Beruflich Dokumente

Kultur Dokumente

RARIC Shaft Current Protection

Hochgeladen von

Satya DeepCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

RARIC Shaft Current Protection

Hochgeladen von

Satya DeepCopyright:

Verfügbare Formate

Shaft current protection

RARIC

1MRK 502 011-BEN

Page 1

Issued January 2003

Revision: Data subject to change without notice

xx02000677.jpg

Features

Sensitive protection for bearings of large

rotating machines

Operates for shaft currents larger than

0.3-0.8 A AC, depending on the diameter

of the shaft

Fundamental or third harmonic operating

principle

AC or DC powered, galvanically isolated

Application

If the bearing insulation on rotating machines

breaks down, the voltage induced between

the shaft ends, due to machine dissymmetries,

creates a shaft current that can damage the

bearings. The damage depends on the magnitude and duration of the shaft current. It is

therefore desirable to provide sensitive protection that can detect shaft currents of 1 A or

less.

The shaft current measuring principle enables

more sensitive protection than shaft voltage

measurements or vibration monitoring.

Vibration monitors only operate after the

bearing is damaged. By applying the shaft

current protection RARIC together with a

special current transformer ILDD, the

machine can be tripped and the cause of the

bearing insulation breakdown can be eliminated before the bearing is damaged.

The RARIC protection is available in two

versions. Version 1, most common, has a linear frequency characteristic and operates on

the fundamental and harmonic components of

the shaft current. If the lowest setting 0.5 mA

Shaft current transformer with test winding

Can be applied to shafts with diameters up

to 2960 mm

Settable time delay

Trip relay with heavy duty contacts and

indicating flag

Test switch

can be used (small disturbances), the protection can detect primary shaft currents of

0.3-0.8 A at machines with shaft diameters in

the range 160 to 3000 mm.

Version 2 is used when the shaft current

transformer is exposed to large fundamental

leakage flux from the machine. This version

measures the third harmonic component of

the shaft current and can, at its lowest setting,

(0.5 mA) detect primary shaft currents of

0.3-0.8 A, 150 Hz. The shaft voltage must

contain a third harmonic component if version 2 is to be used.

The shaft current transformer type ILDD

required for the relay measurement of the

shaft current is a special designed transformer. It is ring shaped to be mounted

around the shaft. Depending on the size of the

diameter it is split up in two or four

(> 2000 mm) sections.

To avoid disturbances the shaft current transformer shall be mounted on that side of the

machine which is free from field bars.

Shaft current protection

RARIC

1MRK 502 011-BEN

Page 2

Design

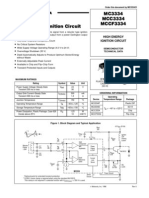

The RARIC protection is built up of a test

switch, terminal bases, plug-in modules and

connection parts in the COMBIFLEX mounting system. It includes the test switch

RTXP 18, an AC/DC converter RXTUB 2 or

a DC/DC converter RXTUG 22H, an overcurrent relay RXIK 1, a time relay RXKL 1

and a trip relay RXME 18 with heavy-duty

contacts and an indicating red flag.

Version 2 also includes a filter unit RXTFB 4

which attenuates the fundamental current into

the overcurrent relay.

The overcurrent relay RXIK 1 includes surge

suppression filtering on the input and the

operation of its output relay is maintained

even in cases of intermittent shaft currents.

The required time delay for tripping is provided by the time relay RXKL 1. The contacts of the trip relay RXME 18 can be

connected for alarm or tripping. A hand reset

red flag indicates operation.

Technical data

The shaft current transformer ILDD is available with diameters from 160 to 3000 mm.

The transformer is made in two or four

(> 2000 mm) sections for mounting between

the rotor and the nearest bearing on the turbine side of the rotor which is free from field

bars.

The transformer is of special design with a

core of high quality magnetic iron. It has an

uniformly distributed measuring winding.

The number of turns and the core cross section area is matched to the overcurrent relay

RXIK 1 for highest possible sensitivity. The

transformer has also a test winding for simple

testing of the protection.

