Beruflich Dokumente

Kultur Dokumente

Bro Cmi Tough Solutions Rough Seas

Hochgeladen von

Andre BlueCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bro Cmi Tough Solutions Rough Seas

Hochgeladen von

Andre BlueCopyright:

Verfügbare Formate

Bonding and Sealing of

Mineral Glass

The direct mineral glazing into frames or directly into the hull

or deck, requires a full understanding of all the important

principles involved. It is essential that the glass meets all the

demands and standards required for the intended application,

such as IMO resolutions or other regulations.

Sika

Worldwide

For insulation glass, total bonding consistency must be

ensured by using Sikaflex adhesives and sealants for the

entire installation. The adhesive bond line must be protected

against UV radiation.

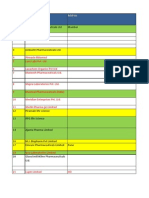

Bonding System

Cleaner

Laminated

Mineral Glass

Insulating

Mineral Glass

Primer

Adhesive

Sealant

Sika Aktivator Sika Primer-206 G+P Sikaflex-296 Sikaflex-296

Sika Aktivator Sika Primer-206 G+P Sikaflex-296 Sikasil WS-605 S

Sika Primer-206 G+P can be eliminated if proper UV protection of the bond line is ensured.

Application Rules and Guidelines

Application Guidelines

Bonding of insulated glass windows shall be

carried out as described in the Sika Marine

Application Guide. Minimum bond line

thickness and width of the backfilling sealant

has to be defined based on window

dimensions.

There are different products used for

secondary sealing of insulated glass

windows. Adhesion and compatibility

between secondary sealing and backfilling

material shall be ensured to avoid problems

because of adhesion loss. Water tightness is

essential to avoid standing water and

corrosion.

Sikaflex-296

Sikasil WS-605 S

Insulating Mineral Glass

Laminated Mineral Glass

Sika is a globally active company supplying the specialty chemicals markets. It is a leader in processing materials used in sealing,

bonding, damping, reinforcing and protecting load-bearing structures in construction (buildings and infrastructure construction) and

in industry (vehicle, building component and equipment production).

Tough Solutions for Rough Seas

Direct Glazing Systems for Marine

Sikas product lines feature high-quality concrete admixtures, specialty mortars, sealants and adhesives, damping and reinforcing

materials, structural strengthening systems, industrial flooring and membranes. Subsidiaries in more than 70 countries worldwide

and approximately 13,000 employees link customers directly to Sika.

UV protection of the bond line shall fulfil Sika

requirements and shall be positioned so that

adhesive will be protected properly.

For detailed application guidelines and

instructions please contact our local

Technical Service Departement or refer to

the Sika Marine Application Guide.

Our most current General Sales Conditions shall apply.

Please consult the most current local Product Data Sheet prior to any use.

www.sika.com

02/2011

Sikaflex-296

Glass Bonding Systems for Marine

Two Substrates

Different Demands

Traditional glazing methods are not common anymore as

they have mayor limitations like glass size, risk of glass

breakage and structural integrity. Modern glazing can be

done with different types of glass like laminated mineral

glass, organic glass, insulating glass and special glasses

(bullet-proof etc.) The latest manufacturing techniques allow

The global Marine industry is a dynamic and challenging

environment. Ship owners demand very individual designs

combined with reliability, durability and safety. One key

element of the design are the different shapes and sizes of

the individual windows used from the hull up to the flybridge

or wheelhouse. Traditionally, mineral glass is used where big

size windows are required which is the case for cruise ships,

windows of superlative performance to be produced in

almost any shape, size and curvature. The traditional role of

glazing as protection against the elements whilst allowing

light and vision to pass through, has been extended to include

the extra benefit of structural member.

Bonding and Sealing of

Organic Glass

ferries and other commercial vessels. The use of organic

glass polycarbonate, (PC) and polymethylmetacrylate

(PMMA) is more common in the yacht and leisure boat

production if the design requires extreme curvatures or

smaller glasses are used.

Mineral Glass

The use of mineral glass is most common on large vessels

like ferries or cruise ships but as well on luxury yachts. Due

to the very large size of the glasses appropriate bonding

Most of the organic glazing materials used in ship building

are either clear acrylic sheet (PMMA), or polycarbonate (PC).

In general, incorrectly installed plastic glazing panels are

prone to environmental stress cracking (ESC). To minimize

the risk of stress cracking the material should be installed

stress-free. Stress cracking can be aggravated by the use of

the wrong adhesive or pre-treatment system. As many

varieties of organic window exist, it is recommended to

ensure that the specific grade selected is suitable for use

with Sikaflex-295 UV.

Bonding System

systems must be used.Calculation of the different loads and

stresses is mandatory considering heavy wind loads and

structural movements of the ship body.

