle

Figure 2.28 The above figure shows the maximum stress

equal to 75.082Mpa, for the GFRP composite pressure

vessel for (+60 , -60 , -60 ,and +60 ) fiber orientation angle

at working pressure of 35Mpa

Table 3.2 shows the burst pressure for different fiber

orientation angles

S.

Angle of fiber orientation

Burst

No

pressure

(Mpa)

1

(+30, -30, -30, +30),symmetrical

110.415

stacking

2

(+35, -35, -35, +35),symmetrical

119.015

stacking

3

(+40, -40, -40, +40),symmetrical

185.497

stacking

4

(+45, -45, -45, +45),symmetrical

181.081

stacking

5

(+50, -50, -50, +50),symmetrical

114.832

stacking

6

(+55, -55, -55, +55),symmetrical

103.79

stacking

7

(+60, -60, -60, +60),symmetrical

80.603

stacking

The results of the maximum stress analysis for

various fiber orientations are plotted graphically

and can be seen in form of below figure. The

analysis of the stress distribution for the different

fiber orientations shows that the maximum stress

in the cylindrical composite pressure vessel is

found to be minimum for ,(+40/-40)s ,fiber

orientation.

200

100

Maximum

stress (Mpa)

0

0 30 35 40 45 50 55 60 65

Figure: 3.1 Graph : variation of Maximum Stress (Mpa)

with different fiber orientation angles

Figure 2.29 The above figure shows the burst pressure

equal to 80.603Mpa , for the GFRP composite pressure

vessel for (+60, -60, -60, and +60 ) fiber orientation angle

III. MATH

The results obtained after analysis are tabulated

and shown below in table 3.1 and table 3.2

Table 3.1 shows the maximum stress for different

fiber orientation angles

Maximum

S.

Angle of fiber orientation

stress

No

(Mpa)

1

(+30, -30, -30, +30),symmetrical

62.937

stacking

2

(+35, -35, -35, +35),symmetrical

61.832

stacking

3

(+40, -40, -40, +40),symmetrical

36.437

stacking

4

(+45, -45, -45, +45),symmetrical

38.645

stacking

5

(+50, -50, -50, +50),symmetrical

41.958

stacking

6

(+55, -55, -55, +55),symmetrical

60.728

stacking

7

(+60, -60, -60, +60),symmetrical

75.082

stacking

158

While , the results burst pressure analysis for

various fiber orientations can be seen in the graph

shown in figure below. The figure shows that the

pressure vessel can bear maximum internal

pressure of 186Mpa at (+40,-40,-40,+40) fiber

orientation angle.

Burst Pressure (Mpa)

Burst

Pressure

(Mpa)

200

0

0 30 35 40 45 50 55 60 65

Figure:3.2 Graph :variation of burst pressure (Mpa) with

different fiber orientation angles.

IV. CONCLUSION & FUTURE SCOPE

The analysis of the stress distribution for the

different fiber orientations shows that the

maximum stress in the cylindrical composite

pressure vessel is found to be minimum for

(+40,-40,-40,+40) fiber orientation angle and is

International Journal for Modern Trends in Science and Technology

Design and Stress Analysis of FRP Composite Pressure Vessel

equal to 36.437Mpa.The burst pressure analysis

for various fiber orientations shows that the

pressure vessel can bear maximum internal

pressure of 185.497Mpa at (+40,-40,-40,+40) fiber

orientation angle.Thus , it can be concluded from

the analysis that (+40,-40,-40 and +40 ), fiber

orientation angle is the optimum angle for the safe

working of the pressure vessel.The GFRP pressure

vessel if designed at (+40,-40,-40 and +40 ),fiber

orientation angle , will have

safe working

conditions which can withstand maximum internal

pressure .

Future Scope: As the present analysis is for

cylindrical pressure vessel, it can be applied for

different

configurations

like

Spherical,

Rectangular, etc. As the present work is for static

analysis ,we can go for dynamical analysis

also.Work for the design of composite pressure

vessels subjected to external pressure can be

taken up.The present work can be extented to

include other types of enclosures like flat and

conical ends and also design of openings,

supports,etc.