To mount the shaft current transformer

around the shaft, an axial distance of 250 mm

or more is recommended. The inner diameter

of the transformer should be 20-50 mm larger

than the shaft diameter,

The test switch RTXP 18 enables a complete

test of RARIC and the shaft current transformer ILDD.

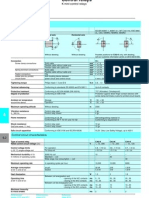

Table 1: Basic data

Current setting range (RXIK)

0,5-2 mA, 50-60 Hz

Operate shaft current at setting

0,5 mA and transformer diameters

160-3000 mm

Version 1: 0.3-0.8 A, 50-60 Hz

Version 2: 0.3-0.8 A, 150 Hz

Reset ratio

> 99%

Filter characteristic, version 2

The filter rejects the fundamental by 70:1

Input impedance

80 ohm resistive

Overload capacity

shaft diameter < 700 mm

shaft diameter 700-1600 mm

shaft diameter 1610-2500 mm

shaft diameter > 2500 mm

50 A shaft current continuously and 200 A in 1 s

65 A shaft current continuously and 250 A in 1 s

75 A shaft current continuously and 300 A in 1 s

100 A shaft current continuously and 400 A in 1 s

Auxiliary rated voltage

100, 110 and 220 V, 50-60 Hz or 24-250 V DC

Power consumption from aux.voltage

AC supply

DC supply

Approx. 2 VA before and 8 VA after operation

Approx. 3 W before and 7 W after operation

Time setting range (RXKL)

30 ms-99 h

Permissible ambient temperature

-5 to +55 C

Permissible range auxiliary voltage

supply

80-110% of rated voltage

Table 2: Electromagnetic compatibility tests

Power frequency test (SS 436 15 03)

0.5 kV, class PL4

Fast transient test (SS 436 15 03)

4-8 kV, class PL4

1 MHz burst test (IEC 60255-22-1)

2.5 kV, class III

Shaft current protection

RARIC

1MRK 502 011-BEN

Page 3

Table 3: Insulating tests (IEC 60255-5)

Dielectric test

2 kV, 50 Hz, 1 min

Impulse voltage test

5.0 kV, 1.2/50 s, 0.5 J

Table 4: Contact data

Trip circuits (RXME 18)

Max system voltage within a

contact set

Current-carrying capacity for already

closed contact

Making and conducting capacity,

L/R < 10 ms

Breaking capacity,

max. 250 Vac, PF > 0.1

Breaking capacity, dc, L/R < 40 ms

450 V dc, 400 V ac

55 A for 200 ms

30 A for 1 s

6 A continuously

30 A for 200 ms

20 A for 1 s

20 A

20 A at 24 V

18 A at 48 V

3 A at 110 V

1 A at 220 V

Alarm circuits (RXKL1, RXTUG22H/RXIK1)

Max. system voltage within a

contact set

Current-carrying capacity for already

closed contact

Making and conducting capacity,

L/R < 10 ms

Breaking capacity, dc, L/R < 40 ms

250/250 V dc

250/250 V ac

30/ A for 200 ms

15/10 A for 1 s

5/4 A continuously

30/20 A for 200 ms

10/10 A for 1 s

2/1.5 A at 24 V

1/0.5 A at 48 V

0.4/0.2 A at 110 V

0.2/0.1 A at 220 V

Table 5: Weights and dimensions

Weight

RARIC, version 1

RARIC, version 2

ILDD

Dimension

RARIC, version 1

RARIC, version 2

ILDD

4 kg

5 kg

10 + 80(D - 300) / 2300 kg

where D is the inner diameter in mm

4U 24C

4U 36C

See Fig. 4

Shaft current protection

RARIC

1MRK 502 011-BEN

Page 4

Diagrams

I

SHAFT CURRENT PROTECTION

RARIC

TRIPPING ETC.

107:31

107:41

101

3B

101

17A

16A

B

4A

3A

7429 010-ADA

100V

110V

220V

0V

101

1A

18A

2A

319:26

12A

101

9A

10A

11A

107:16

+ +

Fig. 1

4B

113:25

ALARM ETC.

S1

S2

Terminal diagram 7429 010-ADA for RARIC, RK 649 101-AD

I

SHAFT CURRENT PROTECTION

RARIC

113:31

113:41

101

3B

4B

TRIPPING ETC.

