Beruflich Dokumente

Kultur Dokumente

Title - Wood Chipper Construction

Hochgeladen von

محمد عبدالدايمOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Title - Wood Chipper Construction

Hochgeladen von

محمد عبدالدايمCopyright:

Verfügbare Formate

July 16, 1968

K. LEDERGERBER

3,392,763

WOOD CHIPPER CONSTRUCTION

Filed May 15, 1967

W26

IN VEN TOR.

I; Y/Kwu Z. EOFRGERBER

JM .i@ Y 32

7701?! Y5

United States Patent 0 '

3,392,763

Patented July 16, 1968

2

port for logs so that a maximum cutting e?iciency is

attained and a more uniform chip product is produced.

In accordance with the present invention, the feed

spout of a chipper is constructed to carry a plurality of

stationary anvils. These stationary anvils are arranged

3,392,763

WOOD CHIPPER CONSTRUCTION

Karl Ledergerber, Box 556,

Wadley, Ga. 30477

Continuation-impart of application Ser. No. 439,325,

Mar. 12, 1965. This application May 15, 1967, Ser.

No. 638,333

6 Claims. (Cl.,144176)

in a curved path which approximates the curvature of a

log at a plane which is cut at an angle to the longitudinl

axis of the log. Further, the plurality of anvils provides

for a construction which is more economically and easily

10

produced for log handling chippers, and relatively large

diameter stock material can be handled at an improved

cutting rate for a given apparatus.

In addition, the present invention provides for an im

proved mounting of chipper discs associated with any ro

spout construction is provided for receiving whole logs 15 tary disc apparatus of the type described above. Prior

for a chipping action. The chipper disc is mounted on a

chipper disc mounting arrangements have provided for a

shaft which is wholly supported by bearings on one side

bearing support at each end of a shaft which carries a

of the disc only, and this arrangement permits a mount

chipper disc for rotational movements within a housing

ing of longer cutting knives on a face of the disc. The

of the wood chipper apparatus. The cutting knives which

feed spout is constructed to receive whole logs, and a plu

20 are normally positioned on one face of the chipper disc

rality of anvils carried by the feed spout are arranged on

have been limited in their individual lengths because it

a curved path to coact with the chipper disc.

was necessary to permit the passage of the shaft through

the entire disc structure and past the mounted positions

ABSTRACT OF THE DISCLOSURE

A wood chipper apparatus is provided with an im

proved mounting of a chipper disc, and an improved feed

Related application

This application is a continuation-in-part of my co

pending application Ser. No. 439,325, ?led Mar. 12, 1965,

now Patent No. 3,332,461.

Background of invention

This invention relates' to an improvement in rotary

of the knives. Also, prior art bearing supports have in

25 terfered with the size and location of feed spouts. The

present invention provides for a novel mounting of a

chipper disc within a housing wherein the shaft upon

which the disc is carried for rotational movements is

mounted in bearing supports located on one side only of

30 the disc. This means that the surface of the disc which is

used for carrying cutting knives may be a surface which is

opposed to the positions of the bearing support members.

disc chippers and is particularly concerned with an im

proved feed spout and chipper disc arrangement for use

with rotary disc wood chippers.

In the wood pulp industry it is necessary to reduce

Thus, the knives may be longer in length and may ap

proach the center axis of rotation for the disc in an ar

35

wood stock such as logs or slabs of wood to a chip form.

rangement which provides for substantially improved cut

ting action for each individual knife. Also, the position

ing of the feed spout relative to the housing may be sub

It is desirable in producing such chips to obtain a-chip

stantially improved for chipper apparatus of this type.

product which has certain uniform characteristics of size

Other advantages of the improved feed spout and chip

and quality in order to provide for better cooking char 40 per disc constructions of this invention will become ap

acteristics of the chip product. Therefore, it is important

parent in the more detailed discussion which follows, and

that the wood stock be cut cleanly with little bruising or

in the discussion reference will be made to the follow

squeezing of the resulting product, and it is important to

obtain a uniform chip product at a maximum rate of

production.

As described in my copending application Ser. No.

