Beruflich Dokumente

Kultur Dokumente

Remelter

Hochgeladen von

Antonio PerezOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Remelter

Hochgeladen von

Antonio PerezCopyright:

Verfügbare Formate

BRIMROCK

SULPHUR REMELTERS

HIGH PERFORMANCE, SKID-MOUNTED

REMELTERS WITH LOW MAINTENANCE

AND OPERATING COSTS

EFFICIENT REMELTING AND

DECONTAMINATION AT UP TO 35 MTPH

The Sandvik Brimrock SR800 is a versatile and

compact unit offering predictable, high capacity

throughput for the efficient remelting and

The self-cleaning features also ensure optimum

heat transfer and decontamination capability

under all conditions, while the control system

maintains the process parameters within ideal

ranges to get the most out of every kW of

decontamination of sulphur. Nominal capacity

is 35 metric tonnes per hour (mtph) with feed

sulphur moisture content of less than 5% and

minimum contaminate levels.

energy used.

For sulphur with higher contaminate levels (up to

5%), we offer the Sandvik Brimrock CSR575.

Skid-mounted for easy transportation by truck,

sea or rail, both models benefit from self-cleaning

features and an interactive process control

system, ensuring maximum throughput rates

and decontamination capability throughout

a wide range of waste sulphur moisture and

contaminate levels.

RELIABLE OPERATION WITH MINIMAL

MANPOWER REQUIREMENTS

Solid sulphur is melted in a settling tank while

heated liquid sulphur is recirculated through the

tank, aiding in the melting process.

The heavier contaminates settle out of the molten

sulphur and are continuously removed and

concentrated via a sludge extraction conveyor.

In the CSR575 the molten sulphur then

flows to a secondary settling tank where more

contaminates (>0.45 mm) are removed prior to

pumping through a two stage filtration system to

remove the last of the entrained particulates.

A single PLC manages key parameters such as

temperature, feed rate and tank levels through

interdependent control loops, with additional

analogue instrumentation monitoring other, noncritical parameters. The result is a steady-state

operation at the highest levels of productivity and

efficacy. Data collection, reporting and storage

will be tailored to your specific requirements.

Predictable, maximum throughput rates

Efficient use of energy

Maximum settling capability, resulting

in reduced particulates at the filters

and mitigating potential for

downstream contamination

DESIGNED FOR LOW COST, HIGH PRODUCTIVITY REMELTING

UNDER ALL CONDITIONS, WITH INTERACTIVE PROCESS

CONTROLS ENSURING OPTIMUM PERFORMANCE

Reduced sulphur concentration in

recovered contaminates

UTILITIES AND PLOT SPACE

Fully instrumented and process controlled

resulting in hands-free operation

Easy to use controls, including ESD and

process trend data collection

Remelter footprint

SR800

CSR575

12m L x 2.5m W x 5m H 16m L x 8m W x 5m H

Primary skid wt.

(dry)

22,680 kg

22,680 kg

Metered and data-logged re-melt rate

Low operating cost; minimal

(wet)

47,680 kg

47,680 kg

Secondary skid wt.

(dry)

21,750 kg

manpower requirements

Low maintenance cost; all stainless steel

construction, proven pumps, instruments

and filters suitable for sulphur service,

robust design

Environmentally and HSE friendly;

low exposed molten sulphur surface area,

fume hoods and dilution fans, continuous,

low dusting feed system, reduced potential

for sulphur spills, limited manual labour or

exposure to potential hazards no manual

contaminate removal required

Cold weather protected; insulated, fully steam

traced, electrical tracing on steam traps and

condensate lines

Self contained, compact, portable and flexible;

skid mounted, fully wired, all piping installed,

single battery limit connection, convertible to

a twin tank arrangement

Designed and constructed to meet all

regulatory requirements world-wide; will

meet or exceed International and North

American codes and standards, CE Certified,

ATEX compliant and SIL rated equipment

and instruments

(wet)

46,750 kg

Sulphur remelt rate

35 mtph*

25 mtph*

Sulphur discharge pressure

0 500 kPa(g)

0 500 kPa(g)

Sulphur discharge temperature

<150 C

<150 C

Steam flow @ standby

430 kg/hr

430 kg/hr

Steam flow @ normal operation

5,500 kg/hr

4,000 kg/hr

Steam pressure

800 kPa(g)

800 kPa(g)

Electrical power connected

60 kW

70 kW

*Assumes <5% moisture, and 0 C ambient conditions

conveyor (>1.25 mm) and the finer contaminates

discharged with the melted sulphur.

