Beruflich Dokumente

Kultur Dokumente

CABLE Rev06 PDF

Hochgeladen von

fadilOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CABLE Rev06 PDF

Hochgeladen von

fadilCopyright:

Verfügbare Formate

LOW VOLTAGE WIRES AND

CABLES

Document Number

SUP/NENG/011

Effective Date

04 May 2006

Revision

03

Document Owner

Power Engineering

FRM/COOP/003

Supporting Document (SUP)

LOW VOLTAGE WIRE AND CABLE SPECIFICATION

SUP Number:

SUP/NENG/011

Document Change History

Revision

Effective

Date

Updated By

Draft 1

Rev.01

16.01.2004

Novel S

Novel S

Rev.02

Rev.03

Rev. 04

01.12.2005

04.05.2006

16.09.2013

Novel S

Novel S

Riyadi Agung Suharto

LOW VOLTAGE WIRE AND CABLES

Copyright by PT XL AXIATA

Description of Change

For reviewed

Change approval list

Add approved manufacturer

Change approval list

Change approval list

Change approval list

2 of 8

Last saved by Power Engineering

FRM/COOP/003

Supporting Document (SUP)

LOW VOLTAGE WIRE AND CABLE SPECIFICATION

SUP Number:

SUP/NENG/011

Approval List

No

1

Name

Stefanus Julianto F

Riyadi Agung Suharto

Position

GM Infrastructure &

Sitac

Manager Power Eng

LOW VOLTAGE WIRE AND CABLES

Copyright by PT XL AXIATA

Signature

Date

3 of 8

Last saved by Power Engineering

FRM/COOP/003

Supporting Document (SUP)

LOW VOLTAGE WIRE AND CABLE SPECIFICATION

SUP Number:

SUP/NENG/011

LOW VOLTAGE WIRES AND CABLES

1.0 SCOPE OF WORK

Work Included

a. Wires and cables for applications up to 600 Volts AC and fire proof cables in

accordance with the Contract Documents. It does not specify wires, cables 24

Volt and 48 Volt DC control systems.

b. Wires and cables for special applications are not included in this section.

2.0 REFERENCE

a. Provision and Regulation by Safety Labour Local Codes.

b. Regulation issued by Ditjen Bina Lindung (Depnaker).

c. Regulation issued by PLN.

d. PUlL 2000

e. National Electric Code (NEC).

3.0 QUALITY ASSURANCE

a. Manufacturer: Firm regularly engaged in manufacture of wire and cable

materials of type and size required, whose products have been in satisfactory

use in similar service for not less than 5 years.

b. Installer: Firm with at least 5 years of successful installation experience on

electrical work projects similar to this project.

c. Code Compliance Comply with applicable portions of electric local codes.

(SPLN)

4.0 SUBMITTALS

a. Product Data Submit manufacturers product data and installation instruction

for each product specified for wires and cables.

b. Submit shop drawing which indicated size and model of all wires and cables

before installation.

c. Submit scaled shop drawings, based on request by PT. XL AXIATA for

execution in site, which indicate general layout and details of this work prior to

actual installation for approval.

d. Submit brochure/catalogue of wires and cables for approval, before they are

released to order.

e. Upon completion of this portion of the work and as a condition of its

acceptance, deliver to PT. XL AXIATA three (3) copies of as built drawings.

5.0 GUARANTEE

a. All equipment, material and workmanship shall be guaranteed by the

Contractor for a period of one year from the date of final acceptance. Upon

receipt of notice from PT. XL AXIATAs Project representative of any failure

during the guaranteed period, the affected part or work shall be replaced

promptly by the Contractor at his expense.

LOW VOLTAGE WIRE AND CABLES

Copyright by PT XL AXIATA

4 of 8

Last saved by Power Engineering

FRM/COOP/003

Supporting Document (SUP)

LOW VOLTAGE WIRE AND CABLE SPECIFICATION

SUP Number:

SUP/NENG/011

b. The guarantee shall not extend to damage incurred through improper

operation and maintenance by the Owner. The Owner shall assume full

responsibility for proper operation and maintenance upon final acceptance.