439,325, now Patent No. 3,332,461, it has been the prac

tice in producing such a chip product from wood stock

to utilize a rotary disc chipper apparatus of the type

shown in US. Patents 1,438,943 and 3,047,244. Such ap

paratus includes a chipper disc mounted for rotation in a

vertical plane, and a number of cutting knives are mount

ed on one face of the disc. The cutting knives coact with

a stationary bed knife, or anvil, in such a way that a

45

ing drawings.

Brief description of the drawings

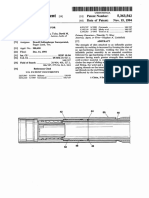

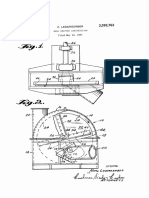

FIGURE 1 is a top plan view of a wood chipper ap

paratus, showing a top section of the apparatus removed

so as to illustrate an improved mounting of a chipper

disc within a housing of the apparatus, and

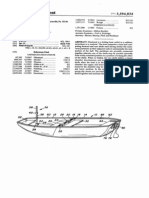

FIGURE 2 is an elevational view of the chipper ap

paratus of FIGURE 1, illustrating an improved feed

spout construction for handling logs.

Detailed description of invention

The wood chipper apparatus of the present invention

scissors action results between the rotating knives and the

stationary knife. Wood stock in the form of logs or slabs

is conveyed to the vicinity of the chipper apparatus, and

may be of any typical construction, and may include the

the wood is then delivered into a feed spout associated

tion Ser. No. 439,325. The descriptive material in my co

constructional features described in my copending applica

pending application is intended to be included as part of

with the chipper apparatus. The feed spout communicates

with the face of the chipper having the cutting knives, 60 the present description by reference thereto. Such a wood

chipper apparatus is shown generally at 10 in the draw

and the feed spout serves to support the wood stock while

ings. The chipper apparatus 10 includes a housing having

the stock is being delivered and drawn into the cutting

a base portion 12 and a cover portion which may be

face of the rotary disc. Other prior art on this subject

as developed in the examination of my copending ap

made up of sections 14 and 16. The cover section 14 may

plication, includes the U5. Patents 1,942,675, 2,712,974, 65 be pivotally mounted by a hinge 18 so that it may be

tilted and opened relative to the section 16. Thus, the

3,069,101 and 3,123,311.

Summary of invention

cover section 14 may swing open to permit an easy access

to the interior of the chipper apparatus. When the sec

tion 14 is in a closed position it may be clamped or

The present invention is directed to improved feed

spout and chipper disc constructions for use in apparatus 70 locked to the adjoining cover section 16 by any suitable

means. A chip removing stack 22 is provided for remov

of the type described above. It has been found that the

ing the chip product out of the apparatus.

improved structures of this invention result in better sup

r 3,392,763

3

Within the housing, a rotating chipper disc 24 is

mounted on. a horizontal axis for rotation in a vertical

plane. A horizontally disposed axle means 26 carries the

chipper disc 24 and provides the axis of rotation for the

'4

compared to previous arrangements for cutting slabs and

other forms of wood stock.

Although it is kown to provide feed spouts having tubu

lar inlet members which introduce stock material into

chipping apparatus, the usual function of such feed spouts

disc. The axle means 26 may pass into a central portion

of the disc 24, but the axle does not extend beyond a

front face 32 of the disc which carries knife elements 34.

is to merely carry or convey stock material, and there

has been no provision for an improved cutting action or

A pair of bearing supports 36, such as pillow block bear

cooperation of an end of such feed spouts with a chipper

ings of well known construcfion, may be provided for

disc rotating in a vertical plane. Also, it is known to pro

supporting the entire axle and disc assembly for rotation 10 vide single piece anvil elements having curved surfaces

about a horizontal axis. An important feature of the

for assisting in the support and conveying of curved

present invention is to mount the entire axle and chipper

stock material into some form of chipper apparatus. How

disc assembly with all bearing supports located on one

ever, prior devices have not been as ef?cient to operate

side only of the chipper disc. This feature provides for

nor as economical to produce as the improved feed spout

the use of longer knife elements 34 on a cutting face 32 15 and anvil structure of the present invention. Referring

of a chipper disc without any interference from an axle

shaft or bearing supports on the cutting side of the disc.