101

17A

16A

119:25

ALARM ETC.

113:16

S1

S2

A

B

4A

3A

+ +

107:118

107:116

18A

101

1A

313:26

101

2A

107:316

107:318

107:317

LOSS OF EL

+

-

U<

24-250V

Fig. 2

Terminal diagram 7429 010-BAA for RARIC, RK 649 101-BA

7429 010-BAA

Shaft current protection

RARIC

1MRK 502 011-BEN

Page 5

SHAFT CURRENT PROTECTION

RARIC

107:231

107:241

101

3B

4B

I

101

17A

TRIPPING ETC.

16A

125:25

119:16

A

B

101

1A

18A

2A

331:26

101

9A

10A

11A

12A

4A

3A

ALARM ETC.

S1

S2

7429 010-FCA

0V

100V

110V

220V

+ +

Fig. 3

Terminal diagram 7429 010-FCA for RARIC, RK 649 101-FC

38

50

Max 70

Alt. 1

D5

Max 85

42

65

AQ

o

Traf

AB

B

A

S S1 S2

Alt. 2

en02000669.vsd

Fig. 4

Shaft current transformer ILDD dimensions in mm.

Shaft current protection

RARIC

1MRK 502 011-BEN

Page 6

Ordering

Specify:

Shaft current protection RARIC

Shaft current transformer ILDD

Ordering No.

Ordering No. 1MRK 002 073-XXX

- Version 1, AC supply: RK 649 101-AD

- Version 1, DC supply: RK 649 101-BA

- Version 2, AC supply: RK 649 101-FC

Quantity

Manufacturer

Quantity

Desired wording on the lower half of the

test switch face plate. Max. 13 lines with

14 characters per line

Ordering No. ex.1: 1MRK 002 073-72 is

an ILDD with 72 cm inner diameter

Mounting:

Ordering No. ex.2: 1MRK 002 073-244 is

an ILDD with 244 cm inner diameter

RARIC is provided on apparatus bars. When

additional mounting is required, specify a 4U

equipment frame for 19" rack mounting or a

type RHGX 8, 12 or 20 case for panel mounting

References

where XXX is the inner diameter in cm

from 16 to 300 cm in steps of 2 cm for

diameters 140 cm and in steps of 4 cm

for diameters > 140 cm

Current relay RXIK 1

1MRK 508 018-BEN

Time relay RXKL

1MRK 508 002-BEN

Auxiliary relay RXME 18

1MRK 508 015-BEN

DC/DC-converter RXTUG 22H

1MRK 513 001-BEN

AC/DC-converter RXTUB 2

1MRK 513 004-BEN

Test system COMBITEST

1MRK 512 001-BEN

Connection and installation components in

COMBIFLEX

1MRK 513 003-BEN

Users Guide RARIC

1MRK 502 001-UEN

ABB Automation Technology Products AB

Substation Automation

SE-721 59 Vsters

Sweden

Telephone: +46 (0) 21 34 20 00

Facsimile: +46 (0) 21 14 69 18

Internet: www.abb.com/substationautomation

Das könnte Ihnen auch gefallen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsVon EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsBewertung: 3 von 5 Sternen3/5 (2)

- 110 Waveform Generator Projects for the Home ConstructorVon Everand110 Waveform Generator Projects for the Home ConstructorBewertung: 4 von 5 Sternen4/5 (1)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsVon EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsBewertung: 3.5 von 5 Sternen3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- 446 CAN Autowatch DiagramDokument5 Seiten446 CAN Autowatch Diagramjohn0% (1)

- 250T Frequency TransmitterDokument13 Seiten250T Frequency Transmitterreality88Noch keine Bewertungen

- 1000W Driver Power Amplifier Namec TEF - Electronic CircuitDokument3 Seiten1000W Driver Power Amplifier Namec TEF - Electronic CircuitK Raja SekarNoch keine Bewertungen

- 220kV Subsattion.Dokument20 Seiten220kV Subsattion.sanju0156100% (1)

- VIP300 Protection Relay For Ringmaster MGMV5477Dokument24 SeitenVIP300 Protection Relay For Ringmaster MGMV5477Ibrahim NashidNoch keine Bewertungen

