Beruflich Dokumente

Kultur Dokumente

Whitepaper2013 UPSSafety.251

Hochgeladen von

negrumih1683Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Whitepaper2013 UPSSafety.251

Hochgeladen von

negrumih1683Copyright:

Verfügbare Formate

The Not-So-Shocking Truths About UPS Safety

A candid Q&A about reducing the risks associated with servicing data center UPSs

Bob Lauricella

Environmental Health and Safety Manager

Eaton

Zachary Greenhaw

EHS Analyst

Eaton

Executive summary

When working with data center and commercial facility electrical systems, shocks of 100mA to more than

2,000mA are possible definitely in the realm of serious harm to humans and property. Energized electrical

equipment also presents the risk of arc flash caused by electrical faults that produce powerful explosions.

When dealing with commercial and industrial electrical systems, such as uninterruptible power systems

(UPSs) and their batteries, data center and facilities managers need to be aware of these risks, especially

since some repair and maintenance procedures require working with a unit that is still energized.

There are ways to minimize the risks to employees, equipment and the field technician performing the

service. This paper answers some common questions about UPS maintenance, how to reduce the risks

associated with servicing UPSs and batteries, and how to qualify a UPS service provider.

Table of contents

Introduction ............................................................................................................................................. 2

A candid conversation about UPS service and safety ....................................................................... 2

What types of services do UPSs need? ................................................................................................... 2

What actions are taken during a preventive maintenance visit? .............................................................. 3

Who performs this service? Can we do it ourselves? .............................................................................. 4

What will the service vendors field technicians do to work safely on my UPS? ...................................... 4

What can we do to minimize the risk? ...................................................................................................... 6

How can we assess the safety practices of a service vendor? ................................................................ 7

Closing thoughts .................................................................................................................................... 7

About Eaton ............................................................................................................................................ 8

About the authors ................................................................................................................................... 8

WP161003EN

www.eaton.com/powerquality

October 2013

Page 2 of 8

Introduction

Get an electrical shock at 1mA and youll feel a mild tingling sensation.

At 5mA, youll feel the shock, but it probably wont seem painful or disturbing.

A shock in the 6mA to 16mA range is painful and can cause injury from involuntary

muscle contractions.

A shock in the 17mA to 99mA range is enough to trigger respiratory arrest and loss of muscle

control, including losing the ability to let go. Fatal consequences are possible.

When working with data center and commercial facility power systems, shocks of 100mA to more than

2,000mA are possible. We dont have to detail the consequences to the human body of taking an electrical

shock of that magnitude. Its not good.

Energized electrical equipment also presents the risk of arc flash the energy release that occurs during an

electrical fault when current flows through the air between two live conductors, causing a short circuit. In a

residential setting, arc flashes usually produce little more than a brief flash of light before extinguishing

themselves harmlessly. In a commercial or industrial setting, however, voltages and current are much

higher, so arc flashes routinely produce powerful explosions marked by searing heat, toxic fumes, blinding

light, deafening noise, flying shrapnel, and massive pressure waves.

According to Electrical Safety Foundation International (ESFI), 2,000 workers are admitted to burn centers

each year for treatment of severe arc flash burns.

When dealing with commercial and industrial electrical systems, such as UPSs and their batteries, the

safest place to be is away. But this equipment requires preventive and restorative maintenance, which

usually requires technicians to be working near the unit, even inside it, and sometimes when its still

energized.

Fortunately, there are ways to minimize the risk to your employees, the equipment and the field technician

performing the service. This paper answers some common questions about UPS maintenance and how to

reduce the risks associated with servicing UPSs and their batteries.

A candid conversation about UPS service and safety

What types of services do UPSs need?

UPSs protect and power the equipment that runs essential business systems, industrial and medical

processes, and communications networks the very pulse of the organization. Unplanned outages can

quickly add up to hundreds of thousands of dollars in lost revenue or even lost lives. Generally, if a UPS

protects the equipment, its because downtime is not an option.

Preventive maintenance dramatically improves the performance, availability and service life of this critical

equipment. It should be intuitive that the better you take care of any equipment, the better it will perform and

the less likely it will experience problems.

