Beruflich Dokumente

Kultur Dokumente

Safe Work Procedures

Hochgeladen von

Juanpablo CelisOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Safe Work Procedures

Hochgeladen von

Juanpablo CelisCopyright:

Verfügbare Formate

[Type text]

No.249, 2 of 2

February 2013

Safe Work Procedures

Hazards / Issues:

Safe work procedures (SWPs) are required when the risk of injury to workers performing a job

task cannot be eliminated by effective work design, work process or equipment.

Employers must ensure SWPs are:

based on information gathered by a risk assessment.

developed in consultation with the safety and health committee or representative.

approved by management.

understood by workers, through training. This includes steps to be taken and equipment

used in order to work safely.

readily available for workers to reference.

Supervisors are responsible to ensure:

workers perform tasks safely, consistent with training and SWPs.

Formatting SWPs

There is no single required format for SWPs. However, SWPs should include the following

information:

1. Name or description of the work task

2. Management approval

3. Date of creation

4. Date of review or revision

5. Any hazards that may cause harm to a worker

6. Equipment / devices, personal protective equipment (PPE), or other considerations

necessary to perform the task safely

7. Required training and / or relevant documentation needed to perform the task

8. Common signs and symptoms of a musculoskeletal injury (MSI), if MSI risk is present

Note: Injuries affecting the muscles, ligaments, and joints (MSI) account for a large

percentage of workplace injuries

9. A statement indicating that workers must be trained on the SWPs, and employers must

ensure that workers follow the procedures

10. Steps to perform the task safely

(See page 2)

Workplace Safety and Health Contact Information:

Winnipeg: (204) 945-3446

Toll-Free: 1-866-888-8186 (in Canada)

24-Hour Emergency Line: (204) 945-0581

Publications/resources available at: www.safemanitoba.com

Page 2 of 4

Safe Work Procedures

Bltn. 249

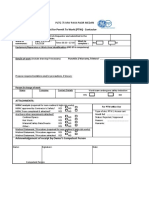

Sample SWP

The following is intended to serve as a sample template for developing SWPs.

Safe Work Procedure Job Title or Task: (1)

Department / Area:

(2)

Approved By:

(3)

Potential Hazards:

Fill in those that apply

H M L risk for injury

Awkward / sustained postures

Forceful exertions

Repetitive motions

Vibration

(6)

Skin Compression

Sharp points / edges

Pinch points

Material falling

Surfaces causing falls

Working at heights

Moving machinery

Chemicals

Biological pathogens

Electrical

Extreme heat / cold

Noise

Combustibles / flammables

Other ______________________

Date Created:

(4)

Review / Revision date:

(5)

Personal protective equipment / Devices

required / other safety considerations

(7)

Training / Reference information

(8)

(9) Common signs and symptoms of a musculoskeletal injury (MSI) can include pain, burning, swelling, stiffness,

numbness/tingling, and/or loss of movement or strength in a body part. Report these to your supervisor.

(10)

Employers must ensure that workers are trained and follow this safe work procedure

Steps to perform this task safely:

(11)

(See page 3)

Page 3 of 4

Safe Work Procedures

Bltn. 249

Filling out SWPs

1. Name or description of the work task.

2. Department or area where the work task is performed.

3. Authority approving the SWP. A senior person in management should approve the SWP

to acknowledge the employers commitment to safety.

4. Date SWP was created.

5. Date the SWP was reviewed or revised. Review SWPs at least every 3 years to ensure

they are accurate and effective. SWPs must be updated when changes to the task or

equipment are introduced. If a SWP has been reviewed and no changes are required,

enter the date of review. Workers and management must be made aware of any

changes to the SWP and workers retrained, as necessary.

6. Document the hazards for the task by identifying those hazards that could cause harm

to a worker (see below: hazard descriptions).

Note: It may be helpful to describe the cause(s) of each hazard in this box. For

example: Forceful exertion - lifting pallets or Noise - impact chisel on metal. You may

add to the list of hazards, or delete hazards that do not apply.

Estimate the level of risk for injury by selecting the H High, M Medium or L Low box

listed before each hazard.