[13] Mirza, S., Bryan, A., Noori, M. Fiber-Reinforced

Composite Cylindrical Vessel with Lugs, Composite

Structures, 53, 143-151. (2001)

[14] Ochoa, O. O. & Reddy, J. N. Finite Element

Analysis of Composite Laminates. Netherland:

Kluwer Academic Publishers. (1992)

[15] Parnas, L. & Katrc, N. Design of Fiber-Reinforced

Composite Pressure Vessels under Various Loading

Conditions, Composite Structures, 58, 83-95.

(2002)

[16] Rao, V. V. S. & Sinha, P. K. Dynamic Response

of

MultidirectionalComposites in Hygrothermal

Environments, Composite Structures,64, 329-338.

(2004)

REFERENCES

[1] Adali, S., Verijenko, V. E. et al. Optimization of

multilayered

composite pressure vessels using

exact elasticity solution, Composites for the

Pressure Vessels Industry, PVP-V302, ASME,

203-312. (1995)

[2] Babu, M., S., Srikanth, G. & Biswas, S. Composite

Fabrication by Filament Winding - An Insight.

Retrived December 4, 2006

[3] Chang, R. R.Experimental and Theoretical Analyses

of First-Ply Failure ofLaminated, Composite

Pressure Vessels, Composite Structures, 49,

237-243.(2000)

[4] Cohen, D., Mantell, S. C. & Zhao, L. The Effect of

Fiber Volume Fraction on Filament Wound

Composite Pressure Vessel Strength, Composites:

Part B, 32,413-429. (2001)

[5] Crawford R.

J. Plastics Engineering (3rd ed.).

Oxford: ButterworthHeinemann (1998)

[6] Hwang, T. K., Hong, C. S., & Kim, C. G. Size Effect

on the Fiber Strength of Composit Pressure Vessels,

Composite Structures, 59, 489-498. (2003)

[7] Jones, R. M. Mechanics of Composite Material

(2nd ed.). Philadelphia: Taylor & Francis. (1998)

[8] Kabir, M. Z . Finite Element Analysis of Composite

Pressure Vessels with aLoad Sharing Metallic Liner,

Composite Structures, 49, 247-255. (2000)

[9] Lekhnitskii, S. G . Theory of Elasticity of an

Anisotropic Body, Mir Publishers, Moscow. (1981)

[10] Liang, C. C., Chen, H.W., Wang, C.H. Optimum

Design of Dome Contour for Filament-Wound

Composite Pressure Vessels Based on a Shape

Factor, Composite Structures, 58, 469-482. (2002)

[11] Mackerle, J. Finite Elements in the Analysis of

Pressure Vessels and Piping, an Addendum: a

Bibliography (1998-2001), International Journal of

Pressure Vessels and Piping, 79, 1-26. (2002)

[12] Mazumdar, S.

K. Composite Manufacturing

:Materials,

Product,

and Process Engineering.

London: Crc Press. (2001)

159

International Journal for Modern Trends in Science and Technology

117

Das könnte Ihnen auch gefallen

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsVon EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNoch keine Bewertungen

- Activated Carbon, Silica-Gel and Calcium Chloride Composite Adsorbents For Energy Efficient Adsorption Cooling SystemsDokument136 SeitenActivated Carbon, Silica-Gel and Calcium Chloride Composite Adsorbents For Energy Efficient Adsorption Cooling SystemsAlexander Vova100% (1)

- Discrete Element Method to Model 3D Continuous MaterialsVon EverandDiscrete Element Method to Model 3D Continuous MaterialsNoch keine Bewertungen

- FRP DesignDokument17 SeitenFRP DesignRUSTSHIELD IndonesiaNoch keine Bewertungen

- Creep And Relaxation Of Nonlinear Viscoelastic Materials With An Introduction To Linear ViscoelasticityVon EverandCreep And Relaxation Of Nonlinear Viscoelastic Materials With An Introduction To Linear ViscoelasticityBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Anchor Bolt CalculationDokument1 SeiteAnchor Bolt CalculationLcm TnlNoch keine Bewertungen