UPSs that receive no preventive maintenance have a 400 percent greater chance of load loss, compared to

properly maintained UPSs. Analysis of millions of operating hours for thousands of UPSs has shown that

mean time between failures (MTBF) for UPSs that receive preventive maintenance twice a year is more

than 20 times better than for UPSs that receive no preventive maintenance. Increase the frequency of

preventive maintenance to quarterly, even monthly, and UPS reliability and service life just keep getting

better. Prevention pays off.

Dont forget batteries in preventive maintenance plans. According to the Institute of Electrical and

Electronics Engineers (IEEE): Proper maintenance will prolong the life of a battery and will help enable the

battery to satisfy its design requirements. A good battery maintenance program will serve as a valuable aid

in maximizing battery life, preventing avoidable failures, and reducing premature replacement.

WP161003EN

www.powerquality.eaton.com

October 2013

Page 3 of 8

Repair service addresses the reality that even the best-made components eventually wear out and need to

be replaced. Capacitors, circuit boards, fans, batteries and power supplies are all consumable parts that

you can expect to periodically replace in a UPS. A well-designed UPS configuration simplifies this process

to minimize mean time to repair (MTTR) and restore function as quickly as possible.

What actions are taken during a preventive maintenance visit?

The field technician will perform a variety of checks and inspections, both visual and with diagnostic tools.

For example, infrared thermography identifies loose connections, which show up hotter than good

connections. Visual inspection of connection points shows evidence of soot marks or degradation that could

signal a short circuit or bad connection. Computer analysis of the error log and alarm history can point to

impending problems, such as a loss of insulating value on a cable.

Following industry guidelines, a customer engineer may conduct the following preventive maintenance

activities:

For the UPS:

Measure and record input AC voltages and currents on all three phases.

Measure and record delta voltage at the static switch.

Measure and record rectifier output DC voltage and adjust if needed.

Measure and record AC voltages and currents on all three phases.

Test static switch for no break transfer.

Test all alarms for proper operation.

Measure and record all DC power supply voltages, and adjust if needed.

Test all indicator lamps and report any that are not operating.

Inspect all ground connections and wire insulation for electrical safety.

Vacuum its interior.

Inspect air filters and replace if needed.

Inspect input and output conductors and tighten to manufacturer specifications.

Document each inspection done along with actions taken or recommendations made.

For UPS batteries:

Check the appearance, safety, cleanliness and temperature of the battery room.

Make sure ventilation equipment is deployed per the manufacturer specifications.

Test each battery with a 100-ampere load applied for 10 seconds.

Measure and record the cell voltage and specific gravity of each battery cell.

Re-torque cell connections and micro-ohm to manufacturer specifications.

Measure internal impedance of all cells to manufacturer specifications.

Check for corrosion on battery terminals and advise whether teardown is needed.

Check batteries for cell leaks or cracks and repair or replace as necessary.

Check battery cables and clean, repair or replace as needed.

Check the integrity of rack mounting, tighten as required, and notify of any structural damage.

Inspect the charger and inverter.

Check grounds, connections, wire insulation and electrical safety, and repair as needed.

Calibrate ammeters and voltmeters to manufacturer specifications.

Calibrate charger DC output current to manufacturer specifications, float and equalize voltage.

Calibrate inverter AC output current to manufacturer specifications, float and equalize voltage.

Calibrate timers, alarm relays and indicator lamps to manufacturer specifications.

This is just a sampling. IEEE Std 450-2010 outlines even more comprehensive guidelines for monthly,

quarterly and annual maintenance.

WP161003EN

www.powerquality.eaton.com

October 2013

Page 4 of 8

Who performs this service? Can we do it ourselves?

You may hear an electrician talk about the dead front in a UPS. Its the unfortunate

nickname for the galvanized steel plate behind the attractive black faceplate of a data

center UPS.

When you remove that handsome, black front panel, this dead front is what separates

people from the electricity. If that plate is removed, the UPS had better be fully shut down,

with no chance of it being energized by a secondary source.

