Beruflich Dokumente

Kultur Dokumente

4-03 Onne Slag Grinding - Production Requirements Rev F

Hochgeladen von

ReubenCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

4-03 Onne Slag Grinding - Production Requirements Rev F

Hochgeladen von

ReubenCopyright:

Verfügbare Formate

Technical Requirements

Documents

Dangote Cement Plc, Onne Port,

Port Harcourt, Nigeria

1.5 MTPA Slag Grinding with 3.0 MTPA Portland

Slag Cement and Blast Furnace Cement

Dispatch including Gypsum &

Slag (GBS) Import Project

Production Requirements

Dangote Cement Plc, Onne Slag Grinding Project, Production Requirements

1/8

Last Saved: April 21, 2016

Date printed: April 21, 2016

For Turnkey Contract

Dangote Cement Plc, Onne Slag Grinding Project, Production Requirements

This document is prepared by

DANGOTE GROUP

Cement Projects Division

Dangote Cement Plc, Onne Slag Grinding Project, Production Requirements

2/8

Last Saved: April 21, 2016

Date printed: April 21, 2016

For Turnkey Contract

Dangote Cement Plc, Onne Slag Grinding Project, Production Requirements

TABLE OF CONTENTS

Cement Production Requirements..........................................3

Cement...............................................................................................3

2.1

Definition of Required Product Qualities - Cement..........................................3

2.2

Definition of Grinding Fineness...........................................................................4

2.3

Quantity of Cement Production...........................................................................4

2.4

Cement dispatch....................................................................................................5

2.5

Production Flexibility.............................................................................................5

Dangote Cement Plc, Onne Slag Grinding Project, Production Requirements

3/8

Last Saved: April 21, 2016

Date printed: April 21, 2016

For Turnkey Contract

Dangote Cement Plc, Onne Slag Grinding Project, Production Requirements

Production Requirements

1 Cement Production Requirements

The Employer decided to install a new modern Slag Grinding and the mixing

facility with the following types of Cement:

Portland Cement : CEM I

Portland Limestone Cement : CEM II/A-L

Portland Limestone Cement : CEM II/B-L

Portland Limestone Cement : CEM II/A-LL

Portland Limestone Cement : CEM II/B-LL

Pozzolana Portland Cement : CEM II/A-P

Pozzolana Portland Cement : CEM II/B-P

Pozzolana Portland Cement : CEM II/A-Q

Pozzolana Portland Cement : CEM II/B-Q

Portland Flyash Cement : CEM II/A-V

Portland Flyash Cement : CEM II/B-V

Portland Flyash Cement : CEM II/A-W

Portland Flyash Cement : CEM II/B-W

and to manufacture, pack and dispatch the Finished Products as below:

Portland slag cement : CEM II/A-S

Portland slag cement : CEM II/B-S

Portland Composite Cement : CEM II/A-M

Portland Composite Cement : CEM II/ B-M

Blast Furnace Cement : CEM III/A

Blast Furnace Cement : CEM III/B

Blast Furnace Cement : CEM III/C

Composite Cement : CEM V/A

Composite Cement : CEM V/B

and import facility for Slag & Gypsum for Dangote Cement Plc, Onne Slag

Grinding Plant, Onne Port, Port Harcourt, Nigeria.

The new slag grinding plant shall have 1.5 MTPA Slag Grinding Capacity and 3.0

MTPA Portland Slag Cement, Portland Composite Cement, Blast Furnace Cement

and Composite Cement Dispatch including Gypsum & Slag (GBS) Import,

handling, storage and loading on to trucks.

.

Dangote Cement Plc, Onne Slag Grinding Project, Production Requirements

4/8

Last Saved: April 21, 2016

Date printed: April 21, 2016

For Turnkey Contract

Dangote Cement Plc, Onne Slag Grinding Project, Production Requirements

2 Cement

2.1 Definition of Required Product Qualities - Cement

The market in this area requires today in general, the types of cement are as

given below.

However, the systems shall also be suitable to produce all the other types of

cements as in EN 197 :2011 for the products in the family of the common

cements.

