Beruflich Dokumente

Kultur Dokumente

Teaching Excel Solver To All Business School Majors

Hochgeladen von

Anda MiaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Teaching Excel Solver To All Business School Majors

Hochgeladen von

Anda MiaCopyright:

Verfügbare Formate

Teaching Excel Solver to All Business School Majors

by

Dr. Robert G. Stoll

Assistant Professor Operations & Supply Chain Management

Department of Business Management

Dauch College of Business and Economics

Ashland University

401 College Avenue

Ashland, OH 44805

419-289-5905

rstoll2@ashland.edu

Dr. Joseph R. Muscatello

Associate Professor Business Management and Technology

Kent State University at Geauga

14111 Claridon-Troy Road

Burton, OH 44021

440 834-4187

jmuscate@kent.edu

Abstract

Many business schools have a required course in Operations Management for

all business majors. Within the Operations Management course,

spreadsheets have become the primary software application for teaching

decision models in most business schools. The most popular software for

analyzing and solving optimization models is Excel Solver. While there are

other programs such as LINDO, Excel is the most popular due to the

prevalence and popularity in the business world. Excel Solver is especially

useful for interdisciplinary courses involving optimization problems. This

article summarizes the use of Excel Solver in spreadsheet modeling and

solving linear programming problems in an introductory Operations

Management course. It is shown how to use and teach spreadsheet modeling

using Excel Solver for solving linear problems. Examples from different areas

such as, transportation, manufacturing, and product mix are discussed to

demonstrate the use and teaching methods of Excel Solver. This article

provides guidelines for teaching Excel Solver and offers simple examples that

can easily be incorporated into the classroom.

key words: excel solver; spreadsheet implementation; optimization

models; analysis

Introduction

Linear programming is a mathematical model used for solving linear

optimization problems through minimization or maximization of a linear

function subject to linear constraints. Optimization problems are real world

problems encountered in many areas such as mathematics, engineering,

science, business and economics. The optimal is the most efficient way of

using limited resources to achieve the objective of the problem. In business,

optimization usually means maximizing the profit or minimizing the cost.

For example, in blending gasoline and other petroleum products, many

intermediate distillates may be available. Prices and octane ratings as well

have upper limits on capacities of input materials that can be used to

produce various grades of fuel are given. The problem is to blend the various

inputs in such a way that cost will be minimized and therefore profits will be

maximized, specified optimum octane ratings will be met and the need for

additional storage capacity will be avoided. In Excel, the model consists of

the three following components:

1. The decision variables or changing cells. These changing cells are

allowed to freely change and cannot contain formulas. The decisions of

the problem are represented using symbols such as X and Y or X 1, X2,

X3,..Xn. These variables represent unknown quantities such as the

number of items to produce, etc.

2. The objective function or objective cell contains the objective to be

minimized or maximized. The objective may be maximizing the profit,

minimizing the cost, distance, time, etc.,

3. The constraints imposed restrictions on the values in the changing

cells. These limitations are expressed as inequalities or equations in

decision variables.

If the model consists of a linear objective function and linear constraints in

decision variables, it is called a linear programming (LP) model. A nonlinear

programming model consists of a nonlinear objective function and nonlinear

constraints will be discussed in a future teaching forum. Linear programming

is a method used to solve models by the Simplex Algorithm developed by

Dantzig (1963). This technique can be used to solve problems in two or more

factors. The paper by Fylstra et al. (1998), which comprehensively describes

how Solver was designed and developed, addresses other practical issues

associated with using Excel Solver.

Model Development

The first part of solving an optimization problem is model development,

consuming most of the effort. Here the student decides what the decision

variables are, what the objective is, what the constraints are and how it all

fits together.

The second step is to optimize. Excel solver performs the optimization by

making the objective as large (for maximization) or small (for minimization)

while satisfying all of the constraints. If all of the constraints are satisfied, the

student has achieved a feasible solution. If any constraint is violated, the

solution is infeasible and is not allowed. Three examples follow.

