Beruflich Dokumente

Kultur Dokumente

Monitoring Report Regarding Repair Rehibiliation & Construction of Road Network in Khyber Pakhtunkhawa

Hochgeladen von

Engr Amir Jamal Qureshi0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

12 Ansichten4 SeitenROAD NETWORK

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenROAD NETWORK

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

12 Ansichten4 SeitenMonitoring Report Regarding Repair Rehibiliation & Construction of Road Network in Khyber Pakhtunkhawa

Hochgeladen von

Engr Amir Jamal QureshiROAD NETWORK

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

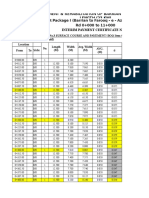

SUBJECT:- MONITORING REPORT REGARDING REPAIR / REHIBILIATION & CONSTRUCTION

OF ROAD NETWORK IN KHYBER PAKHTUNKHAWA (200 KMS) ADP NO:

350/100037/2013-14

SH: S.NO-I: ROAD TAKING OFF FROM SOWARAI QAISAR ABAD SHALBANDI BY PASS VIA

TAKHTABAND ROAD.

S.N

o

1

Observation

Replay

The material used in the execution phase has not

under gone through laboratory test as replied by the

concerned staff of the executing department, giving a

crystal clear image of usage of substandard material.

It is recommended that the work carried out must be

checked through laboratory test and appropriate

action under the role must be taken against the

relevant staff of the executing agency.

Laboratory test are being carried in routine for

every work along-with field tests and visual

examinations of the material. All the necessary

tests have been done and record is available for

verification. The test reports were not available

at site and instruction has been issued to field

staff to maintain separate file for all laboratory

test at site and copies thereof will be available

to M&E at site in future.

Following are the observation regarding substandard

workmanship, supervision and quality of the work

maintained at the site by the C & W Department

District Buner.

At RD 0+000 round aggregate were used in the box

culvert pic-1 attached also the pipe culvert at the

same RD was closed Pic-2 with no proper drainage

system.

II

At RD 0+125, 0+350, 0+900 and at 1+200 the width

of the black top was 13, 12, 12 and 9 respectively

as shown in photograph, which was to be of 14 this

shows lack of proper supervision from the concerned

department.

III

Dry stone masonry was executed in the retaining wall

instead of round rubble masonry at RD 0+100 Pic-1

at RD 0+275 Pic-2 and at 0+850 Pic-3. At the RD

0+275 and RD 0+850 marble pieces were used in the

retaining walls portions instead of approved stone

masonry Pic-2 and Pic-3 respectively

The crush from approved sources was allowed

in construction of Box Culvert. Slight

proportion of round aggregate as noticed assist

in achieving better workability of the concrete

mix.

The pipe culvert was blocked reportedly by the

some locals and has now been got opened by

the contractor.

Due to non provision of land acquisition cost

in the PC-I, at these RDs as mentioned the

land owners did not allow the widening of road

and hence Blacktopping was carried out in

available width and payment was made

accordingly as per Blacktopping, while width

of road for other portion of road is up to the

mark i.e. 14

The stone masonry at the RDs as mentioned

has been executed as Dry RRM and payment

has also been made for Dry Masonry. The

contractor has been directed to rectify the

defective masonry work as pointed out with

that of proper stones sized and specifications.

Final payment shall be released after

rectification has been completed by the

contractor.

IV

Cracks were noticed in the retaining wall at RD The cracks as pointed out by M&E Team are in

0+325 and at RD 0+775 as shown in Photographs

coping and not in RR Masonry. The damaged

portion of coping has been removed and recasted which can be verified.

Page-1/3

The thickness of the PCC work at RD

1+250 and at RD 1+175 was physically checked and

found to be of 5 Pic-1 and & 4 Pic-2 respectively

instead of 6. Also the area of the PCC was not

properly compacted and sub-standard material was

used mixed with clay (Pic-3)

The thickness of PCC at mentioned RDs

have been taken by M&E in PCC berms

for which the thickness at Blacktopping

edge is 6 and at edge of berm is 4 in

order to provide cross-slop in the berm.