The more complicated the equipment becomes, the more important it is to have experts perform the

maintenance to keep it running smoothly. Without the right safety training, and without expensive (and often

complex and proprietary) diagnostic, analysis and connectivity tools, UPS owners can perform only very

limited service themselves. For example, a technician might be able to scroll through the alarm history and

see voltage fluctuations, but not gain clarity into why these events are happening or know what to do about

it.

Some self-sufficiency is possible with interactive learning programs. For example, Eaton sells a DVD that

TM

trains users to do some basic maintenance on their Power Xpert 9395 UPS and some other models.

Such training is like learning to change the oil and rotate the tires, but not to deal with the dreaded check

engine light. The inner workings of modern UPSs are more complex than a standard electrician is prepared

to handle.

Furthermore, because large UPSs carry dangerous electrical voltages, all types of service to these units

presents the potential for personal harm and property damage to anyone without extensive safety training.

Even powering down the unit is complex. Consider that UPSs and their surrounding electrical

infrastructures are designed to prevent the power from going off, so even if the main power source is

switched off and the UPS itself is turned off, the equipment could still be getting power from other sources,

such as battery, generator or secondary utility feed. Consider also that some procedures, such as infrared

thermography and measurements of voltage, currency, resistance, and capacitance, must be done with the

unit fully operational.

Do you want anyone other than a highly trained UPS service engineer to be tackling that risk, when its so

easy to take advantage of that expertise through service contracts?

UPSs under warranty or extended service contracts after the warranty period receive recommended

preventive maintenance and repair services from authorized, trained field technicians as needed. For

smaller single-phase UPSs, manufacturers typically have authorized and trained independent contractors to

provide this service. For the larger three-phase UPSs, you can expect the field technician to be factorytrained and certified by the manufacturer.

In rare instances, UPSs are in such remote locations that the only practical solution is for the manufacturer

to train the customers employees to service the UPS themselves. In that case, it must be configured such

that everything in the UPS cabinet can be completely de-energized. More on that later.

What will the service vendors field technicians do to work safely on my UPS?

Field technicians follow risk reduction and mitigation strategies set forth by the Occupational Safety and

Health Administration (OSHA) and the National Fire Protection Association (NFPA), which have written

standards and regulations that build on one another to help protect workers from electrical hazards in the

workplace.

Wear protective gear. Even when working with a de-energized unit, the field technician should be wearing

non-conductive safety glasses, safety clothing designed to withstand heat up to 8 cal/cm, and leather

safety boots. Working with an energized unit requires either Level 2 (bodywear rated to 8 cal/cm) or Level

4 (protection rated to 40 cal/cm), depending on calculations. At Level 4, the field technician will also wear a

40-cal/cm arc flash protection hood, hearing protection and two sets of gloves. Anything that exceeds 40

cal/cm requires an escalation in safety level, because the energy associated with a possible blast is

extremely dangerous.

WP161003EN

www.powerquality.eaton.com

October 2013

Page 5 of 8

Personal protective equipment requires increased supervision and its effectiveness may be limited. For

instance, an EH hardhat with tinted face shield protects the face but does not offer side impact protection.

Nitrile gloves provide chemical resistance but do not protect against punctures and abrasion. Defects or

excessive wear can inhibit the effectiveness of any gear. Gloves should be inspected daily and regularly recertified. Hardhats should be replaced every five years.

Furthermore, employees may wear incorrect personal protective equipment (PPE) for the task at hand.

Wearing Level 2 PPE for a task with an energy level associated with Level 4 can result in a catastrophe.

This is why proper training on safety gear and a culture of excellent safety are extremely important.

NFPA standards for PPE are set forth in Table 130.7(C)(16) of the NFPA 70 national electrical code safety

standard: Protective Clothing and Personal Protective Equipment.

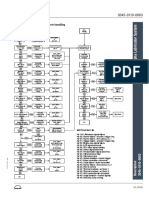

Keep appropriate distance from the unit. Only employees with work justification should enter arc

flash/shock protection boundaries. Shock protection boundaries are listed in NFPA 70 Table 140.4(C)(a):

Approach Boundaries to Energized Electrical Conductors or Circuit Parts for Shock Protection for

Alternating Current Systems, and Table 130.4(C)(a): Approach Boundaries to Energized Electrical

Conductors or Circuit Parts for Shock Protection for Direct Current Systems.