Cement types:

1. CEM I 52.5 R is with 0-5% minor additives. Additive is Limestone / Pozzolona /

Volcanic Ash

2. CEM I 42.5 R is with 0-5% minor additives. Additive is Limestone / Pozzolona /

Volcanic Ash

3. CEM II A-L 42.5 R is with 6-20% additives. Target is 20% Limestone addition

4. CEM II B-L 42.5 N is with 21-35% additives. Target is >20% Limestone

addition.

5. CEM II/A-S 42.5 R is with 6-20% additive. Additive is Ground Blast Furnace

Slag

6. CEM II/B-S 42.5 R is with 21-35% additive. Additive is Ground Blast Furnace

Slag

7. CEM II/A-M 42.5 R is with 6-20% additive. Additive is Ground Blast Furnace

Slag

8. CEM II/B-M 42.5 R is with 21-35% additive. Additive is Ground Blast Furnace

Slag

9. CEM III A 42.5 N is with 36-65% additive. Additive is Granulated Blast Furnace

Slag

10. CEM III B 42.5 N is with 66-80% additive. Additive is Granulated Blast

Furnace Slag

11. CEM III C 32.5 N is with 81-95% additive. Additive is Granulated Blast

Furnace Slag

12. CEM V/A 42.5 N is with 18-30% additives. Additive is Granulated Blast

Furnace Slag

13. CEM V/B 42.5 N is with 31-50% additives. Additive is Granulated Blast

Furnace Slag

Remark: Today CEM I 52.5 R, CEM I 42.5 R, CEM II/A-L 42.5R, CEM II/B-L 42.5N,

CEM II A-S 42.5R, CEM II B-S 42.5R, CEM II/A-M 42.5 R, CEM II/B-M 42.5 R , CEM

III/A 42.5N, CEM III/B 42.5N, CEM III/C 42.5N, CEM V/A 42.5N and CEM V/B 42.5N

has a production share of 100 %.

Dangote Cement Plc, Onne Slag Grinding Project, Production Requirements

5/8

Last Saved: April 21, 2016

Date printed: April 21, 2016

For Turnkey Contract

Dangote Cement Plc, Onne Slag Grinding Project, Production Requirements

The design of the new slag mills shall be optimized for above mentioned cement

types.

Composition of the Cement by weight based on standard:

EU Standards

TYPE

Additives %*

Clinker %

CEM I 52.5 R

0-5

95-100

CEM I 42.5 R

0-5

95-100

CEM II A-L 42.5 R

6-20

80-94

CEM II B-L 42.5 N

21-35

65-79

CEM II A-LL 42.5 R

6-20

80-94

CEM II B-LL 42.5 N

21-35

65-79

CEM II/A-S 42.5 R

6-20

80-94

CEM II/B-S 42.5 R

21-35

65-79

CEM II/A-M 42.5 R

6-20

80-94

CEM II/B-M 42.5 R

21-35

65-79

CEM III A 42.5N

36-65

35-64

CEM III B 42.5N

66-80

20-34

CEM III C 32.5N

81-95

5-19

CEM V/A 42.5N

18-30

40-64

CEM V/B 42.5N

31-50

20-38

*) The Gypsum (4 to 5%) is not included in to the sum.

2.2 Definition of Grinding Fineness

TYPE

Blaine (cm/g)

CEM II/A-S 42.5 R

4,500

CEM II/A-S 42.5 N

4,500

CEM II/B-S 42.5 R

4,500

CEM II/A-M 42.5 R

4,500

Dangote Cement Plc, Onne Slag Grinding Project, Production Requirements

6/8

Last Saved: April 21, 2016

Date printed: April 21, 2016

For Turnkey Contract

Dangote Cement Plc, Onne Slag Grinding Project, Production Requirements

CEM II/B-M 42.5 R

CEM III/A 42.5 R

5,000

CEM III/B 42.5 N

5,000

CEM III/C 32.5 N

5,000

CEM V/A 42.5 R

5,000

CEM V/B 42.5 N

5,000

5,000

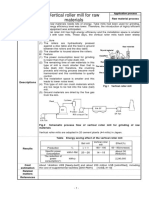

2.3 Quantity of Cement Production

In Onne Slag Grinding Plant, there shall be one vertical slag grinding mill.