Targeting a forced solution

Consider the problem X + Y = 10. If one attempts to solve this equation, it

can be shown that there are an infinite number of solutions. For example, if X

= 1, then Y = 9 or if X = 2, then Y = 8, etc. Therefore, we will add constraints

(or conditions). The constraints are X > 5 and X must be a positive integer.

Now the solution set, while still large, has been limited. For example, if X = 6,

then Y = 4 or if X = 10, then Y = 0, etc. Adding more constraints such as Y >

3 and Y must be a positive integer limits the problem to only one feasible

solution; X = 6 and Y = 4. What was just performed was the process of

solving equations. In Excel, the following is performed:

In cells B1 & B2, arbitrary numbers have been inserted. Cell B3 is the sum B1

& B2. Cell B3 is the objective cell or target cell. Now click on the Data Tab

and choose solver. The changing cells are B1 & B2. The constraints (X > 6, Y

> 3, X and Y are integers) must be added. The optimal solution will be

presented in cells B1 & B2.

Product Mix Problem (Profit Maximization)

ABC Corporation wishes to produce two products, Product A and Product B.

Product A results in a $6.00 profit and Product B results in a $4.00 profit.

Product A requires 4 minutes on Machine 101 and 6 minutes on Machine 102.

Product A requires 4 minutes on Machine 101 and 2 minutes on Machine 102.

There are 24 minutes available on Machine 101 and 16 minutes available on

Machine 102. How much of Product A and Product B should ABC make to

maximize its profit?

Table 1

Machine 101

Machine 102

Profit/Unit

Product A

4 minutes

4 minutes

$6.00

Product B

6 minutes

2 minutes

$4.00

Time Available

24 minutes

16 minutes

Maximize Profit (Objective function) $6.00x + $4.00y.

Subject to The following constraints 4x + 6y 24 and 4x + 2y 16 and x

0 and y 0.

The changing cells are x is units produced of Product A and y is units

produced of Product B.

The solution shows that it is optimal to produce 3 units of Product A and 2

units of Product B for a maximum profit of $26.00 using all of the capacity.

Shipping Cost Problem (Cost Minimization)

ABC Industries has two Manufacturing plants in Cleveland and Cincinnati. The

Cleveland plant has a production capacity of 450 while the Cincinnati plant

has a capacity of 150. There are two warehouses for the U.S. East and West.

The customer demand for the east is 350 units and customer demand for

the west is 250. This is a classic supply and demand problem with the supply

coming from the manufacturing plants and the demand coming from the

warehouses. The unit shipping costs are found in the Table 2. For example,

the cost to ship a product from the Cleveland plant to the Western

warehouse is $278. The objective is to find the least cost method of shipping

product from the plants to the warehouses that maintains plant capacities

and meets regional demand.

Table 2

Cleveland

Plant

Cincinnati

Plant

Demand

Warehouse East

(shipping costs /

units)

325 / X1

Warehouse West

(shipping costs /

units)

278 / X2

Capacity

290 / X3

295 / X4

150

350

250

600

450

Minimize Cost (Objective function) 325X1 + 278X2 + 290X3 + 295X4

Subject to the following constraints:

o Number sent out of each plant Plant capacity

X1 + X2 450 and X3 + X4 150

o Number sent to each warehouse Demand

X1 + X3 350 and X2 + X4 250

The changing cells are X1, X2, X3 and X4 the number of products sent

from each plant to each warehouse.

The solution shows that it is optimal to send 350 units from Cleveland to East

Warehouse and 100 units from Cleveland to West Warehouse. There will not

be any units sent from Cincinnati to East Warehouse and 150 units from

Cincinnati to West Warehouse. The minimum cost to ship is $185,800.00

while meeting supply and demand constraints.

Conclusion

Optimization problems in nearly all educational fields can be modeled and

solved using Excel Solver. It does not require knowledge of complex matrix

algebra behind the solution algorithms. Therefore, this method is useful for

students to solve real world problems who lack the overall mathematical

skills. It would be very helpful to begin teaching these basic Solver skills in

high school prior to admission to a comprehensive university.

