Beruflich Dokumente

Kultur Dokumente

RIL CoE Earthing Specs

Hochgeladen von

DINESHCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

RIL CoE Earthing Specs

Hochgeladen von

DINESHCopyright:

Verfügbare Formate

BEST MAINTENANCE PRACTICE

RIL-CoMEE/BPD/E/017

EARTHING

Reliance

9 Specifications for Earthing system (Generic)

9.1

Specifications

The specifications for Earthing system shall include the following

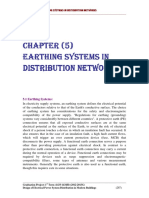

Fig 15:

1.

2.

2nd Letter

1st Letter

Situation of installation frames

Situation of supply

T = Exposed frames directly earthed

T = Direct connection of

Transformer Neutral with the earth

I = Neutral unearthed or

High Impedance-earthed

N = Frames connected to the supply point

which is earthed,

either by a separate Protective Earth

conductor (S).

Or combined with the Neutral (C)

a) TN system - has one or more points of the source of energy directly earthed, and the exposed

and extraneous conductive parts of the installation are connected by means of protective

conductors to the earthed point(s) of the source, that is, there is a metallic path for earth fault

currents to flow from the installation to the earthed point(s) of the source. TN systems are

further sub-divided into TN-C, TN-S and TN-C-S systems.

Prepared by:Uma

Rev No: 00

Visvanathan

Date of Issue:

Reviewed by:

H.K.Moorthy

Centre of Maintenance & Engineering Excellence

(For Internal Circulation Only)

27/07/2010

Page 50 of 65

Approved by:

A.Venkatraman

The copyright of this document is vested in Reliance Industries Ltd, Mumbai. All rights reserved. Neither the whole nor any part of this document may be

reproduced, stored in any retrieval system or transmitted in any form or by any means (electronic, mechanical reprographic, recording or otherwise) without the

prior written consent of the copyright owner.

BEST MAINTENANCE PRACTICE

RIL-CoMEE/BPD/E/017

EARTHING

Reliance

b) TT system - has one or more points of the source of energy directly earthed and the exposed

and extraneous conductive parts of the installation are connected to a local earth electrode or

electrodes are electrically independent of the source earth(s).

c) IT system - has the source either unearthed or earthed through a high impedance and the

exposed conductive parts of the installation are connected to electrically independent earth

electrodes.

In practice, a system may be an admixture of the above types, which may be designated as

follows.

TN-S System (for 240 V single phase domestic/commercial supply) - Systems where there

are separate neutral and protective conductors throughout the system. A system where the

metallic path between the installation and the source of energy is the sheath and armouring of

the supply cable

Indian TN-S System (for 415 V three phase domestic commercial supply) - An independent

earth electrode within the consumers premises is necessary

Indian TN-C-System - The neutral and protective functions are combined in a single

conductor throughout the system (for example earthed concentric wiring.

TN-C-S System - The neutral and protective functions are combined in a single conductor but

only in part of the system

T-TN-S System (for 6.6/11 kV three-phase bulk supply) - The consumers installation, a TN-S

system receiving power at a captive substation through a delta connected transformer

primary

TT System (for 415V three-phase industrial supply) - has one or more points of the source of

energy directly earthed and the exposed and extraneous conductive parts of the installation

are connected to a local earth electrode or electrodes are electrically independent of the

source earth(s).

Prepared by:Uma

Rev No: 00

Visvanathan

Date of Issue:

Reviewed by:

H.K.Moorthy

Centre of Maintenance & Engineering Excellence

(For Internal Circulation Only)

27/07/2010

Page 51 of 65

Approved by:

A.Venkatraman

The copyright of this document is vested in Reliance Industries Ltd, Mumbai. All rights reserved. Neither the whole nor any part of this document may be

reproduced, stored in any retrieval system or transmitted in any form or by any means (electronic, mechanical reprographic, recording or otherwise) without the

prior written consent of the copyright owner.

BEST MAINTENANCE PRACTICE

RIL-CoMEE/BPD/E/017

EARTHING

Reliance

IT System - has the source either unearthed or earthed through a high impedance and the

exposed conductive parts of the installation are connected to electrically independent earth

electrodes.

9.2

Marking on the Earthing Conductor

The earthing and protective conductor shall be marked as given in Table below.

