Beruflich Dokumente

Kultur Dokumente

Chocolate Fat Bloom Article

Hochgeladen von

Clarissa GomezOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chocolate Fat Bloom Article

Hochgeladen von

Clarissa GomezCopyright:

Verfügbare Formate

Chocolate Fat Bloom

Fat bloom is inevitable, but once you understand the

fundamentals you can prevent it from occurring prior to

the end of shelf life.

Melissa Tisoncik

Blommer Chocolate Company

at bloom is a common occurrence

when working with chocolate products.

It is a physical defect that appears during

storage of chocolate and is characterized as

a whitish layer on the outer surface (Figure 1). Chocolate with fat bloom is not only

visually unappealing, but also impacts the

flavor and textural qualities, which are important determinants of consumer preference. The phenomenon is not fully understood, but research suggests there are many

factors which may contribute to fat bloom

formation such as poor tempering, mixture

of incompatible fats, disrupted cooling

methods, temperature fluctuations, storage

conditions and abrasion or finger marking.

Fat bloom impacts all of us: manufacturers, suppliers and customers alike. It is important to understand when and why it is

occurring to hone in on the problem and

implement a corrective action. Overall, fat

bloom is inevitable, but once you understand the fundamentals you can prevent it

from occurring prior to the end of shelf life.

tags are the building blocks of a strong foundation. A tag molecule is composed of a

glycerol backbone with three fatty acid chains

linked by ester bonds. This molecule is most

commonly illustrated in a chair-like or tuningfork formation. These tags can crystallize in

six different polymorph formations (Forms IVI), which have specific melting points. Polymorph Form V is the ideal form to achieve

when working with chocolate. When cocoa

butter is in this form, chocolate achieves

many favorable attributes such as a smooth,

even melting, clean snap and nice gloss. This

can be accomplished by tempering.

Melissa Tisoncik is

the research and development manager

product development

at Blommer Chocolate

in the companys

Chicago R&D team.

Previously, she worked

at the USDA labs.

Chocolate Fat Bloom

Figure 1

Molecular Chocolate Matrix

CHOCOLATE STRUCTURE

Chocolate has a complex flavor profile and

compositional matrix consisting of sugar, cocoa particles and emulsifiers dispersed in a

continuous phase of cocoa butter (Figure 2).

Cocoa butter is a polymorphic fat composed

of three main triglycerides (tag s). These

Figure 2

The Manufacturing Confectioner April 2013 65

Chocolate Fat Bloom

Dirty moulds can

initiate fat bloom

due to a residue

chocolate layer

being left on the

mould that acts

as seed or site of

crystal nucleation

for subsequent

deposited

chocolate.

Envision that all the tag molecules are

individual and mobile when cocoa butter

is in its liquid state at 120F. As the mass

begins to cool, crystals begin to form and

eventually a crystalline lattice is created

(Figure 3). If the tag molecules create a

disorderly nonuniform stacking, fat bloom

formation can occur in the finished chocolate product. This can be initiated by temperature fluctuations, improper application techniques, improper handling or

processing failures when working with

chocolate.

INVESTIGATING FAT BLOOM

It is important to ask the following questions when investigating cause of bloom:

mould that acts as seed or site of crystal

nucleation for subsequent deposited

chocolate. This newly deposited chocolate

will form surface bloom. Proper cleaning

of moulds is essential.

Temper (during application) Figure 5 is a

great representation of improper temper

that caused fat bloom. Can you see the

layers formed? This indicates that in each

layer the chocolate was already crystalizing as it was deposited into the mould. It is

important to note that the cross-sectional

view of a chocolate product can give insight to your bloom investigation as well.

Cooling (postapplication) Figure 6 reveals

a common case of fat bloom found right

after the cooling tunnel or on retail

How does fat bloom affect our product?

Where is it seen on the production line?

When do we see it occurring?

Cocoa Butter Solidifying Schematic

What is the cause?

What challenges do we experience while

working with chocolate prior to production, during production or postproduction?

Fat bloom can appear in many different

ways, but the following case studies will

give you general guidelines to help determine the root cause and answer the questions posed above.

