Beruflich Dokumente

Kultur Dokumente

Product Data Fr100 FRP

Hochgeladen von

Anonymous r3MoX2ZMTOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Product Data Fr100 FRP

Hochgeladen von

Anonymous r3MoX2ZMTCopyright:

Verfügbare Formate

PRODUCT DATA

FR100

FIRE RESISTANT COATING

FOR INDUSTRIAL USE ONLY

DESCRIPTION

FR100 is a premium quality water based, nontoxic, thin film

intumescent coating formulated to provide a fire retardant,

resistant barrier on a variety of interior substrates, including FRP

composite laminates. It is suitable for residential, multifamily,

commercial and industrial projects, for both new and

reconstruction projects. FR100 is approved only for interior use

on C-Clad, E-Clad and PS-C FRP composite systems, and is not

designed for use on structural steel.

ADVANTAGES

Non toxic

Water based

Class A rated for use with C-Clad, E-Clad and PS-C FRP

composite systems (ASTM E84).

Apply two coats of

FR100 with a minimum total dry film thickness of 20 mils

over LinForce -C, -E and -CS FRP composite systems to

achieve the intended ASTM E 84 results in accordance with

Test Report Number RJ1434-1.

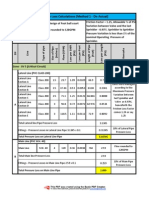

TYPICAL DATA

Physical Properties

Colors

Standard: off-white. May be custom tinted. Please

consult FRP Solutions for approved tinting products.

Sheen

Flat

Self Life One (1) year from the date of purchase when kept at

recommended storage conditions and in original

unopened containers.

CAUTION

Not designed for use on structural steel.

Approved for interior use (for exterior use, please contact

FRP Solutions).

Do not freeze or expose FR100 to freezing temperatures.

DO NOT THIN OR STRAIN.

Minimum surface application temperature is 50F (10C).

PACKAGING

FR100 is supplied in 5 gallon buckets. For projects requiring

larger containers, please contact FRP Solutions sales office.

COVERAGE

1 Gallon FR100 yields a theoretical spread rate of 114 sq ft/gal

per 1 coat when applied at a rate of 14 mils wet (10 mils dry).

STORAGE

Store dry at 40F (4C) - 85F (29C).

HOW TO USE

NOTE:

FR100 must be applied by a licensed painter experienced in

performing the work on projects of similar scope and scale. FRP

Solutions will provide proper application instructions to the

licensed painter contractor selected by the General Contractor

or Owner.

SURFACE PREPARATION:

All surfaces to be coated must be clean, cured, firm, dry and

free of dust, dirt, oil, wax, grease, mildew, loose flaking paint,

efflorescence or any other contamination or condition that would

adversely affect the performance of the coating. Fill holes and

surface irregularities with a suitable patching compound to

match surface profile. Etch or prime glossy, glazed or dense

surfaces with a latex primer or fast dry oil base primer/sealer

where permissible. Always prime oil based finish coatings with

an oil based fast dry primer/sealer. Spot prime all patched areas

with appropriate primer. Metal surfaces must be free of rust.

APPLICATION:

Precautions:

Do not use the product and discard if it has been frozen or has

come into contact with contaminants prior to use. Do not apply

at temperatures below 50F. Do not thin. Apply at can

consistency.

FR100 may be applied by brush or roller. For brush application,

a fully loaded brush should be used. A laying on technique will

reduce the brush marking. A short nap roller can be used but

this may result in a slight textured finish.

For spray applications, use an airless sprayer with a dedicated

spray line. For a list of recommended spray equipment, please

contact FRP Solutions.

If multiple coats of FR100 are required, the surface must be

thoroughly dry to the touch prior to the application of each

additional coat.

FR100 has a flat finish but may be top coated with most paints

to achieve the desired texture and finish.

Enamel finish coat:

Apply one (1) coat of a latex primer or fast dry oil base

primer/sealer over FR100 before applying a latex enamel or oil

base enamel finish coat.

Wall covering applications:

Apply one (1) coat of wall primer over product before applying

wall covering.

For information on approved compatible primers and finish

paints, contact FRP Solutions. Apply additional finish coats only

after previously applied coats are thoroughly dry.

DRYING:

Dry time is when the surface is thoroughly dry to the touch.