7. Note any personal protective equipment (PPE) or other equipment that must be used to

perform the task safely. Other considerations (e.g. requiring assistance from another

worker, removing jewelry, containing loose hair/clothing, or specifying a safe body

position/movement) may also be noted in this section.

8. List any training, documentation, videos, or competency tests required to perform this

task. Training must be provided in a way that workers can understand and apply.

Reference or support information may also be listed in this section, including: manuals,

policies, related SWPs, CSA standards, or legislative references.

9. List common signs and symptoms of a musculoskeletal injury (MSI). This informs

workers what they might see or feel if a task may lead to or aggravate a MSI. If a task

has no risks for developing a MSI, this section may be deleted.

10. Include a statement about requirements for employers to train workers on the SWP and

ensure workers follow it. Spot-check observations by supervisors will help ensure that

workers are following SWPs.

11. Summarize the steps to perform the task safely. Pictures may help to make the steps

more clear. Unless already noted in box 7, describe how to eliminate or control hazards

that could lead to injuries. Be specific when describing safe body positions or

movements; instructions such as, always lift safely do not describe how to perform a

task safely.

Hazard Descriptions

Note: This list does not include all hazards that may be associated with a job. A job task may

expose workers to more than one hazard at a time.

Awkward or Sustained Posture: A working or static position which increases stress on the

joints or soft tissues of the body (i.e., twisting, over-reaching, bending at the waist, prolonged

sitting). Can lead to or aggravate a MSI.

Forceful Exertion: Performing a task requiring much physical effort (i.e., moving a heavy

object or forceful gripping). Can overload body tissues, and lead to or aggravate a MSI.

(See page 4)

Page 4 of 4

Safe Work Procedures

Bltn. 249

Hazard Descriptions (cont.)

Repetitive Motions: Performing the same action(s) for an extended period with little or no

rest for the muscles being used (i.e., working the same station on an assembly line). Over

time, repetitive movements can fatigue muscles, increasing the risk for a MSI.

Vibration: The direct transfer of shaking or rapid back and forth movement from a machine

or tool to the body. Vibration can occur from hand-arm (i.e., using a vibrating hand tool) or

through whole body vibration (i.e., vibrating equipment causing the whole body to move). Can

lead to or aggravate a MSI.

Skin Compression: External pressure against the outside of the body, at high force or for

prolonged periods of time (i.e., using your hand as a hammer, resting knees on a concrete

floor for long periods, or the edge of a workstation pressing into the body). Mechanical

compression can damage soft tissues of the body, leading to or aggravating a MSI.

Sharp Points or Edges: Surfaces, tools or materials adjacent to or used by a worker which

are able to cause punctures or cuts (i.e., blades, needles).

Pinch Points: Equipment, devices or practices that could catch, squeeze, or crush part of a

workers body (i.e., rollers, moving machinery).

Material Falling: Goods or other materials that could fall into or onto a worker due to

insufficient bracing, shoring or securing.

Surfaces Causing Falls: Uneven, broken, cluttered or slippery surfaces that could cause a

worker to lose their balance and trip, slip or fall.

Working at Heights: Working above the ground (i.e., on ladders, platforms, or roofs etc.)

where a worker is at risk of injury from falls.

Moving Machinery: Equipment being used by a worker or in operation nearby that could trap,

catch, hit, cut or crush the whole or part of a workers body.

Chemicals: Exposure to gases, liquids, solids, aerosols, vapors, dusts, fumes, mists, or

smokes that can cause an injury to a worker.

Biological Pathogens: Exposure to bacteria, fungi, viruses, dusts or moulds, blood or body

fluids that can cause ill effects or injury to a worker.

Electrical: Electrical energy that could be transferred to a worker through contact with a

power source, carrier or conductor.

Extreme Heat or Cold: Temperature extremes which can cause a workers body to function

less effectively both physically and/or mentally (i.e., working in a freezer or close to a smelter).

Noise: Exposure to sounds at excessive levels that could lead to noise induced hearing loss.

Combustibles or Flammables: Substances naturally more susceptible to fire or explosion.