The chipper disc 24 may include a hub element 38 which

is secured to the disc for providing a tight mounting of the

to FIGURE 2, it can be seen that the feed spout 50 is

horizontally disposed to enter the chipper apparatus hous

ing at an angle, and thus, a circular feed spout will form

a communication through an opening in the vertical hous

disc on an end of the axle 26. Means for rotating the disc 20 ing wall. The opening which is formed through the hous

ing wall to receive the feed spout 50, and to carry logs

may include a motor and drive belt means of well known

therethrough, has essentially an elliptical shape, as illus

constructions, as exempli?ed in the above mentioned

patents or in my copending application. The driving means

trated. As viewed in FIGURE 2, the left hand side of the

elliptical opening through the housing Wall is provided

is preferably positioned on the same side of the chipper

r with a series of separate anvil elements 52 which are dis

disc as are the pillow block bearings 36.

Because of the improved arrangement for mounting a

chipper disc with all bearing support means located on

one side only of the disc, it is possible to provide a better

placement and construction for knife elements 34 on a

cutting face of a disc. Referring to FIGURE 2, it can be

seen that the knife elements 34 are relatively long, com

pared to prior art arrangements, and the illustrated em

bodiment shows four knife elements 34 placed about a disc

face, although any suitable number of knives may be used.

The four knife elements 34 are placed at substantially 35

right angles to one another, however, each knife element

is offset slightly from a perfectly aligned position with

posed about the curved inner terminal end of the feed

spout 50 so as to provide ?xed surfaces against which the

cutting knives 34 can move a log which is being reduced

to chips. The elements 52 make up the anvil means for

the feed spout construction, and the anvil elements

start at a top point of the feed spout and are placed

downwardly and outwardly, as illustrated, until they reach

a midpoint of the longitudinal axis of the feed spout.

From there, the elements 52 are placed downwardly and

inwardly until they reach a bottom point on the circular

opening formed through the housing wall. Thus the ?xed

anvil means of the present invention is in the form of

an anvil which is made up of a plurality of single anvil

the central axis of the chipper disc. Each knife element

elements placed along a curved path which describes an

34 is ?xed to the face of the disc so that a cutting edge 40

leads the knife in its movement with the rotation of the 40 ellipse or some other preferred curve. The single anvil

elements 52 are easily manufactured and heat-treated be

disc. The end 42 of each cutting edge slightly leads an

cause they are formed with straight surfaces, and thus,

end 44 of the same knife as related to a line drawn through

no costly machining and treating operations are required

the central axis of the disc and along the plane of the

in the manufacture of the elements 52. However, even

cutting face 32. The knife element 34 may be bolted or

though the elements 52 are formed with straight surfaces,

otherwise af?xed to the front face of the disc so as to be

they are disposed about the inner end of the feed spout

replaceable when worn. Also, each knife element 34 may

be mounted over an opening 46 which is formed com

50 so as to form an essentially curved anvil surface against

pletely through the chipper disc in a well known manner

to provide for a movement of chips away from the cut

which a log may be placed While it is being reduced to

chips. The anvil elements 52 may be mounted at the in

ner end of the feed spout 50 in any convenient manner,

ting edge of the knives and through the disc.

In addition to the elements just described, the chipper 50 and a preferred construction has been illustrated. Plate

apparatus further includes an inlet means for feeding stock

material to the cutting face of the rotating chipper disc.

The inlet means is in the form of a feed spout 50 which

members 54 are affixed to a vertical portion of the chip

per housing wall, and each plate element 54 includes a

curved inner edge which de?nes a portion of the elliptical

opening formed through the housing wall. The anvil ele

is shown as a horizontally disposed tubular member which

leads into a side wall of the chipper apparatus housing so 55 ments 52 are then bolted, or otherwise a?ixed directly

as to communicate at an angle with the lower half of the

rotating disc face 32, In this manner, an opening is pro

vided for feeding logs or other stock material into the

to the plate members 54 so as to follow the curved edges

of the plates. When all elements are in place, an es

sentially curved anvil means is presented toward the in

side of the chipper apparatus so as to cooperate with

The feed spout 50 is preferably circular or oval in its 60 the movement of knives 34 past the position of the anvil.