Hence the thicknesses as mentioned in

report are at PCC berm edges and are up

to mark. The PCC was done on compacted

sub-grade with proper material of

approved sources.

VI

Round aggregates were used in the slab culvert

constructed at RD 1+525 as shown in Photograph,

showing that no quality assurance methods were

followed

VII

The electric poles are erected in the premises of road

as shown in photograph the C&W department not

been able to play their part in their safe removal to

avoid accident in future, which reflects the poor

management from the executing department.

The crush from approved sources allowed

in construction of Box Culvert. Slight

proportion of round aggregate as noted

assist in achieving better workability of

the concrete mix.

The testing of concrete has been carried

out and the results are found satisfactory.

The electric poles are outside the

blacktopped portion, in the shoulder area.

Due to non availability of free land on

opposite side, alignment of road cannot be

shifted towards it.

Similarly shifting of pole would, have had

its cost impact, not covered in the

approved PC-I, hence matter could not be

taken up with PESCO. Warning/

Informatory sign shall be installed near

these poles for safety of Drivers.

Page 2/3

EXECUTIVE ENGINEER

SUB DIVISIONAL OFFICER

C&W DIVISION BUNER

C&W DIVISION BUNER

SUB ENGINEER

C&W DIVISION BUNER

SH:-S.No-II IMPROVEMENT, WIDENING & BLACK TOPPING OF DAKARA CHARKOT ROAD

1

The material used in the construction phase of the

road were not tested in the laboratory by the

executing agency as replied by the relevant staff of

the C&W Department, clearly showing that low

quality of material is used which will weaken the

stability of the structure it the recommended that all

the construction material must be processed through

standard procedures in the laboratory so that the

safety of the structure is assured

The executing agency is intentionally delaying the

process of Technical Sanction so as cover the

reversions in implementation & Planning of the

scheme. Technical Sanction must be in the hand and

be approved before the commencement of work but

as per saying of the Sub Divisional Officer of C&W

Department Technical sanction is under process of

approval it is recommended that the concerned

department should ascertain the process of Technical

Sanction without any further loss of time.

Laboratory test are being carried in routine for

every work along-with field tests and visual

examinations of the material. All the necessary

tests have been done and record is available for

verification. The test reports were not available

at site and instruction has been issued to field

staff to maintain separate file for all laboratory

test at site and copies thereof will be available

to M&E at site in future.

Technical Sanction Estimate was earlier

submitted to Chief Engineer (North) Office and

was returned for attending certain observations.

The same has been re-submitted after attending

the observations and shall be available for

verification in short time.

Following are the observations regarding substandard

workmanship, supervision and quality of work

maintained at the site by the C&W Department Buner.

The water bound macadam used in the road was

physically checked at RD 0+200 at RD 0+425 and

1+500 on site which was found as of ranged from

4to 6 down Pic-1,Pic-2,Pic-3 respectively ), while

the approved water bound macadam is of 3 down.

This shows lack of proper supervision from the

concerned department and making the use of

standard material all over the road questionable.

This is to state that all possible efforts are made for

proper supervision of schemes, but as most of

engineering positions are lying vacant in C&W

Division Buner, and Highway Sub Division is being

run without a single Sub Engineer. Higher

Authorities have been requested time and again but

outcome is yet awaited. For this reason, the desired

level of supervision cannot be achieved. However,

for instance case, direction has been issued to

contractor for rectification of defective WBM before

starting B/Topping work. No further payment shall

be released to contractor until proper rectification is

completed.

II

The concrete of parapet wall of the culvert was not

in plumb Pic-1 Binding wire Pic-2 and framework

sheets Pic-3 were left embedded in the slab of the

culvert also honey combing was observed Pic-4 in

the same culvert constructed at RD 0+250. The

exposure of steel will gives rise to corrosion of steel

bars which will affect the strength of the structure.