Eaton uses a conservative general rule of 10 for the arc flash boundary. Annex D of the NFPA 70E

standard provides a calculation to determine exact boundaries. Annex D of the NFPA 70E standard

provides a calculation to determine exact boundaries. Eaton has a conservative rule of 10 for the arc flash

boundary and only qualified persons with the necessary skills, training, tools and personal protective

equipment (PPE) should be within 4 of an energized unit.

Figure 1. Establish safety zones and protocols for qualified and unqualified personnel.

Have appropriate training and certification. Field technicians must have training and knowledge to

perform their jobs effeciently while maintaining a safe work enviroment, as per OSHA requirements,

specifically:

OSHA Part 1910, Occupational Safety and Health Standards

OSHA Part 1926, Safety and Health Regulations for Construction

This training should be comprehensive, covering principles of electrical hazards such as arc flash,

procedures for incident reporting, personal protective equipment, driving safety, back safety and

ergonomics, hazard recognition and communication, and waste handling. This training should be validated

and/or refreshed periodically, at least annually.

WP161003EN

www.powerquality.eaton.com

October 2013

Page 6 of 8

What can we do to minimize the risk?

Prepare ahead and keep good records. Keep single-line diagrams up-to-date, so theres a reliable record

of the data centers or facilitys electrical system. Hold pre-job meetings and brief employees on their roles

and safe work practices.

Implement an employee training program to ensure data center personnel understand arc flash dangers

and how to avoid them. Be sure every existing and new employee receives this training.

Configure each UPS with a maintenance bypass. The last thing any data center manager would want to

hear is, Sorry, but Im going to have to turn off your data center while I work on the UPS. A maintenance

bypass provides an alternate power path that bypasses the UPS circuitry altogether. A field technician can

then safely service or replace a UPS without interrupting power to loads and without danger of electrical

shock.

Smaller UPSs, in the range of 2 to 30kVA, might have an internal maintenance bypass located on or inside

the UPS cabinet. When a field technician switches to maintenance bypass operation, almost all of the UPS

cabinet is de-energized. The portion of the UPS cabinet thats still poweredwhere the maintenance

bypass residesis shielded behind metal baffling or a metal wall. The engineer has safe access to the

most frequently serviced components and can do fairly extensive work without undue risk.

For larger UPSs, loads are generally so critical that an external maintenance bypass is used, usually in a

wall-mounted cabinet. Because the bypass path is physically separate, the entire UPS cabinet can be

completely de-energized, and field technicians can work in confidence.

A maintenance bypass is not required, but it is strongly recommended on every hardwired UPS, even when

the UPS has been configured for redundancy. It is a relatively simple device that provides a strong benefit

for most any application from 2kVA and uppowerful insurance for a modest additional cost. It is the safest

way for field technicians to work on the unit, the safest configuration for your employees, and the safest way

to protect the equipment and the load.

Implement arc flash reduction strategies. Every arc flash mitigation program should begin with a hazard

analysisusually performed with help from a qualified power systems engineerto calculate the amount of

energy an arc flash could release at various points along the power chain.

IT and facilities managers can dramatically mitigate arc flash likelihood and severity by:

Reducing the amount of available fault current

Decreasing the time required to clear faults

Anticipating and eliminating the conditions that cause faults

Redirecting the blast force of an arc flash through the use of arc-resistant switchgear

Post signage on equipment warning of arc flash danger. The NFPA 70E standard requires employers

to post signage notifying employees of potential arc flash dangers. Organizations that overlook this directive

dramatically increase their chances of paying serious fines and losing lawsuits after arc flash incidents.

The arc flash hazard risk category cannot accurately be determined until the energy potential is evaluated in

context. The parameters of a potential arc flash eventhow much force/fire are likely and how long it will

lastare functions of how much power is being connected in the unit and how quickly the interruption

device (such as fuse, breaker or the UPS itself) will activate. Since this risk rating can vary for each aisle of

a power setup, manufacturers should not apply arc flash labels to equipment as it ships out. Onsite

evaluation is available as a service once the equipment is installed.

To ensure data center employees are always aware of potential arc flash hazards, companies should mark

arc flash hazard zones on the floor so workers not wearing PPE can clearly see how far they must keep

away from electrical equipment to avoid potential injury.