Also, it can be seen from FIGURE 2 that the feed

cross section so as to handle the circular con?gurations of

spout 50 and the opening through which it communicates

whole logs which are to be reduced in the chipper appa

into the chipper apparatus may be ideally positioned so

ratus. A terminal end of the feed spout enters the hous

as to receive a full sweep of the cutting edges of each

ing of the chipper apparatus so as to present the end of

a log against the rotating face 32 of the disc 24. With the 65 knife element 34. This positioning is further made pos

sible by the removal of any bearing support structures

disc rotating clockwise, as viewed in FIGURE 2, it can be

which would otherwise interfere with the location of a

seen that the cutting edges 40 of the disc move across the '

feed spout into one side of a housing for a chipper ap

exposed end of the log generally from right to left so as to

cutting face of the rotating disc.

slice chips from the log. As already discussed, the cutting

paratus.

action of chipper devices of this type results from a 70

With the apparatus which has been described and illus

movement of a plurality of knives past ?xed anvils so as

trated, a log can be introduced into the feed spout 50 for

to accomplish a scissors-like action between the knives

reduction to chips. Once the log is moving along the

and the anvils. The present invention is concerned with

length of the feed spout, one end of the log will be in

providing a novel arrangement of a plurality of anvils so

troduced into the rotating, cutting face/32 of the chipper

as to improve the cutting action against whole logs, as 75 disc 24. As soon as the knife elements 34 contact an end

3,392,763

of the log, the log will be pushed against the anvil means

which is formed from the plurality of anvil elements 52,

2. The improvement of claim 1 wherein said plurality

knives, as coupled with the cooperation of the curved

anvil means 52 results in the log being drawn into the

housing which encloses said chipper disc.

4. The improvement of claim 1 wherein said chipper

disc is mounted at an end of a horizontally disposed axle

of anvil elements are arranged on a curved path which

describes a portion of an ellipse.

and then, a scissors action will cause the log to be reduced

3. The improvement of claim 1 wherein said plurality

to chips as the knives sweep past the log end in a clockwise

direction. It has been found that the cutting action of the 5 of anvil elements are mounted on vertical portions of a

chipper apparatus. Thus, the entire log is advanced into

the cutting face of the chipper disc 24 until it has been

means which is mounted for rotation in bearing means,

said bearing means being positioned only on a side of

the chipper disc which is opposed to the face of the disc

which carries the cutting knives.

5. In a wood chipper apparatus of the type having a

chipper disc which is mounted for rotation within a hous

completely reduced to chips.

With the invention just described, it is possible to

handle logs without ?rst reducing them to slabs or other

con?gurations, and a more efficient and economical chip

ping action and rate are attained. Although the invention

has been described with reference to a preferred embodi 15 ing, and a plurality of knives mounted on a ?rst face of

ment, variations will become apparent to those skilled in

the chipper disc, the improvement in the mounting of said

the art, and such variations are intended to be included

disc which comprises:

within the scope of the present invention, as claimed.

an axle means which is mounted for being driven so as

What is claimed is:

to rotate the chipper disc, and means to secure the

1. In a wood chipper apparatus of the type having a

chipper disc to a terminal end of the axle means so

chipper disc which rotates in a vertical plane, said disc

that the axle does not extend beyond said ?rst face

having a plurality of cutting knives mounted on a face

of the chipper disc, and

thereof, the improvement comprising:

a tubular feed spout extending into the wood chipper

apparatus for delivering a log into the face of the 25

chipper disc having the plurality of knives mounted

thereon, said feed spout being disposed on a sub

stantially horizontal plane and at an angle to the

chipper disc so that logs being fed through the feed

bearing means for supporting said axle means, said

bearing means being positioned only on an opposite

side of the chipper disc from said ?rst face.