- PV Elite ResultDokument239 SeitenPV Elite ResultChaitanya Sai TNoch keine Bewertungen

- Flow Characteristics in Mixers Agitated by Helical Ribbon Blade ImpellerDokument15 SeitenFlow Characteristics in Mixers Agitated by Helical Ribbon Blade Impellerkalyan555Noch keine Bewertungen

- Design of Pressure VesselsDokument8 SeitenDesign of Pressure Vesselsanswer1Noch keine Bewertungen

- FKT NiehII Statik GRP StressDokument98 SeitenFKT NiehII Statik GRP StressSakshi AgrawalNoch keine Bewertungen

- Design Fiber Glass Reinforcement Vesselt For AgitatorDokument11 SeitenDesign Fiber Glass Reinforcement Vesselt For AgitatorAnonymous T8aah3JfNoch keine Bewertungen

- 2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFDokument12 Seiten2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFvlad lupasteanuNoch keine Bewertungen

- Welding Neck Flanges 1Dokument3 SeitenWelding Neck Flanges 1bikkelbobNoch keine Bewertungen

- Beams On Elastic FoundationsDokument3 SeitenBeams On Elastic FoundationsIgnatius SamrajNoch keine Bewertungen

- RT IOM Eng PDFDokument96 SeitenRT IOM Eng PDFsergio catañoNoch keine Bewertungen

- Mechanical Calculations for Fiberglass Tank ManufacturingDokument7 SeitenMechanical Calculations for Fiberglass Tank ManufacturingAlfonso López JiménezNoch keine Bewertungen

- Atmatec - Fibreglass Products For Drainage Systems PDFDokument44 SeitenAtmatec - Fibreglass Products For Drainage Systems PDFHafiz KamalNoch keine Bewertungen

- 2400 Tema DCDokument7 Seiten2400 Tema DCMasoodMiyanNoch keine Bewertungen

- Welding SymbolsDokument12 SeitenWelding SymbolsrsrtnjNoch keine Bewertungen

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Dokument7 SeitenUsing The ASME VIII-1 Nozzle F Factor (UG-37)stalin_83Noch keine Bewertungen

- Broadway Hilti Handrail Base PDFDokument4 SeitenBroadway Hilti Handrail Base PDFjijinjohnNoch keine Bewertungen

- PHB Strength Calculation - Softener Pressure Vessel 09.09.19Dokument7 SeitenPHB Strength Calculation - Softener Pressure Vessel 09.09.19Abu SuraisyNoch keine Bewertungen

- Lect 9 FRP Shear Design1Dokument8 SeitenLect 9 FRP Shear Design1FanooNoch keine Bewertungen

- Fea For Design EngineersDokument2 SeitenFea For Design EngineersOmer HayatNoch keine Bewertungen

- Deflection Calculation Due To Imposed Load On Corridor JoistDokument14 SeitenDeflection Calculation Due To Imposed Load On Corridor JoistranjitNoch keine Bewertungen

- NORSOK Piping Details Standard for Instrument ConnectionsDokument41 SeitenNORSOK Piping Details Standard for Instrument ConnectionsAli BariNoch keine Bewertungen

- 22BMJ 045 FEA 07 - Rev 0 - 23.07.05Dokument13 Seiten22BMJ 045 FEA 07 - Rev 0 - 23.07.05TEP DesignNoch keine Bewertungen

- Pressure Vessel Inspection ReportDokument33 SeitenPressure Vessel Inspection ReportJinlong SuNoch keine Bewertungen

- Machine Design Project ReportDokument11 SeitenMachine Design Project ReportMuhammad Abdullah100% (1)

- CFD ApplicationsDokument5 SeitenCFD ApplicationsavailmeNoch keine Bewertungen

- Bolted Connections: 1.1 Range and Class of The Screw FastenersDokument8 SeitenBolted Connections: 1.1 Range and Class of The Screw FastenersksNoch keine Bewertungen

