Beruflich Dokumente

Kultur Dokumente

Mil Cid A A 52083

Hochgeladen von

kpOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Mil Cid A A 52083

Hochgeladen von

kpCopyright:

Verfügbare Formate

INCH-POUND

A-A-52083C

23 February 2004

SUPERSEDING

A-A-52083B

23 May 1998

COMMERCIAL ITEM DESCRIPTION

TAPE, LACING AND TYING, GLASS

The General Services Administration has authorized the use of this commercial item

description as a replacement for Type IV of MIL-T-43435B for all federal agencies.

1. SCOPE. This Commercial Item Description (CID) covers glass tape, flat braided, for lacing and tying.

2. CLASSIFICATION. Tape shall conform to the sizes and finishes as specified. (see 3.3 and 3.6)

2.1 Size. The size shall be identified as 1,2,3,4 or 5. (see Table 1)

2.2 Finish. The finish shall be identified as C, D or F. (see 3.6)

3. SALIENT CHARACTERISTICS.

3.1 Material. The yarn used in the fabrication of the tape shall be electrical grade, continuous filament,

glass yarn having high insulation resistance, high dielectric strength, high resistance to aging and low moisture pickup. The material shall be free from any alkali metal oxides, such as soda or potash, and from foreign particles, dirt, or

other impurities.

3.2 Construction. The tape shall be a flat braid construction.

3.3 Physical Requirements. Tape shall conform to the requirements of Table 1.

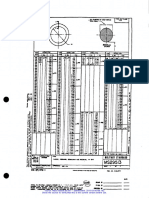

TABLE 1: Tape, Lacing and Tying, Glass

Size

1

2

3

4

5

Width

in Inches

Min

Max

.203

.248

.099

.121

.077

.094

.054

.066

.045

.055

Thickness

in Inches

Min

Max

.013

.019

.013

.019

.013

.019

.013

.019

.013

.019

Breaking

Strength

(Lbs, min)

200

100

75

50

--

3.4 Elongation. Maximum elongation at breaking strength shall not be greater than 5% when tested as

specified in Fed-Std-191 Method 4108. This test to be performed simultaneously with breaking strength. Elongation

for size 5 is not rated.

3.5 Color. The color of this tape shall be natural. No other colors are available.

Beneficial comments, recommendations, additions, deletions, clarifications, etc., and any other data which may improve this

document should be sent to: Defense Industrial Supply Center, ATTN.: DISC-BBEE, 700 Robbins Avenue, Philadelphia, PA

19111-5096

AMSC/NA

FSC 4020

Source: https://assist.dla.mil -- Downloaded: 2015-03-06T06:48Z

Check the source to verify that this is the current version before use.

A-A-52083B

3.6 Finish. A finish option shall be specified, in accordance with 3.6.1 through 3.6.3. Tape finishes shall not

contain any mercury or copper. All finishes shall be able to be used freely in direct contact with insulated cable or

wire.

3.6.1 Finish C - Synthetic rubber. Tape shall be uniformly impregnated with a synthetic rubber or elastomer

finish. Treated tape shall contain 7-17% rubber by weight. (see 5.2.1)

3.6.2 Finish D - TFE-Fluorocarbon coating. Tape shall be uniformly impregnated before braiding. Treated

tape shall contain 10-20% TFE-fluorocarbon by weight. (see 5.2.1)

3.6.3 Finish F - Silicone resin impregnated. Tape shall be uniformly impregnated, and shall contain 7-17%

silicone resin material by weight. (see 5.2.1)

3.7 Knot Slip Resistance. (finish C and F only). Stress applied to a specimen made by joining two ends of

the braided tape with a square knot shall result in the breakage of the tape specimen rather than the slippage or

pulling out of the knot to the point of separation when tested as specified in 5.2.2. If application necessitates the

need for finish D, an additional coat of synthetic elastomer may be added when knot holding characteristics are

desired.

3.8 Put-up. Unless otherwise specified, the tape shall be furnished on parallel wind spools (reels) or

universal wind tubes (holders). Size 1 and 2 tapes shall be put-up in a minimum of 250 yard lengths, and size 3, 4, and

5 tapes shall be put-up in a minimum of 500 yard lengths. The tape shall be free from twists, lumps, or projecting ends

and shall be evenly wound so that each turn and layer is free from entanglement and twisting. There shall be no more

than four pieces per reel or holder, and no piece shall be less than 50 yards in length.