At the RD 1+300 the steel reinforcement of the

culvert was exposed as shown in the Photographs

making it is easy to be attacked by corrosion will

flow in the concrete and steel bonding line by

The necessary rectification works as pointed out

have been completed.

III

The concrete in the affected portion has been

dismantled and reconstructed properly which

can be verified at site.

reducing the inter bond between them which will

result in structure failure.

IV

In the retaining wall constructed at RD 0+425 and at

RD 0+850 dry masonry was done Pic-1, Pic-2 while

it should be of round rubble masonry. This shows

that no proper supervision was maintained at site by

the executing department.

Page 3/3

The retaining works at the mentioned RDs

have been constructed as Dry Masonry as per

approved PC-I and payment has been made for

Dry RRM as well. Hence no over-payment is

made to the contractor.

EXECUTIVE ENGINEER

SUB DIVISIONAL OFFICER

C&W DIVISION BUNER

C&W DIVISION BUNER

SUB ENGINEER

C&W DIVISION BUNER

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- BANDI Stone Pitched DrainDokument62 SeitenBANDI Stone Pitched Draingtarun22gupta100% (1)

- Eco-Friendly Walls: AAC BlocksDokument101 SeitenEco-Friendly Walls: AAC Blockspoonam_ceNoch keine Bewertungen

- 4 Masonry Retaining Walls PDFDokument27 Seiten4 Masonry Retaining Walls PDFCarlos GilNoch keine Bewertungen

- Letter To Consultants For Mobilization at SiteDokument2 SeitenLetter To Consultants For Mobilization at SiteEngr Amir Jamal Qureshi57% (7)

- Case Study NiftDokument19 SeitenCase Study NiftGowri Shankari67% (6)

- SpecsDokument1.051 SeitenSpecsمعاذ كروبينNoch keine Bewertungen

- High Rise Building ScheduleDokument32 SeitenHigh Rise Building Scheduleshinto_thekkekkara80% (5)

- Plan and Profile STA. 04+550 TO STA. 04+900Dokument1 SeitePlan and Profile STA. 04+550 TO STA. 04+900Engr Amir Jamal QureshiNoch keine Bewertungen

- Plan and Profile STA. 04+200 TO STA. 04+550Dokument1 SeitePlan and Profile STA. 04+200 TO STA. 04+550Engr Amir Jamal QureshiNoch keine Bewertungen

- Plan and Profile STA. 03+150 TO STA. 03+500Dokument1 SeitePlan and Profile STA. 03+150 TO STA. 03+500Engr Amir Jamal QureshiNoch keine Bewertungen

- Plan and Profile STA. 03+850 TO STA. 04+200Dokument1 SeitePlan and Profile STA. 03+850 TO STA. 04+200Engr Amir Jamal QureshiNoch keine Bewertungen

- Plan and Profile STA. 03+150 TO STA. 03+500Dokument1 SeitePlan and Profile STA. 03+150 TO STA. 03+500Engr Amir Jamal QureshiNoch keine Bewertungen

- ABOpp 13b PDFDokument1 SeiteABOpp 13b PDFEngr Amir Jamal QureshiNoch keine Bewertungen

- BR-,3a.dwg A3Dokument1 SeiteBR-,3a.dwg A3Engr Amir Jamal QureshiNoch keine Bewertungen

- Abopp 9Dokument1 SeiteAbopp 9Engr Amir Jamal QureshiNoch keine Bewertungen

- Slab, Diaphragm and Exp JT D PDFDokument1 SeiteSlab, Diaphragm and Exp JT D PDFEngr Amir Jamal QureshiNoch keine Bewertungen

- BR-R 000.Dwg Layout1Dokument1 SeiteBR-R 000.Dwg Layout1Engr Amir Jamal QureshiNoch keine Bewertungen