An optional duplex or quadplex filter system can

be used to remove finer contaminates.

The result is molten sulphur that meets or

exceeds the following purity specifications,

allowing the recovered sulphur to be

re-introduced into the supply chain:

PURITY SPECIFICATIONS SOLID

ELEMENTAL SULPHUR IN BULK

Ash (max)

0.050% (500 ppmw)

Carbon (max)

0.025% (250 ppmw)

Free sulphur

99.90% min

(dry basis)

Colour

Bright yellow

WASTE (EFFLUENT) GENERATION

The design basis for the remelter assumes that

the discharged waste will contain 50% sulphur

and 50% contaminates. This ratio can be affected

by the particle size distribution of the solids as

finer material will have more particle surface area

that can be wetted by molten sulphur.

The remelting system is capable of removing

contaminates such as stones, foreign debris,

sand, and soils. The coarsest material will be

discharged from a filter basket (>6 mm), small

material will be discharged from the screw

CSR575 model available for wetter,

more contaminated sulphur

S-PS430-D-ENG-14

Sandvik Process Systems

Division of Sandvik Materials Technology Deutschland GmbH, Salierstr. 35, 70736 Fellbach, Germany

Phone +49 711 5105-0, Fax +49 711 5105-152, E-mail: info.spsde@sandvik.com

www.processsystems.sandvik.com

Das könnte Ihnen auch gefallen

- Polymer Composite Systems in Pipeline Repair: Design, Manufacture, Application, and Environmental ImpactsVon EverandPolymer Composite Systems in Pipeline Repair: Design, Manufacture, Application, and Environmental ImpactsSanjay Mavinkere RangappaNoch keine Bewertungen

- Sulphur Tank Paper Rev6 - BrimstoneDokument18 SeitenSulphur Tank Paper Rev6 - BrimstonevikramNoch keine Bewertungen

- Road Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaVon EverandRoad Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaNoch keine Bewertungen

- Process Plants 08 FinalDokument4 SeitenProcess Plants 08 FinalHakan EkinciNoch keine Bewertungen

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyVon EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNoch keine Bewertungen

- COBRAS 2015 Outotec SulfurHandlingDokument18 SeitenCOBRAS 2015 Outotec SulfurHandlingIrsan Bin MustaminNoch keine Bewertungen

- Appendix A - DATASHEET - BilectricDokument11 SeitenAppendix A - DATASHEET - BilectricChakravarthy BharathNoch keine Bewertungen

- Merrill CroweDokument7 SeitenMerrill CroweAlejandro ClavijoNoch keine Bewertungen

- 05 - Sulzer - Separator InternalsDokument53 Seiten05 - Sulzer - Separator InternalsVicente RegulezNoch keine Bewertungen

- Ote Higmill Brochure 2019 WebDokument8 SeitenOte Higmill Brochure 2019 WebTandil Amira Matus HernándezNoch keine Bewertungen

- Random PackingDokument4 SeitenRandom PackingAadam AryanNoch keine Bewertungen

- MDEA Safety Data SheetDokument8 SeitenMDEA Safety Data SheetGhifaris VashaNoch keine Bewertungen

- Chilled Ammonia CO2 Capture Process at AEP MountaineerDokument19 SeitenChilled Ammonia CO2 Capture Process at AEP MountaineerBánh Cuốn Tôm ThịtNoch keine Bewertungen

- AFT Software Prices (2015SWOrderForm)Dokument3 SeitenAFT Software Prices (2015SWOrderForm)Ender ZenginobuzNoch keine Bewertungen

- Att2 Baretti InternalsDokument36 SeitenAtt2 Baretti InternalsAli MetinNoch keine Bewertungen

- Velan PDFDokument40 SeitenVelan PDFpablopasqualini18Noch keine Bewertungen

- Corrugated Plate Separator (CPS) enDokument2 SeitenCorrugated Plate Separator (CPS) enspattacutNoch keine Bewertungen