3.9 Breaking Strength. Minimum breaking strength shall be as stated in Table 1 when tested as specified in

Fed-Std-191 Method 4108.

3.10 Fungus Resistance. No tape shall show visible growth (to the naked eye) of fungus on the surface of

the test specimens when tested as specified in Fed-Std-191 Method 5760.

3.11 Blocking. There shall be no visible damage or removal of the coatings on finish C, D and F, tapes when

tested as specified in paragraph 5.2.3.

3.12 Accelerated Aging. When specified (see 7.4), finish C, D and F tapes shall show no evidence of

stiffness, brittleness, softness, or tackiness when tested as specified in Fed-Std-191 Method 5852, except that the

specimen shall be six inches in length by the full width of the tape.

3.13 Identification. Tape shall be tagged with a label or ticket containing at least the following information:

CID part number, National Stock Number, date of manufacture, and manufacturers name. When put-up or color is

non-standard, the tag shall indicate the actual color or length.

4. REGULATORY REQUIREMENTS.

4.1 The offerer/contractor is encouraged to use recovered materials to the maximum extent practicable, in

accordance with paragraph 23.403 of the Federal Acquisition Regulation (FAR).

5. QUALITY ASSURANCE PROVISIONS.

5.1 Product Conformance. The products provided shall meet the salient characteristics of this commercial

item description, conform to the producers own drawings, specifications, standards, and quality assurance practices

and be the same product offered for sale in the commercial market. The government reserves the right to require

proof of such conformance..

2

Source: https://assist.dla.mil -- Downloaded: 2015-03-06T06:48Z

Check the source to verify that this is the current version before use.

A-A-52083B

5.2 Inspection Requirements

5.2.1 Determination of Percentage of Finish. The percentage of finish C, D and F impregnating materials

on the respective type tapes shall be determined during processing, by the manufacturer, by weighing an identical

sample of tape or yarn (see 3.6), before and after the impregnating process. The test specimen shall be a minimum of

30 yards of tape or 120 yards of yarn as applicable. Weight (Length per pound) shall be determined in accordance

with Method 4010 of FED- STD-191. The percentage of finish shall be calculated as follows:

Percent Finish A-B x 100

B

Where: A = Length per pound of untreated tape or yarn, as applicable.

B = Length per pound of treated tape or yarn, as applicable.

5.2.2 Determination of Knot Slip Resistance. The knot slip resistance of the tapes shall be determined in

accordance with Fed-Std-191 Method 4108, except as modified herein. The test specimens shall be cut in half and

then the two halves shall be firmly tied together with a square knot. The two protruding ends at the knot shall be cut

so that one-half inch protrudes. The specimen shall be aligned so that the knot is approximately halfway between the

clamps. The machine shall be operated until the knot slips or pulls out or the specimen breaks at or in proximity to

the knot. Breaks closer than 1/2 inch of the jaws shall be discarded. Five good readings shall be obtained. If knot

slippage is obtained on only one of five readings, an additional specimen shall be tested and if a good reading is

obtained, the reading indicating knot slippage shall be discarded.

5.2.3 Determination of Blocking. Ten turns of the tape shall be wound on a one-quarter inch

diameter clean metal mandrel under a two pound tension and the end secured through holes in the mandrel. Eight

turns of tape shall then be wound on top of the first layer under the two pound tension and the ends secured as

before. The wound mandrel shall then be placed in a temperature controlled oven at 70 + 1o C for two hours, and in

such a manner that no part of the specimen comes in contact with the surface of the oven. The specimen shall then

be removed and cooled at room temperature. After cooling, the outer layer shall be unwound and examined for

evidence of damage to the coatings due to adhesion between layers of turns. The first layer shall be examined while

still in place for similar evidence of adherence and damage.

6. PACKAGING.

6.1 Preservation, packing and marking shall be as specified in the contract or order.

7. NOTES.

7.1 Intended use. The tape is intended for lacing and tying electrical wire and cable bundles. The

application of an additional finish to glass tape with Finish D may be used when better knot holding characteristics

are desired. Tape with finish C provides the best knot holding characteristics. Useful temperature range of glass

tape is -100 F to 800 F.