Table 6:

Designation of

conductor

Identification by

Alpha numeric

Colour

Graphical symbol

notation

Earth

No colour other than

the colour of the bare

conductor

Protective conductor

PB

Green & Yellow

Use of Bi-Colour Combination - Green and Yellow - The bi-colour combination, green and yellow

(green/yellow), shall be used for identifying the protective conductor and for no other purpose. This is

the only colour code recognized for identifying the protective conductor, as per IS 3043.

Bare conductors or bus bars, used as protective conductors, shall be coloured by equally broad green

and yellow stripes, each 15 mm up to 100 mm wide, close together, either throughout the length of

each conductor or in each compartment or unit or at each accessible position. If adhesive tape is used,

only bi-coloured tape shall be applied.

Prepared by:Uma

Rev No: 00

Visvanathan

Date of Issue:

Reviewed by:

H.K.Moorthy

Centre of Maintenance & Engineering Excellence

(For Internal Circulation Only)

27/07/2010

Page 52 of 65

Approved by:

A.Venkatraman

The copyright of this document is vested in Reliance Industries Ltd, Mumbai. All rights reserved. Neither the whole nor any part of this document may be

reproduced, stored in any retrieval system or transmitted in any form or by any means (electronic, mechanical reprographic, recording or otherwise) without the

prior written consent of the copyright owner.

BEST MAINTENANCE PRACTICE

RIL-CoMEE/BPD/E/017

EARTHING

Reliance

For insulated conductors, the combination of the colours, green and yellow, shall be such that, on any

15 mm length of insulated conductor, one of these colours covers at least 30 percent and not more

than 70 percent of the surface of the conductor, the other colour covering the remainder of that

surface.

NOTE - Where the protective conductor can be easily identified from its shape, construction or

position, for example, a concentric conductor, then colour coding throughout its length is not

necessary but the ends or accessible positions should be clearly identified by a symbol or the bi-colour

combination, green and yellow.

10 Failure Modes Analysis

The integrity of the Earthing system may get affected on account of the following Improper Design

Inadequate capacity of Electrodes

Improper Installation

Corrosion

Exposure to chemical / solvents

Mechanical damage

Loose connection

Exposure to undue vibration

Human error

Unauthorized modification, repair or adjustments

Inappropriate maintenance

Prepared by:Uma

Rev No: 00

Visvanathan

Date of Issue:

Reviewed by:

H.K.Moorthy

Centre of Maintenance & Engineering Excellence

(For Internal Circulation Only)

27/07/2010

Page 53 of 65

Approved by:

A.Venkatraman

The copyright of this document is vested in Reliance Industries Ltd, Mumbai. All rights reserved. Neither the whole nor any part of this document may be

reproduced, stored in any retrieval system or transmitted in any form or by any means (electronic, mechanical reprographic, recording or otherwise) without the

prior written consent of the copyright owner.

Das könnte Ihnen auch gefallen

- 02 - Smartscreen Handout 01 - Supplies & Earthing-1Dokument5 Seiten02 - Smartscreen Handout 01 - Supplies & Earthing-1Daniel HollandsNoch keine Bewertungen

- l3 305-01 Handout Supplies & Earthing 2017Dokument5 Seitenl3 305-01 Handout Supplies & Earthing 2017Iffi KingggNoch keine Bewertungen

- Earthing System: Presented By: Md. Noman Saber KhanDokument78 SeitenEarthing System: Presented By: Md. Noman Saber Khansardarmkhan100% (2)

- Instrumentation Earthing System: - June 10, 2010Dokument14 SeitenInstrumentation Earthing System: - June 10, 2010indira_tungNoch keine Bewertungen

- 2005 16 Autumn Wiring Matters Earthing Your Questions AnsweredDokument7 Seiten2005 16 Autumn Wiring Matters Earthing Your Questions AnsweredDemetrios GkikasNoch keine Bewertungen

- Naming Electricity System Earthing ArrangementsDokument11 SeitenNaming Electricity System Earthing ArrangementsRazek WardNoch keine Bewertungen

- Earthing SchemesDokument16 SeitenEarthing SchemesKatik XalxoNoch keine Bewertungen

- TT, TN, and IT Earthing Systems ExplainedDokument21 SeitenTT, TN, and IT Earthing Systems ExplainedAamir AliNoch keine Bewertungen

- He HeheDokument47 SeitenHe HeheWinwinwin DeldeldeldelNoch keine Bewertungen

- Suppy Sytem and UPS GroundingDokument38 SeitenSuppy Sytem and UPS GroundinggabrielmpfNoch keine Bewertungen