Figure 3

Extreme Temperature Fluctuations

TYPES AND CAUSES OF FAT BLOOM

Extreme temperature fluctuations (postapplication) The image in Figure 4 shows that

environmental handling conditions were

not ideal. In this case study, bloom has impacted the structural integrity of the chocolate product and completely deformed it.

This is caused during transportation or distribution, e.g., the shipping truck sitting at

temperatures 5 to 10 above the melting

point of chocolate.

Dirty moulds (during application) Dirty

moulds can initiate fat bloom due to a

residue chocolate layer being left on the

66 April 2013 The Manufacturing Confectioner

Figure 4

Poor Tempering

Figure 5

Chocolate Fat Bloom

shelves. This is due to improper cooling.

Chocolate is more susceptible to this type

of bloom if you have poor temper as well.

Insufficient Cooling

Figure 6

Poor Tempering/Depositing Problems

Figure 7

Formulation Issue

Figure 9

Interaction with Inclusions

Figure 10

You must look at the cooling capacity and

check the temper prior to moulding.

Temper/depositing (during application)

This is a unique case of fat bloom (Figure 7) which needs to be investigated further. At first glance, it appears to look like

a milk/dark drops mixture; however, taking a closer look, you can see the streaking

in the individual drops. You can perform a

quick visual and sensory analysis to test

for fat bloom. Looking at the cross-section

(Figure 8), one can see that the dark drop

on the bottom is very uniform whereas

the light drop on the top is very speckled

and crumbly looking. The taste is also very

dry, void of flavor and crumbly in the

mouth. When you melt down the drops,

the color slide indicates the same color

chocolate. These tests helped draw the

conclusion that this was not a mixture of

milk and dark drops, but it was fat bloom.

Formulation (prior to application) If you

see extensive bloom (Figure 9) and you

have ruled out all environmental factors

and production as a factor that may cause

bloom, you need to look at the formula.

There may be an inherit formulation issue

that caused the chocolate to bloom at a

quicker rate when exposed to high heat

temperatures. This type of bloom forms

within 2 to 4 weeks after depositing and is

caused by a mixture of incompatible fats.

Interaction with inclusions (postapplication) Figure 10 reveals fat bloom formation due to cocoa butter interacting with

incompatible oils, such as peanut oil. These

liquid oils will migrate into the chocolate

shell by dissolving cocoa butter liquid fractions, then migrate to the surface and form

bloom. It helps to create a thicker chocolate shell around the center to prevent invasive migration and bloom on the surface

from occurring too rapidly.

Fat bloom can develop at many differ-

It helps to create a

thicker chocolate

shell around the

center to prevent

invasive migration

and bloom on the

surface from

occurring too

rapidly.

Visual/Sensory

Analysis of Bloom

Flavor/texture test

Wet slide test

Figure 8

The Manufacturing Confectioner April 2013 67

Chocolate Fat Bloom

Combining cocoa

butter and a lauric

fat such as palm oil

or coconut oil will

promote blooming

and result in a soft

texture due to their

eutectic effect.

ent stages. The timeline in Figure 11 is an

excellent gauge to help identify the root

cause of bloom based on when it appears

throughout production. Once identified,

a corrective action can be taken, but there

are also various preventive methods you

can utilize to inhibit fat bloom formation.

PREVENTATIVE METHODS

Tempering

It is essential to understand that the subtleties in this time/temperature process can

impact your product further down the line.

If chocolate is not properly tempered, the

incorrect crystalline structure is formed,

which in turn can lead to bloom. A great

test to check temper is using the Tricor tempermeter instrument. It is a quick method

for operators to use on the line. The easy

readouts are translated into a number indicating good, great or need to retemper.

Knowledgeable Formulation

During formulation it is important to think

about the end application and how the

chocolate will function. You must consider

the other fats in the final formulation and

weigh the risk of incompatibility. Combining cocoa butter and a lauric fat such as

palm oil or coconut oil will promote

blooming and result in a soft texture due

to their eutectic effect. A good rule of

thumb: a maximum of 5 percent cocoa

butter or lauric oil on a total fat basis can

Timeline Gauge for Bloomed Product

Bloom can occur at different times and for different reasons prior to, during or postapplication.