6.0 TECHNICAL SPECIFICATION

6.1 APPROVED MANUFACTURES

a. Power Cable

Kabelindo, Kabel Metal, Supreme, Tranka or Voksel

b. Lighting/Socket Outlet Cable:

c. Kabelindo, Kabel Metal, Supreme, Tranka or Voksel

d. Control Cable

e. Kabelindo, Kabel Metal, Supreme, Tranka or Voksel

6.2 WIRES AND CABLE

a. General

Provide wires and cables with a minimum insulation rating of 600 volts.

b. Conductor

Electrical grade, annealed copper, tinned if rubber insulated, and fabricated in

accordance with JEC, SIT, JIS & SPLN standards.

c. Insulation

Type CV cross-linked polyethylene insulation or NYY PVC insulation suitable

for use in wet locations up to 90 C. Use type NYM multi- conductor cable for

lighting, receptable and motor branch circuits installed in cable tray.

d. Color Coding:

1. Provide consistent color coding of all feeders, sub-feeders, motor circuits and

the likes as follows:

Phase R Red

Phase S Yellow

Phase TBlack

Neutral Blue

Ground Green with yellow stripes

2. Color code wiring for control systems installed in conjunction with mechanical

and/or miscellaneous equipment in accordance with the wiring diagrams

furnished with the equipment.

e. Drop Voltage

1. The maximum drop voltage a long the cable used from AC PDB to the load

is 3% of the nominal voltage by using the following formula:

V = 2(I x x L) / A

Where:

V

: Drop voltage

I

: Current (A)

: Cable resistivity (Ohm.mm/Meter)

L

: Cable length (M)

A

: Cable diameter (mm)

LOW VOLTAGE WIRE AND CABLES

Copyright by PT XL AXIATA

5 of 8

Last saved by Power Engineering

FRM/COOP/003

Supporting Document (SUP)

LOW VOLTAGE WIRE AND CABLE SPECIFICATION

SUP Number:

SUP/NENG/011

2. Drop voltage for special application (where the drop voltage is designed on

the specific percentage more than 3% ) may be implemented upon

approval by XL- Engineering.

6.3 CONNECTORS

a. Make connections, splices, taps and joints with solder less devices,

mechanically and electrically secure. Protect exposed wires and connecting

devices with electrical tape or insulation to provide not less than that of the

conductor.

b. Branch Circuit Wires: Use any of the following types of terminals and

connecting devices.

1. Terminal Cable Key

Coiled tapered, spring wound devices with a conducting corrosionresistant coating over the spring steel and a plastic cover and skirt

providing full insulation for splice and wired ends. Screw connector on by

hand

2. Tool Applied

Steel cap, with conduction and corrosion resistant metallic plating, open at

both ends, fitted around the twisted ends of the wire and compressed or

crimped by means of special die designed for the purpose. Specially fitted

plastic or rubber insulting cover wrap over each connector.

6.4 LUBRICANT

Use lubricant only where the possibility of damage to conductors exist. Use oniy

lubricant approved by the cable manufacturer and one which is inert to cable and

raceways.

6.5 FIRE PROOF CABLE

a. Fire proof cable shall be installed in accordance with the manufacturer

recommendations and instructions. Fire proof cable shall be run on

proprietary make horizontal cable trays, vertical cable ladders, trunkings or

conduits depending on the sizes. For horizontal runs, fire proof cable

Of larges sizes shall be secured neatly on the cable trays or ladders at close

interval.

b. All installation accessories shall be of manufacturers standard products.

Cable glands shall be of fire rating equal. The bending radius of the cables

measured from the inside of the bend shall be not less than eight times the

diameter of the cable.

c. Fire proof cable shall be low acid, low corrosive gas emission and low or zero

halogen (low smoke emission and non toxic).

d. Fire proof cable shall be in accordance to IEC-331 for 3 hours duration

7500C at full load current without derating. MI cables shall conform to BS

6207 (manufacturing standards) and passed BS 6387 with highest

LOW VOLTAGE WIRE AND CABLES

Copyright by PT XL AXIATA

6 of 8

Last saved by Power Engineering

FRM/COOP/003

Supporting Document (SUP)

LOW VOLTAGE WIRE AND CABLE SPECIFICATION

SUP Number:

SUP/NENG/011

Categories CWZ

- C = 950 C for 3 hours fire

- W = 650 C fire with water

- Z = 950 C fire with mechanical lock

e. Approved Manufacturer

- FR Cable Elcu Flarnex, Fuji

- MI Cable : Pyrotenax, LMI

7.0 IMPLEMENTATION

a. Provide a complete system of conductors in race way system. Mount wiring

through a specified raceway, regardless of voltage application.

b. Do not install wire in complete conduits runs nor until after the concrete work

and plastering is completed and moisture is swabbed from conduits. Eliminate

splices wherever possible. Where necessary, make splices only in readily

accessible.

c. Flashover insulation value of joints to be equal to that of the conductor.