- Electrostatic Desalter Process Data SheetDokument10 SeitenElectrostatic Desalter Process Data SheetfedemochileroNoch keine Bewertungen

- PDS Milk of LimeDokument2 SeitenPDS Milk of Limenachiappan_rameshNoch keine Bewertungen

- Sulphur ProcessingDokument6 SeitenSulphur ProcessingSimon BolivarNoch keine Bewertungen

- Cyclonic Wellhead DesanderDokument2 SeitenCyclonic Wellhead DesanderKapwell LimitedNoch keine Bewertungen

- Ammonia Plant 2520Location&LayoutDokument4 SeitenAmmonia Plant 2520Location&Layoutapi-3714811100% (1)

- Data Sheet of Reciprocating Compressor 1Dokument3 SeitenData Sheet of Reciprocating Compressor 1Alvin SmithNoch keine Bewertungen

- BOC Nitrogen VIE'sDokument10 SeitenBOC Nitrogen VIE'sHIPAPNoch keine Bewertungen

- Tubular Backwashing or Pressure Leaf Both FSD Systems Eliminate Bags and CartridgesDokument4 SeitenTubular Backwashing or Pressure Leaf Both FSD Systems Eliminate Bags and CartridgesQuarkant100% (1)

- BBS-10-W8-DS-011 - C - Glycol Surge Drum DS PDFDokument2 SeitenBBS-10-W8-DS-011 - C - Glycol Surge Drum DS PDFAdianto RahmanNoch keine Bewertungen

- Acid Storage DesignDokument1 SeiteAcid Storage DesignEugenio OlivaresNoch keine Bewertungen

- Bulk Water SeparationDokument1 SeiteBulk Water SeparationSean MiddletonNoch keine Bewertungen

- Tivar 88-2: Drop-In Liners Solve Flow ProblemsDokument1 SeiteTivar 88-2: Drop-In Liners Solve Flow Problemsacas35100% (1)

- Product & ServicesDokument12 SeitenProduct & Servicesreign226Noch keine Bewertungen

- UOP Separex Membrane Technology Tech PresentationDokument44 SeitenUOP Separex Membrane Technology Tech PresentationKarunakarNoch keine Bewertungen

- 170630-1201 MultiPoint-Flare-SS FINAL JZHCDokument4 Seiten170630-1201 MultiPoint-Flare-SS FINAL JZHCManajemen Gas UI 2018Noch keine Bewertungen

- 2020 w1 d2 m1 JD SynCORDokument11 Seiten2020 w1 d2 m1 JD SynCORNhân Trương VănNoch keine Bewertungen

- Amine SlimeDokument24 SeitenAmine SlimeganeshpicoNoch keine Bewertungen

- Boiler Performance & Technical Data JT-K13467-E01-0Dokument15 SeitenBoiler Performance & Technical Data JT-K13467-E01-0Puntanata Siagian0% (1)

- Zauliyah Gas Plant Project: Initial Operation Period Activities / Support RecordDokument18 SeitenZauliyah Gas Plant Project: Initial Operation Period Activities / Support RecordPazhamalai RajanNoch keine Bewertungen

- 6580 - 67 - r0 - OWT Open DrainDokument10 Seiten6580 - 67 - r0 - OWT Open DrainMohammad MohseniNoch keine Bewertungen

- Techno-Economic Assessment About Sodium HydroxideDokument3 SeitenTechno-Economic Assessment About Sodium HydroxideIntratec SolutionsNoch keine Bewertungen

- ECAT Analysis GuideDokument12 SeitenECAT Analysis GuideElder RuizNoch keine Bewertungen

- NPS Chart - Nominal Pipe Size Conversion TableDokument2 SeitenNPS Chart - Nominal Pipe Size Conversion Tablepenny412100% (1)

- 4 SPE-77495-Increasing Separation Capacity With New and Proven TechnologiesDokument6 Seiten4 SPE-77495-Increasing Separation Capacity With New and Proven TechnologiesDavid VMNoch keine Bewertungen

- AAV ThermaxDokument2 SeitenAAV Thermax123habib123fikriNoch keine Bewertungen

- Volume IIA Technical SpecificationDokument83 SeitenVolume IIA Technical SpecificationSanjeev Kumar DasNoch keine Bewertungen