1. Immediate: within 12-28 hours

2. Intermediate: 1-2 weeks

3. Long term: 3-8 weeks

Figure 11

68 April 2013 The Manufacturing Confectioner

be added to a lauric oil-based or a cocoa

butter-based product respectively. Other

products used in final formulations with

chocolate are nut oils (enrobed nuts), coconut oil (meltaways) and soybean oil (liquid chips). Creating a barrier between the

two incompatible fats is another key idea

to consider. A great example of strategic

layering is seen in candy bar products,

where sugar caramels create a barrier between the nuts and the enrobed chocolate

layer. Also, a common ingredient added to

inhibit bloom (within the standard of identity for chocolate) is milk fat. The medium

chain fatty acids in milk fat can interact

with cocoa butter structure to prevent migration and bloom.

Proper Storage

This is something we can try to control

while transporting chocolate. Proper storage, whether it be postproduction, warehouse, distribution, customer end or retail

shelving, is essential to prevent bloom from

occurring before the shelf life expires. At

this point, chocolate is most susceptible to

temperature fluctuations. The best conditions for chocolate storage are a controlled

environment at room temperature and 40

to 60 percent relative humidity.

CONCLUSION

Currently, there is ongoing research in industry and academia which aims to understand fat bloom phenomenon in chocolate. Some studies suggest that ingredients

such as emulsifiers, seeding agents or even

fruit juices can help inhibit bloom. Fat

bloom will naturally occur after a long period of time (~2 years), but if we aim to

truly understand and investigate how it

may occur, we can minimize or prevent it,

thus producing the best possible chocolate product.

n

Presented at the AACT National Technical Seminar

Das könnte Ihnen auch gefallen

- The Materials Science of ChocolateDokument5 SeitenThe Materials Science of ChocolateAmarillo PerezNoch keine Bewertungen

- 5 - Cocoa 2019Dokument61 Seiten5 - Cocoa 2019Qiun LeeNoch keine Bewertungen

- Emulsifier in ChocolateDokument2 SeitenEmulsifier in ChocolateyongqeeNoch keine Bewertungen

- ADM Cocoa ProductsDokument4 SeitenADM Cocoa ProductsJurislav BabicNoch keine Bewertungen

- ChocolatesDokument15 SeitenChocolatesvinay4u_92Noch keine Bewertungen

- Tempering ChocolateDokument2 SeitenTempering ChocolatesidiahidraNoch keine Bewertungen

- Callebaut Guide To Dark CouvertureDokument4 SeitenCallebaut Guide To Dark CouvertureHuai Chien SooNoch keine Bewertungen

- The Little Book of Questions on Caramels (Q & A Series)Von EverandThe Little Book of Questions on Caramels (Q & A Series)Noch keine Bewertungen

- Confectionery Science and Technology - ChocolateDokument62 SeitenConfectionery Science and Technology - ChocolateTran Duy ThaNoch keine Bewertungen

- Cocoa ProductionDokument57 SeitenCocoa ProductionumeshNoch keine Bewertungen

- Alkalized Cocoa Powders Article PDFDokument8 SeitenAlkalized Cocoa Powders Article PDFhozhabr100% (1)

- Experiments in Tempering ChocolateDokument7 SeitenExperiments in Tempering Chocolateklruppe3950Noch keine Bewertungen

- Wafers: Basic Wafer TypesDokument7 SeitenWafers: Basic Wafer TypesSebastianHornaNoch keine Bewertungen

- AWT HF Pectins in Egg Free CreamsDokument5 SeitenAWT HF Pectins in Egg Free CreamsDayana AriasNoch keine Bewertungen

- Lollipop and Other Sugar ProductsDokument19 SeitenLollipop and Other Sugar ProductsAnurag SrivastavaNoch keine Bewertungen

- Nougat, Fruit Chews & Taffy: Barb KlubertanzDokument45 SeitenNougat, Fruit Chews & Taffy: Barb KlubertanzJulio Kinen100% (1)

- Confectionery and Chocolate Engineering: Principles and ApplicationsVon EverandConfectionery and Chocolate Engineering: Principles and ApplicationsNoch keine Bewertungen