6. The improvement of claim 5 and including driving

means for rotating said axle means and said chipper disc,

said driving means being positioned on said opposite side

of the chipper disc.

spout are drawn into the chipper apparatus and re 30

duced to chips by the action of the knives on the

References Cited

UNITED STATES PATENTS

chipper disc, and

a curved anvil means carried by a side wall of the feed

spout for coacting with the cutting knives of the

1,942,675

1/1934 Wigger et al.

chipper disc, said curved anvil means further com 35 2,174,593 10/1939 rPelot et al _____ __ 144176 XR

2,299,248 10/ 1942 Ottersland ____ __ 144-176 XR

prising a plurality of anvil elements which are ar

3,061,207 10/1962 Clark _____________ __ 241-92

ranged on a curved path which essentially follows a

portion of the curvature of the tubular feed spout

WILLIAM W. DYER, JR., Primary Examiner.

at its terminal end portion which extends into the

wood chipper apparatus.

40 W. D. BRAY, Assistant Examiner.

Das könnte Ihnen auch gefallen

- Title - Wood Chipper Disc and Knife MountingDokument5 SeitenTitle - Wood Chipper Disc and Knife Mountingمحمد عبدالدايمNoch keine Bewertungen

- Drum Chipper MachineDokument28 SeitenDrum Chipper MachinechienhamthepNoch keine Bewertungen

- Value Leader Wood Chipper WC Series ManualDokument19 SeitenValue Leader Wood Chipper WC Series ManualBetstProducts67% (3)

- Stieber TDokument96 SeitenStieber Tadem özdilNoch keine Bewertungen

- Eei PM1 El02Dokument61 SeitenEei PM1 El02Mohd A IshakNoch keine Bewertungen

- R 27Dokument668 SeitenR 27Adan Arribasplata SeguinNoch keine Bewertungen

- 8010028-01-OM-001 - O&M-Manual Rio Turbio 1+2 - enDokument62 Seiten8010028-01-OM-001 - O&M-Manual Rio Turbio 1+2 - enjose almironNoch keine Bewertungen

- Wood Pellet Production ProcessDokument6 SeitenWood Pellet Production ProcessmuhammadnainNoch keine Bewertungen

- 0414868761Dokument4 Seiten0414868761henry delgadoNoch keine Bewertungen

- Design of Composite Cardan ShaftDokument17 SeitenDesign of Composite Cardan ShaftManshi AgrawalNoch keine Bewertungen

- Manual Reductor SumitomoDokument11 SeitenManual Reductor SumitomoPhilip WalkerNoch keine Bewertungen

- Recommended Lubricants for Gear UnitsDokument9 SeitenRecommended Lubricants for Gear UnitsWaris La Joi WakatobiNoch keine Bewertungen

- 8702en PDFDokument32 Seiten8702en PDFWaris La Joi WakatobiNoch keine Bewertungen

- MARCY 8 X 6 Ball Mill, Shell, Gear and Liners, Parts UnitDokument2 SeitenMARCY 8 X 6 Ball Mill, Shell, Gear and Liners, Parts UnitRicardo Rodriguez100% (1)

- Quarries ErnalulamDokument32 SeitenQuarries ErnalulamArun Vasudev.M.NNoch keine Bewertungen

- Kumera Helical and Bevel Gear UnitsDokument138 SeitenKumera Helical and Bevel Gear UnitsPIRATASANTANA100% (1)

- Mill Gear Set Alignment Per Temperature GradientDokument9 SeitenMill Gear Set Alignment Per Temperature GradientlowelowelNoch keine Bewertungen

- BELT DRIVE FLAILHEAD ALIGNMENTDokument3 SeitenBELT DRIVE FLAILHEAD ALIGNMENTAnonymous KdnOsd9Noch keine Bewertungen

- Jiangsu Jiangcheng BrochureDokument38 SeitenJiangsu Jiangcheng Brochuresaurabh sanchetiNoch keine Bewertungen

- HAISUNG Good3 - Cycloid Drive - CatalogDokument92 SeitenHAISUNG Good3 - Cycloid Drive - Catalog032indesignNoch keine Bewertungen

- Thrust Bearing CatalogueDokument38 SeitenThrust Bearing Cataloguemech_eng_indNoch keine Bewertungen

- Deep Groove Ball BearingDokument87 SeitenDeep Groove Ball BearingFendy SepueroeNoch keine Bewertungen

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Dokument7 SeitenSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaNoch keine Bewertungen

- Us1955360 PDFDokument8 SeitenUs1955360 PDFRodrigoPomaNoch keine Bewertungen

- Unlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973Dokument4 SeitenUnlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973fgrt45Noch keine Bewertungen