- Deno, Deso, and Co Removal Technology For Power PlantDokument5 SeitenDeno, Deso, and Co Removal Technology For Power PlantcumiiNoch keine Bewertungen

- Filters FbaDokument1 SeiteFilters FbaSpoonful BurnsideNoch keine Bewertungen

- Brochure DoosanSkoda SteamTurbines & GeneratorsDokument13 SeitenBrochure DoosanSkoda SteamTurbines & GeneratorsNestramiNoch keine Bewertungen

- 2007 The TOYO Urea Granulation TechnologyDokument14 Seiten2007 The TOYO Urea Granulation Technologyaaa206Noch keine Bewertungen

- GMC15 161 CAPEX and OPEX Considerations For Gas Dehydration Technologies PDFDokument5 SeitenGMC15 161 CAPEX and OPEX Considerations For Gas Dehydration Technologies PDFSUBRAMANAN NARAYANANNoch keine Bewertungen

- Treating Crude Oil Wastewater with MVRDokument10 SeitenTreating Crude Oil Wastewater with MVRdesai sanketNoch keine Bewertungen

- CyrogenicDokument4 SeitenCyrogenicBayu SaputraNoch keine Bewertungen

- CO2 Capture System With Chilled Ammonia: Pilot To Demonstration To Commercial ScaleDokument40 SeitenCO2 Capture System With Chilled Ammonia: Pilot To Demonstration To Commercial Scalerecsco2Noch keine Bewertungen

- Ausmelt Matte Smelting PDFDokument12 SeitenAusmelt Matte Smelting PDFgtdomboNoch keine Bewertungen

- 2016 - Thermal Performance Calculation and Analysis of Heat Transfer Tube in Super Open Rack VaporizerDokument10 Seiten2016 - Thermal Performance Calculation and Analysis of Heat Transfer Tube in Super Open Rack VaporizerLong Nguyễn HoàngNoch keine Bewertungen

- Manual de Vaporizadores AmbientalesDokument9 SeitenManual de Vaporizadores AmbientalesJose Luis Tadeo SabinoNoch keine Bewertungen

- Gas Liquid Separation TechnologyDokument24 SeitenGas Liquid Separation TechnologyCuong TranHungNoch keine Bewertungen

- Rotary FeederDokument6 SeitenRotary Feedersham7523100% (1)

- Factsheet TurritellaDokument2 SeitenFactsheet TurritellaJeganeswaranNoch keine Bewertungen

- Best Rotary Kiln Incinerator Manufacturers in India - BL EngineeringDokument2 SeitenBest Rotary Kiln Incinerator Manufacturers in India - BL Engineeringbl engineeringNoch keine Bewertungen

- Sulphur Remelters PDFDokument4 SeitenSulphur Remelters PDFNenadNoch keine Bewertungen

- T R Ea Tment PR OcessDokument8 SeitenT R Ea Tment PR Ocessrichard gutierrezNoch keine Bewertungen

- Us 4428223Dokument9 SeitenUs 4428223Antonio PerezNoch keine Bewertungen

- Brookes Bell-Carriage of SulphurDokument4 SeitenBrookes Bell-Carriage of SulphurAntonio Perez100% (1)

- TESON Benchmark Report and Overview PDFDokument32 SeitenTESON Benchmark Report and Overview PDFAntonio PerezNoch keine Bewertungen

- Math g7 m1 Topic C Lesson 11 TeacherDokument9 SeitenMath g7 m1 Topic C Lesson 11 TeacherAntonio PerezNoch keine Bewertungen

- Ad 630Dokument13 SeitenAd 630Antonio PerezNoch keine Bewertungen

- Niobium-Stabilized Alloys Enable Higher-Temperature Steam ReformingDokument5 SeitenNiobium-Stabilized Alloys Enable Higher-Temperature Steam ReformingAntonio PerezNoch keine Bewertungen

- State of The Art RFT - Meeting The Ferromagnetic Tube Challenge State of The Art RFT Meeting Ferromagnetic Tube Challenge PDFDokument2 SeitenState of The Art RFT - Meeting The Ferromagnetic Tube Challenge State of The Art RFT Meeting Ferromagnetic Tube Challenge PDFAntonio PerezNoch keine Bewertungen