WP161003EN

www.powerquality.eaton.com

October 2013

Page 7 of 8

Select a service vendor with a strong safety record. Whether you choose to get your UPS service from the

manufacturer or a third-party vendor, choose a provider with a proven track record of safe performance. To

reduce liability and injury risk, ask to see records that show a solid safety record in terms of protecting field

technicians and customers employees and property in the RFP process.

How can we assess the safety practices of a service vendor?

UPS service vendors must be able to show you several tangible measures of their safety performance and

commitment as evidenced in safety practices and reportable incidents.

Recordable incident rate. Incidence rates can be used to show the relative level of injuries and illnesses

among different industries, firms or operations within a single firm. Because a common base and a specific

period of time are involved, these rates can help determine both problem areas and progress in preventing

work-related safety incidents.

Experience modification rate. In workers compensation experience ratings, the actual payroll and loss

data of the individual employer are analyzed over a period of time. Usually, the latest available three years

of data are compared to similarly grouped risks to calculate the experience modification.

In general, an employer with better-than-average loss experience receives a credit, while an employer with

worse-than-average experience carries a debit rating. The experience rating is generated by taking the

average loss experience and modifying it based on the individuals own loss experience.

Training and safety protocols. Eliminating safety incidents is a matter of recognizing and evaluating the

risks, then implementing the correct controls to prevent or mitigate them. Review the service providers

procedures related to insurance, employment checks, safety programs, OSHA/EPA citations in the previous

three years, management systems (such as ISO 14001 and OHSAS 18001), and initial and refresher

training for field technicians.

At a minimum, training programs should include instruction in the following areas:

OSHA 10/30 general industry/construction requirements

NFPA 70E arc flash safety protocols

Electrical safe work practices, including proper use of personal protective gear

Lockout-tagout (LOTO) safety procedures to ensure that electrical gear is properly shut off and not

started up again until the maintenance or service work has been completed

First aid and cardio-pulmonary resuscitation (CPR)

Closing thoughts

The risks associated with high-energy voltages are serious, but there are many ways to prevent incidents or

reduce their effects. Prevention is foremost; mitigation is the second line of defense. To put it in other terms,

if you have activated your cars air bag, youre already having a bad day. Its much better to have good

visibility, tires and brakes so you can avoid the incident in the first place.

For more information on arc flash safety, please refer to Eatons white papers, What You Need to Know

About Arc Flashes and Arc Flash Safety in 400V Data Centers. The NFPA National Electrical Code is also

available online.

WP161003EN

www.powerquality.eaton.com

October 2013

Page 8 of 8

About Eaton

Eaton is a diversified power management company providing energy-efficient solutions that help our

customers effectively manage electrical, hydraulic and mechanical power. With 2012 sales of $16.3 billion,

Eaton is a global technology leader in electrical products, systems and services for power quality,

distribution and control, power transmission, lighting and wiring products; hydraulics components, systems

and services for industrial and mobile equipment; aerospace fuel, hydraulics and pneumatic systems for

commercial and military use; and truck and automotive drivetrain and powertrain systems for performance,

fuel economy and safety. Eaton acquired Cooper Industries plc in 2012. Eaton has approximately 103,000

employees and sells products to customers in more than 175 countries.

For more information, visit www.eaton.com.

About the authors

Bob Lauricella is the Sub-Regional Environmental Health and Safety Manager for the Southeast Region of

the US. He has a Bachelors of Science degree in Mechanical Engineering from Michigan Technological

University and has been working with Eaton for the past 6 years. He can be reached at

BobLauricella@Eaton.com

Zach Greenhaw is EHS Analyst for Eatons UPS Field Service organization in Eatons Power Quality

Division in Raleigh, North Carolina. He has a degree in Environmental & Occupation Management from

Methodist University and has been working in the EHS field for nearly 5 years. He can be reached at

ZacharyGreenhaw@Eaton.com

WP161003EN

www.powerquality.eaton.com

October 2013

Das könnte Ihnen auch gefallen

- Staff Mobility For TeachingDokument3 SeitenStaff Mobility For Teachingnegrumih1683Noch keine Bewertungen