- Geoff CronshawDokument51 SeitenGeoff Cronshawselmir_9Noch keine Bewertungen

- Earthing Systems ExplainedDokument7 SeitenEarthing Systems ExplainedNoor Zamri SudinNoch keine Bewertungen

- Earthing SystemsDokument6 SeitenEarthing SystemsRob PettitNoch keine Bewertungen

- Types of Earthing SystemsDokument2 SeitenTypes of Earthing Systemsalimran.tec1Noch keine Bewertungen

- Electrical Grounding Systems ExplainedDokument5 SeitenElectrical Grounding Systems ExplainedEri Febriansya100% (1)

- 2011 40 Autumn Wiring Matters EarthingDokument8 Seiten2011 40 Autumn Wiring Matters EarthingsourcNoch keine Bewertungen

- Earthing SystemDokument14 SeitenEarthing SystemNelson A. García RodríguezNoch keine Bewertungen

- Figure: High Touch Voltage Created by Improper GroundingDokument3 SeitenFigure: High Touch Voltage Created by Improper Groundinglvb123Noch keine Bewertungen

- Earthing system types and their characteristicsDokument8 SeitenEarthing system types and their characteristicsTony KontisNoch keine Bewertungen

- Types of Earthing Systems - What Is TT, IT & TN EarthingDokument9 SeitenTypes of Earthing Systems - What Is TT, IT & TN EarthingKamranNoch keine Bewertungen

- What Is The IslandingDokument11 SeitenWhat Is The IslandingSatheesh Kumar NatarajanNoch keine Bewertungen

- LV Distribution: Chapter EDokument14 SeitenLV Distribution: Chapter EVitor MachadoNoch keine Bewertungen

- T: Direct Connection of A With Earth Point (French: Terre)Dokument5 SeitenT: Direct Connection of A With Earth Point (French: Terre)Rajendra Prasad ShuklaNoch keine Bewertungen

- Earthing System: Eletrical Installation (EET0142)Dokument27 SeitenEarthing System: Eletrical Installation (EET0142)Khalied HafeezNoch keine Bewertungen

- Earthing SystemsDokument21 SeitenEarthing SystemsGia BảoNoch keine Bewertungen

- Earthing System - Wikipedia, The Free EncyclopediaDokument7 SeitenEarthing System - Wikipedia, The Free EncyclopediaSharaf Ali ZyoudNoch keine Bewertungen

- Te1.1e AaDokument57 SeitenTe1.1e AaSicoe VasileNoch keine Bewertungen

- Diff Earthing in AC Power Systems - TN TT and ITDokument16 SeitenDiff Earthing in AC Power Systems - TN TT and ITamitabhsrivastavaNoch keine Bewertungen

- Question Bank For SEWA Electrical Engineer ExamDokument7 SeitenQuestion Bank For SEWA Electrical Engineer ExamShahida Babeesh100% (2)

- Broken Earth Neutral Faults in Distribution Systems With Traffic Signal LoadsDokument13 SeitenBroken Earth Neutral Faults in Distribution Systems With Traffic Signal LoadsRajendra Prasad ShuklaNoch keine Bewertungen

- EarthingDokument8 SeitenEarthingSatyender Kumar Jain100% (1)

- Abstracts From Eg 201 147, Tr-nwt-000295, Tr-nwt-000154 and Gr-947-Core With Specific Reference To Grounding Requirements in Telecommunications EquipmentDokument4 SeitenAbstracts From Eg 201 147, Tr-nwt-000295, Tr-nwt-000154 and Gr-947-Core With Specific Reference To Grounding Requirements in Telecommunications Equipmentpmarshall6479Noch keine Bewertungen

- Grounding System MethodsDokument5 SeitenGrounding System MethodsgaxyvNoch keine Bewertungen

- PTDU - Distribution Systems-General (B)Dokument30 SeitenPTDU - Distribution Systems-General (B)Bilal AhmadNoch keine Bewertungen

- Earthing SystemDokument10 SeitenEarthing SystemnishanthaindikaNoch keine Bewertungen

- Earthing System - Wikipedia, The Free EncyclopediaDokument7 SeitenEarthing System - Wikipedia, The Free EncyclopediagiriNoch keine Bewertungen

- Erection Procedures of Earthing Arrangements TNC TNS TNCS and TTDokument7 SeitenErection Procedures of Earthing Arrangements TNC TNS TNCS and TTPierre Enrique Carrasco Fuentes0% (1)

- IEC Earthing Types TN, TT, ITDokument5 SeitenIEC Earthing Types TN, TT, ITNavneet Singh100% (1)