- Agitator Power Requirement and Mixing Intensity CalculationDokument28 SeitenAgitator Power Requirement and Mixing Intensity CalculationVasu DevanNoch keine Bewertungen

- Fatigue Analysis in Ansys WorkbenchDokument14 SeitenFatigue Analysis in Ansys WorkbenchAshokkumar VelloreNoch keine Bewertungen

- ASCE 7-05 Table 15-4-2Dokument1 SeiteASCE 7-05 Table 15-4-2barouniamineNoch keine Bewertungen

- Agitator DesignDokument3 SeitenAgitator DesignSmrutiNoch keine Bewertungen

- CR4 - Thread - How To Calculate Flat Plate Thickness of Flat Bottom Storage Tank - PDFDokument3 SeitenCR4 - Thread - How To Calculate Flat Plate Thickness of Flat Bottom Storage Tank - PDFInamullah KhanNoch keine Bewertungen

- Report On Desiging CompanyDokument53 SeitenReport On Desiging CompanyArpit ThumarNoch keine Bewertungen

- Design and Static Analysis of Different Pressure Vessels and Materials Using Fem MethodDokument7 SeitenDesign and Static Analysis of Different Pressure Vessels and Materials Using Fem MethodSuryaprakashNoch keine Bewertungen

- Design and Finite Element Assessment of Mounded Bullet PDFDokument14 SeitenDesign and Finite Element Assessment of Mounded Bullet PDFc0g100% (1)

- Spring CalculationDokument3 SeitenSpring CalculationAkshay JadhavNoch keine Bewertungen

- bs4994 Case Study PDFDokument4 Seitenbs4994 Case Study PDFA.Subin DasNoch keine Bewertungen

- ASME VIII Div.1 Cyclic Loading Verification ManualDokument4 SeitenASME VIII Div.1 Cyclic Loading Verification ManualGovindan KrishnamoorthybashyamNoch keine Bewertungen

- IIT Hyderabad Faculty Housing Design CalculationsDokument33 SeitenIIT Hyderabad Faculty Housing Design CalculationssmijusNoch keine Bewertungen

- Theory of Stress and StrainDokument34 SeitenTheory of Stress and StrainMd ReyazNoch keine Bewertungen

- Project JG Summit Stage1 Expansion Title: Screening Procedure As Per ASME Section VIII, Div 2. PE3-E6552Dokument1 SeiteProject JG Summit Stage1 Expansion Title: Screening Procedure As Per ASME Section VIII, Div 2. PE3-E6552Darshan PanchalNoch keine Bewertungen

- 3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankDokument4 Seiten3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankNurul HudaNoch keine Bewertungen

- Fiber TestingDokument11 SeitenFiber TestingSandy YansikuNoch keine Bewertungen

- Pin Base ModuleDokument16 SeitenPin Base ModuleMd Ahsanul KabirNoch keine Bewertungen

- Comp 2Dokument9 SeitenComp 2YYo YudiNoch keine Bewertungen

- PDF2 L Hydraulic CylinderDokument56 SeitenPDF2 L Hydraulic CylinderShyam Srinivasan100% (1)

- Structural Retrofitting of A Reinforced Concrete ChimneyDokument6 SeitenStructural Retrofitting of A Reinforced Concrete ChimneyIJAERS JOURNALNoch keine Bewertungen

- Anti-corrosion Lining for Concrete PoolsDokument4 SeitenAnti-corrosion Lining for Concrete Poolsmuchamad yasinNoch keine Bewertungen

- Asme Sec X 2017Dokument6 SeitenAsme Sec X 2017SARSAN NDTNoch keine Bewertungen

- Tk-02 Cone Roof - Roof & Bottom SolutionDokument2 SeitenTk-02 Cone Roof - Roof & Bottom Solutionpescanova3Noch keine Bewertungen

- Sample Vessel Design (Sec - VIII Div.1)Dokument34 SeitenSample Vessel Design (Sec - VIII Div.1)Chano HanokNoch keine Bewertungen