7.2 Part Identification Number (PIN). The PIN shall consist of the basic CID number, followed by the finish

code letter from 3.5, followed by the size number from Table 1.

PIN Example:

AA52083- A-2

Size from Table 1

Finish from 3.6

Basic CID number

3

Source: https://assist.dla.mil -- Downloaded: 2015-03-06T06:48Z

Check the source to verify that this is the current version before use.

A-A-52083B

7.3 Source of Documents.

7.3.1 Federal Standards are available from the Superintendent of Documents, U.S. Government Printing

Office, Washington DC, 20402.

7.4 Ordering Data.

a. Title, Number and Date of this Commercial Item Description.

b. Size and Finish required. (see 3.3 and 3.6)

c. Color, if other than specified. (see 3.5)

d. Put-up if other than specified. (see 3.8)

e. When accelerated aging is required. (see 3.12)

f. Selection of applicable levels of packaging and packing. (see 6)

7.5 National Stock Numbers (NSNs). The following is a list of NSNs assigned which correspond to this

CID. This list may not be indicative of all possible NSNs associated with the CID.

NSN

4020-00-823-6997

4020-00-100-9067

4020-01-354-7284

4020-01-411-2548

4020-00-492-3975

4020-00-053-5738

4020-00-123-8675

Type

4

4

4

4

4

4

4

Size

1

2

2

3

3

4

5

Finish

D

D

F

C

D

D

D

Color

Natural

Natural

Natural

Natural

Natural

Natural

Natural

MILITARY INTERESTS:

CUSTODIANS:

Army - GL

Navy - SH

Air Force - 99

CIVIL AGENCY COORDINATING ACTIVITIES:

GSA - FSS

PREPARING ACTIVITY:

DLA - IS

REVIEWERS:

Army - AR, CR, CR4, MD, MI

Navy - AS, MC, OS

Air Force - 82

(Project 4020-1052)

4

Source: https://assist.dla.mil -- Downloaded: 2015-03-06T06:48Z

Check the source to verify that this is the current version before use.

Das könnte Ihnen auch gefallen

- Mil Cid A A 52084Dokument4 SeitenMil Cid A A 52084kpNoch keine Bewertungen

- Mil Cid A A 52082Dokument4 SeitenMil Cid A A 52082kpNoch keine Bewertungen

- A-A-52084D 2018 Aramid Lacing and Tying TapeDokument5 SeitenA-A-52084D 2018 Aramid Lacing and Tying TapebabshuagNoch keine Bewertungen

- CBLCT-3.4 Cable TilesDokument11 SeitenCBLCT-3.4 Cable Tilesdhayalasundaram5689Noch keine Bewertungen

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIVon EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IITatsuki OhjiNoch keine Bewertungen

- Astm F477-08Dokument4 SeitenAstm F477-08ALARCONISTANoch keine Bewertungen

- MIl Spec Mil-S-3725EDokument21 SeitenMIl Spec Mil-S-3725Ecjnjr1Noch keine Bewertungen

- Self-Adhering Polymer Modified Bituminous Sheet Materials Used As Steep Roofing Underlayment For Ice Dam ProtectionDokument5 SeitenSelf-Adhering Polymer Modified Bituminous Sheet Materials Used As Steep Roofing Underlayment For Ice Dam ProtectiondaovandongpktNoch keine Bewertungen

- Advances in Ceramic Armor XIVon EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNoch keine Bewertungen

- F 477 - 02 RJQ3NWDokument4 SeitenF 477 - 02 RJQ3NWHumberto GutierrezNoch keine Bewertungen

- Pttchem SP P 121 000 - Wrapping PDFDokument12 SeitenPttchem SP P 121 000 - Wrapping PDFCivil FriendNoch keine Bewertungen

- Mil DTL 5886HDokument21 SeitenMil DTL 5886HjohnneracalNoch keine Bewertungen

- Astm d1871Dokument5 SeitenAstm d1871Edwin RamirezNoch keine Bewertungen

- Is 15466 (2004)Dokument16 SeitenIs 15466 (2004)slamienkaNoch keine Bewertungen

- D 1970 - 00 Rde5nzatukveDokument7 SeitenD 1970 - 00 Rde5nzatukvedaovandongpktNoch keine Bewertungen