- AD544Dokument12 SeitenAD544Antonio PerezNoch keine Bewertungen

- Design of A 10kHz FilterDokument11 SeitenDesign of A 10kHz FilterEriNoch keine Bewertungen

- Internal Rotating Inspection SystemDokument2 SeitenInternal Rotating Inspection SystemAntonio PerezNoch keine Bewertungen

- Ni-Resist Alloy Properties and Applications GuideDokument40 SeitenNi-Resist Alloy Properties and Applications GuidePrasad Aher100% (1)

- Conductivity IronDokument6 SeitenConductivity IronAntonio PerezNoch keine Bewertungen

- AppsDokument53 SeitenAppsAntonio PerezNoch keine Bewertungen

- RAMS Brochure 49096aDokument12 SeitenRAMS Brochure 49096aAntonio PerezNoch keine Bewertungen

- MMU English Qualification Requirements For Euroinkanet 2nd COHORTDokument1 SeiteMMU English Qualification Requirements For Euroinkanet 2nd COHORTAntonio PerezNoch keine Bewertungen

- English Language Requirements - NTNUDokument6 SeitenEnglish Language Requirements - NTNUAntonio PerezNoch keine Bewertungen

- Numerical Value Analysis of Eddy Current Probe Coil of Placement Model Based On ANSYSDokument8 SeitenNumerical Value Analysis of Eddy Current Probe Coil of Placement Model Based On ANSYSnazari_smeirNoch keine Bewertungen

- Op Amp Circuit Collection - National SemiconductorDokument33 SeitenOp Amp Circuit Collection - National Semiconductorkok6Noch keine Bewertungen

- Communicating Your IdeasDokument15 SeitenCommunicating Your IdeasAntonio PerezNoch keine Bewertungen

- English Language Requirements - NTNUDokument6 SeitenEnglish Language Requirements - NTNUAntonio PerezNoch keine Bewertungen

- Ielts Test Dates 2017Dokument1 SeiteIelts Test Dates 2017Antonio PerezNoch keine Bewertungen

- Broc Ilook 01 UsDokument5 SeitenBroc Ilook 01 UsAntonio PerezNoch keine Bewertungen

- Inductance Calculation TechniquesDokument11 SeitenInductance Calculation Techniquesgcamarca100% (1)

- Communicating Your IdeasDokument15 SeitenCommunicating Your IdeasAntonio PerezNoch keine Bewertungen

- Jac Hfc4250kr1k3Dokument7 SeitenJac Hfc4250kr1k3Antonio PerezNoch keine Bewertungen

- Maz 643018 PDFDokument2 SeitenMaz 643018 PDFAntonio PerezNoch keine Bewertungen

- JAC HFC4250KR1K3 Tractor Unit (Batch #252) Made in ChinaDokument5 SeitenJAC HFC4250KR1K3 Tractor Unit (Batch #252) Made in ChinaAntonio PerezNoch keine Bewertungen

- Bobbin Probe Technical SpecificationsDokument1 SeiteBobbin Probe Technical SpecificationsAntonio PerezNoch keine Bewertungen

- Hoskin Lx2v.pdf 419e14a147d31Dokument7 SeitenHoskin Lx2v.pdf 419e14a147d31Antonio PerezNoch keine Bewertungen

- 32 I D Tubing ProbesDokument1 Seite32 I D Tubing ProbesAntonio PerezNoch keine Bewertungen

- Urea NanufacturingDokument14 SeitenUrea NanufacturingKaran JoharNoch keine Bewertungen

- Automatic Level Control SystemsDokument10 SeitenAutomatic Level Control Systemshafidhrahadiyan2100% (1)

- Rankine Regenerative CycleDokument4 SeitenRankine Regenerative CyclePhúc BạchNoch keine Bewertungen

- GTU BE Semester 1&2 Exam Winter 2018 Basic Mechanical EngineeringDokument2 SeitenGTU BE Semester 1&2 Exam Winter 2018 Basic Mechanical EngineeringRavi ModiNoch keine Bewertungen

- JMCC Industries Inc.: Reysons Food ProcessingDokument4 SeitenJMCC Industries Inc.: Reysons Food ProcessingJenniferValleNoch keine Bewertungen