- "A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Dokument7 Seiten"A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Guillermo Avila RiveraNoch keine Bewertungen

- 11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555Dokument5 Seiten11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555mohammadreza91Noch keine Bewertungen

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDokument6 SeitenDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloNoch keine Bewertungen

- Us 3688484Dokument4 SeitenUs 3688484James LindonNoch keine Bewertungen

- United States Patent (19) : Grote Et A1Dokument9 SeitenUnited States Patent (19) : Grote Et A1RodrigoPomaNoch keine Bewertungen

- United States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDokument7 SeitenUnited States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDanister GladwinNoch keine Bewertungen

- United States Patent (19) : Filed: July 27, 1976 57Dokument3 SeitenUnited States Patent (19) : Filed: July 27, 1976 57Alexandre Magno Bernardo FontouraNoch keine Bewertungen

- Bag cutting mechanism for adjustable bag lengthDokument3 SeitenBag cutting mechanism for adjustable bag lengthJhonnatan E Avendaño Florez100% (1)

- (1966, May 3) US3248803 Rotary Drum Heat ExchangerDokument6 Seiten(1966, May 3) US3248803 Rotary Drum Heat ExchangeraegosmithNoch keine Bewertungen

- Vernier DesignDokument9 SeitenVernier DesignRakeshNoch keine Bewertungen

- Coco Inven PDFDokument4 SeitenCoco Inven PDFsushil-funNoch keine Bewertungen

- United States Patent: (10) Patent N0.: (45) Date of PatentDokument8 SeitenUnited States Patent: (10) Patent N0.: (45) Date of PatentwererNoch keine Bewertungen

- Filed Oct. 22, 1951: P. C. HuttonDokument5 SeitenFiled Oct. 22, 1951: P. C. HuttonGalo YambayNoch keine Bewertungen

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDokument6 SeitenWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNoch keine Bewertungen

- European Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)Dokument10 SeitenEuropean Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)shamsNoch keine Bewertungen

- EP 1 262 663 A2 Rotor for Variable Displacement Swash Plate CompressorDokument16 SeitenEP 1 262 663 A2 Rotor for Variable Displacement Swash Plate CompressorSelvaraji MuthuNoch keine Bewertungen

- Variable displacement compressor hinge mechanismDokument13 SeitenVariable displacement compressor hinge mechanismSelvaraji MuthuNoch keine Bewertungen

- US2447117Dokument6 SeitenUS2447117MahnooshNoch keine Bewertungen

- Tube Saport PDFDokument4 SeitenTube Saport PDFjr110livecomNoch keine Bewertungen

- United States PatentDokument8 SeitenUnited States PatentBarmak CheraghiNoch keine Bewertungen

- Inflatable Packer Reinforcement MethodDokument5 SeitenInflatable Packer Reinforcement Methodmohammadreza91Noch keine Bewertungen

- 915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWDokument15 Seiten915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWMetin MehelNoch keine Bewertungen

- Conveyor Belt Transfers Ice Bodies From Storage to Dispensing AreaDokument6 SeitenConveyor Belt Transfers Ice Bodies From Storage to Dispensing AreaRodrigoPomaNoch keine Bewertungen

- United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0257940 A1Dokument13 SeitenUnited States: (12) Patent Application Publication (10) Pub. No.: US 2012/0257940 A1gowdas2011Noch keine Bewertungen

- Method of Increasing Strength of Welded Slat Assembly for Inflatable PackersDokument6 SeitenMethod of Increasing Strength of Welded Slat Assembly for Inflatable Packersmohammadreza91Noch keine Bewertungen

- Coffee Depulping MachineDokument5 SeitenCoffee Depulping MachineKevin VillacisNoch keine Bewertungen

- US Patent for Cutting Food Products MachineDokument4 SeitenUS Patent for Cutting Food Products MachineRodrigoPomaNoch keine Bewertungen

- Foldable Boat FlierDokument5 SeitenFoldable Boat FlierRakeshNoch keine Bewertungen

- Concrete Mixer Drum ReinforcementDokument10 SeitenConcrete Mixer Drum Reinforcementdaygo21Noch keine Bewertungen