The Slag Grinding Mill in the Contract Plant shall have the following minimum

grinding capacities on dry basis. (Refer mass flow for mill type)

TYPE

Ground

Ground

Ground

Ground

Ground

Grinding Capacity

Blast

Blast

Blast

Blast

Blast

Furnace

Furnace

Furnace

Furnace

Furnace

Slag

Slag

Slag

Slag

Slag

250

220

180

150

120

tph@4,200

tph@4,500

tph@5,000

tph@5,500

tph@6,000

(t/h)

cm/gr

cm/gr

cm/gr

cm/gr

cm/gr

(Slag

(Slag

(Slag

(Slag

(Slag

95%+Gypsum

95%+Gypsum

95%+Gypsum

95%+Gypsum

95%+Gypsum

5%).

5%).

5%).

5%).

5%).

The Contractor should specify the Slag Grinding Capacity for each of the

grinding fineness from 4,200 to 6,000 cm/g (with an increment of each 200

Blaine) for mixing ground blast furnace slag with different types of cement and

to as manufacture the Cement Types specified in 2.1 above for the other

common types of cement as in EN 197:2011.

2.4 Cement dispatch

Cement dispatch shall be in the following forms

TYPE

Percentage

Bulk Cement and Big Bag Cement

0 - 25%

Bagged Cement

75 - 100%

Cement dispatch shall be realized hundred (100) percent by truck transport.

Dangote Cement Plc, Onne Slag Grinding Project, Production Requirements

7/8

Last Saved: April 21, 2016

Date printed: April 21, 2016

For Turnkey Contract

Dangote Cement Plc, Onne Slag Grinding Project, Production Requirements

2.5 Production Flexibility

The Slag Grinding Mills in Onne Slag Grinding Project shall have the possibility of

manufacturing different type of cements as there are separate silos for the

ground blast furnace slag, Cement and the final finished cement products.

The EPC Contractor should follow the guidelines from the Employer from time to

time in producing the cement product during the Trial Runs and the performance

tests in producing the best quality in the respective process areas.

Dangote Cement Plc, Onne Slag Grinding Project, Production Requirements

8/8

Last Saved: April 21, 2016

Date printed: April 21, 2016

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- HGL Opp - ST 46087 Opp - ST 62048 9382Dokument3 SeitenHGL Opp - ST 46087 Opp - ST 62048 9382ReubenNoch keine Bewertungen

- HGL Opp - ST 46087 Opp - ST 62048 9382Dokument3 SeitenHGL Opp - ST 46087 Opp - ST 62048 9382ReubenNoch keine Bewertungen

- 93.02 Model 175 Disc GrinderDokument4 Seiten93.02 Model 175 Disc GrinderReubenNoch keine Bewertungen

- 0.1 Outline of Operation & Maintenance Training For Cement PlantDokument7 Seiten0.1 Outline of Operation & Maintenance Training For Cement PlantReubenNoch keine Bewertungen

- Technology Paper Report CSI 31-03-09Dokument98 SeitenTechnology Paper Report CSI 31-03-09jmpbarrosNoch keine Bewertungen

- Grinding Aids-Term PaperDokument6 SeitenGrinding Aids-Term Papershyam anandjiwalaNoch keine Bewertungen

- Grindability of Commercial Clinkers With High MgO LevelDokument7 SeitenGrindability of Commercial Clinkers With High MgO LevelAnonymous NxpnI6jCNoch keine Bewertungen

- Sustainability 12 04609 v2Dokument30 SeitenSustainability 12 04609 v2Jeff VistaNoch keine Bewertungen

- Cement Manufacturing ProcessDokument2 SeitenCement Manufacturing ProcessMorning Kalal0% (1)

- Angle of Repose and Its PropertiesDokument9 SeitenAngle of Repose and Its Propertieswaynil100% (1)