Drying times are dependent upon a number of factors including

temperature, air movement, humidity, product thickness, and

Product Data FR100 Rev. 0410.1

Page 1 of 2

PRODUCT DATA

FR100

FIRE RESISTANT COATING

FOR INDUSTRIAL USE ONLY

method of application. If unsure, please contact FRP Solutions

Technical Services.

Dry film thickness:

During the drying process, FR100 shrinks due to evaporation.

The final dry film thickness will vary according to specific

construction assemblies. The dry film thickness required will

depend on the specific fire rating and substrates to be protected.

Please contact FRP Solutions Technical Services for assistance

with determining the appropriate dry film thickness of the

coating.

INSPECTION AND MEASUREMENT OF THICKNESS:

During application, the wet film thickness should be checked

using a wet film thickness gauge. To use the gauge, insert the

teeth into the wet basecoat. The last tooth to be coated indicates

the wet film thickness achieved. It is important to ensure that the

wet film is applied in a sufficient thickness to give the required

dry film thickness.

All applicable surfaces coated with FR100 should be inspected

by a third party special inspection agency, an ICC certified

professional, or a FRP Solutions QA/QC qualified inspector to

verify that FR100 has been properly and uniformly applied in

the required thickness.

If an independent testing agency is retained, it should ensure

that preparation of substrate is in accordance with

manufacturers recommendations. It should randomly obtain and

test samples during application to verify that wet film thickness

of the intumescent coating complies with manufacturers

requirements.

DISCLAIMER OF WARRANTIES AND LIMITATION OF

LIABILITY

FRP Solutions INC. ("Seller") warrants its products to be free of defects in

material and workmanship for a period of ONE (1) YEAR from the date of

purchase.

Under this Warranty and limitation of liability, FRP Solutions will

provide, at no charge, product and containers to replace any product. FRP

Solutions's obligation hereunder, is limited solely to such replacement and is

subject to receipt by FRP Solutions of a written notice of any alleged defects,

promptly after discovery thereof, within the warranty period. Absence of such

notice in writing during the warranty period constitutes a waiver of all claims with

respect to such product. This Warranty excludes discoloration or change in visual

appearance of the product due to the accumulation of or streaking of dirt or other

airborne materials deposited on the surface from the atmosphere. FRP Solutions

does not warrant the colorfastness of any product unless specifically stated

otherwise. Before application, the Buyer shall determine the suitability of the

product for the intended use and Buyer assumes all risks and liabilities

whatsoever in connection therewith. THIS WARRANTY IS MADE IN LIEU OF

ANY AND ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND/OR FITNESS

FOR A PARTICULAR PURPOSE, WHICH ARE HEREBY DISCLAIMED. IT IS

UNDERSTOOD AND AGREED THAT BUYER'S SOLE REMEDY, AND

THEREFORE SELLER'S LIABILITY, WHETHER IN CONTRACT, TORT,

WARRANTY, IN NEGLIGENCE, OR OTHERWISE, SHALL BE LIMITED TO

THE RETURN OF THE PURCHASE PRICE PAID BY PURCHASER OR

REPLACEMENT OF ANY DEFECTIVE GOODS SOLD BY SELLER AND

UNDER NO CIRCUMSTANCES SHALL SELLER BE LIABLE FOR SPECIAL,

INCIDENTAL, INDIRECT OR CONSEQUENTIAL DAMAGES. THE PRICE

STATED FOR THE GOODS IS A CONSIDERATION IN LIMITING SELLER'S

LIABILITY. The terms of this paragraph may not be orally modified. THERE ARE

NO WARRANTIES, WHICH EXTEND BEYOND THE FACE HEREOF.

MANUFACTURER INFORMATION

For more information about this product, please contact

CLEANUP:

Wash brushes, rollers, spray guns & pumps and other painting

tools in cold clean water promptly after painting. Clean and

remove any dried product with the use of Goof Off or similar

cleaning products. To clean up spills, absorb with inert material.

Technical Division

FRP SOLUTIONS, INC.

th

982 W 10 Street

Azusa, CA 91702

USA

Dispose of all waste properly according to applicable

federal, state and local disposal requirements.

Tel.: +1 626-815-3978

Fax: +1 626-812-9583

MAINTENANCE:

Surfaces which have been coated with FR100 should be

protected from abuse and abrasion. Damaged surfaces should

be repaired and FR100 should be reapplied to the original

specified dry film thickness to maintain specific rating.