Reference to legal requirements under workplace safety and health legislation:

o Safe Work Procedures: Manitoba Regulation 217/2006 Part 2.1

o Content of Program: Workplace Safety and Health Act W210 Part 7.4(5)

Additional workplace safety and health information available at www.safemanitoba.com

o SAFE Work Bulletin #249 part 1 Job Hazard Analysis

o Safe Work Procedure (SWP) Templates

o Sample Safe Work Procedures (SWPs)

This information is available in alternate formats upon request.

Ces renseignements sont offerts dans de multiples formats sur demande.

Das könnte Ihnen auch gefallen

- Safe System Of Work A Complete Guide - 2020 EditionVon EverandSafe System Of Work A Complete Guide - 2020 EditionNoch keine Bewertungen

- General Work PermitDokument1 SeiteGeneral Work Permitgurvinder singhNoch keine Bewertungen

- Wire Brush Safety InstructionsDokument2 SeitenWire Brush Safety InstructionsMohamed FaroukNoch keine Bewertungen

- Safety - Permit To Dig: PART A: To Be Completed For ALL Operations Involving Breaking GroundDokument4 SeitenSafety - Permit To Dig: PART A: To Be Completed For ALL Operations Involving Breaking GroundParashuram PatilNoch keine Bewertungen

- Powder Actuated ToolsDokument1 SeitePowder Actuated ToolsJayvee Baradas ValdezNoch keine Bewertungen

- SOP Excavation and PermittingDokument4 SeitenSOP Excavation and PermittingTengku & Wan ResourcesNoch keine Bewertungen

- Pressure Test Work PermitDokument2 SeitenPressure Test Work PermitMd Abdul Raja83% (6)

- COSHH Risk AssessmentDokument6 SeitenCOSHH Risk AssessmentKyle RobertsonNoch keine Bewertungen

- 5X5 Matrix RA For Installation Fo CHC-2A Conveyor SystemDokument16 Seiten5X5 Matrix RA For Installation Fo CHC-2A Conveyor SystemSandeep Jain100% (2)

- Ladders Inspection Register: Location: TSM ARABIADokument4 SeitenLadders Inspection Register: Location: TSM ARABIAmuhammad imtiazNoch keine Bewertungen

- Request For Permit To Work (PTW) - Contactor Application: PLTG 75 MW Paya Pasir MedanDokument2 SeitenRequest For Permit To Work (PTW) - Contactor Application: PLTG 75 MW Paya Pasir MedanDimas Dwi SwarnaNoch keine Bewertungen

- 07 Packing, Marking & Shipping Instructions - DomesticDokument2 Seiten07 Packing, Marking & Shipping Instructions - DomesticLuisNoch keine Bewertungen

- Title: Hot Work Procedure: Occupational Health and Safety Act 2004 Occupational Health and Safety Regulations 2007Dokument5 SeitenTitle: Hot Work Procedure: Occupational Health and Safety Act 2004 Occupational Health and Safety Regulations 2007Adeyinka MichealNoch keine Bewertungen

- R-16 Safety Management Review MeetingDokument2 SeitenR-16 Safety Management Review MeetingSandeep Kumar100% (1)

- JGS SHES JHRA 002 13 Scaffolding Erection and DismantlingDokument2 SeitenJGS SHES JHRA 002 13 Scaffolding Erection and Dismantlingarnel sungkip100% (1)

- Job Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewDokument4 SeitenJob Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewMoaatazz Nouisri100% (1)

- Osh Communication: Document ID: MSP-005Dokument7 SeitenOsh Communication: Document ID: MSP-005Kingsley AhanonuNoch keine Bewertungen

- PP-HSE-FORM-005 PTW-Confined SpaceDokument2 SeitenPP-HSE-FORM-005 PTW-Confined SpaceDimas Dwi SwarnaNoch keine Bewertungen

- Contractor Personnel and Safety Statistics Monthly Summary - Form S2052Dokument1 SeiteContractor Personnel and Safety Statistics Monthly Summary - Form S2052Safety professionalNoch keine Bewertungen

- Safe Work Method StatementDokument2 SeitenSafe Work Method Statementbuddyhello1Noch keine Bewertungen

- Environment, Health & Safety Policy - PPT-rev3Dokument48 SeitenEnvironment, Health & Safety Policy - PPT-rev3Isabel ImNoch keine Bewertungen