- Web Technical Note 2-Meshing and FEADokument3 SeitenWeb Technical Note 2-Meshing and FEAnegrumih1683Noch keine Bewertungen

- Whitepaper2013 UPSSafety.251Dokument8 SeitenWhitepaper2013 UPSSafety.251negrumih1683Noch keine Bewertungen

- Phospholipids From Herring Roe. BjorndalDokument33 SeitenPhospholipids From Herring Roe. Bjorndalnegrumih1683Noch keine Bewertungen

- Xlswrite Write Microsoft Excel Spreadsheet FileDokument4 SeitenXlswrite Write Microsoft Excel Spreadsheet Filenegrumih1683Noch keine Bewertungen

- Pleiadian SoulDokument2 SeitenPleiadian Soulnegrumih1683Noch keine Bewertungen

- Title of The Paper (14pt Times New Roman, Bold, Left Alignment)Dokument2 SeitenTitle of The Paper (14pt Times New Roman, Bold, Left Alignment)negrumih1683Noch keine Bewertungen

- ADEM 2014 Registration FormDokument1 SeiteADEM 2014 Registration Formnegrumih1683Noch keine Bewertungen

- UV Creates Vitamin D and Skin Cancer - 2009Dokument6 SeitenUV Creates Vitamin D and Skin Cancer - 2009negrumih1683Noch keine Bewertungen

- Agenda Ansysr 2013Dokument1 SeiteAgenda Ansysr 2013negrumih1683Noch keine Bewertungen

- Editing Instructions For Authors-CE-PhD2014Dokument3 SeitenEditing Instructions For Authors-CE-PhD2014negrumih1683Noch keine Bewertungen

- Post Conference InvitationDokument1 SeitePost Conference Invitationnegrumih1683Noch keine Bewertungen

- Pliant ICMSAV 2014 - Call2Dokument2 SeitenPliant ICMSAV 2014 - Call2negrumih1683Noch keine Bewertungen

- Abstract 1Dokument3 SeitenAbstract 1negrumih1683Noch keine Bewertungen

- Lsda Ada21210ucvDokument2 SeitenLsda Ada21210ucvnegrumih1683Noch keine Bewertungen

- Alimente - Medicament PDFDokument6 SeitenAlimente - Medicament PDFArina_m100% (1)

- SFSFSFSFDokument2 SeitenSFSFSFSFChristian Gerald DanielNoch keine Bewertungen

- Pleiadian SoulDokument2 SeitenPleiadian Soulnegrumih1683Noch keine Bewertungen

- Agenda Ansysr 2013Dokument1 SeiteAgenda Ansysr 2013negrumih1683Noch keine Bewertungen

- SFSFSFSFDokument2 SeitenSFSFSFSFChristian Gerald DanielNoch keine Bewertungen

- Agenda Ansysr 2013Dokument1 SeiteAgenda Ansysr 2013negrumih1683Noch keine Bewertungen

- ETABS v9.5.0 - File: Final - May 10,2013 21:50 3-D View - KN-M UnitsDokument1 SeiteETABS v9.5.0 - File: Final - May 10,2013 21:50 3-D View - KN-M Unitsnegrumih1683Noch keine Bewertungen

- Post Conference InvitationDokument1 SeitePost Conference Invitationnegrumih1683Noch keine Bewertungen

- Seismic Building Codes in JapanDokument2 SeitenSeismic Building Codes in Japanpushpak2312Noch keine Bewertungen

- FINAL-Arch Steel Building Optimization Used in Civil Engineering, by Finite Element MethodDokument6 SeitenFINAL-Arch Steel Building Optimization Used in Civil Engineering, by Finite Element Methodnegrumih1683Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Manual Te 805 EnuDokument11 SeitenManual Te 805 EnuMutu Daniel100% (2)

- Class 12 Cbse Investigatory Project On RC CircuitDokument4 SeitenClass 12 Cbse Investigatory Project On RC CircuitRishav Sureka0% (1)

- Dynex Hisense Service Manual DX L40 10ADokument50 SeitenDynex Hisense Service Manual DX L40 10Acmh88888100% (1)