References

Albright, S. C., W. L. Winston, C. Zappe. 2009. Data Analysis & Decision

Making with Microsoft Excel, Revised 3e. South-Western, Cengage.

Bazaraa, M. S., J. Jarvis, H. Sherali. 1990. Linear Programming and Network

Flows, 2nd ed. Wiley, New York.

Conway, D. G., C. T. Ragsdale. 1997. Modeling optimization problems in the

unstructured world of spreadsheets. Omega 25(3)

313322.

Eck, R. D. 1976. Operations Research for Business. Wadsworth, Belmont, CA,

129131.

Evans, J. R. 2007. Statistics Data Analysis and Decision Modeling, 3e.

Prentice-Hall, Upper Saddle River, NJ.

Fylstra, D., L. Lasdon, J. Watson, A. Waren. 1998. Design and use of the

Microsoft Excel Solver. Interfaces 28(5) 2955.

Liu J. J. 2012. Supply Chain Management and Transport Logistics. Routledge,

New York.

Powell, S. G., K. R. Baker. 2004. The Art of Modeling with Spreadsheets. John

Wiley & Sons, New York.

Ragsdale, C. T. 2001. Spreadsheet Modeling and Decision Analysis, 3e.

South-Western College Publishing, Cincinnati.

Winston, W. L., S.C. Albright. 2012. Practical Management Science, 4e. SouthWestern, Cengage.

Das könnte Ihnen auch gefallen

- Microsoft 365 Excel: The Only App That Matters: Calculations, Analytics, Modeling, Data Analysis and Dashboard Reporting for the New Era of Dynamic Data Driven Decision Making & InsightVon EverandMicrosoft 365 Excel: The Only App That Matters: Calculations, Analytics, Modeling, Data Analysis and Dashboard Reporting for the New Era of Dynamic Data Driven Decision Making & InsightBewertung: 3 von 5 Sternen3/5 (2)

- BSNS 6001 Exam 2 (Summer 2016) PDFDokument4 SeitenBSNS 6001 Exam 2 (Summer 2016) PDFReneNoch keine Bewertungen

- Mba Semester Ii MB0048 - Operation Research-4 Credits (Book ID: B1137) Assignment Set - 1 (60 Marks)Dokument20 SeitenMba Semester Ii MB0048 - Operation Research-4 Credits (Book ID: B1137) Assignment Set - 1 (60 Marks)Rajesh SinghNoch keine Bewertungen

- Linear Program 1Dokument52 SeitenLinear Program 1ChaOs_Air75% (4)

- MS Chapter1Dokument32 SeitenMS Chapter1renna_magdalenaNoch keine Bewertungen

- 1590524648optimization of Chemical Engineering ProcessesDokument10 Seiten1590524648optimization of Chemical Engineering ProcessesSefa Ceren KANDEMİRNoch keine Bewertungen

- Chapter 1Dokument10 SeitenChapter 1Wonwoo JeonNoch keine Bewertungen

- MGT410 Take Home Final 1 - Fall2010Dokument10 SeitenMGT410 Take Home Final 1 - Fall2010Belinda Elois ToNoch keine Bewertungen

- Read ConsultingDokument24 SeitenRead ConsultingmgurunathanNoch keine Bewertungen

- Excel Solver TutorialDokument7 SeitenExcel Solver Tutorialsnip3r25Noch keine Bewertungen

- Master of Business Administration-MBA Semester 1 MB0048 - Operations Research - 4 Credits (Book ID: B1631) Assignment Set - 1 (60 Marks)Dokument7 SeitenMaster of Business Administration-MBA Semester 1 MB0048 - Operations Research - 4 Credits (Book ID: B1631) Assignment Set - 1 (60 Marks)Vikas WaliaNoch keine Bewertungen

- Solver in Excel (Easy Tutorial) 4Dokument1 SeiteSolver in Excel (Easy Tutorial) 4Slaven IvanovicNoch keine Bewertungen

- Grand Canyon BUS 352 Entire CourseDokument7 SeitenGrand Canyon BUS 352 Entire CoursepitersunNoch keine Bewertungen