Provide SPLN listed connectors, etc., rated at 600 volts for general use and

1.000 volts for use between ballasts and lamps of gaseous discharge fixtures.

d. Use terminating fittings, connectors, etc., of the type suitable for the specified

cable furnished. Make bends in cable at termination prior to installing

compression device. Make fittings tight.

e. Install wires in raceways and make up terminations in accordance with the

manufacturers recommendations using special washers, nuts, lubricant etc.,

as required. Strip insulation so as to avoid nicking of wire.

f. Extend wire sizing for the entire length of a circuit, feeder, etc., unless

specifically noted otherwise.

g. Provide bare copper ground conductor in each feeder or in group of feeders,

with the total current carrying capacity to be taken in consideration.

h. Cables inside ceiling shall be installed inside PVC High Impact conduits

and/or cable trays.

i. Cables of lighting and receptables at open area shall be installed with steel

conduit pipe.

j. The configuration of DC cable on the cable tray shall be installed with the

following :

DC Cables

Cable tray

Positive polarity

Negative

LOW VOLTAGE WIRE AND CABLES

Copyright by PT XL AXIATA

7 of 8

Last saved by Power Engineering

FRM/COOP/003

Supporting Document (SUP)

LOW VOLTAGE WIRE AND CABLE SPECIFICATION

SUP Number:

SUP/NENG/011

k. Cable NYFGbY shall be used for outdoor installation and buried

l.

Cable NYY/NYA may be used for outdoor installation and buried only if

installed inside the galvanized steel pipe.

LOW VOLTAGE WIRE AND CABLES

Copyright by PT XL AXIATA

8 of 8

Last saved by Power Engineering

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Opto CouplerDokument9 SeitenOpto CouplerPadmo PadmundonoNoch keine Bewertungen

- Excel Training - Level 1Dokument95 SeitenExcel Training - Level 1Cristiano Aparecido da SilvaNoch keine Bewertungen

- Excel Training - Level 1Dokument95 SeitenExcel Training - Level 1Cristiano Aparecido da SilvaNoch keine Bewertungen

- Radio Receiver BC-348-B User and Service Tech ManualDokument89 SeitenRadio Receiver BC-348-B User and Service Tech Manualdr7zyqNoch keine Bewertungen

- Capacity Management Process - HS2016Dokument23 SeitenCapacity Management Process - HS2016fadilNoch keine Bewertungen

- Railway Protection Code of Practice Oct 2014Dokument107 SeitenRailway Protection Code of Practice Oct 2014fadil100% (1)

- Electrical Systems in A BuildingDokument76 SeitenElectrical Systems in A BuildingPitz Shady ShinNoch keine Bewertungen

- History of Grounding Earthing Practices in The United StatesDokument14 SeitenHistory of Grounding Earthing Practices in The United StatesObatai Khan100% (1)

- Access Management HS2016Dokument47 SeitenAccess Management HS2016fadil100% (2)

- ITIL - A Guide To Request Fulfilment PDFDokument2 SeitenITIL - A Guide To Request Fulfilment PDFKamran AbkNoch keine Bewertungen

- To Determine Resistance and Impendance of An Inductor With or Without Iron CoreDokument8 SeitenTo Determine Resistance and Impendance of An Inductor With or Without Iron CoreABHISHEK TIWARI94% (32)

- 5G-State of The Art.2Dokument1 Seite5G-State of The Art.2fadilNoch keine Bewertungen

- BGP Master of Computer Science 2020Dokument4 SeitenBGP Master of Computer Science 2020fadilNoch keine Bewertungen

- RTA-16-95 - Polymer Wall To Protect Underground Structures From Earthquakes - Development and InstallationDokument1 SeiteRTA-16-95 - Polymer Wall To Protect Underground Structures From Earthquakes - Development and InstallationfadilNoch keine Bewertungen

- Penawaran Topik Dan Judul Penelitian Thesis Untuk S2 Teknik IndustriDokument12 SeitenPenawaran Topik Dan Judul Penelitian Thesis Untuk S2 Teknik IndustrifadilNoch keine Bewertungen

- BGP Master of Computer Science 2020Dokument4 SeitenBGP Master of Computer Science 2020fadilNoch keine Bewertungen

- Transmisi Radio Microwave.Dokument8 SeitenTransmisi Radio Microwave.fadilNoch keine Bewertungen

- Problem Management HS2016Dokument48 SeitenProblem Management HS2016fadil100% (1)

- Aau Redefines Site Architecture - 20150209Dokument9 SeitenAau Redefines Site Architecture - 20150209agungcomlNoch keine Bewertungen

- Map Info Professional User GuideDokument525 SeitenMap Info Professional User GuideL'Homme De GammeNoch keine Bewertungen

- Introduction To Solid State Relays and The Advantages and DisadvantagesDokument3 SeitenIntroduction To Solid State Relays and The Advantages and DisadvantagesKen Dela CernaNoch keine Bewertungen