- 18A - FO - Permit To Work LogDokument2 Seiten18A - FO - Permit To Work Lograjesh_rathNoch keine Bewertungen

- HSE FRM-32 Incident Investigation ReportDokument4 SeitenHSE FRM-32 Incident Investigation ReportPerwez21Noch keine Bewertungen

- Safe Work Method StatementDokument2 SeitenSafe Work Method StatementFrank Barnes100% (1)

- 7.electrical LOTO Check List InspectionDokument1 Seite7.electrical LOTO Check List Inspectionfitri widyaNoch keine Bewertungen

- Confined Space Rescue Plan: Description of The WorkDokument2 SeitenConfined Space Rescue Plan: Description of The Workidigiti100% (1)

- Permit To Work ProceduceDokument4 SeitenPermit To Work ProceduceQuý Hoàng ChuNoch keine Bewertungen

- Job Safety Analysis - Clinker StorageDokument4 SeitenJob Safety Analysis - Clinker StorageMohammed MinhajNoch keine Bewertungen

- Work Permit Request For HydrotestingDokument3 SeitenWork Permit Request For HydrotestingZeyad Rezk50% (2)

- Hse FormDokument2 SeitenHse FormPhilip Tcs100% (1)

- Report Log of Unsafe Acts, Unsafe Conditions and Almost AccidentsDokument3 SeitenReport Log of Unsafe Acts, Unsafe Conditions and Almost AccidentsTatiana Garcia MendozaNoch keine Bewertungen

- Work at HeightDokument1 SeiteWork at HeightVikas Yamagar100% (2)

- PPE Issue ReordDokument1 SeitePPE Issue ReordHuman ResourcesNoch keine Bewertungen

- Hse Plan - ArkDokument109 SeitenHse Plan - Arkjiks_i4u100% (2)

- P99-HS-200223-Activity Briefing Form-Rev 2Dokument2 SeitenP99-HS-200223-Activity Briefing Form-Rev 2Darius AdeNoch keine Bewertungen

- EHS-GF-02 A Safety InductionDokument1 SeiteEHS-GF-02 A Safety Inductionshamshad ahamedNoch keine Bewertungen

- Autoclaves - Generic Assessment - L Use of AutoclavesDokument1 SeiteAutoclaves - Generic Assessment - L Use of AutoclavesaKureishiNoch keine Bewertungen

- Method Statement For LPG DismantlingDokument8 SeitenMethod Statement For LPG DismantlingHusain abidiNoch keine Bewertungen

- Register - EHS Legal RequirementsDokument4 SeitenRegister - EHS Legal Requirementsanoushia alviNoch keine Bewertungen

- Stop Work Policy: Roles AND Responsibilities: EmployeesDokument3 SeitenStop Work Policy: Roles AND Responsibilities: Employeesfirdous tantaryNoch keine Bewertungen

- 06-F03 Ohs Introduction & Induction: Safety Induction Training Check-ListDokument2 Seiten06-F03 Ohs Introduction & Induction: Safety Induction Training Check-ListSn AhsanNoch keine Bewertungen

- HSE-P-07 Work Permit Procedure Issue 2.1Dokument30 SeitenHSE-P-07 Work Permit Procedure Issue 2.1eng20072007100% (1)

- Work at Heights PermitDokument4 SeitenWork at Heights Permitrashid zamanNoch keine Bewertungen

- 7 Hand Held Power ToolsDokument4 Seiten7 Hand Held Power ToolsGilmar MonteiroNoch keine Bewertungen

- Safety Signs On Construction SiteDokument1 SeiteSafety Signs On Construction SiteBëBå Wossen AssefaNoch keine Bewertungen

- PPE Procedure, WHSPRO-014 CMDokument3 SeitenPPE Procedure, WHSPRO-014 CMAshana RajpersaudNoch keine Bewertungen

- JSA Template 5 - Plumbing and Wastewater System InspectionsDokument13 SeitenJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- Safe Working PracticesDokument7 SeitenSafe Working PracticesDiana ParkerNoch keine Bewertungen