- Australian Standard: Extruded Rod and TubeDokument14 SeitenAustralian Standard: Extruded Rod and TubeWidodo MuisNoch keine Bewertungen

- Coal-Tar-Saturated Organic Felt Used in Roofing and WaterproofingDokument3 SeitenCoal-Tar-Saturated Organic Felt Used in Roofing and WaterproofingRufo CascoNoch keine Bewertungen

- Fiberglass Reinforced PlasticsDokument6 SeitenFiberglass Reinforced Plasticsnaimz88Noch keine Bewertungen

- D 5168 - 03 - RduxnjgDokument6 SeitenD 5168 - 03 - Rduxnjgjamaljamal20Noch keine Bewertungen

- Bitumen-Saturated Cotton Fabrics 2Dokument4 SeitenBitumen-Saturated Cotton Fabrics 2A MahmoodNoch keine Bewertungen

- Astm D-1752Dokument2 SeitenAstm D-1752Franchute83Noch keine Bewertungen

- Astm D-113 PDFDokument3 SeitenAstm D-113 PDFjulianovmNoch keine Bewertungen

- Scotchcast Polyolefin Fibers: For Use in Wet-Mix ShotcreteDokument2 SeitenScotchcast Polyolefin Fibers: For Use in Wet-Mix Shotcretejack21abNoch keine Bewertungen

- D 5047 - 95 - RduwndctotuDokument3 SeitenD 5047 - 95 - RduwndctotuSérgio CallaiNoch keine Bewertungen

- GL PD 08 81BDokument18 SeitenGL PD 08 81BgearshoutNoch keine Bewertungen

- C 509 - 00 - QzuwoqDokument5 SeitenC 509 - 00 - Qzuwoqmercab150% (1)

- Mandrel Bend Test of Attached Organic Coatings: Standard Test Methods ForDokument4 SeitenMandrel Bend Test of Attached Organic Coatings: Standard Test Methods ForKarlos Albert Xukizuta100% (1)

- 2019 Exam With ExplanationDokument100 Seiten2019 Exam With ExplanationMarlatif SakandalNoch keine Bewertungen

- C 1497 - 04 Qze0otcDokument4 SeitenC 1497 - 04 Qze0otcRufo CascoNoch keine Bewertungen

- ASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFDokument7 SeitenASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFApolos CastNoch keine Bewertungen

- Norma D-6904-03 Wind Diven Rain Test PDFDokument3 SeitenNorma D-6904-03 Wind Diven Rain Test PDFflorentinoNoch keine Bewertungen

- C 1173 - 97 Qzexnzmtotc - PDFDokument4 SeitenC 1173 - 97 Qzexnzmtotc - PDFMung Duong XuanNoch keine Bewertungen

- D 2626 - 97 Rdi2mjyDokument3 SeitenD 2626 - 97 Rdi2mjydaovandongpktNoch keine Bewertungen

- D7530D7530M-10 Standard Specification For Self-Adhesive Glass Fiber Fabric Reinforced Polymer Modified Asphalt Steep Slope Roll Roofing Surfaced With Mineral GranulesDokument5 SeitenD7530D7530M-10 Standard Specification For Self-Adhesive Glass Fiber Fabric Reinforced Polymer Modified Asphalt Steep Slope Roll Roofing Surfaced With Mineral GranulesSatya kaliprasad vangaraNoch keine Bewertungen

- Specification For FRP DuctDokument6 SeitenSpecification For FRP DuctAli HassanNoch keine Bewertungen

- D 2091 - 96 - RdiwotetotyDokument3 SeitenD 2091 - 96 - RdiwotetotymorchedtounsiNoch keine Bewertungen

- Astm C 171 2007Dokument2 SeitenAstm C 171 2007sabruno100% (3)

- 1v005 045Dokument24 Seiten1v005 045Romany AllamNoch keine Bewertungen

- Greige Woven Glass Fabrics: Standard Specification ForDokument17 SeitenGreige Woven Glass Fabrics: Standard Specification ForTuyên RùaNoch keine Bewertungen

- 48 TMSS 01 R0Dokument0 Seiten48 TMSS 01 R0renjithas2005Noch keine Bewertungen

- 23 TMSS 02 R0Dokument0 Seiten23 TMSS 02 R0renjithas2005Noch keine Bewertungen

- C 1032 - 96 r02 QzewmzitukveDokument5 SeitenC 1032 - 96 r02 QzewmzitukveHumberto GutierrezNoch keine Bewertungen