- Plan and Profile STA. 04+450 TO STA. 04+800Dokument1 SeitePlan and Profile STA. 04+450 TO STA. 04+800Engr Amir Jamal QureshiNoch keine Bewertungen

- General Arragement - DWG LayoDokument1 SeiteGeneral Arragement - DWG LayoEngr Amir Jamal QureshiNoch keine Bewertungen

- Summary of The Chief Minister KPK DraftDokument2 SeitenSummary of The Chief Minister KPK DraftEngr Amir Jamal Qureshi100% (1)

- Typical Cross Section For Cut and Fill Area: Annex 2 - 2Dokument3 SeitenTypical Cross Section For Cut and Fill Area: Annex 2 - 2Engr Amir Jamal QureshiNoch keine Bewertungen

- Asphaltic Wearing Course Calculation Sheet PK-1Dokument52 SeitenAsphaltic Wearing Course Calculation Sheet PK-1Engr Amir Jamal QureshiNoch keine Bewertungen

- HARI PUR BYPASS Alignment With DetailsDokument1 SeiteHARI PUR BYPASS Alignment With DetailsEngr Amir Jamal QureshiNoch keine Bewertungen

- Location Map Thanidani Nathiagali 3Dokument1 SeiteLocation Map Thanidani Nathiagali 3Engr Amir Jamal QureshiNoch keine Bewertungen

- Location Map Thanidani Nathiagali 2Dokument1 SeiteLocation Map Thanidani Nathiagali 2Engr Amir Jamal QureshiNoch keine Bewertungen

- Bridges Progress-May 2016Dokument3 SeitenBridges Progress-May 2016Engr Amir Jamal QureshiNoch keine Bewertungen

- Location Map Thanidani Nathiagali 1Dokument1 SeiteLocation Map Thanidani Nathiagali 1Engr Amir Jamal QureshiNoch keine Bewertungen

- SING BOARDS List SpecimensDokument25 SeitenSING BOARDS List SpecimensEngr Amir Jamal QureshiNoch keine Bewertungen

- Draft MOM - DD 25-7-16Dokument4 SeitenDraft MOM - DD 25-7-16Engr Amir Jamal QureshiNoch keine Bewertungen

- Location Map Thanidani Nathiagali 2Dokument1 SeiteLocation Map Thanidani Nathiagali 2Engr Amir Jamal QureshiNoch keine Bewertungen

- Draft MOM - DD 25-7-16Dokument4 SeitenDraft MOM - DD 25-7-16Engr Amir Jamal QureshiNoch keine Bewertungen

- NWFP Public Propert (Removal of Encroachment) Act 1977Dokument6 SeitenNWFP Public Propert (Removal of Encroachment) Act 1977Engr Amir Jamal QureshiNoch keine Bewertungen

- Government of Khyber Pakhtunkhwa11Dokument1 SeiteGovernment of Khyber Pakhtunkhwa11Engr Amir Jamal QureshiNoch keine Bewertungen

- Progress Report-April 2016Dokument4 SeitenProgress Report-April 2016Engr Amir Jamal QureshiNoch keine Bewertungen

- PLOT Sizes For Fuel and CNGDokument1 SeitePLOT Sizes For Fuel and CNGEngr Amir Jamal QureshiNoch keine Bewertungen

- NOC Fuel Station PannianDokument1 SeiteNOC Fuel Station PannianEngr Amir Jamal QureshiNoch keine Bewertungen

- Analysis of Rates 8Dokument1 SeiteAnalysis of Rates 8Aman ThakurNoch keine Bewertungen

- BoQs - Constructing An Elevated Concrete Water Tank With Capacity of 150...Dokument2 SeitenBoQs - Constructing An Elevated Concrete Water Tank With Capacity of 150...Airesh Go100% (2)

- Grouting in Structures: The Grout LineDokument5 SeitenGrouting in Structures: The Grout LineGan DorjNoch keine Bewertungen