- Ed01 (EN) PDFDokument40 SeitenEd01 (EN) PDFsebastian50% (2)

- 220 KV Cost DataDokument97 Seiten220 KV Cost Dataanandaholur100% (9)

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Von EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Bewertung: 4.5 von 5 Sternen4.5/5 (3)

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionNoch keine Bewertungen

- ANNEXURE 2 (Electrical Data Sheets) PDFDokument113 SeitenANNEXURE 2 (Electrical Data Sheets) PDFGuha ArnabNoch keine Bewertungen

- Types of Transmission Structures: Fact Sheet Fact SheetDokument2 SeitenTypes of Transmission Structures: Fact Sheet Fact Sheetpinku_thakkarNoch keine Bewertungen

- Auxiliary Relays RXMB 1 RXMB 2 and RXMC 1Dokument12 SeitenAuxiliary Relays RXMB 1 RXMB 2 and RXMC 1jenskg100% (1)

- CEA ElecDokument31 SeitenCEA Elecajith143420Noch keine Bewertungen

- A Compilation by Virendra SahdevDokument108 SeitenA Compilation by Virendra SahdevVirendra Sahdev100% (1)

- Air Circuit BreakerDokument13 SeitenAir Circuit BreakercjtagayloNoch keine Bewertungen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- IEC 61730-1 Pragati's Report NISE (SGS)Dokument11 SeitenIEC 61730-1 Pragati's Report NISE (SGS)pragatirajputNoch keine Bewertungen

- Abb Shaft Current ProtectionDokument6 SeitenAbb Shaft Current ProtectionSreenivasNoch keine Bewertungen

- RadhaDokument6 SeitenRadhaNeelakandan MasilamaniNoch keine Bewertungen

- 1mrk502001-Uen B en Raric Shaft-Current RelayDokument18 Seiten1mrk502001-Uen B en Raric Shaft-Current Relaybacuoc.nguyen356Noch keine Bewertungen

- 1MRK509016-BEN en Multi-Purpose Percentage Restraint Differential Protection RADSCDokument8 Seiten1MRK509016-BEN en Multi-Purpose Percentage Restraint Differential Protection RADSCRAPRATSINNoch keine Bewertungen

- Re7rm11bu PDFDokument7 SeitenRe7rm11bu PDFToth VasileNoch keine Bewertungen

- Datos Tecnicos Leroy Sommer Lsa40Dokument12 SeitenDatos Tecnicos Leroy Sommer Lsa40caprit_her_771605Noch keine Bewertungen

- Metasol MC E 1108Dokument160 SeitenMetasol MC E 1108codelnorNoch keine Bewertungen

- DatasheetDokument13 SeitenDatasheetebertecnicoNoch keine Bewertungen

- Motor Controllers Type RSXK: AC Semiconductor Motor ControllerDokument13 SeitenMotor Controllers Type RSXK: AC Semiconductor Motor Controllergasparcj5Noch keine Bewertungen

- ABB AR Auxiliary RelayDokument16 SeitenABB AR Auxiliary Relaylj_treelsNoch keine Bewertungen

- MK 2 PiDokument7 SeitenMK 2 PiA Whick Bumbum TralalaNoch keine Bewertungen

- MC MetasolDokument160 SeitenMC Metasolvietanh283Noch keine Bewertungen

- RxtcsDokument6 SeitenRxtcsEr Anoop GuptaNoch keine Bewertungen

- MTE Line Reactor For Harmonics AvoidanceDokument6 SeitenMTE Line Reactor For Harmonics AvoidancemaheshrsaNoch keine Bewertungen

- Finder 16A 12V DC Relay Datasheet.Dokument10 SeitenFinder 16A 12V DC Relay Datasheet.velizarkoNoch keine Bewertungen

- RL Line/Load Reactors: Driving Power QualityDokument6 SeitenRL Line/Load Reactors: Driving Power Qualityjorapa7Noch keine Bewertungen

- 01-RXM Plugin Relay PDFDokument8 Seiten01-RXM Plugin Relay PDFshaikhsajid242Noch keine Bewertungen