Grinding

Primer

Adhesive

Abrasive pad very fine

Sika Primer-209 D

Sikaflex-295 UV

Application Rules and Guidelines

Sika Primer-209 D

Direct glazing systems from Sika have become the primary

method of installing windows due to the extensive list of

benefits:

Better protection against the elements than framed

windows

Significantly improved design and styling capabilities for

the marine architect by elimination of trims, frames and

screws

Reduction of the natural frequencies and vibrations,

leading to an improved ride comfort for both passengers

and crew

Sikaflex-295 UV

Sikaflex-295 UV

Organic Glass

Improved aerodynamics with reduced wind noise

Better bridging of tolerances which has the advantages of

quicker assembly and reduced requirement for accuracy

Improved safety in operation

Increasing glass surface area

Organic glass is mostly used for smaller ships like sailing and

motor yachts but as well on commercial vessels like cruise

ships, ferries and river boats. Organic or composite glass is

not common for flybridges, bulkhead windows and hatches.

When using organic glasses special attention towards stress

cracking and protection of the bond lines is mandatory.

Application Guidelines

When installing organic glass windows, thermal expansion

and stress cracking characteristics must be taken into

account. The thermal expansion ratio of PMMA is higher than

other typical materials used in yacht building therefore the

adhesive and backfilling sealant has to allow displacements

caused by temperature changes. Minimum gap between

frame and window as well as bond line thickness shall be

defined according to Sika guidelines.

Stress cracking occurs when PMMA or PC is assembled

under stress or material is under permanent stress because

of thermal expansion. Curved windows shall be moulded in

production phase so that the geometry fits with the frame

without additional bending. Use of enough flexible adhesive

and backfilling ensures that thermal expansion can occur

free. The UV protection of the bond line has to be carried out

as well in accordance to the Sika guidelines.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Godrej Nirvaan FlipcharDokument58 SeitenGodrej Nirvaan FlipcharManav PrasadNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Design ProcessDokument54 SeitenDesign Processteoteoteo1988100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Accreditation of Inspection Bodies A Tool For Development JUNE 15 RajDokument22 SeitenAccreditation of Inspection Bodies A Tool For Development JUNE 15 RajAndre BlueNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- SanDokument24 SeitenSanAndre BlueNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Mechanical Systems Commissioning Fundamentals PDFDokument30 SeitenMechanical Systems Commissioning Fundamentals PDFkhwaishpatelNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- 04 Master Production Scheduling 2011springDokument44 Seiten04 Master Production Scheduling 2011springAndre BlueNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- CsDokument20 SeitenCsAndre BlueNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- MBG - 531-09 Metal Bar Grating ManualDokument36 SeitenMBG - 531-09 Metal Bar Grating ManualCarlo Monsalve100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Route To Signing The IAF or ILAC ArrangementsDokument8 SeitenThe Route To Signing The IAF or ILAC ArrangementsAndre BlueNoch keine Bewertungen

- AsDokument9 SeitenAsAndre BlueNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- MBA14QTDokument15 SeitenMBA14QTsushmaxNoch keine Bewertungen

- BsDokument20 SeitenBsAndre BlueNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Presentation On Lean ShipbuildingDokument32 SeitenA Presentation On Lean ShipbuildingAndre BlueNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- OJS FileDokument9 SeitenOJS FileSivananthaa MurtheeNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Workplace AccidentsDokument138 SeitenWorkplace Accidentsina23ajNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Offshore Structural Steel: Stock ProgramDokument12 SeitenOffshore Structural Steel: Stock ProgramAndre BlueNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Modsonic CatalogueDokument44 SeitenModsonic CatalogueAndre BlueNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- Fender Marine CatalogueDokument24 SeitenFender Marine CatalogueAndre BlueNoch keine Bewertungen

- Características CuNi 90-10 & 70-30Dokument32 SeitenCaracterísticas CuNi 90-10 & 70-30matodelanusNoch keine Bewertungen

- Mechanical Systems Commissioning Fundamentals PDFDokument30 SeitenMechanical Systems Commissioning Fundamentals PDFkhwaishpatelNoch keine Bewertungen

- M HandbookDokument34 SeitenM HandbookAndre BlueNoch keine Bewertungen

- Copper Alloys For Marine EnvironmentsDokument32 SeitenCopper Alloys For Marine EnvironmentsMohamed FaragNoch keine Bewertungen

- Norsok L-004-CR Ror OgDokument29 SeitenNorsok L-004-CR Ror OgWissam Jarmak100% (2)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Hydraulic Hose SelectionDokument16 SeitenHydraulic Hose Selectiondavo87Noch keine Bewertungen

- Bro Cmi Marine Elastic Adhesive SealingDokument6 SeitenBro Cmi Marine Elastic Adhesive SealingAndre BlueNoch keine Bewertungen