- Excavation Safety ProcedureDokument8 SeitenExcavation Safety ProcedureJamilNoch keine Bewertungen

- 7-Block Work Risk Assessment ReportDokument7 Seiten7-Block Work Risk Assessment ReportSyed Ali Hassan100% (4)

- Incident Investigation ProcedureDokument7 SeitenIncident Investigation ProcedureJobaer100% (1)

- Planned Task Observation ReportDokument6 SeitenPlanned Task Observation Reportmerganser26100% (2)

- HSE Form No.8 Warning Notice - 1Dokument8 SeitenHSE Form No.8 Warning Notice - 1Myungki OhNoch keine Bewertungen

- Confined Space Entry Permit Rev 01Dokument3 SeitenConfined Space Entry Permit Rev 01Neel Vadera100% (1)

- Inspection Form Lockout TagoutDokument4 SeitenInspection Form Lockout TagoutCarina Kouamé100% (1)

- Plant Checklist PDFDokument2 SeitenPlant Checklist PDFmj santosNoch keine Bewertungen

- Subject: Work at Height: Unit: Maihar Cement WorksDokument3 SeitenSubject: Work at Height: Unit: Maihar Cement Workskaka100% (1)

- Checklist For Generator SetDokument1 SeiteChecklist For Generator SetKrsna ManahanNoch keine Bewertungen

- Heat Stress ProcedureDokument13 SeitenHeat Stress ProcedureKneekEy CastleNoch keine Bewertungen

- Musculoskeletal Radiology NotesDokument62 SeitenMusculoskeletal Radiology Notesmeshmatic1234567100% (3)

- Drekkana The D-3 Chart Dreshkhamsha A Graphic Representation of The Placement of Each Radix Graha Into One of The 36 DrekkanaDokument15 SeitenDrekkana The D-3 Chart Dreshkhamsha A Graphic Representation of The Placement of Each Radix Graha Into One of The 36 DrekkanaANTHONY WRITER100% (1)

- Can Physiotherapists Contribute To Care in The Emergency Department?Dokument3 SeitenCan Physiotherapists Contribute To Care in The Emergency Department?J Roberto Meza OntiverosNoch keine Bewertungen

- Flowchart Tort of NegligenceDokument3 SeitenFlowchart Tort of NegligenceYogita Hauradhun100% (8)

- General Defences Shortest (Last Minute)Dokument23 SeitenGeneral Defences Shortest (Last Minute)Raj DasNoch keine Bewertungen

- STITCHES Lyrics and Chords SHAWN MENDES @Dokument21 SeitenSTITCHES Lyrics and Chords SHAWN MENDES @Rova Lavi SynNoch keine Bewertungen

- Keys Man Ec4500Dokument25 SeitenKeys Man Ec4500amokhtaNoch keine Bewertungen

- Air & Space Law AssignmentDokument5 SeitenAir & Space Law AssignmentPartha Mehrotra100% (1)

- Letters To God by Patrick Doughtie and John Perry, ExcerptDokument22 SeitenLetters To God by Patrick Doughtie and John Perry, ExcerptZondervan100% (3)

- Tanduay DistillersDokument8 SeitenTanduay DistillersAnna BautistaNoch keine Bewertungen

- Congenital AbnormalitiesDokument37 SeitenCongenital AbnormalitiesrezkadehaNoch keine Bewertungen

- Motion Sensitivity TestDokument6 SeitenMotion Sensitivity TestWlf OoNoch keine Bewertungen

- Judicial Affidavit HomicideDokument6 SeitenJudicial Affidavit HomicideDonnel BustamanteNoch keine Bewertungen

- Lazy Girl WorkoutDokument17 SeitenLazy Girl Workoutسميره محمدNoch keine Bewertungen

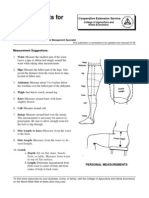

- Measurements For Fitting Pants: Guide C-209Dokument2 SeitenMeasurements For Fitting Pants: Guide C-209Ranil Hashan FNoch keine Bewertungen

- Business Law Quiz QuestionsDokument2 SeitenBusiness Law Quiz QuestionsNikki Revil0% (1)