- GroundingDokument28 SeitenGroundingDewanto WicaksonoNoch keine Bewertungen

- Earthing SystemDokument7 SeitenEarthing SystemUvmnour BarwaryNoch keine Bewertungen

- Types of Earthing (As Per IEC Standards)Dokument7 SeitenTypes of Earthing (As Per IEC Standards)visakhgsNoch keine Bewertungen

- Earthing Systems PDFDokument7 SeitenEarthing Systems PDFJORGE SILVANoch keine Bewertungen

- Good Earthing Practices For Generator System (Presentation) PDFDokument20 SeitenGood Earthing Practices For Generator System (Presentation) PDFMokr AchourNoch keine Bewertungen

- UPS Application Guide: 16 Neutral SystemsDokument9 SeitenUPS Application Guide: 16 Neutral SystemstceterexNoch keine Bewertungen

- 016 - UPS Applications Guide General ElectricDokument9 Seiten016 - UPS Applications Guide General ElectricDante FilhoNoch keine Bewertungen

- Earthing System Types Explained - ELEK SoftwareDokument21 SeitenEarthing System Types Explained - ELEK SoftwareFESCO WAPDANoch keine Bewertungen

- Types of Earthing System 1642354875Dokument6 SeitenTypes of Earthing System 1642354875Bahaa MounirNoch keine Bewertungen

- 2005 16 Autumn Wiring Matters Earthing Your Questions AnsweredDokument7 Seiten2005 16 Autumn Wiring Matters Earthing Your Questions AnsweredAbhijeet KulkarniNoch keine Bewertungen

- AGN 038 - Earthing: Application Guidance Notes: Technical Information From Cummins Generator TechnologiesDokument10 SeitenAGN 038 - Earthing: Application Guidance Notes: Technical Information From Cummins Generator TechnologiesariwibowoNoch keine Bewertungen

- 02.04 - Earthing Systems Used in LVDokument4 Seiten02.04 - Earthing Systems Used in LVNivona27Noch keine Bewertungen

- TN, TT, ItDokument14 SeitenTN, TT, ItTuan Anh Le CongNoch keine Bewertungen

- Earthing SystemDokument9 SeitenEarthing SystemmaheshshettymteducarNoch keine Bewertungen

- Civil Grounding System ReportDokument10 SeitenCivil Grounding System ReportMessi ArabNoch keine Bewertungen

- 41.R2 - DC EOP Specification SheetDokument9 Seiten41.R2 - DC EOP Specification SheetsuperthambiNoch keine Bewertungen

- Barreto Electromagnetic InterferenceDokument6 SeitenBarreto Electromagnetic InterferenceGiuseppe FerrariNoch keine Bewertungen

- Earthing System: From Wikipedia, The Free EncyclopediaDokument6 SeitenEarthing System: From Wikipedia, The Free EncyclopediaAliq FazliNoch keine Bewertungen

- Characteristics of TT TN and IT Systems - 2Dokument6 SeitenCharacteristics of TT TN and IT Systems - 2okk chuNoch keine Bewertungen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionNoch keine Bewertungen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- FireShot Capture 037 - Forward & Reverse Direction of Induction Motor and DC Motor - ElectriDokument1 SeiteFireShot Capture 037 - Forward & Reverse Direction of Induction Motor and DC Motor - ElectriDINESHNoch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- FireShot Capture 034 - What Is MCB, Construction, Working, Types of MCB B, C, D, K - ElectDokument1 SeiteFireShot Capture 034 - What Is MCB, Construction, Working, Types of MCB B, C, D, K - ElectDINESHNoch keine Bewertungen

- FireShot Capture 035 - Why PT Burden Is High Compare With CT Burden - Electrical4uDokument1 SeiteFireShot Capture 035 - Why PT Burden Is High Compare With CT Burden - Electrical4uDINESHNoch keine Bewertungen

- FireShot Capture 031 - What Is MPCB, Working, Construction, Selection, AdvantageDokument1 SeiteFireShot Capture 031 - What Is MPCB, Working, Construction, Selection, AdvantageDINESHNoch keine Bewertungen

- FireShot Capture 032 - What Is Busbar Current Carrying Capacity Calculation 5 Types of BusbaDokument1 SeiteFireShot Capture 032 - What Is Busbar Current Carrying Capacity Calculation 5 Types of BusbaDINESHNoch keine Bewertungen