- SAGEM Link F User GuideDokument123 SeitenSAGEM Link F User Guidemsplm28100% (2)

- DSP - Nov 19 Q&a PDFDokument17 SeitenDSP - Nov 19 Q&a PDFAnonymous yO7rcec6vuNoch keine Bewertungen

- (550 0105 M) SPKEManualDokument1 Seite(550 0105 M) SPKEManualDALGUERRENoch keine Bewertungen

- Verilog Coding For Digital SystemDokument12 SeitenVerilog Coding For Digital SystemBalajeNoch keine Bewertungen

- Beckwith-Generator Protection 1Dokument188 SeitenBeckwith-Generator Protection 1Catrina FedericoNoch keine Bewertungen

- Adams Motor Build From Old Cds - Vs 1Dokument16 SeitenAdams Motor Build From Old Cds - Vs 1Léo Pénicaud100% (1)

- Centurion List PriceDokument3 SeitenCenturion List Pricehubul_watanNoch keine Bewertungen

- Training Report: Bharat Electronics Limited, PanchkulaDokument22 SeitenTraining Report: Bharat Electronics Limited, PanchkulaSajalNoch keine Bewertungen

- Rymsa At15-250 Panel Uhf Pol. HorizontalDokument1 SeiteRymsa At15-250 Panel Uhf Pol. HorizontalLuis RamosNoch keine Bewertungen

- 63 Sequence Diagram For Alarm HandlingDokument1 Seite63 Sequence Diagram For Alarm HandlingNick SkiadasNoch keine Bewertungen

- Cable Arrangement For Reduced Magnetic FieldDokument5 SeitenCable Arrangement For Reduced Magnetic FieldzwerrNoch keine Bewertungen

- Investigatory Project of PhysicsDokument19 SeitenInvestigatory Project of Physicsshubham singhNoch keine Bewertungen

- Siemens: Programming GuideDokument459 SeitenSiemens: Programming Guideplantaolaminado07Noch keine Bewertungen

- TPG 3 (Stringset)Dokument4 SeitenTPG 3 (Stringset)rostyo tioNoch keine Bewertungen

- GES Pricelist Solar PanelDokument18 SeitenGES Pricelist Solar PanelKapil MishraNoch keine Bewertungen

- Gallien Krueger bl112 Poweramp 206 0151Dokument17 SeitenGallien Krueger bl112 Poweramp 206 0151electromusicworkshopNoch keine Bewertungen

- FPGA On SOM Example 469 EuroDokument30 SeitenFPGA On SOM Example 469 Euroyahia elshakhsNoch keine Bewertungen

- EK 2009 Complete EDokument260 SeitenEK 2009 Complete EABELWALIDNoch keine Bewertungen

- Syllabus ECE 30500 - SchubertDokument2 SeitenSyllabus ECE 30500 - Schubertnawinnawmu1026Noch keine Bewertungen

- Q Q Q Q Q Q Q: Functional DescriptionDokument10 SeitenQ Q Q Q Q Q Q: Functional DescriptionDiego Pacheco VelaNoch keine Bewertungen

- Bankura MapDokument27 SeitenBankura MapSUSOVAN BISWASNoch keine Bewertungen

- JVS Manual JRP 011Dokument12 SeitenJVS Manual JRP 011Tamilventhan_sNoch keine Bewertungen

- DC Machines1.1 1Dokument19 SeitenDC Machines1.1 1Janaka Chathuranga AbeywardenaNoch keine Bewertungen

- Diagramas Esquematicos TV LED LGDokument49 SeitenDiagramas Esquematicos TV LED LGLuis Alonso Rosero Velez100% (1)

- Power Xpert Solar 250 KW Inverter - Harvest The Power of The SunDokument2 SeitenPower Xpert Solar 250 KW Inverter - Harvest The Power of The SunEmilio EscalanteNoch keine Bewertungen

- 1 - Installation Manual - OTS3-PigtailsDokument8 Seiten1 - Installation Manual - OTS3-PigtailsJavier LeónNoch keine Bewertungen

- High Voltage Transient AnalysisDokument11 SeitenHigh Voltage Transient AnalysiskasunchamaraNoch keine Bewertungen