- Earthquake load calculations as per IS1893-2002Dokument9 SeitenEarthquake load calculations as per IS1893-2002irshad313Noch keine Bewertungen

- Buckling of Thin-Walled Conical Shells Under Uniform External PressureDokument14 SeitenBuckling of Thin-Walled Conical Shells Under Uniform External PressureAnonymous wWOWz9UnWNoch keine Bewertungen

- Creeps Analysis of ThermoplasticsDokument7 SeitenCreeps Analysis of ThermoplasticsIgor AlarcónNoch keine Bewertungen

- FEA of Ellipsoidal Head Pressure Vessel - by - VikramDokument7 SeitenFEA of Ellipsoidal Head Pressure Vessel - by - VikramaruatscribdNoch keine Bewertungen

- Finite Element Analysis of Gasket in Pressure VesselDokument6 SeitenFinite Element Analysis of Gasket in Pressure VesselIJRASETPublicationsNoch keine Bewertungen

- Emerging Public Health Concern and Air Pollution: A Case Study of Delhi's Air Pollution GovernanceDokument6 SeitenEmerging Public Health Concern and Air Pollution: A Case Study of Delhi's Air Pollution GovernanceIJMTST-Online JournalNoch keine Bewertungen

- Implementation of ANN Controller Based Interleaved Hybrid ConverterDokument4 SeitenImplementation of ANN Controller Based Interleaved Hybrid ConverterIJMTST-Online JournalNoch keine Bewertungen

- Design, Fabrication and Performance Evaluation of Hybrid Vertical Axis Wind TurbineDokument7 SeitenDesign, Fabrication and Performance Evaluation of Hybrid Vertical Axis Wind TurbineIJMTST-Online JournalNoch keine Bewertungen

- Wireless Charging For Autonomous Under Water VehiclesDokument9 SeitenWireless Charging For Autonomous Under Water VehiclesIJMTST-Online JournalNoch keine Bewertungen

- Supply Monitoring Using IoTDokument3 SeitenSupply Monitoring Using IoTIJMTST-Online JournalNoch keine Bewertungen

- Performance Evaluation and Optimization of Wind-Solar PV Hybrid Electricity Generation and Application To Electric VehicleDokument17 SeitenPerformance Evaluation and Optimization of Wind-Solar PV Hybrid Electricity Generation and Application To Electric VehicleIJMTST-Online JournalNoch keine Bewertungen

- Finite Element Analysis of Cylindrical and Spherical Concrete VaultsDokument5 SeitenFinite Element Analysis of Cylindrical and Spherical Concrete VaultsIJMTST-Online JournalNoch keine Bewertungen

- Automatic Load Disconnection and Reconnection To Power System Using Controllable LoadsDokument6 SeitenAutomatic Load Disconnection and Reconnection To Power System Using Controllable LoadsIJMTST-Online JournalNoch keine Bewertungen

- An Multi-Input ZCS DC-DC Front-End - Converter Based Multilevel Inverter For The Integration of Renewable Energy SourcesDokument4 SeitenAn Multi-Input ZCS DC-DC Front-End - Converter Based Multilevel Inverter For The Integration of Renewable Energy SourcesIJMTST-Online JournalNoch keine Bewertungen

- Arduino Based Traffic Monitoring and Controlling SystemDokument4 SeitenArduino Based Traffic Monitoring and Controlling SystemIJMTST-Online JournalNoch keine Bewertungen

- IoT Mining Tracking &worker Safety Emergency AlertDokument4 SeitenIoT Mining Tracking &worker Safety Emergency AlertIJMTST-Online JournalNoch keine Bewertungen

- Analysis & Demonstration of Impact of Air PollutionDokument5 SeitenAnalysis & Demonstration of Impact of Air PollutionIJMTST-Online JournalNoch keine Bewertungen

- Automatic Plaster MachineDokument4 SeitenAutomatic Plaster MachineIJMTST-Online JournalNoch keine Bewertungen