- Guidelines for Hazardous Materials InventoryDokument50 SeitenGuidelines for Hazardous Materials InventoryAndre BlueNoch keine Bewertungen

- Standard For GalvanizingDokument4 SeitenStandard For GalvanizingA.K.A. HajiNoch keine Bewertungen

- Is 277 Galvanised Steel Sheets StandardsDokument10 SeitenIs 277 Galvanised Steel Sheets StandardsvikrantathavaleNoch keine Bewertungen

- ENGINEERING DESIGN GUIDELINES FOR PAVEMENT DESIGNDokument13 SeitenENGINEERING DESIGN GUIDELINES FOR PAVEMENT DESIGNShida ShidotNoch keine Bewertungen

- A Fresh Look at Online GroceryDokument10 SeitenA Fresh Look at Online GroceryNishtha JakharNoch keine Bewertungen

- Sample BOQDokument89 SeitenSample BOQkanishkaNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Pegas Metalicos PDFDokument9 SeitenPegas Metalicos PDFruytguerraNoch keine Bewertungen

- Mumbai Pharma CompanyDokument8 SeitenMumbai Pharma CompanyPankaj BaghNoch keine Bewertungen

- 2024 Aluminum Plate SuppliersDokument9 Seiten2024 Aluminum Plate Supplierssanghvi overseas incNoch keine Bewertungen

- Asrs For AutomationDokument25 SeitenAsrs For AutomationJavedNoch keine Bewertungen

- Tata Steel - Company ProfileDokument33 SeitenTata Steel - Company ProfileRAjan Pratap Singh ChauhanNoch keine Bewertungen

- SP-1096 Specification For Welding of Duplex Stainless Steel Pipelines Amendments Suppliments ASME B31.3Dokument47 SeitenSP-1096 Specification For Welding of Duplex Stainless Steel Pipelines Amendments Suppliments ASME B31.3kart_rl100% (2)

- SDRC TR1Dokument44 SeitenSDRC TR1syafiqfat100% (1)

- Saab 2000Dokument7 SeitenSaab 2000AlexandraAndreea100% (2)

- Impact of Just-In-Time Inventory Systems On OEM Suppliers: Imds 106,2Dokument18 SeitenImpact of Just-In-Time Inventory Systems On OEM Suppliers: Imds 106,2newview111Noch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ICC-ES Evaluation Report ESR-2218Dokument12 SeitenICC-ES Evaluation Report ESR-2218Mark J LeingangNoch keine Bewertungen

- Executive Summary (Inlcuding Annexure - A)Dokument7 SeitenExecutive Summary (Inlcuding Annexure - A)sunildubey02Noch keine Bewertungen

- Innovation in The Shipping IndustryDokument15 SeitenInnovation in The Shipping IndustrySoumya IyerNoch keine Bewertungen

- MS Casting Concrete For Box Culvert 20feb2016Dokument7 SeitenMS Casting Concrete For Box Culvert 20feb2016Joel AlcantaraNoch keine Bewertungen

- 06 PPCDokument75 Seiten06 PPCizharkhan12345Noch keine Bewertungen

- Deloitte Uk Transport Digital AgeDokument24 SeitenDeloitte Uk Transport Digital AgeSenthil NathNoch keine Bewertungen

- Accident ReportDokument1 SeiteAccident ReportCirca NewsNoch keine Bewertungen

- ACCDokument18 SeitenACCSanchit AgarwalNoch keine Bewertungen

- Helicopter Safety Foundation - Crashworthiness - 1989 PDFDokument6 SeitenHelicopter Safety Foundation - Crashworthiness - 1989 PDFSharol Vera BravoNoch keine Bewertungen

- Arrival To Volos Through ThessalonikiDokument3 SeitenArrival To Volos Through ThessalonikiEliane MasonNoch keine Bewertungen

- Estimating Labor Unit Data For Concrete Concrete Construction Unit Ratesconstruction - tcm45-344396Dokument13 SeitenEstimating Labor Unit Data For Concrete Concrete Construction Unit Ratesconstruction - tcm45-344396tkarasonNoch keine Bewertungen

- Load Unload Materials 3202Dokument8 SeitenLoad Unload Materials 3202anon_249993261Noch keine Bewertungen

- Wrapid BondDokument2 SeitenWrapid BondgrtunaNoch keine Bewertungen

- Haul Cables and Care For InfrastructureDokument11 SeitenHaul Cables and Care For InfrastructureSathiyaseelan VelayuthamNoch keine Bewertungen

- HDPE ButtFusionJoiningParametersDokument7 SeitenHDPE ButtFusionJoiningParametersCrstnScribid100% (1)

- LSCM Transportation ModesDokument22 SeitenLSCM Transportation ModesAnu AnushaNoch keine Bewertungen

- Act3173 ProjectDokument17 SeitenAct3173 ProjectMohd Danial Mohd YazidNoch keine Bewertungen