- US3448518Dokument4 SeitenUS3448518liebersax8282Noch keine Bewertungen

- United States Patent 1111 3,595,128Dokument9 SeitenUnited States Patent 1111 3,595,128rte678Noch keine Bewertungen

- United States Patent (19) : Miiller (45) Date of PatentDokument8 SeitenUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaNoch keine Bewertungen

- Improved Tesla Turbine DesignDokument12 SeitenImproved Tesla Turbine DesignNemanja StojanovicNoch keine Bewertungen

- Multi-Purpose Oscillating Sifter MachineDokument4 SeitenMulti-Purpose Oscillating Sifter MachineSantos JustinNoch keine Bewertungen

- Paint Booth ChecklistDokument4 SeitenPaint Booth Checklistمحمد عبدالدايمNoch keine Bewertungen

- Mazej ENGLISH ManualDokument1 SeiteMazej ENGLISH Manualمحمد عبدالدايمNoch keine Bewertungen

- Mazej ENGLISH ManualDokument1 SeiteMazej ENGLISH Manualمحمد عبدالدايمNoch keine Bewertungen

- Air Flow Chart Estimates CFM Through OrificesDokument1 SeiteAir Flow Chart Estimates CFM Through Orificesمحمد عبدالدايمNoch keine Bewertungen

- Mazej ENGLISH ManualDokument1 SeiteMazej ENGLISH Manualمحمد عبدالدايمNoch keine Bewertungen

- Mazej ENGLISH ManualDokument1 SeiteMazej ENGLISH Manualمحمد عبدالدايمNoch keine Bewertungen

- 63C Series: Thermostatic Mixing Valve Aquamix For Radiant Panel Heating Systems Technical Data SheetDokument4 Seiten63C Series: Thermostatic Mixing Valve Aquamix For Radiant Panel Heating Systems Technical Data Sheetمحمد عبدالدايمNoch keine Bewertungen

- 38957Dokument8 Seiten38957mangal deo pathakNoch keine Bewertungen

- How Does A Hammer Mill Work - Rev1Dokument1 SeiteHow Does A Hammer Mill Work - Rev1محمد عبدالدايمNoch keine Bewertungen

- Disc Chipper: H SeriesDokument2 SeitenDisc Chipper: H Seriesمحمد عبدالدايمNoch keine Bewertungen

- Ahmed Daoud Motors - 50HzDokument14 SeitenAhmed Daoud Motors - 50Hzمحمد عبدالدايمNoch keine Bewertungen

- Bearing Selection GuideDokument11 SeitenBearing Selection GuideKishor Kumar Vishwakarma100% (1)

- Piping and Valves For Water and Wastewater PlantDokument184 SeitenPiping and Valves For Water and Wastewater PlantAlex PazmiñoNoch keine Bewertungen

- Valves Shell Design StrengthDokument10 SeitenValves Shell Design Strengthمحمد عبدالدايمNoch keine Bewertungen

- Grades of Bolts Guide for Corvette OwnersDokument1 SeiteGrades of Bolts Guide for Corvette Ownersمحمد عبدالدايمNoch keine Bewertungen

- Fabrication of Wood ShredderDokument32 SeitenFabrication of Wood ShredderInternational Journal of Innovative Science and Research Technology100% (1)

- Winter Chipper MaxDokument37 SeitenWinter Chipper MaxSorinNoch keine Bewertungen

- TWECOM Best Practice Guide On Hedgerow Harvesting and MachineryDokument24 SeitenTWECOM Best Practice Guide On Hedgerow Harvesting and MachineryHanne MengelsNoch keine Bewertungen

- INTIMIDATOR™ 18XP / 1590: Operating & Parts ManualDokument185 SeitenINTIMIDATOR™ 18XP / 1590: Operating & Parts ManualFatyan YanNoch keine Bewertungen

- Whisper Disc MDokument44 SeitenWhisper Disc MJose Vargas100% (2)

- Morbark - 5048B WCL Track Whole Tree ChipperDokument1 SeiteMorbark - 5048B WCL Track Whole Tree ChipperAndré GraeffNoch keine Bewertungen