- Marshmallows: Marshmallows: Marshmallows: Marshmallows: MarshmallowsDokument4 SeitenMarshmallows: Marshmallows: Marshmallows: Marshmallows: Marshmallowscklcat1437100% (1)

- Emulsifiers in Chocolate V7Dokument26 SeitenEmulsifiers in Chocolate V7Prasanna GopalrathinamNoch keine Bewertungen

- SS 2507Dokument5 SeitenSS 2507Madan YadavNoch keine Bewertungen

- Brochure Chocolate ExperiencesInFlandersAndBrussels PDFDokument80 SeitenBrochure Chocolate ExperiencesInFlandersAndBrussels PDFGuino Vargas100% (3)

- Almond Chocolate Bar 2Dokument3 SeitenAlmond Chocolate Bar 2parvenderNoch keine Bewertungen

- 010-Particle Size Analysis of Cocoa PowdersDokument3 Seiten010-Particle Size Analysis of Cocoa PowdersAlvian Maulana SNoch keine Bewertungen

- SSP Pumps in The Confectionery Industry PDFDokument29 SeitenSSP Pumps in The Confectionery Industry PDFfatamorgganaNoch keine Bewertungen

- Adam Lechter: Resident Course in Confectionery TechnologyDokument73 SeitenAdam Lechter: Resident Course in Confectionery TechnologyJulio KinenNoch keine Bewertungen

- Basic Laminating Technology 4Dokument16 SeitenBasic Laminating Technology 4Ronaldo latumanuwyNoch keine Bewertungen

- Pregel Dessert IngredientsDokument4 SeitenPregel Dessert IngredientsM Suman RaoNoch keine Bewertungen

- ChocolateDokument4 SeitenChocolateخالد الرزيقNoch keine Bewertungen

- Fulltext 12088 PDFDokument83 SeitenFulltext 12088 PDFkharajurgNoch keine Bewertungen

- Metal Joining ProcessDokument28 SeitenMetal Joining ProcessVenkatesh Modi100% (2)

- Chocolate Functional FoodDokument0 SeitenChocolate Functional FoodrendaoNoch keine Bewertungen

- Wills1998 - Water Activity and Its Importance in Making CandyDokument4 SeitenWills1998 - Water Activity and Its Importance in Making CandyKSX100% (1)

- Viscosity GLC SyrupsDokument18 SeitenViscosity GLC SyrupsJán PeterNoch keine Bewertungen

- Tempering Chocolate With Mycryo Cocoa ButterDokument1 SeiteTempering Chocolate With Mycryo Cocoa ButterBryden McKinnie100% (1)

- Chromate Conversion Coatings and Their Current AppDokument5 SeitenChromate Conversion Coatings and Their Current AppDeni HermawanNoch keine Bewertungen

- B) Chocolate (Same) C) Non - Chocolate Confectionary ProductDokument33 SeitenB) Chocolate (Same) C) Non - Chocolate Confectionary ProductMickey Singh100% (1)

- AW ApplicationNote ChocolateDokument4 SeitenAW ApplicationNote Chocolateulva mohtarNoch keine Bewertungen

- Caveman Chemistry Book 2Dokument237 SeitenCaveman Chemistry Book 2stormrunner002100% (2)

- POGIL - Strength of Acids PDFDokument6 SeitenPOGIL - Strength of Acids PDFAmy Tony0% (13)

- Fat Bloom in Chocolate and Compound CoatingDokument34 SeitenFat Bloom in Chocolate and Compound CoatingSartika Mutiarasani100% (1)

- Chocolate CrumbleDokument2 SeitenChocolate CrumbleSridhar ManickamNoch keine Bewertungen

- Chocolate ProcessDokument49 SeitenChocolate Processsarpal1234Noch keine Bewertungen

- Class - X Lesson Plan Chapter-2: Acids, Bases and SaltsDokument19 SeitenClass - X Lesson Plan Chapter-2: Acids, Bases and SaltsBhawana Singh100% (1)

- Kraft Pulping and Recovery Process BasicsDokument50 SeitenKraft Pulping and Recovery Process BasicsPhilip MathewsNoch keine Bewertungen

- 5 Tempering ChocolateDokument2 Seiten5 Tempering ChocolateTagas Bagase100% (1)