- Datasheet MC3334Dokument6 SeitenDatasheet MC3334odipasNoch keine Bewertungen

- Contactors and Overload Relays: Meta SolutionDokument120 SeitenContactors and Overload Relays: Meta SolutionLindsey Bentley100% (1)

- Type RXIGDec. 99Dokument10 SeitenType RXIGDec. 99Ahmed BadrNoch keine Bewertungen

- Rollarc R400Dokument24 SeitenRollarc R400catalinccNoch keine Bewertungen

- Catalog LS PDFDokument30 SeitenCatalog LS PDFManh NguyenNoch keine Bewertungen

- Stamford UCI274D Data SheetDokument9 SeitenStamford UCI274D Data SheetFelipe LimaNoch keine Bewertungen

- Features: 40 Series - Miniature PCB/Plug-in Relays 12 - 16 ADokument4 SeitenFeatures: 40 Series - Miniature PCB/Plug-in Relays 12 - 16 AUrsula JohnsonNoch keine Bewertungen

- EuroSMC Let Range - BrochureDokument4 SeitenEuroSMC Let Range - BrochurersgrsgrsgNoch keine Bewertungen

- Ca3kn22bd Telemecanique - Unit5.relayDokument8 SeitenCa3kn22bd Telemecanique - Unit5.relaykapenziNoch keine Bewertungen

- ATV32HU75N4Dokument11 SeitenATV32HU75N4bmshivakumarNoch keine Bewertungen

- ABB T1maxDokument6 SeitenABB T1maxharrisvasNoch keine Bewertungen

- Specificatii Tehnice Schneider RM4TR32Dokument7 SeitenSpecificatii Tehnice Schneider RM4TR32wwcbaNoch keine Bewertungen

- Recloser - OSM15!27!38 Brochure en NOJA-560-01Dokument12 SeitenRecloser - OSM15!27!38 Brochure en NOJA-560-01Jesús Oziel MartínezNoch keine Bewertungen

- HCI 434F/444F - Winding 311: Technical Data SheetDokument9 SeitenHCI 434F/444F - Winding 311: Technical Data SheetddzoningcomNoch keine Bewertungen

- Rele Temporizador ScheinederDokument4 SeitenRele Temporizador ScheinederJasson da GiedreNoch keine Bewertungen

- ATV32HD15N4Dokument12 SeitenATV32HD15N4gasm22Noch keine Bewertungen

- UCDI274K - Technical Data SheetDokument8 SeitenUCDI274K - Technical Data SheetshinichieNoch keine Bewertungen

- ATV71H075N4: Product Data SheetDokument4 SeitenATV71H075N4: Product Data SheetOtto AcnNoch keine Bewertungen

- ULTRA-700 0 - 1040 0-1400 0-EN-New DC Recombiner PDFDokument4 SeitenULTRA-700 0 - 1040 0-1400 0-EN-New DC Recombiner PDFAdrian Ioan POPNoch keine Bewertungen

- 1MRK509008-BEN en Transformer and Generator Time-Overexcitation Relay and Protection Assemblies RXLK 2H RALKDokument10 Seiten1MRK509008-BEN en Transformer and Generator Time-Overexcitation Relay and Protection Assemblies RXLK 2H RALKdaniel_sa2011Noch keine Bewertungen

- HCI 534F/544F - Technical Data SheetDokument8 SeitenHCI 534F/544F - Technical Data Sheet3efooNoch keine Bewertungen

- Telemecanique ContactorDokument26 SeitenTelemecanique ContactorgeoghoNoch keine Bewertungen

- CAG14Dokument8 SeitenCAG14aja295Noch keine Bewertungen

- 1MRK504002-BEN en Transformer Differential Protection RADSBDokument10 Seiten1MRK504002-BEN en Transformer Differential Protection RADSBK Vijay Bhaskar ReddyNoch keine Bewertungen

- PI734BDokument8 SeitenPI734BsusantojNoch keine Bewertungen

- UGZ D2 - Double Pole Voltage Transformer (1/2) : Technical SpecificationsDokument2 SeitenUGZ D2 - Double Pole Voltage Transformer (1/2) : Technical SpecificationsjeanNoch keine Bewertungen