CAUTION - FOR INDUSTRIAL USE ONLY

Use with adequate ventilation. Do not breathe spray mist or

sanding dust. Avoid contact with eyes and prolonged or

repeated contact with skin. Wear eye protection and or gloves

during application or sanding. A dust/particulate respirator

approved by NIOSH should be worn when sanding or spraying.

Close the product container after each use. First Aid: If you

experience difficulty breathing, leave the area to obtain fresh air.

Product Data FR100 Rev. 0410.1

Page 2 of 2

Das könnte Ihnen auch gefallen

- Quality Assurance: Application Guide Jotafloor SealerDokument1 SeiteQuality Assurance: Application Guide Jotafloor SealerTamerTamerNoch keine Bewertungen

- X-Shield SF Primer PDFDokument2 SeitenX-Shield SF Primer PDFAhmed TahaNoch keine Bewertungen

- ApplicationDokument2 SeitenApplicationPaul GartheNoch keine Bewertungen

- Interwall S.a.C. - Garantía Policarbonato Compacto Makrolon Bayer SL Sun LifeDokument2 SeitenInterwall S.a.C. - Garantía Policarbonato Compacto Makrolon Bayer SL Sun LifeBruno AmacifuenNoch keine Bewertungen

- Cloverdale EcosheetDokument2 SeitenCloverdale EcosheetJennyNoch keine Bewertungen

- ASF Blast Mitigation Daylight ApplicationDokument5 SeitenASF Blast Mitigation Daylight ApplicationmarkstonellNoch keine Bewertungen

- Armorgrout 100Dokument3 SeitenArmorgrout 100Ua AnyanhunNoch keine Bewertungen

- Flamex One: Flexible Intumescent SealantDokument3 SeitenFlamex One: Flexible Intumescent SealantBalasubramanian AnanthNoch keine Bewertungen

- Properties Foster Duct-Fas® Adhesive (Non-Flammable) : Product Data SheetDokument2 SeitenProperties Foster Duct-Fas® Adhesive (Non-Flammable) : Product Data SheetOscar ZelayaNoch keine Bewertungen

- 450S PDS AiDokument2 Seiten450S PDS Ai전상문Noch keine Bewertungen

- 892HS PDSDokument2 Seiten892HS PDSgabriel__regioNoch keine Bewertungen

- Concrete Bonder & Fortifier: SafetyDokument1 SeiteConcrete Bonder & Fortifier: SafetyBrianNoch keine Bewertungen

- 7 535099 Series Valspar Reserve Interior Latex Flat PaintDokument2 Seiten7 535099 Series Valspar Reserve Interior Latex Flat PaintCarlos Choque0% (1)

- Armor Expanseal 100: General Purpose Construction Polysulphide Joint SealantDokument2 SeitenArmor Expanseal 100: General Purpose Construction Polysulphide Joint SealantRey BanriNoch keine Bewertungen

- Clariant Flyer EXOLIT AP 435 201703 ENDokument2 SeitenClariant Flyer EXOLIT AP 435 201703 EN20154001Noch keine Bewertungen

- PPGPMC AmershieldDokument2 SeitenPPGPMC AmershieldMad HouseNoch keine Bewertungen

- Polyprime NP: Primer For Non-Porous JointsDokument2 SeitenPolyprime NP: Primer For Non-Porous JointsaahtagoNoch keine Bewertungen

- Alseal 598Dokument2 SeitenAlseal 598Hernan GirautNoch keine Bewertungen

- @PSX 700 InfoDokument3 Seiten@PSX 700 InfoAnandNoch keine Bewertungen

- Hardtop f20Dokument7 SeitenHardtop f20nuryati jahariNoch keine Bewertungen

- Interprime 160Dokument0 SeitenInterprime 160Mehman NasibovNoch keine Bewertungen

- 90S PDSDokument2 Seiten90S PDS전상문Noch keine Bewertungen

- DC786 TechnicalDokument3 SeitenDC786 TechnicalfanofphonicsNoch keine Bewertungen

- 10 Year Limited WarrantyDokument2 Seiten10 Year Limited WarrantyBERSE MAJU INDONESIANoch keine Bewertungen

- Increte Clear SealDokument2 SeitenIncrete Clear SealBrembertNoch keine Bewertungen