- FireShot Capture 028 - Top 6 Difference Between Copper and Aluminium Cables - Electrical4uDokument1 SeiteFireShot Capture 028 - Top 6 Difference Between Copper and Aluminium Cables - Electrical4uDINESHNoch keine Bewertungen

- FireShot Capture 032 - What Is Busbar Current Carrying Capacity Calculation 5 Types of BusbaDokument1 SeiteFireShot Capture 032 - What Is Busbar Current Carrying Capacity Calculation 5 Types of BusbaDINESHNoch keine Bewertungen

- FireShot Capture 036 - Why Capacitor Is Required For Single Phase Motor - Electrical4uDokument1 SeiteFireShot Capture 036 - Why Capacitor Is Required For Single Phase Motor - Electrical4uDINESHNoch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- FireShot Capture 029 - What Is Normally Open & What Is Normally Closed (Video Included) - ElDokument1 SeiteFireShot Capture 029 - What Is Normally Open & What Is Normally Closed (Video Included) - ElDINESHNoch keine Bewertungen

- FireShot Capture 026 - Earthing Procedure For Electrical Panel & Home Appliances - ElectricaDokument1 SeiteFireShot Capture 026 - Earthing Procedure For Electrical Panel & Home Appliances - ElectricaDINESHNoch keine Bewertungen

- Earthing Bonding Variable Speed DrivesDokument26 SeitenEarthing Bonding Variable Speed Drivesmitesh.rivonkarNoch keine Bewertungen

- FireShot Capture 029 - What Is Normally Open & What Is Normally Closed (Video Included) - ElDokument1 SeiteFireShot Capture 029 - What Is Normally Open & What Is Normally Closed (Video Included) - ElDINESHNoch keine Bewertungen

- FireShot Capture 028 - Top 6 Difference Between Copper and Aluminium Cables - Electrical4uDokument1 SeiteFireShot Capture 028 - Top 6 Difference Between Copper and Aluminium Cables - Electrical4uDINESHNoch keine Bewertungen

- Electrical Earthing - Definition, Types of Electrical Earthing & GroundingDokument8 SeitenElectrical Earthing - Definition, Types of Electrical Earthing & GroundingDINESHNoch keine Bewertungen

- FireShot Capture 031 - What Is MPCB, Working, Construction, Selection, AdvantageDokument1 SeiteFireShot Capture 031 - What Is MPCB, Working, Construction, Selection, AdvantageDINESHNoch keine Bewertungen

- Pyranometer - Design, Types, Advantages, Disadvantages & ApplicationsDokument8 SeitenPyranometer - Design, Types, Advantages, Disadvantages & ApplicationsDINESHNoch keine Bewertungen

- FireShot Capture 026 - Earthing Procedure For Electrical Panel & Home Appliances - ElectricaDokument1 SeiteFireShot Capture 026 - Earthing Procedure For Electrical Panel & Home Appliances - ElectricaDINESHNoch keine Bewertungen

- Drift Current and Diffusion Current and Their DifferencesDokument6 SeitenDrift Current and Diffusion Current and Their DifferencesDINESHNoch keine Bewertungen

- Earthing Bonding Variable Speed DrivesDokument3 SeitenEarthing Bonding Variable Speed DrivesDINESHNoch keine Bewertungen

- Residential Wiring Guide IntroductionDokument32 SeitenResidential Wiring Guide Introductionfree bird100% (1)

- CN Unit 5Dokument19 SeitenCN Unit 5GokulakrishnanNoch keine Bewertungen

- Ibps Po' PDF: 25 Important Questions of Spotting The Error (English Language)Dokument7 SeitenIbps Po' PDF: 25 Important Questions of Spotting The Error (English Language)DINESHNoch keine Bewertungen

- 03 Slights Electrical Wiring PDFDokument39 Seiten03 Slights Electrical Wiring PDFDINESHNoch keine Bewertungen

- Unit 4Dokument67 SeitenUnit 4RK KNoch keine Bewertungen

- Unit 3Dokument32 SeitenUnit 3RK KNoch keine Bewertungen

- Blood Relation Questions For IBPS PO 2017Dokument7 SeitenBlood Relation Questions For IBPS PO 2017sanjay shuklaNoch keine Bewertungen

- Electric Machinery Fundamentals-1Dokument28 SeitenElectric Machinery Fundamentals-1AmaniDarwishNoch keine Bewertungen

- CN Unit 2 - 2Dokument55 SeitenCN Unit 2 - 2bhuvi2312Noch keine Bewertungen

- POwer House For Blue PrintDokument1 SeitePOwer House For Blue Printahah pogiNoch keine Bewertungen