- Synthesis of Natural Food Colour From Carotenoid Using Flower PetalsDokument10 SeitenSynthesis of Natural Food Colour From Carotenoid Using Flower PetalsIJMTST-Online JournalNoch keine Bewertungen

- Image Enhancement Techniques For Acute Leukemia ImagesDokument5 SeitenImage Enhancement Techniques For Acute Leukemia ImagesIJMTST-Online JournalNoch keine Bewertungen

- A Study On The Attitude and Purchase Intention of Consumer Regarding Green ElectronicsDokument13 SeitenA Study On The Attitude and Purchase Intention of Consumer Regarding Green ElectronicsIJMTST-Online JournalNoch keine Bewertungen

- Optimization of Fluent Turbulence Models For Annular DiffuserDokument4 SeitenOptimization of Fluent Turbulence Models For Annular DiffuserIJMTST-Online JournalNoch keine Bewertungen

- Design and Implementation of Women Safety SystemDokument5 SeitenDesign and Implementation of Women Safety SystemIJMTST-Online JournalNoch keine Bewertungen

- Industry 4.0 and Developing Countries: Innovation Perspective of Ethiopia, India and BangladeshDokument9 SeitenIndustry 4.0 and Developing Countries: Innovation Perspective of Ethiopia, India and BangladeshIJMTST-Online JournalNoch keine Bewertungen

- Advance Surveillance Robot Using Raspberry PiIotDokument4 SeitenAdvance Surveillance Robot Using Raspberry PiIotIJMTST-Online JournalNoch keine Bewertungen

- 8 Ijmtst0606016 PDFDokument4 Seiten8 Ijmtst0606016 PDFIJMTST-Online JournalNoch keine Bewertungen

- Blast Analysis On In-Filled Steel Tube ColumnsDokument4 SeitenBlast Analysis On In-Filled Steel Tube ColumnsIJMTST-Online JournalNoch keine Bewertungen

- Recent Development and Advancement of Regenerative Braking in Electric BikeDokument4 SeitenRecent Development and Advancement of Regenerative Braking in Electric BikeIJMTST-Online JournalNoch keine Bewertungen

- Identification of Brain Tumor Using MATLABDokument4 SeitenIdentification of Brain Tumor Using MATLABIJMTST-Online JournalNoch keine Bewertungen

- Biosynthesis of Silver Nanoparticles Through Biomass of Fungus Aspergillusniger and Their Antibacterial PotentialDokument6 SeitenBiosynthesis of Silver Nanoparticles Through Biomass of Fungus Aspergillusniger and Their Antibacterial PotentialIJMTST-Online JournalNoch keine Bewertungen

- Osteoporosis Detection Using Deep LearningDokument4 SeitenOsteoporosis Detection Using Deep LearningIJMTST-Online JournalNoch keine Bewertungen

- Underwater Image Enhancement Using Color Balance and FusionDokument3 SeitenUnderwater Image Enhancement Using Color Balance and FusionIJMTST-Online JournalNoch keine Bewertungen

- An Efficient & Secure Timer Based Baiting Approach To Detect Black Hole Attacks in MANETDokument4 SeitenAn Efficient & Secure Timer Based Baiting Approach To Detect Black Hole Attacks in MANETIJMTST-Online JournalNoch keine Bewertungen

- Design and Potential Analysis of Regenerative Braking in Electric BikeDokument4 SeitenDesign and Potential Analysis of Regenerative Braking in Electric BikeIJMTST-Online JournalNoch keine Bewertungen

- Prevalence of Non-Responsiveness To An Indigenous Recombinant Hepatitis B Vaccine: A Study Among Health Care Workers in A Tertiary HospitalDokument5 SeitenPrevalence of Non-Responsiveness To An Indigenous Recombinant Hepatitis B Vaccine: A Study Among Health Care Workers in A Tertiary HospitalIJMTST-Online JournalNoch keine Bewertungen

- C 7000Dokument109 SeitenC 7000Alex Argel Roqueme75% (4)