- A Guide For FLUOR & BASF Painting Specification of Typical Storage Tanks (Part 03 of 05)Dokument5 SeitenA Guide For FLUOR & BASF Painting Specification of Typical Storage Tanks (Part 03 of 05)Adam Michael GreenNoch keine Bewertungen

- Formula 150 Primer (MILDTL-24441)Dokument4 SeitenFormula 150 Primer (MILDTL-24441)Trịnh Minh KhoaNoch keine Bewertungen

- 830431Dokument3 Seiten830431number_25Noch keine Bewertungen

- AG 15400 Steelmaster+120SB Euk GBDokument10 SeitenAG 15400 Steelmaster+120SB Euk GBparathasiNoch keine Bewertungen

- Relipoxy P 301: Epoxy Based PrimerDokument3 SeitenRelipoxy P 301: Epoxy Based PrimerPRERAKNoch keine Bewertungen

- Penguard PrimerDokument5 SeitenPenguard PrimerPutroedidohNoch keine Bewertungen

- Futura Classic: Technical Data Sheet Application GuideDokument7 SeitenFutura Classic: Technical Data Sheet Application GuideyugandharNoch keine Bewertungen

- Hardtop XP: Technical Data Sheet Application GuideDokument7 SeitenHardtop XP: Technical Data Sheet Application GuideAye Min TunNoch keine Bewertungen

- DS 122 Rev 01 Epilux 4 High Build Epoxy FinishDokument2 SeitenDS 122 Rev 01 Epilux 4 High Build Epoxy FinishSuriya NaanNoch keine Bewertungen

- Hayparoof: Technical Data SheetDokument3 SeitenHayparoof: Technical Data SheetHisham BerrasaliNoch keine Bewertungen

- 9 PDSDokument2 Seiten9 PDS전상문Noch keine Bewertungen

- FlameOFF ApplicationGuideDokument15 SeitenFlameOFF ApplicationGuideAlpha DekoNoch keine Bewertungen

- Nitoproof 10Dokument2 SeitenNitoproof 10Balasubramanian Ananth67% (3)

- Dunlop FC Jointing Compound DatasheetDokument1 SeiteDunlop FC Jointing Compound Datasheetppdd792Noch keine Bewertungen

- Alk-774 TDSDokument2 SeitenAlk-774 TDSManuel Antonio Oñate CarvajalNoch keine Bewertungen

- Enviroline 2405 Application Guidelines: Protective Coatings Technical SupportDokument12 SeitenEnviroline 2405 Application Guidelines: Protective Coatings Technical SupportskNoch keine Bewertungen

- 791 SiliconeDokument3 Seiten791 SiliconeSufen ZhangNoch keine Bewertungen

- Fos Roc Polyurea FLMDokument4 SeitenFos Roc Polyurea FLMAhmed TahaNoch keine Bewertungen

- FlameStopI FicheTechnique EngDokument1 SeiteFlameStopI FicheTechnique EngTestNoch keine Bewertungen

- Dulux Sealer BinderDokument2 SeitenDulux Sealer BindercoatingsNoch keine Bewertungen

- Basf Masterrheobuild 1000 TdsDokument3 SeitenBasf Masterrheobuild 1000 TdsDevendraNoch keine Bewertungen

- Hardtop XP: Technical Data Sheet Application GuideDokument7 SeitenHardtop XP: Technical Data Sheet Application GuideAlmaNoch keine Bewertungen

- Bamboo Products WarrantyDokument2 SeitenBamboo Products Warrantyjonzak1234Noch keine Bewertungen

- D5402Dokument3 SeitenD5402masv79251267% (3)

- Intercare 123Dokument4 SeitenIntercare 123Trịnh Minh KhoaNoch keine Bewertungen

- Carboline 4688: Selection Data Specification DataDokument2 SeitenCarboline 4688: Selection Data Specification DatalambtranNoch keine Bewertungen

- Technical Information Sheet: 7-1862 Epoxy Grey Fast Cure Repair MaterialDokument3 SeitenTechnical Information Sheet: 7-1862 Epoxy Grey Fast Cure Repair Materialalex6inNoch keine Bewertungen

- Plasteroc MPRDokument2 SeitenPlasteroc MPRTori SmallNoch keine Bewertungen

- Expoband One : Flexible Expansion Joint MembraneDokument4 SeitenExpoband One : Flexible Expansion Joint MembraneVenkata Raju KalidindiNoch keine Bewertungen