- CRS - 2018SNE2714601137 - LCP Wiring Diagram - Rev02 CRSDokument5 SeitenCRS - 2018SNE2714601137 - LCP Wiring Diagram - Rev02 CRSsalman1111aNoch keine Bewertungen

- Push Push VFODokument4 SeitenPush Push VFOName100% (2)

- New 600 Amp Loadbreak Technology Provides Efficient, Reliable Visible Break and Visible GroundDokument4 SeitenNew 600 Amp Loadbreak Technology Provides Efficient, Reliable Visible Break and Visible Groundsincos1983Noch keine Bewertungen

- Data Sheet For Electrical Medium Voltage Variable Speed Drive System (Emvsds)Dokument7 SeitenData Sheet For Electrical Medium Voltage Variable Speed Drive System (Emvsds)michael esoNoch keine Bewertungen

- Peavey Full LayoutDokument1 SeitePeavey Full LayoutFernanda GutierrezNoch keine Bewertungen

- Bipolar Junction TransistorDokument6 SeitenBipolar Junction TransistorPadirikuppam PavithraNoch keine Bewertungen

- Lect 17-18 19EEE111 BJT FullDokument87 SeitenLect 17-18 19EEE111 BJT FullDenifer DeepNoch keine Bewertungen

- 6SL3210 1KE17 5UB1 Datasheet enDokument2 Seiten6SL3210 1KE17 5UB1 Datasheet enleonbrazNoch keine Bewertungen

- EC2251 C1 Linear and Digital Integrated CircuitsDokument1 SeiteEC2251 C1 Linear and Digital Integrated CircuitsRakesh Kumar DNoch keine Bewertungen

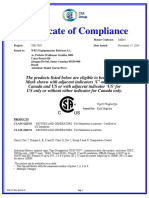

- CSA CUS W22 Low Voltage Class I Div 2Dokument2 SeitenCSA CUS W22 Low Voltage Class I Div 2Lim SjahrialNoch keine Bewertungen

- PVC Flexible CableDokument3 SeitenPVC Flexible CableMWNoch keine Bewertungen

- Service Manual: Star T3/T3R UPS 1kVA 3kVA 220VACDokument14 SeitenService Manual: Star T3/T3R UPS 1kVA 3kVA 220VACMuhaimin Muhammad romadhonNoch keine Bewertungen

- Tender Excel To PDFDokument21 SeitenTender Excel To PDFMuhamad Rizki Putra GhifariNoch keine Bewertungen

- Solution Sheet 2 Electronic CircuitsDokument15 SeitenSolution Sheet 2 Electronic CircuitsWajdi BELLILNoch keine Bewertungen

- Powermos Transistors Irfp460 Avalanche Energy Rated: Features Symbol Quick Reference DataDokument7 SeitenPowermos Transistors Irfp460 Avalanche Energy Rated: Features Symbol Quick Reference DataRio CandrapurwitaNoch keine Bewertungen

- Electric Power Distribution - Wikipedia, The Free EncyclopediaDokument3 SeitenElectric Power Distribution - Wikipedia, The Free EncyclopediasacuarsNoch keine Bewertungen

- JA Solar JAM5 (L) - 72-200 - SI (200W) Solar PanelDokument2 SeitenJA Solar JAM5 (L) - 72-200 - SI (200W) Solar PanelVictor OliveiraNoch keine Bewertungen

- Earth Fault Protection Failure in The Distribution Transformer 11/0.4 KV SupplyDokument11 SeitenEarth Fault Protection Failure in The Distribution Transformer 11/0.4 KV SupplySolaiappan KtNoch keine Bewertungen

- Switch Panel Borad Short Circuit Current Ratings2700db9901Dokument14 SeitenSwitch Panel Borad Short Circuit Current Ratings2700db9901Dinesh PitchaivelNoch keine Bewertungen

- Elite Nixie': Assembly Instructions and User GuideDokument44 SeitenElite Nixie': Assembly Instructions and User GuideWasawat JoongjaiNoch keine Bewertungen

- Make This Simplest Transformerless Power Supply Circuit Using IC LR645Dokument2 SeitenMake This Simplest Transformerless Power Supply Circuit Using IC LR645master chibukingNoch keine Bewertungen

- A Copy of Permission: Check ListDokument2 SeitenA Copy of Permission: Check ListMohd AfzalNoch keine Bewertungen

- Denon DN-D4500 Doppel CD PlayerDokument16 SeitenDenon DN-D4500 Doppel CD Player1234Noch keine Bewertungen

- Physical Handout NotesDokument121 SeitenPhysical Handout NotesJimmy MachariaNoch keine Bewertungen