- Astm D4437 08Dokument2 SeitenAstm D4437 08Carolina SayagoNoch keine Bewertungen

- Wavistrong Installation ManualDokument63 SeitenWavistrong Installation ManualRenganathan Prabunath0% (1)

- C 475 C 475m 01 Qzq3ns9dndc1ts1sruq PDF FreeDokument3 SeitenC 475 C 475m 01 Qzq3ns9dndc1ts1sruq PDF FreeManuela AvendañoNoch keine Bewertungen

- D 522 - 93 Rduymi05m0eDokument4 SeitenD 522 - 93 Rduymi05m0ewpwmhatNoch keine Bewertungen

- Astm D1751-99Dokument2 SeitenAstm D1751-99Nadya Chandra50% (2)

- D1751Dokument2 SeitenD1751grats_singco100% (1)

- D 228 - 03 Rdiyoc0wmwDokument10 SeitenD 228 - 03 Rdiyoc0wmwdaovandongpktNoch keine Bewertungen

- Styrene-Rubber (SR) Plastic Drain Pipe and Fittings: Standard Specification ForDokument6 SeitenStyrene-Rubber (SR) Plastic Drain Pipe and Fittings: Standard Specification FormasoudNoch keine Bewertungen

- Cryogel Z Specification Guidelines 3-0Dokument15 SeitenCryogel Z Specification Guidelines 3-0Joseph Van LooNoch keine Bewertungen

- FOC Specs (Figure 8) - FTTHDokument4 SeitenFOC Specs (Figure 8) - FTTHLuis OdictaNoch keine Bewertungen

- Binding Sites Per Per Unit Length or Width of Pile Yarn Floor CoveringsDokument7 SeitenBinding Sites Per Per Unit Length or Width of Pile Yarn Floor CoveringsJuanNoch keine Bewertungen

- Adhesive Compounds'2 Component For Sealing Wire and Light in PavementDokument4 SeitenAdhesive Compounds'2 Component For Sealing Wire and Light in PavementDevrim GürselNoch keine Bewertungen

- Huck® Interactive CD Rom: Specifications: Hydraulic Installation ToolDokument2 SeitenHuck® Interactive CD Rom: Specifications: Hydraulic Installation ToolkpNoch keine Bewertungen

- Huck® Interactive CD Rom: Specifications: Pneudraulic Powered Installation ToolDokument2 SeitenHuck® Interactive CD Rom: Specifications: Pneudraulic Powered Installation ToolkpNoch keine Bewertungen

- Ventec VT 47Dokument3 SeitenVentec VT 47kpNoch keine Bewertungen

- Kemet PHE840MDokument2 SeitenKemet PHE840MkpNoch keine Bewertungen

- Langed OLE Rommet: NMC G24 - (Series)Dokument2 SeitenLanged OLE Rommet: NMC G24 - (Series)kpNoch keine Bewertungen

- Huck® Interactive CD Rom: Specifications: Pneudraulic Powered Installation ToolDokument2 SeitenHuck® Interactive CD Rom: Specifications: Pneudraulic Powered Installation ToolkpNoch keine Bewertungen

- NMC G51Dokument2 SeitenNMC G51kpNoch keine Bewertungen

- Eng CD Atum-19x4-0 2Dokument1 SeiteEng CD Atum-19x4-0 2kpNoch keine Bewertungen

- KEMET Part Number: PHE450MD6270JR06L2: (F450DT274J630Z)Dokument1 SeiteKEMET Part Number: PHE450MD6270JR06L2: (F450DT274J630Z)kpNoch keine Bewertungen

- HF Highly Flexible Heat-Shrinkable TubingDokument2 SeitenHF Highly Flexible Heat-Shrinkable TubingkpNoch keine Bewertungen

- Eng CD DR-25 B1Dokument1 SeiteEng CD DR-25 B1kpNoch keine Bewertungen

- Altera MT2000 Modified, Medical Grade, Polyolefin, Heat - Shrinkable TubingDokument2 SeitenAltera MT2000 Modified, Medical Grade, Polyolefin, Heat - Shrinkable TubingkpNoch keine Bewertungen