- Foster 81 10Dokument2 SeitenFoster 81 10Muneer Ahamed ShaikNoch keine Bewertungen

- Safeguard Universal AGDokument7 SeitenSafeguard Universal AGMar PardalesNoch keine Bewertungen

- Fosroc Trafficguard UR: Constructive SolutionsDokument2 SeitenFosroc Trafficguard UR: Constructive SolutionsSaud PathiranaNoch keine Bewertungen

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionVon EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNoch keine Bewertungen

- Your Home Inspected: An Addendum for Residential Home Inspection ReportsVon EverandYour Home Inspected: An Addendum for Residential Home Inspection ReportsNoch keine Bewertungen

- 301compression MoldingDokument2 Seiten301compression MoldingAnonymous r3MoX2ZMTNoch keine Bewertungen

- User Instructions - Original Instruction-: ISC2 SeriesDokument14 SeitenUser Instructions - Original Instruction-: ISC2 SeriesAnonymous r3MoX2ZMTNoch keine Bewertungen

- FRIMO Technology Pressing Forming USDokument17 SeitenFRIMO Technology Pressing Forming USAnonymous r3MoX2ZMTNoch keine Bewertungen

- Iec 60617 SymbolsDokument53 SeitenIec 60617 SymbolsAnonymous r3MoX2ZMT100% (1)

- 61 Pagine 1396272475 Ni Ti ZR Caratteristiche Meccaniche ChimicheDokument2 Seiten61 Pagine 1396272475 Ni Ti ZR Caratteristiche Meccaniche ChimicheAnonymous r3MoX2ZMTNoch keine Bewertungen

- Solid Lubricants - Unique LubricationDokument7 SeitenSolid Lubricants - Unique LubricationAnonymous r3MoX2ZMTNoch keine Bewertungen

- Brochure Composites enDokument4 SeitenBrochure Composites enAnonymous r3MoX2ZMTNoch keine Bewertungen

- The Requirements Engineering Body of Knowledge (Rebok) : September 2013Dokument4 SeitenThe Requirements Engineering Body of Knowledge (Rebok) : September 2013Anonymous r3MoX2ZMTNoch keine Bewertungen

- Araldite 2014-2: Advanced MaterialsDokument6 SeitenAraldite 2014-2: Advanced MaterialsAnonymous r3MoX2ZMTNoch keine Bewertungen

- Guidelines For Monitoring Stand-Alone Photovoltaic Power SystemsDokument43 SeitenGuidelines For Monitoring Stand-Alone Photovoltaic Power SystemsAnonymous r3MoX2ZMTNoch keine Bewertungen

- Engineered Composites: Technical Data SheetDokument2 SeitenEngineered Composites: Technical Data SheetAnonymous r3MoX2ZMTNoch keine Bewertungen

- Sigrafine - TDS Ek2240Dokument1 SeiteSigrafine - TDS Ek2240Anonymous r3MoX2ZMTNoch keine Bewertungen

- Durability Testing of Adhesively Bonded Composites - CompositesWorldDokument7 SeitenDurability Testing of Adhesively Bonded Composites - CompositesWorldAnonymous r3MoX2ZMTNoch keine Bewertungen

- Executive Summary - MachineryDokument5 SeitenExecutive Summary - MachineryAnonymous r3MoX2ZMTNoch keine Bewertungen

- What Is CFCC Grid??Dokument2 SeitenWhat Is CFCC Grid??Anonymous r3MoX2ZMTNoch keine Bewertungen

- Forged Composites Replace Complex Metal Parts - CompositesWorldDokument3 SeitenForged Composites Replace Complex Metal Parts - CompositesWorldAnonymous r3MoX2ZMTNoch keine Bewertungen

- Increasing Demand For Composite Driveshafts Leads To Automated Production - CompositesWorldDokument7 SeitenIncreasing Demand For Composite Driveshafts Leads To Automated Production - CompositesWorldAnonymous r3MoX2ZMTNoch keine Bewertungen

- Tabella Resistenze Chimiche Asv StubbeDokument203 SeitenTabella Resistenze Chimiche Asv StubbeAnonymous r3MoX2ZMTNoch keine Bewertungen

- Lesson 5 T-BeamsDokument7 SeitenLesson 5 T-BeamsJoshua John JulioNoch keine Bewertungen