- Meg 5-LF-35-36 Aux Steam SystemDokument23 SeitenMeg 5-LF-35-36 Aux Steam SystemAkash KandwalNoch keine Bewertungen

- Water Balance & Sources of Wastewater in Sugar Mill & RefineryDokument20 SeitenWater Balance & Sources of Wastewater in Sugar Mill & RefineryArun Gupta0% (1)

- Project ScienceDokument10 SeitenProject ScienceJD MaestreNoch keine Bewertungen

- AB-516 PESRUserGuideDokument92 SeitenAB-516 PESRUserGuiderenato pintabonaNoch keine Bewertungen

- Saldimpianti Company Presentation - 1Dokument86 SeitenSaldimpianti Company Presentation - 1Karim BELABEDNoch keine Bewertungen

- Satyam Shrey SHAHIDokument203 SeitenSatyam Shrey SHAHINeha Suman100% (2)

- Optimising Digestion Flash Tank Design For The Alumina IndustryDokument5 SeitenOptimising Digestion Flash Tank Design For The Alumina IndustryJuan Manuel ChavarríaNoch keine Bewertungen

- Feasibility Report of Sugar Mill Cogen Power PlantDokument17 SeitenFeasibility Report of Sugar Mill Cogen Power Plantknsaravana100% (1)

- S-G000-535Z-001 - Specification Nozzle Loads On Mechanical EquipmentDokument13 SeitenS-G000-535Z-001 - Specification Nozzle Loads On Mechanical Equipment전아진Noch keine Bewertungen

- StandardsDokument117 SeitenStandardsaharish_iitkNoch keine Bewertungen

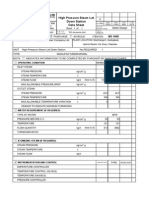

- High Pressure Steam Let Down Station Data SheetDokument5 SeitenHigh Pressure Steam Let Down Station Data SheetSabeeh AhmedNoch keine Bewertungen

- Instructions On How To Properly Fill in The WAIRDokument17 SeitenInstructions On How To Properly Fill in The WAIRBenedick Conrad R. GlifuniaNoch keine Bewertungen

- Hosokawa Micron BV - DRY.ENG.17.07.B44 PDFDokument44 SeitenHosokawa Micron BV - DRY.ENG.17.07.B44 PDFCornelius Toni KuswandiNoch keine Bewertungen

- Overview of The Wayang Windu Geothermal Field, West Java, IndonesiaDokument19 SeitenOverview of The Wayang Windu Geothermal Field, West Java, IndonesiaKristian Edwin SalambaNoch keine Bewertungen

- ECONOMIZERDokument17 SeitenECONOMIZERTrần Văn Trọng 7350Noch keine Bewertungen

- HW 4 3.12Dokument33 SeitenHW 4 3.12Anonymous U3DpVvqVWx0% (3)

- Directorate of Factories and Boilers, OrissaDokument19 SeitenDirectorate of Factories and Boilers, OrissaBIRANCHINoch keine Bewertungen

- Deaerator, Boiler Feed Water Tank - EWT Water TechnologyDokument3 SeitenDeaerator, Boiler Feed Water Tank - EWT Water TechnologyZulal AliNoch keine Bewertungen

- The Marcet BoilerDokument5 SeitenThe Marcet BoilerEiman UzmiNoch keine Bewertungen

- Steam Chest & Flaker Startup-R190723Dokument4 SeitenSteam Chest & Flaker Startup-R190723BCPACKAGING SERVICENoch keine Bewertungen

- User Manual Serie CastleDokument13 SeitenUser Manual Serie CastlezambranofNoch keine Bewertungen

- Pipes and Tubes - Recommended Insulation Thickness PDFDokument4 SeitenPipes and Tubes - Recommended Insulation Thickness PDFSandi ApriandiNoch keine Bewertungen

- Power Plant Engineering Lecture Notes on Flow Through NozzlesDokument13 SeitenPower Plant Engineering Lecture Notes on Flow Through NozzlesBharat SharmaNoch keine Bewertungen

- GrasimDokument10 SeitenGrasimGaurav SinghNoch keine Bewertungen