- Master in Business Administration: Data AnalyticsDokument20 SeitenMaster in Business Administration: Data AnalyticsSovan Dash100% (1)

- Lin Prog With ExcelDokument3 SeitenLin Prog With ExcelAshhab Zaman RafidNoch keine Bewertungen

- Introduction To Solver: Smalcolm - Doc, and The Excel File Malcolm - XLS) - The Sample ExcelDokument6 SeitenIntroduction To Solver: Smalcolm - Doc, and The Excel File Malcolm - XLS) - The Sample ExcelYusuf HusseinNoch keine Bewertungen

- Chapter 01 - IntroductionDokument18 SeitenChapter 01 - IntroductionAfaq AhmedNoch keine Bewertungen

- Introduction To MATHDokument26 SeitenIntroduction To MATHNASIR UDDINNoch keine Bewertungen

- Unit 6.linear ProgrammingDokument7 SeitenUnit 6.linear ProgrammingJoenan DecandoloNoch keine Bewertungen

- Problem-Solving Tools For Engineering StudentsDokument6 SeitenProblem-Solving Tools For Engineering StudentsVamsee309Noch keine Bewertungen

- Solutions Supp C-Instructor ManualDokument11 SeitenSolutions Supp C-Instructor ManualLinda Atcha0% (1)

- Solver: Solver Tutorial For Optimization UsersDokument15 SeitenSolver: Solver Tutorial For Optimization UsersLeon FouroneNoch keine Bewertungen

- Excel Solver TutorialDokument17 SeitenExcel Solver TutorialIfeanyi SnydersNoch keine Bewertungen

- BUS 36106 Syllabus Spring 2015Dokument10 SeitenBUS 36106 Syllabus Spring 2015MukundMultaniNoch keine Bewertungen

- A Spreadsheet Model: em 602 Management ScienceDokument13 SeitenA Spreadsheet Model: em 602 Management SciencevamshiNoch keine Bewertungen

- Unit 1 - Introduction To Management ScienceDokument8 SeitenUnit 1 - Introduction To Management ScienceAlyana GeriNoch keine Bewertungen

- DrugDokument47 SeitenDrugmaimonuNoch keine Bewertungen

- Succeeding in Business With Microsoft Excel 2010 A Problem Solving Approach 1st Edition Gross Solutions ManualDokument20 SeitenSucceeding in Business With Microsoft Excel 2010 A Problem Solving Approach 1st Edition Gross Solutions ManualSheilaColonqcaoz100% (9)

- Solving Linear Programs Using Excel: Arpee Arruejo, MITDokument46 SeitenSolving Linear Programs Using Excel: Arpee Arruejo, MITbuntynikhilNoch keine Bewertungen

- The Process To Formulate A Linear Programming ProblemDokument14 SeitenThe Process To Formulate A Linear Programming ProblemSweety 12Noch keine Bewertungen

- Itdm Individual Assignment Submitted To: Boudhayan Ganguly Using Excel Solver in Optimization ProblemsDokument5 SeitenItdm Individual Assignment Submitted To: Boudhayan Ganguly Using Excel Solver in Optimization ProblemsRavi PrakashNoch keine Bewertungen

- Chegg UnlockDokument3 SeitenChegg UnlockOdedeMapuaNoch keine Bewertungen

- Unit 19 - Linear Programming - Allocation ModelsDokument9 SeitenUnit 19 - Linear Programming - Allocation ModelsramdasNoch keine Bewertungen

- Modul 1 - Linear ProgrammingDokument20 SeitenModul 1 - Linear ProgrammingMarissa Adelia ManikNoch keine Bewertungen

- IM - BUMA 30083 - Fundamentals of Prescriptive Analytics (BSBA-MM TG 4-1) - Week 5Dokument9 SeitenIM - BUMA 30083 - Fundamentals of Prescriptive Analytics (BSBA-MM TG 4-1) - Week 5SteveN.MalunesNoch keine Bewertungen