- A Part of Normet CorporationDokument58 SeitenA Part of Normet CorporationRodrigo MendizabalNoch keine Bewertungen

- Brush Chipper: AttentionDokument140 SeitenBrush Chipper: AttentionFrancisco ConchaNoch keine Bewertungen

- Grain Thresher PlansDokument6 SeitenGrain Thresher PlansGreg HillNoch keine Bewertungen

- Technical Data Heizohack 201112 - 20120101 PDFDokument37 SeitenTechnical Data Heizohack 201112 - 20120101 PDFSanthosh Kumar VempatiNoch keine Bewertungen

- Chipping, Screening and Cleaning-FDokument39 SeitenChipping, Screening and Cleaning-Fvivekbhuchem100% (1)

- 250XP 255XP PDFDokument168 Seiten250XP 255XP PDFluis torresNoch keine Bewertungen

- Timberwolf TW 190TVGTR Wood Chipper Instruction ManualDokument56 SeitenTimberwolf TW 190TVGTR Wood Chipper Instruction ManualthuanNoch keine Bewertungen

- TP 100 Mobile: User Manual and Spare Parts CatalogueDokument54 SeitenTP 100 Mobile: User Manual and Spare Parts CatalogueAlexander MedinaNoch keine Bewertungen

- Size Reduction & Densification Directory 2017: Company Comments Country WEBDokument6 SeitenSize Reduction & Densification Directory 2017: Company Comments Country WEBGeorge SheytanovNoch keine Bewertungen

- Force Relations and Dynamics of Cutting Knife in A Vertical Disc Mobile Wood Chipper - Leonardo El J Pract TechnolDokument14 SeitenForce Relations and Dynamics of Cutting Knife in A Vertical Disc Mobile Wood Chipper - Leonardo El J Pract TechnolNguyenHuanNoch keine Bewertungen

- Chipper-Shredder Safety ManualDokument40 SeitenChipper-Shredder Safety ManualJonathan Giovanni Asti CastilloNoch keine Bewertungen

- 1-Vicky, Quotation of Drum Type Wood Chipper, RICHIDokument8 Seiten1-Vicky, Quotation of Drum Type Wood Chipper, RICHIVladimir Ignacio Fica EspinozaNoch keine Bewertungen

- Bandit ChippersDokument25 SeitenBandit Chippers85treees100% (1)

- Document Design and Construction of A Wood Chipper-NHDokument9 SeitenDocument Design and Construction of A Wood Chipper-NHHuy NguyenmbvNoch keine Bewertungen

- Title - Wood Chipper ConstructionDokument4 SeitenTitle - Wood Chipper Constructionمحمد عبدالدايمNoch keine Bewertungen

- Bandit 90xp 150xp 200xpDokument178 SeitenBandit 90xp 150xp 200xpAnonymous KYxcHiRPJ100% (1)

- 990XP Bandit ChipperDokument5 Seiten990XP Bandit ChipperFrancisco ConchaNoch keine Bewertungen

- MODEL 2290: 20" Capacity Whole Tree ChipperDokument2 SeitenMODEL 2290: 20" Capacity Whole Tree ChippersudiroNoch keine Bewertungen

- 1890HD 1890Dokument173 Seiten1890HD 1890Mauricio ZapataNoch keine Bewertungen

- RZ dh608 Engl Web PDFDokument2 SeitenRZ dh608 Engl Web PDFOliveira eletricidadeNoch keine Bewertungen

- Wood Chippers: AFAG604 (Rev1)Dokument6 SeitenWood Chippers: AFAG604 (Rev1)lkjofiNoch keine Bewertungen

- Intimidator - 15xp1390 Parts ManualDokument181 SeitenIntimidator - 15xp1390 Parts ManualDaniel BrooksNoch keine Bewertungen

- Wood Energy TechnologiesDokument51 SeitenWood Energy TechnologiesRobert BarnesNoch keine Bewertungen

- 18HD Specifications: Powerful, Efficient Feed System With 32Cc Hydraulic Drive MotorsDokument2 Seiten18HD Specifications: Powerful, Efficient Feed System With 32Cc Hydraulic Drive Motorscarlos manuel jose carvajal solisNoch keine Bewertungen