- Poly 50W - 55W Technical Data Sheet660x530x25Dokument3 SeitenPoly 50W - 55W Technical Data Sheet660x530x25Juan Cristóbal ViscarraNoch keine Bewertungen

- A Capacitor Voltage Balancing Method For Nested Neutral Point Clamped (NNPC) InverterDokument9 SeitenA Capacitor Voltage Balancing Method For Nested Neutral Point Clamped (NNPC) InverterSaravanan MaleNoch keine Bewertungen

- Smart PV Controller: SUN2000-60KTL-M0Dokument2 SeitenSmart PV Controller: SUN2000-60KTL-M0Imam TyoNoch keine Bewertungen

- TEBS G2 схемыDokument30 SeitenTEBS G2 схемыDimaNoch keine Bewertungen

- ATS OkDokument20 SeitenATS Okducabc123Noch keine Bewertungen

- Motor Starter Components Finder - ATS48C25QDokument7 SeitenMotor Starter Components Finder - ATS48C25QJames FitzGeraldNoch keine Bewertungen

- Gallien-Krueger MB Combo ManualDokument10 SeitenGallien-Krueger MB Combo Manualyerfdog65Noch keine Bewertungen

- Funai LCD-B1504 - LCD-B2004Dokument67 SeitenFunai LCD-B1504 - LCD-B2004fy6109Noch keine Bewertungen

- CHAPTER 3 Induction Machine PDFDokument32 SeitenCHAPTER 3 Induction Machine PDFhailay haderaNoch keine Bewertungen

- Ee6604 Design of Electrical MachineDokument1 SeiteEe6604 Design of Electrical MachinevigneshcjNoch keine Bewertungen

- Smart PV Controller: Higher Yields Active Safety Flexible CommunicationDokument2 SeitenSmart PV Controller: Higher Yields Active Safety Flexible CommunicationRao FarhanNoch keine Bewertungen

- Canal IsDokument36 SeitenCanal IsGordon WalkerNoch keine Bewertungen

- Conectores Pfisterer SN HV Connex en 2011Dokument16 SeitenConectores Pfisterer SN HV Connex en 2011renzo_navaNoch keine Bewertungen

- Solutions To The Suggested Problems of Ch.27Dokument35 SeitenSolutions To The Suggested Problems of Ch.27Blaze FrostNoch keine Bewertungen

- Motor Sincrono SYNCGUIDEDokument48 SeitenMotor Sincrono SYNCGUIDEluisfilipeminenervaNoch keine Bewertungen

- WWW - Iranswitching.Ir: 220 W Led TV Design Power SupplyDokument1 SeiteWWW - Iranswitching.Ir: 220 W Led TV Design Power SupplydraNoch keine Bewertungen

- Activity No. 3-Ambas, DLDokument8 SeitenActivity No. 3-Ambas, DLDevee AmbasNoch keine Bewertungen

- Insert: Ems and Jib Parts ManualDokument74 SeitenInsert: Ems and Jib Parts Manualmauricio carmonaNoch keine Bewertungen

- Homework 2 Digital Integrated Circuit Design: N-Channel MOSFET EQUATIONDokument3 SeitenHomework 2 Digital Integrated Circuit Design: N-Channel MOSFET EQUATIONKhánh TrầnNoch keine Bewertungen

- 74HC27Dokument4 Seiten74HC27jingsong heNoch keine Bewertungen

- Cabluri Monofilare Fara Manta Unsheathed Single-Core Cables: Test Voltage: 3 KV, 50 HZ, 5 Minutes in WaterDokument2 SeitenCabluri Monofilare Fara Manta Unsheathed Single-Core Cables: Test Voltage: 3 KV, 50 HZ, 5 Minutes in WaterCirtiu SandaNoch keine Bewertungen

- LM741 Pin ConfigurationDokument4 SeitenLM741 Pin ConfigurationSantiago PulupaNoch keine Bewertungen

- 18Ees101J-Basic Electrical & Electronics Engineering: Unit 1Dokument57 Seiten18Ees101J-Basic Electrical & Electronics Engineering: Unit 1Mohammed JavidhNoch keine Bewertungen