- PL MitDokument7 SeitenPL MitMeldelzNoch keine Bewertungen

- Ga Optimization For Excel 1 2Dokument8 SeitenGa Optimization For Excel 1 2imran_chaudhryNoch keine Bewertungen

- ch09 SolDokument12 Seitench09 SolJohn Nigz Payee100% (1)

- Computer Applications Sample TestDokument12 SeitenComputer Applications Sample TestMohd Khairil Hilmi Halim100% (1)

- PowerPoint Presentation (3036922) - 2Dokument164 SeitenPowerPoint Presentation (3036922) - 2Naga LakshmaiahNoch keine Bewertungen

- Linear Programming ProblemDokument13 SeitenLinear Programming Problemraj100% (1)

- Solver ProgrammingDokument4 SeitenSolver Programmingpoopoosingh100% (1)

- Business Driven Technology Plug-In T4 - Decision Making Using ExcelDokument5 SeitenBusiness Driven Technology Plug-In T4 - Decision Making Using ExcelThao TrungNoch keine Bewertungen

- Lin Prog With ExcelDokument3 SeitenLin Prog With ExcelNabendu GhoshNoch keine Bewertungen

- MB0048Dokument12 SeitenMB0048prasannasuddapalliNoch keine Bewertungen

- Microsoft Excel Multiple-Choice Questions MCQs and AnswersDokument20 SeitenMicrosoft Excel Multiple-Choice Questions MCQs and Answers09whitedevil90Noch keine Bewertungen

- Operation Management (MB0048)Dokument7 SeitenOperation Management (MB0048)Sagar TankNoch keine Bewertungen

- Section A This Section Consists of 10 Multiple-Choice Questions. Circle The Most Suitable AnswerDokument10 SeitenSection A This Section Consists of 10 Multiple-Choice Questions. Circle The Most Suitable Answernissan91Noch keine Bewertungen

- Iima Teaching Note MertonDokument8 SeitenIima Teaching Note MertonHarshal NaikNoch keine Bewertungen

- MCD2080 T1 2022 Assignment-QuestionsDokument5 SeitenMCD2080 T1 2022 Assignment-Questionsmohamad ewo zeesNoch keine Bewertungen

- Merton Trucks Case Note: I I M A IIMA/QM-xxxDokument8 SeitenMerton Trucks Case Note: I I M A IIMA/QM-xxxAyush GuptaNoch keine Bewertungen

- MB0048 Spring Drive 2012 SolvedDokument14 SeitenMB0048 Spring Drive 2012 Solvedashish15666100% (1)

- Engineering Methods in Microsoft Excel: Kwabena Ofosu, PH.D., P.E., PTOEDokument88 SeitenEngineering Methods in Microsoft Excel: Kwabena Ofosu, PH.D., P.E., PTOECarlo M. FloresNoch keine Bewertungen

- CGE Classroom ExcelDokument39 SeitenCGE Classroom ExcelPaf Veterans-FamiliesNoch keine Bewertungen

- Next Generation Excel: Modeling In Excel For Analysts And MBAs (For MS Windows And Mac OS)Von EverandNext Generation Excel: Modeling In Excel For Analysts And MBAs (For MS Windows And Mac OS)Noch keine Bewertungen

- Management Science using Excel: Harnessing Excel's advanced features for business optimization (English Edition)Von EverandManagement Science using Excel: Harnessing Excel's advanced features for business optimization (English Edition)Noch keine Bewertungen

- Fundamentals of Optimization Techniques with AlgorithmsVon EverandFundamentals of Optimization Techniques with AlgorithmsBewertung: 5 von 5 Sternen5/5 (1)

- 5950 2019 Assignment 7 Spearman RhoDokument1 Seite5950 2019 Assignment 7 Spearman RhoNafis SolehNoch keine Bewertungen

- 7084 An Efficient and Robust FramewDokument14 Seiten7084 An Efficient and Robust FramewSwastik KNoch keine Bewertungen

- Derivatives #3Dokument49 SeitenDerivatives #3tolgonai2705Noch keine Bewertungen

- Full VB DocumentationDokument34 SeitenFull VB DocumentationAnil Batra100% (1)