- Backup and Recovery ScenariosDokument8 SeitenBackup and Recovery ScenariosAmit JhaNoch keine Bewertungen

- Impact of Coronavirus On Livelihoods of RMG Workers in Urban DhakaDokument11 SeitenImpact of Coronavirus On Livelihoods of RMG Workers in Urban Dhakaanon_4822610110% (1)

- RTL8316C GR RealtekDokument93 SeitenRTL8316C GR RealtekMaugrys CastilloNoch keine Bewertungen

- Well Control Kill Sheet (Low Angle Wells)Dokument8 SeitenWell Control Kill Sheet (Low Angle Wells)Tatita ValenciaNoch keine Bewertungen

- TEST BANK: Daft, Richard L. Management, 11th Ed. 2014 Chapter 16 Motivating EmplDokument37 SeitenTEST BANK: Daft, Richard L. Management, 11th Ed. 2014 Chapter 16 Motivating Emplpolkadots939100% (1)

- Oop Assignment # 2 Submitted By: Hashir Khan Roll #: 22f-7465 Date: 3-3-2023Dokument14 SeitenOop Assignment # 2 Submitted By: Hashir Khan Roll #: 22f-7465 Date: 3-3-2023Hashir KhanNoch keine Bewertungen

- Gattu Madhuri's Resume for ECE GraduateDokument4 SeitenGattu Madhuri's Resume for ECE Graduatedeepakk_alpineNoch keine Bewertungen

- Gaspardo Operation Manual Campo 22-32-2014 01 f07011089 UsaDokument114 SeitenGaspardo Operation Manual Campo 22-32-2014 01 f07011089 UsaМихайленко МиколаNoch keine Bewertungen

- Tata Chemicals Yearly Reports 2019 20Dokument340 SeitenTata Chemicals Yearly Reports 2019 20AkchikaNoch keine Bewertungen

- Ten Golden Rules of LobbyingDokument1 SeiteTen Golden Rules of LobbyingChaibde DeNoch keine Bewertungen

- 2CG ELTT2 KS TitanMagazine Anazelle-Shan PromoDokument12 Seiten2CG ELTT2 KS TitanMagazine Anazelle-Shan PromoJohn SmithNoch keine Bewertungen

- POS CAL SF No4 B2 BCF H300x300 7mmweld R0 PDFDokument23 SeitenPOS CAL SF No4 B2 BCF H300x300 7mmweld R0 PDFNguyễn Duy QuangNoch keine Bewertungen

- Micromaster 430: 7.5 KW - 250 KWDokument118 SeitenMicromaster 430: 7.5 KW - 250 KWAyman ElotaifyNoch keine Bewertungen

- Mayor Byron Brown's 2019 State of The City SpeechDokument19 SeitenMayor Byron Brown's 2019 State of The City SpeechMichael McAndrewNoch keine Bewertungen

- Weka Tutorial 2Dokument50 SeitenWeka Tutorial 2Fikri FarisNoch keine Bewertungen

- Individual Differences: Mental Ability, Personality and DemographicsDokument22 SeitenIndividual Differences: Mental Ability, Personality and DemographicsAlera Kim100% (2)

- iec-60896-112002-8582Dokument3 Seiteniec-60896-112002-8582tamjid.kabir89Noch keine Bewertungen

- Global Cleantech Innovation Programme IndiaDokument122 SeitenGlobal Cleantech Innovation Programme Indiaficisid ficisidNoch keine Bewertungen

- Lister LRM & SRM 1-2-3 Manual and Parts List - Lister - Canal WorldDokument4 SeitenLister LRM & SRM 1-2-3 Manual and Parts List - Lister - Canal Worldcountry boyNoch keine Bewertungen

- Growatt SPF3000TL-HVM (2020)Dokument2 SeitenGrowatt SPF3000TL-HVM (2020)RUNARUNNoch keine Bewertungen

- "60 Tips On Object Oriented Programming" BrochureDokument1 Seite"60 Tips On Object Oriented Programming" BrochuresgganeshNoch keine Bewertungen