- Analysis of ChocolateDokument26 SeitenAnalysis of ChocolatedhanisthNoch keine Bewertungen

- Cho ColeyDokument30 SeitenCho ColeyCristian VasilescuNoch keine Bewertungen

- Lebovitz Chocolate-Hazelnut-Spread PDFDokument1 SeiteLebovitz Chocolate-Hazelnut-Spread PDFTarak ZayaniNoch keine Bewertungen

- Chocolate (Pralines) : NeededDokument5 SeitenChocolate (Pralines) : NeededCristian VasilescuNoch keine Bewertungen

- Jafinox Gourmet Chocolate LRDokument2 SeitenJafinox Gourmet Chocolate LRSantiago Zapata BoadaNoch keine Bewertungen

- The Journey From Cacao Pod To ChocolateDokument9 SeitenThe Journey From Cacao Pod To Chocolateronalit malintadNoch keine Bewertungen

- Wafer TechnologyDokument28 SeitenWafer Technologyahmed aliNoch keine Bewertungen

- Enrobing in The Confectionery Industry: January 2014Dokument4 SeitenEnrobing in The Confectionery Industry: January 2014Trần Xuân NhãNoch keine Bewertungen

- CW Concept PDFDokument23 SeitenCW Concept PDFShaik Riyaz PeerNoch keine Bewertungen

- Chocolate Science and TechnologyDokument2 SeitenChocolate Science and TechnologyAzis PangestuNoch keine Bewertungen

- Sensory of Chocolate: M. Voltz and S.T. BeckettDokument1 SeiteSensory of Chocolate: M. Voltz and S.T. BeckettArslan KhanNoch keine Bewertungen

- Analysis On Chocolate IndustryDokument19 SeitenAnalysis On Chocolate IndustryPavan VaghelaNoch keine Bewertungen

- Wafer in IndiaDokument2 SeitenWafer in Indiawaleedaraim0% (1)

- Preparation of Ice Cream Mix: Dairy Technology B.K.Singh, Dairy TechnologyDokument19 SeitenPreparation of Ice Cream Mix: Dairy Technology B.K.Singh, Dairy TechnologyRnav rnavNoch keine Bewertungen

- Wafer BatterDokument12 SeitenWafer BatternanahidayatNoch keine Bewertungen

- Prepare and Cook Egg Dishes: First Quarter Learning Outcome 2Dokument16 SeitenPrepare and Cook Egg Dishes: First Quarter Learning Outcome 2Meiyuzu AiharaNoch keine Bewertungen

- Nutela WikiDokument3 SeitenNutela WikinecitacNoch keine Bewertungen

- Chocolate ProcessingDokument4 SeitenChocolate Processingaconibet9040Noch keine Bewertungen

- Chocolate Making NotesDokument6 SeitenChocolate Making Notesapi-240759474Noch keine Bewertungen

- The Essential Guide To BakingDokument57 SeitenThe Essential Guide To BakinghymerchmidtNoch keine Bewertungen

- ChemicalsDokument6 SeitenChemicalsClarissa GomezNoch keine Bewertungen

- Fs Topic FormatDokument3 SeitenFs Topic FormatClarissa GomezNoch keine Bewertungen

- Chap 7 Reynolds ExpDokument2 SeitenChap 7 Reynolds ExpClarissa GomezNoch keine Bewertungen

- Flowchart Graduation Clearance - PaymentsDokument1 SeiteFlowchart Graduation Clearance - PaymentsClarissa GomezNoch keine Bewertungen

- Chap 7 Reynolds ExpDokument2 SeitenChap 7 Reynolds ExpClarissa GomezNoch keine Bewertungen

- Friction FactorDokument6 SeitenFriction FactorClarissa GomezNoch keine Bewertungen

- Particle Problem SetDokument1 SeiteParticle Problem SetClarissa GomezNoch keine Bewertungen

- Exp 5 (From Omar)Dokument5 SeitenExp 5 (From Omar)Clarissa GomezNoch keine Bewertungen

- Issues in The Solution of Equations in ModelDokument10 SeitenIssues in The Solution of Equations in ModelClarissa GomezNoch keine Bewertungen