- UpcDokument14 SeitenUpcGerard MP100% (1)

- Forecasting Time Series With R - DataikuDokument16 SeitenForecasting Time Series With R - DataikuMax GrecoNoch keine Bewertungen

- Capgemini Coding Live Sessions Part 5 (30 Aug 2022)Dokument7 SeitenCapgemini Coding Live Sessions Part 5 (30 Aug 2022)Aniket BankapurNoch keine Bewertungen

- Cost289 Final ReportDokument88 SeitenCost289 Final ReportkyfeeeNoch keine Bewertungen

- Session 2Dokument113 SeitenSession 2Aditi BadwayaNoch keine Bewertungen

- Radial and Angular Parts of Atomic OrbitalsDokument3 SeitenRadial and Angular Parts of Atomic OrbitalsW47K3R 27886Noch keine Bewertungen

- Strand7 R246 Verification Manual TOC PDFDokument20 SeitenStrand7 R246 Verification Manual TOC PDFAbel BerhanmeskelNoch keine Bewertungen

- Quantitative AssignmentDokument6 SeitenQuantitative AssignmentAlemu Muleta KebedeNoch keine Bewertungen

- 4pm1 02r Que 20230121Dokument36 Seiten4pm1 02r Que 20230121M.A. HassanNoch keine Bewertungen

- Noise Attenuation TechniquesDokument2 SeitenNoise Attenuation TechniquesadobiNoch keine Bewertungen

- Algebra and Trigonometry 10th Edition Sullivan Test Bank Full Chapter PDFDokument68 SeitenAlgebra and Trigonometry 10th Edition Sullivan Test Bank Full Chapter PDFmatthewjordankwnajrxems100% (14)

- HS20Dokument8 SeitenHS20kumarg_19Noch keine Bewertungen

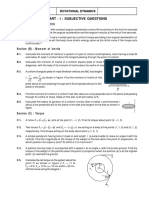

- CPP1 RotationaldynamicsDokument14 SeitenCPP1 RotationaldynamicsBNoch keine Bewertungen

- Reshore Design For Concrete BuildingsDokument7 SeitenReshore Design For Concrete BuildingsJason Toralde100% (1)

- Topics in Number Theory, Algebra, and Geometry: Ambar N. Sengupta December, 2006Dokument79 SeitenTopics in Number Theory, Algebra, and Geometry: Ambar N. Sengupta December, 2006Mandela Bright QuashieNoch keine Bewertungen

- Instruction Set 1 Rev.Dokument54 SeitenInstruction Set 1 Rev.msantoshkkdNoch keine Bewertungen

- Romanian Mathematical Competitions 1999Dokument33 SeitenRomanian Mathematical Competitions 1999kabitoszerNoch keine Bewertungen

- Bits NozzlesDokument197 SeitenBits Nozzlesiman100% (2)

- 2 Sampling Neuman CH 8Dokument35 Seiten2 Sampling Neuman CH 8Hassaan NasirNoch keine Bewertungen

- The Rule of Reason - The Philosophy of Charles Sanders PeirceDokument329 SeitenThe Rule of Reason - The Philosophy of Charles Sanders PeirceJR Salatiel100% (7)

- MiniZinc - Tutorial PDFDokument82 SeitenMiniZinc - Tutorial PDFDavidNoch keine Bewertungen

- Cherenkov 3Dokument6 SeitenCherenkov 3Christina Ria ErnawatiNoch keine Bewertungen

- Heat and Wave EquationDokument4 SeitenHeat and Wave EquationIvan ShaneNoch keine Bewertungen

- Operations Management Unit IIDokument93 SeitenOperations Management Unit IISheetal VermaNoch keine Bewertungen

- Systemic Functional Linguistics: A Brief Introduction: ArticleDokument4 SeitenSystemic Functional Linguistics: A Brief Introduction: ArticleHarinder Singh HundalNoch keine Bewertungen

- Projek RC 1Dokument5 SeitenProjek RC 1Hani BarjokNoch keine Bewertungen