- BBPP MPV BMTI/Automotive Reskilling & Upskilling 2020 Ignition System RepairDokument6 SeitenBBPP MPV BMTI/Automotive Reskilling & Upskilling 2020 Ignition System RepairNengah Saputra WijayaNoch keine Bewertungen

- Aromat 5v 6 Pin RelayDokument2 SeitenAromat 5v 6 Pin RelaycarolsangiorgeNoch keine Bewertungen

- Lista Chint ExelDokument27 SeitenLista Chint ExelRodolfo Calvo0% (1)

- By 238Dokument5 SeitenBy 238Merényi Oszkár100% (1)

- Schematic Page 1 2 Notes 3: A Original Release Designer DateDokument3 SeitenSchematic Page 1 2 Notes 3: A Original Release Designer DateAhsan ShabbirNoch keine Bewertungen

- Sensor Conector DOL 1204 G02MDokument4 SeitenSensor Conector DOL 1204 G02MGVS-ValentimNoch keine Bewertungen

- Electrical Part List PDFDokument18 SeitenElectrical Part List PDFDELTA TELECOMNoch keine Bewertungen

- Operating Mannual of Digital Automatic Voltage Regulator (Davr)Dokument31 SeitenOperating Mannual of Digital Automatic Voltage Regulator (Davr)ArvindPrasadNoch keine Bewertungen

- Circuit Symbols of Electronic ComponentsDokument8 SeitenCircuit Symbols of Electronic ComponentsGautam VadnereNoch keine Bewertungen

- EATON Vol04 - Tab03Dokument135 SeitenEATON Vol04 - Tab03Anonymous Ot5Wg7yAFNoch keine Bewertungen

- Catálogo Completo ContatoresDokument239 SeitenCatálogo Completo ContatoresdiegoparodeNoch keine Bewertungen

- 1150079001-002 - Manual 30kVA UPS PDFDokument275 Seiten1150079001-002 - Manual 30kVA UPS PDFCarlos Torrez80% (5)

- Assignment 4: Self-Excited Compound-Wound DC GeneratorDokument11 SeitenAssignment 4: Self-Excited Compound-Wound DC GeneratorRenz MykoNoch keine Bewertungen

- Vaishno Pricelist 10.07Dokument6 SeitenVaishno Pricelist 10.07Mohit KhatriNoch keine Bewertungen

- Bureau of Design: Schedule of Loads and Computations: General NotesDokument1 SeiteBureau of Design: Schedule of Loads and Computations: General NotesJuan IstilNoch keine Bewertungen

- 45relay Rm4ua PDFDokument1 Seite45relay Rm4ua PDFtamky SubstationNoch keine Bewertungen

- Technical specs panel control systemDokument18 SeitenTechnical specs panel control systemDeni DendenNoch keine Bewertungen

- Outdoor Live Tank SF6 Circuit Breaker Type EDF SKDokument6 SeitenOutdoor Live Tank SF6 Circuit Breaker Type EDF SKAltagracia Sugeidy PadillaNoch keine Bewertungen

- 7UT51xx Catalog SIP2004s enDokument2 Seiten7UT51xx Catalog SIP2004s enHeudes JuniorNoch keine Bewertungen

- A4-P 1.0 enDokument1.020 SeitenA4-P 1.0 enTrần Văn Phúc100% (1)

- Circuit Symbols of Electronic ComponentsDokument8 SeitenCircuit Symbols of Electronic ComponentsCasandra ClarkNoch keine Bewertungen

- Induction MachineDokument5 SeitenInduction MachineRaj Kumar PatelNoch keine Bewertungen

- SGIM-3268H - GMI Breaker PDFDokument52 SeitenSGIM-3268H - GMI Breaker PDFJavi MosqueraNoch keine Bewertungen

- Sy8089aaac - C78988 OriginalDokument10 SeitenSy8089aaac - C78988 Originaljonathan hernandezNoch keine Bewertungen

- Training - Power System Protection - AREVADokument461 SeitenTraining - Power System Protection - AREVAMallikarjun Reddy100% (47)

- Electronic Devices and Circuits Unit GuideDokument109 SeitenElectronic Devices and Circuits Unit GuideALEX SAGARNoch keine Bewertungen

- Key - SLD - R2Dokument1 SeiteKey - SLD - R2Satya Narayana BandaruNoch keine Bewertungen

- Revision of The CBEMA CurveDokument39 SeitenRevision of The CBEMA Curveyasir_639Noch keine Bewertungen