- Eng CD JS-XX-XX HDokument1 SeiteEng CD JS-XX-XX HkpNoch keine Bewertungen

- Thermomagnetic Device Circuit Breaker - TMC 81D 02A - 2907627Dokument3 SeitenThermomagnetic Device Circuit Breaker - TMC 81D 02A - 2907627kpNoch keine Bewertungen

- Source: Https://assist - Dla.mil - Downloaded: 2015-03-06T06:16Z Check The Source To Verify That This Is The Current Version Before UseDokument2 SeitenSource: Https://assist - Dla.mil - Downloaded: 2015-03-06T06:16Z Check The Source To Verify That This Is The Current Version Before UsekpNoch keine Bewertungen

- 12phase 525 ALLDokument3 Seiten12phase 525 ALLkpNoch keine Bewertungen

- Thermal Interface Material (TIM) Design Guidance For Flip Chip BGA Package Thermal PerformanceDokument6 SeitenThermal Interface Material (TIM) Design Guidance For Flip Chip BGA Package Thermal PerformancekpNoch keine Bewertungen

- Stanley Engineering TB68-1 Corrosion MethodsDokument8 SeitenStanley Engineering TB68-1 Corrosion MethodskpNoch keine Bewertungen

- Ald1107/ald1117: A L D IDokument6 SeitenAld1107/ald1117: A L D ISantiago Cadena AlvarezNoch keine Bewertungen

- Various Optical Amplifiers (EDFA, FRA, and SOA) - Anritsu Asia PacificDokument4 SeitenVarious Optical Amplifiers (EDFA, FRA, and SOA) - Anritsu Asia Pacificvishal yadavNoch keine Bewertungen

- Unit 4 - Bipolar Junction TransistorDokument38 SeitenUnit 4 - Bipolar Junction TransistorCel LuviaNoch keine Bewertungen

- Grounding and CablingDokument40 SeitenGrounding and CablingUjjal Kumar BhattacharyaNoch keine Bewertungen

- (TE 074 HU) Analog Multimeter 1Dokument6 Seiten(TE 074 HU) Analog Multimeter 1Gasdiesel MechanicNoch keine Bewertungen

- I. Project Background and DescriptionDokument18 SeitenI. Project Background and DescriptionBelle Boholts Busis100% (1)

- Org A No Metallic CompoundsDokument17 SeitenOrg A No Metallic Compoundsthestar55100% (2)

- How To Make A Simple DC To DC Cell Phone Charger CircuitDokument31 SeitenHow To Make A Simple DC To DC Cell Phone Charger CircuitShibu Kumar SNoch keine Bewertungen

- Design A 60hz Notch Filter With The Uaf42 (Sbfa012)Dokument3 SeitenDesign A 60hz Notch Filter With The Uaf42 (Sbfa012)rafaelchristNoch keine Bewertungen

- Automatic Visitor Counter CircuitDokument4 SeitenAutomatic Visitor Counter CircuithloNoch keine Bewertungen

- Mems PDFDokument79 SeitenMems PDFPavithra KumarNoch keine Bewertungen

- Sparsh Chopra Personal StatementDokument3 SeitenSparsh Chopra Personal StatementSparshChopraNoch keine Bewertungen

- "Multilevel Inverter With Reduced Switches": A Major-Project Report OnDokument66 Seiten"Multilevel Inverter With Reduced Switches": A Major-Project Report OnKshitija KalyankarNoch keine Bewertungen

- LCR Meter: Presented By: Diya RoyDokument8 SeitenLCR Meter: Presented By: Diya Roydiya royNoch keine Bewertungen

- Maintenance Guide SA-10,20Dokument16 SeitenMaintenance Guide SA-10,20Ayaovi Jorlau100% (4)

- B 5233-1/-2 / H51q-HS/HRS (0605)Dokument14 SeitenB 5233-1/-2 / H51q-HS/HRS (0605)mshahabahmadNoch keine Bewertungen

- Pressure Sensor PDFDokument19 SeitenPressure Sensor PDFdavidNoch keine Bewertungen

- Solar Energy Materials & Solar CellsDokument19 SeitenSolar Energy Materials & Solar Cellsyaash3sharmaNoch keine Bewertungen