- Families of CirclesDokument10 SeitenFamilies of CirclesClarissa GomezNoch keine Bewertungen

- Post Lab Report PDFDokument15 SeitenPost Lab Report PDFClarissa Gomez0% (1)

- Experiment 1 Physical Constants of Solid and Liquid and Organic CompoundsDokument7 SeitenExperiment 1 Physical Constants of Solid and Liquid and Organic CompoundsClarissa GomezNoch keine Bewertungen

- 2012 Petruccietal Afeasibilitystudy CETDokument7 Seiten2012 Petruccietal Afeasibilitystudy CETMuhammad RehanNoch keine Bewertungen

- Part I: Polymer Chemistry: Chapter 3: Molar Mass & Degree of PolymerizationDokument34 SeitenPart I: Polymer Chemistry: Chapter 3: Molar Mass & Degree of PolymerizationThanh Đình Lộc LêNoch keine Bewertungen

- wch13 01 Que 20231018Dokument20 Seitenwch13 01 Que 20231018zainab zeinNoch keine Bewertungen

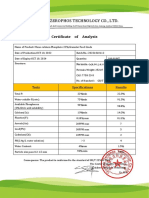

- MCP22% G CoaDokument1 SeiteMCP22% G CoaJosue UriñaNoch keine Bewertungen

- DELTA-FC 1720 Tds - EngDokument2 SeitenDELTA-FC 1720 Tds - EngFarouk El Naggar100% (1)

- LaTeX ExampleDokument13 SeitenLaTeX ExampleBon BonNoch keine Bewertungen

- Lawson Products, Inc - Open Gear Wire RopeDokument3 SeitenLawson Products, Inc - Open Gear Wire Ropejaredf@jfelectric.com100% (1)

- Faria 2004Dokument10 SeitenFaria 2004Nicholas CheongNoch keine Bewertungen

- Product CatalogueDokument12 SeitenProduct Cataloguesusu222000Noch keine Bewertungen

- Chemistry1st ChapDokument4 SeitenChemistry1st ChapyumnaNoch keine Bewertungen

- NACK U3 Maeder Nanoparticle SynthesisDokument56 SeitenNACK U3 Maeder Nanoparticle SynthesisGursimranjit SinghNoch keine Bewertungen

- Draw LewisDokument3 SeitenDraw LewisclrgeekNoch keine Bewertungen

- Manual For The Geochemical Analyses of Marine Sediments and Suspended Particulate MatterDokument49 SeitenManual For The Geochemical Analyses of Marine Sediments and Suspended Particulate MatternelsonNoch keine Bewertungen

- (Chemical Laws) Yr 10intl Wk1Dokument23 Seiten(Chemical Laws) Yr 10intl Wk1Victor OkosunNoch keine Bewertungen

- Oil and DrillingDokument3 SeitenOil and DrillingAmri YogiNoch keine Bewertungen

- 07 Dermatological Formulation and Transdermal SystemsDokument81 Seiten07 Dermatological Formulation and Transdermal SystemsAlberto JacobusNoch keine Bewertungen

- 2064-2110 - Magnetic Iron Oxide Nanoparticles - Synthesis, Stabilization, VectorizationDokument47 Seiten2064-2110 - Magnetic Iron Oxide Nanoparticles - Synthesis, Stabilization, Vectorizationehagar60Noch keine Bewertungen

- MCQ CMDokument12 SeitenMCQ CMAviNoch keine Bewertungen

- STPM 2019 Sem 2 Mock AnsDokument2 SeitenSTPM 2019 Sem 2 Mock AnsNicholson NicholsonNoch keine Bewertungen

- 3.2.1. Bonding - The Structure of Matter PDFDokument2 Seiten3.2.1. Bonding - The Structure of Matter PDFClinton ChikengezhaNoch keine Bewertungen

- Experiment 2 PDFDokument5 SeitenExperiment 2 PDFLornaAhlaami0% (1)

- 2006 Paper 1-BIDokument10 Seiten2006 Paper 1-BIAfrina Lee DonghaeNoch keine Bewertungen

- ch3 - MichalskiDokument48 Seitench3 - MichalskirquinesNoch keine Bewertungen