- Unit 8.2 Industrial Drives: R.Reddy Prasad Assistant Professor EEE Dept. Mobile No:+91 9494747497Dokument30 SeitenUnit 8.2 Industrial Drives: R.Reddy Prasad Assistant Professor EEE Dept. Mobile No:+91 9494747497reshma suryawanshiNoch keine Bewertungen

- Bauxite To Alumina Book 2018Dokument33 SeitenBauxite To Alumina Book 2018Amogh VaishnavNoch keine Bewertungen

- Comminution Circuit Design 1995 PDFDokument7 SeitenComminution Circuit Design 1995 PDFLMNoch keine Bewertungen

- Mineral Beneficiation: D.V. Subba RaoDokument6 SeitenMineral Beneficiation: D.V. Subba RaoNeelkamal Rongali100% (1)

- Different Departments of Glass and Fertilizer Industries (CH-18028)Dokument10 SeitenDifferent Departments of Glass and Fertilizer Industries (CH-18028)Maya's InsightNoch keine Bewertungen

- Automatic Pigment Muller Laboratory Grinder: FeaturesDokument1 SeiteAutomatic Pigment Muller Laboratory Grinder: Featuresdevang asherNoch keine Bewertungen

- Ebook Ipal ComminutorDokument7 SeitenEbook Ipal ComminutorPradana RonyeNoch keine Bewertungen

- Best Practice - Ball Charge Level ManagementDokument11 SeitenBest Practice - Ball Charge Level Managementsalahromdhani89Noch keine Bewertungen

- Universidade Federal de Santa Catarina Curso de Graduação em Engenharia de MateriaisDokument40 SeitenUniversidade Federal de Santa Catarina Curso de Graduação em Engenharia de MateriaisgustavorhuanNoch keine Bewertungen

- Minerals 12 01037 v2Dokument12 SeitenMinerals 12 01037 v2Marcos Antonio ParoliniNoch keine Bewertungen

- Grinding Cicuit ModelisationDokument17 SeitenGrinding Cicuit ModelisationHabib MOUSTAPHANoch keine Bewertungen

- Design and Fabrication of Pneumatic Sheet Metal Cutting MachineDokument34 SeitenDesign and Fabrication of Pneumatic Sheet Metal Cutting Machine4008- Manoj KumarNoch keine Bewertungen

- RICE MIlls InfoDokument7 SeitenRICE MIlls InfoParthajit SenguptaNoch keine Bewertungen

- Seminar Report ShailendraDokument20 SeitenSeminar Report ShailendraShailendra Singh0% (1)

- Vertical Roller Mill For Raw MaterialsDokument1 SeiteVertical Roller Mill For Raw Materialsअहा मधुमक्खीपालनNoch keine Bewertungen

- Mine To Mill OptimizationDokument18 SeitenMine To Mill Optimizationa7meNoch keine Bewertungen

- Lactoscope Fta Cheese-3 EngDokument13 SeitenLactoscope Fta Cheese-3 EngAleksxxNoch keine Bewertungen

- VRM Operation SOPsDokument3 SeitenVRM Operation SOPsAlaa MaherNoch keine Bewertungen

- Prodcution TechnologyDokument568 SeitenProdcution TechnologyVaibhav Vithoba NaikNoch keine Bewertungen

- 4 Roll RollingDokument6 Seiten4 Roll Rollingsatish_trivediNoch keine Bewertungen

- Highlight 1 2008Dokument40 SeitenHighlight 1 2008mahreza189Noch keine Bewertungen

- Equipment Used in Meat Processing - 2021Dokument66 SeitenEquipment Used in Meat Processing - 2021Pedro SaezNoch keine Bewertungen

- Polycom HPGRDokument11 SeitenPolycom HPGRWilson VicencioNoch keine Bewertungen

- The Structural Design of Large Grinding Mills With Reference To Shell Mounted BearingsDokument7 SeitenThe Structural Design of Large Grinding Mills With Reference To Shell Mounted BearingsXiaogang Min100% (1)