- Medium Voltage Distribution: U-Series Three-Phase Recloser/ W-Series Single-Phase Recloser With ADVC ControllerDokument24 SeitenMedium Voltage Distribution: U-Series Three-Phase Recloser/ W-Series Single-Phase Recloser With ADVC ControllerTỏa SángNoch keine Bewertungen

- BF200Dokument3 SeitenBF200Bhadreshkumar SharmaNoch keine Bewertungen

- (Ebook) Radio & Electronics Course - 81 - Power Supply 12 Volt 3 Amp PDFDokument1 Seite(Ebook) Radio & Electronics Course - 81 - Power Supply 12 Volt 3 Amp PDFDavidNoch keine Bewertungen

- Bai Tap - Vat Lieu Hoc - Phan Tinh Chat - NTS - v1Dokument26 SeitenBai Tap - Vat Lieu Hoc - Phan Tinh Chat - NTS - v1Hoàng BeeNoch keine Bewertungen

- 40-Gb/s Transimpedance Amplifier in 0.18 - M CMOS Technology: Jun-De Jin and Shawn S. H. HsuDokument4 Seiten40-Gb/s Transimpedance Amplifier in 0.18 - M CMOS Technology: Jun-De Jin and Shawn S. H. HsuTshering Sangmo SherpaNoch keine Bewertungen

- Berges Acm STDDokument64 SeitenBerges Acm STDAdan Solano50% (4)

- Sony-KDL-50-60-70-R551A-R550A-R555A-R557A-RB1FK CHASSIS-L3Dokument50 SeitenSony-KDL-50-60-70-R551A-R550A-R555A-R557A-RB1FK CHASSIS-L3pasantito67% (3)

- Static DriveDokument74 SeitenStatic DriveDrive SynqNoch keine Bewertungen

- Sla6868mz - Ds LoneDokument18 SeitenSla6868mz - Ds LoneRivaldyNoch keine Bewertungen

- Si924x - Class D Audio Driver With Precision Dead-Time GeneratorDokument1 SeiteSi924x - Class D Audio Driver With Precision Dead-Time GeneratorBen M'rad SkanderNoch keine Bewertungen

- Logic Families MCQs SimpleDokument8 SeitenLogic Families MCQs SimplebijukumargNoch keine Bewertungen

- Monolithic PLL IC 565 ApplicationsDokument10 SeitenMonolithic PLL IC 565 Applicationslord_Moran50% (2)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesVon EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNoch keine Bewertungen

- A Place of My Own: The Architecture of DaydreamsVon EverandA Place of My Own: The Architecture of DaydreamsBewertung: 4 von 5 Sternen4/5 (242)

- Civil Engineer's Handbook of Professional PracticeVon EverandCivil Engineer's Handbook of Professional PracticeBewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialVon EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNoch keine Bewertungen

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionVon EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionBewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishVon EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishBewertung: 4 von 5 Sternen4/5 (3)

- Building Construction Technology: A Useful Guide - Part 1Von EverandBuilding Construction Technology: A Useful Guide - Part 1Bewertung: 4 von 5 Sternen4/5 (3)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsVon EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseVon EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseBewertung: 5 von 5 Sternen5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyVon EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyBewertung: 4 von 5 Sternen4/5 (1)

- History of Smart Textiles: A Comprehensive Guide To E-TextilesVon EverandHistory of Smart Textiles: A Comprehensive Guide To E-TextilesNoch keine Bewertungen

- Power Electronics Diploma Interview Q&A: Career GuideVon EverandPower Electronics Diploma Interview Q&A: Career GuideNoch keine Bewertungen

- Estimating Construction Profitably: Developing a System for Residential EstimatingVon EverandEstimating Construction Profitably: Developing a System for Residential EstimatingNoch keine Bewertungen

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEVon EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEBewertung: 4 von 5 Sternen4/5 (1)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideVon Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideBewertung: 3.5 von 5 Sternen3.5/5 (7)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsVon EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsBewertung: 1 von 5 Sternen1/5 (4)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftVon EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftBewertung: 5 von 5 Sternen5/5 (5)

- Real Life: Construction Management Guide from A-ZVon EverandReal Life: Construction Management Guide from A-ZBewertung: 4.5 von 5 Sternen4.5/5 (4)