- Major ProjectDokument2 SeitenMajor ProjectSOMSUBHRA SINGHANoch keine Bewertungen

- RRB Je CBT - Ii: Printable Syllabus For Civil & Allied Engineering Exam Group - JEDokument2 SeitenRRB Je CBT - Ii: Printable Syllabus For Civil & Allied Engineering Exam Group - JEShashank Raj OnkarNoch keine Bewertungen

- Brick Work UgandaDokument8 SeitenBrick Work UgandaEmmanuel okelloNoch keine Bewertungen

- Types of Brick Bonds - The Construction Civil PDFDokument8 SeitenTypes of Brick Bonds - The Construction Civil PDFAbubakar Sidique0% (2)

- Cost Including Materials: SR - No. Description of Item Units Qty Rate Nala Diverting - 125 RMTDokument6 SeitenCost Including Materials: SR - No. Description of Item Units Qty Rate Nala Diverting - 125 RMTkeshav pNoch keine Bewertungen

- 06 - Part A - UCRDokument2 Seiten06 - Part A - UCRkartick adhikaryNoch keine Bewertungen

- Final Review CapstoneDokument50 SeitenFinal Review CapstoneMaruthi BaddiNoch keine Bewertungen

- Tek 01-01FDokument4 SeitenTek 01-01FHisham MohamedNoch keine Bewertungen

- BCM Question Bank 1Dokument4 SeitenBCM Question Bank 1Mahesh RamtekeNoch keine Bewertungen

- Construction Cost Summary: Hinatuan Building Shell Aquino Street, Hinatuan, Surigao Del SurDokument15 SeitenConstruction Cost Summary: Hinatuan Building Shell Aquino Street, Hinatuan, Surigao Del SurmogsiNoch keine Bewertungen

- VGC50 VGC Product Data: Vinylester Glass Capsule Anchoring AdhesiveDokument5 SeitenVGC50 VGC Product Data: Vinylester Glass Capsule Anchoring AdhesiveJonathan DouglasNoch keine Bewertungen

- DSR 2016 in Ms ExcelDokument718 SeitenDSR 2016 in Ms ExcelVINOD82% (68)

- Particulars Unit BOQ NO. BOQ QTY: Bill of Quantity Bill of QuantityDokument8 SeitenParticulars Unit BOQ NO. BOQ QTY: Bill of Quantity Bill of QuantityAbbasNoch keine Bewertungen

- Fema 156Dokument80 SeitenFema 156Scribd2015Noch keine Bewertungen

- Glass Unit Masonry 042300Dokument6 SeitenGlass Unit Masonry 042300fadlilfikruddinNoch keine Bewertungen

- Feasibility Report For Compressed Stabilised Earth Block (CSEB) Production and Use in The North and East of Sri Lanka - CompressedDokument212 SeitenFeasibility Report For Compressed Stabilised Earth Block (CSEB) Production and Use in The North and East of Sri Lanka - CompressedmagnifcoNoch keine Bewertungen

- Pressed Soil-Cement Block: An Alternative Building Material For MasonryDokument9 SeitenPressed Soil-Cement Block: An Alternative Building Material For MasonryaefNoch keine Bewertungen

- Icc Esr 4143 (Hilt Hy 270)Dokument20 SeitenIcc Esr 4143 (Hilt Hy 270)SACHINNoch keine Bewertungen

- Volume Rumah GensetDokument34 SeitenVolume Rumah GensetIbnu SalamNoch keine Bewertungen

- ADM - Estidama Temp Program Simplified Submittal - Form 2 - (3) 22.01.14Dokument1 SeiteADM - Estidama Temp Program Simplified Submittal - Form 2 - (3) 22.01.14Chawki Al AsmarNoch keine Bewertungen

- Listado de Normas ACIDokument13 SeitenListado de Normas ACIJillian HowardNoch keine Bewertungen