- Distance Measuring EquipmentDokument12 SeitenDistance Measuring Equipmentमेनसन लाखेमरूNoch keine Bewertungen

- ASSAM - Uniform Zoning Regulation 2000Dokument35 SeitenASSAM - Uniform Zoning Regulation 2000rajatesh1Noch keine Bewertungen

- Cryogenic and Its ApplicationDokument11 SeitenCryogenic and Its ApplicationBhoomika MansharamaniNoch keine Bewertungen

- Ball ValvesDokument4 SeitenBall ValvesIgde Agung ChandraNoch keine Bewertungen

- Issue 1 MMNR Short DumpDokument6 SeitenIssue 1 MMNR Short DumppookusmasNoch keine Bewertungen

- b-737 - Rev 59 PDFDokument402 Seitenb-737 - Rev 59 PDFCatevario NegroNoch keine Bewertungen

- Ihs Kingdom Hot Keys ReferenceDokument1 SeiteIhs Kingdom Hot Keys ReferenceMuhammad Jahangir100% (1)

- Modern PetrochemicalsDokument179 SeitenModern PetrochemicalsHani Kirmani100% (9)

- Friction Loss Calculations of Irrigation Design A Foot Ball CourtDokument13 SeitenFriction Loss Calculations of Irrigation Design A Foot Ball Courtmathewmanjooran100% (2)

- Mobile Network LayerDokument25 SeitenMobile Network LayerAmrendra Kumar Mishra100% (2)

- 1.ar-315 BC&BL Lighting & IlluminationDokument28 Seiten1.ar-315 BC&BL Lighting & IlluminationUsha Sri GNoch keine Bewertungen

- Codex 2017 enDokument713 SeitenCodex 2017 enJIgnacio123Noch keine Bewertungen

- SEMIKRON Product Catalogue 2014 2015Dokument167 SeitenSEMIKRON Product Catalogue 2014 2015cesar oliveira0% (1)

- Gen00036-04 Wa600-6 Wheel LoaderDokument98 SeitenGen00036-04 Wa600-6 Wheel LoaderJuan Araya BarrazaNoch keine Bewertungen

- Fischer Technical Services Safety ManualDokument15 SeitenFischer Technical Services Safety ManualHenry FlorendoNoch keine Bewertungen

- Copeland Scroll Compressors For Refrigeration Zs09kae Zs11kae Zs13kae Application Guidelines en GB 4214008Dokument24 SeitenCopeland Scroll Compressors For Refrigeration Zs09kae Zs11kae Zs13kae Application Guidelines en GB 4214008Cesar Augusto Navarro ChirinosNoch keine Bewertungen

- 6 3 AnswersDokument4 Seiten6 3 Answersshiwaisanxian100% (1)

- WWW - Manaresults.Co - In: Set No. 1Dokument4 SeitenWWW - Manaresults.Co - In: Set No. 1Chanumolu DushyanthNoch keine Bewertungen

- New Premium ListDokument10 SeitenNew Premium ListAshwani SainiNoch keine Bewertungen

- CU-2RE PBE Service ManualDokument110 SeitenCU-2RE PBE Service ManualcoronaqcNoch keine Bewertungen

- Infinique Structured Cabling Installation ChecklistDokument2 SeitenInfinique Structured Cabling Installation Checklistroot75% (4)

- SCELDokument46 SeitenSCELzacklawsNoch keine Bewertungen

- B0210D PDFDokument9 SeitenB0210D PDFAldo TonatoNoch keine Bewertungen

- Benq mp510 Level1Dokument212 SeitenBenq mp510 Level1Juan Duarte Lopez100% (1)

- RA ARCH0118 e PDFDokument61 SeitenRA ARCH0118 e PDFPhilBoardResultsNoch keine Bewertungen

- Work at Height Questions For Height PassDokument3 SeitenWork at Height Questions For Height PassPravash Mohanty100% (1)

- 8×8 LED Matrix MAX7219 With Scrolling Text & Android Control Via BluetoothDokument15 Seiten8×8 LED Matrix MAX7219 With Scrolling Text & Android Control Via BluetoothakashlogicNoch keine Bewertungen

- Drainage Sewerage Piping Work Risk AssessmentsDokument5 SeitenDrainage Sewerage Piping Work Risk Assessmentsboa jean marieNoch keine Bewertungen