- Royal Enfield Market PositioningDokument7 SeitenRoyal Enfield Market PositioningApoorv Agrawal67% (3)

- Geneva IntrotoBankDebt172Dokument66 SeitenGeneva IntrotoBankDebt172satishlad1288Noch keine Bewertungen

- Fundamental of Investment Unit 5Dokument8 SeitenFundamental of Investment Unit 5commers bengali ajNoch keine Bewertungen

- Short Term Training Curriculum Handbook: General Duty AssistantDokument49 SeitenShort Term Training Curriculum Handbook: General Duty AssistantASHISH BARAWALNoch keine Bewertungen

- Self-Assessment On Accountability: I. QuestionsDokument2 SeitenSelf-Assessment On Accountability: I. QuestionsAjit Kumar SahuNoch keine Bewertungen

- Analyze Oil Wear DebrisDokument2 SeitenAnalyze Oil Wear Debristhoma111sNoch keine Bewertungen

- ABS Rules for Steel Vessels Under 90mDokument91 SeitenABS Rules for Steel Vessels Under 90mGean Antonny Gamarra DamianNoch keine Bewertungen

- Jurisdiction On Criminal Cases and PrinciplesDokument6 SeitenJurisdiction On Criminal Cases and PrinciplesJeffrey Garcia IlaganNoch keine Bewertungen

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseVon EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseBewertung: 4.5 von 5 Sternen4.5/5 (50)

- Control of Power Electronic Converters and Systems: Volume 1Von EverandControl of Power Electronic Converters and Systems: Volume 1Bewertung: 5 von 5 Sternen5/5 (1)

- Design of Foundations for Offshore Wind TurbinesVon EverandDesign of Foundations for Offshore Wind TurbinesBewertung: 5 von 5 Sternen5/5 (3)

- Aerodynamics for Engineering StudentsVon EverandAerodynamics for Engineering StudentsBewertung: 5 von 5 Sternen5/5 (5)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationVon EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationBewertung: 4 von 5 Sternen4/5 (18)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionVon EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- The Laws of Thermodynamics: A Very Short IntroductionVon EverandThe Laws of Thermodynamics: A Very Short IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsVon EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationVon EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationBewertung: 1 von 5 Sternen1/5 (1)

- Introduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionVon EverandIntroduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionBewertung: 2.5 von 5 Sternen2.5/5 (3)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsVon EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNoch keine Bewertungen

- Oil and Gas Pipelines: Integrity and Safety HandbookVon EverandOil and Gas Pipelines: Integrity and Safety HandbookNoch keine Bewertungen

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- Handbook of Mechanical and Materials EngineeringVon EverandHandbook of Mechanical and Materials EngineeringBewertung: 5 von 5 Sternen5/5 (4)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideVon Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideBewertung: 3.5 von 5 Sternen3.5/5 (7)

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeVon EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeBewertung: 3.5 von 5 Sternen3.5/5 (4)

- CNC Trade Secrets: A Guide to CNC Machine Shop PracticesVon EverandCNC Trade Secrets: A Guide to CNC Machine Shop PracticesNoch keine Bewertungen

- Albert Einstein's Theory Of Relativity Explained SimplyVon EverandAlbert Einstein's Theory Of Relativity Explained SimplyNoch keine Bewertungen

- Operational Amplifier Circuits: Analysis and DesignVon EverandOperational Amplifier Circuits: Analysis and DesignBewertung: 4.5 von 5 Sternen4.5/5 (2)

- 301 Top Tips for Design Engineers: To Help You 'Measure Up' in the World of EngineeringVon Everand301 Top Tips for Design Engineers: To Help You 'Measure Up' in the World of EngineeringBewertung: 5 von 5 Sternen5/5 (1)

- Three Laws of Nature: A Little Book on ThermodynamicsVon EverandThree Laws of Nature: A Little Book on ThermodynamicsBewertung: 4.5 von 5 Sternen4.5/5 (10)