- The Core Mobility Series: A Dynamic Warm-Up Tool: Ó National Strength and Conditioning AssociationDokument7 SeitenThe Core Mobility Series: A Dynamic Warm-Up Tool: Ó National Strength and Conditioning AssociationsimranNoch keine Bewertungen

- Recovery of Persons From The WaterDokument60 SeitenRecovery of Persons From The WaterGamalMahranNoch keine Bewertungen

- BTLS TraumaDokument42 SeitenBTLS TraumaGendrux Zibbzibb67% (3)

- Chapter 8: Somatosensory Neurotransmission: Touch, Pain, & TemperatureDokument21 SeitenChapter 8: Somatosensory Neurotransmission: Touch, Pain, & Temperatureanon_794697676100% (1)

- Minimum Antiterrorism StandardsDokument6 SeitenMinimum Antiterrorism Standardseeshan2Noch keine Bewertungen

- Giles A1Dokument27 SeitenGiles A1Jem Rhod CamenseNoch keine Bewertungen

- Urological Emergencies: DR Ahmed BekeerDokument31 SeitenUrological Emergencies: DR Ahmed BekeerAh BakaNoch keine Bewertungen

- Meniscal TearDokument6 SeitenMeniscal TearAdrian Diago TevesNoch keine Bewertungen

- Daftar PustakaDokument3 SeitenDaftar Pustakaerman marzNoch keine Bewertungen

- 23 External Ear (Done)Dokument4 Seiten23 External Ear (Done)osamaeNoch keine Bewertungen

- Silent Hill 4Dokument43 SeitenSilent Hill 4Surya BendotNoch keine Bewertungen

- The The To The Out The The The To: DetailsDokument10 SeitenThe The To The Out The The The To: DetailsjachicoNoch keine Bewertungen

- Week 21 - SDL Preview QuestionsDokument4 SeitenWeek 21 - SDL Preview QuestionsAAMNA HAROONNoch keine Bewertungen

- Dorin The Dwarf SpellsDokument3 SeitenDorin The Dwarf Spellspotato123123aNoch keine Bewertungen

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceVon EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceBewertung: 4 von 5 Sternen4/5 (19)

- Transformed: Moving to the Product Operating ModelVon EverandTransformed: Moving to the Product Operating ModelBewertung: 4 von 5 Sternen4/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureVon EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureBewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsVon EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNoch keine Bewertungen

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableVon EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNoch keine Bewertungen

- Analog Design and Simulation Using OrCAD Capture and PSpiceVon EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNoch keine Bewertungen

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisVon EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsVon EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsBewertung: 5 von 5 Sternen5/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tVon EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tBewertung: 4.5 von 5 Sternen4.5/5 (27)

- Laws of UX: Using Psychology to Design Better Products & ServicesVon EverandLaws of UX: Using Psychology to Design Better Products & ServicesBewertung: 5 von 5 Sternen5/5 (9)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneVon EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Design for How People Think: Using Brain Science to Build Better ProductsVon EverandDesign for How People Think: Using Brain Science to Build Better ProductsBewertung: 4 von 5 Sternen4/5 (8)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchVon EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchBewertung: 4 von 5 Sternen4/5 (10)

- Guidelines for Auditing Process Safety Management SystemsVon EverandGuidelines for Auditing Process Safety Management SystemsNoch keine Bewertungen

- A Complete Guide to Safety Officer Interview Questions and AnswersVon EverandA Complete Guide to Safety Officer Interview Questions and AnswersBewertung: 4 von 5 Sternen4/5 (1)

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsVon EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsBewertung: 4 von 5 Sternen4/5 (2)

- Understanding Automotive Electronics: An Engineering PerspectiveVon EverandUnderstanding Automotive Electronics: An Engineering PerspectiveBewertung: 3.5 von 5 Sternen3.5/5 (16)

- Rules of Thumb for Maintenance and Reliability EngineersVon EverandRules of Thumb for Maintenance and Reliability EngineersBewertung: 4.5 von 5 Sternen4.5/5 (12)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersVon EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersBewertung: 4 von 5 Sternen4/5 (13)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsVon EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNoch keine Bewertungen