Beruflich Dokumente

Kultur Dokumente

André 2 - A Plasma Lens For Magnetron Sputtering

Hochgeladen von

Ramani ChandranOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

André 2 - A Plasma Lens For Magnetron Sputtering

Hochgeladen von

Ramani ChandranCopyright:

Verfügbare Formate

2528

IEEE TRANSACTIONS ON PLASMA SCIENCE, VOL. 39, NO. 11, NOVEMBER 2011

A Plasma Lens for Magnetron Sputtering

Andr Anders, Fellow, IEEE, and Jeff Brown

AbstractA plasma lens, consisting of a solenoid and potentialdefining ring electrodes, has been placed between a magnetron and

substrates to be coated. Photography reveals qualitative information on excitation, ionization, and the transport of plasma to the

substrate.

Index TermsPlasma devices, plasma materials processing,

plasma transport processes, sputtering, thin films.

AGNETRON sputtering is a widely used coating technology [1]. In essence, a magnetically enhanced glow

discharge with closed electron drift is operated at relatively low

pressure, of order 1 Pa, such that the cathode of the discharge is

targeted by positive ions. Surface atoms of the cathode (target) are removed and used for the deposition of thin films and

coatings. Several distinct versions of magnetron sputtering have

been developed over the years, and in particular, high-power

impulse magnetron sputtering (HIPIMS) is a much talked about

new addition to the family of sputtering technologies for the

deposition of thin films [2].

In reactive deposition, the magnetron is operated in a mixture

of noble gas (usually argon) and reactive gas, such as oxygen in

case an oxide coating is desired. For example, aluminum-doped

zinc oxide (AZO) [3] is a recently much researched transparent

conducting oxide (TCO) because it is a low-cost alternative to

the more costly indiumtinoxide widely used in displays, solar

cells, light-emitting diodes, etc.

The electric field that accelerates positive ions to the target

also accelerates negative ions away from the target toward

the substrate. Reactive deposition with oxygen implies that

negative oxygen ions are present, and therefore, apparently

unavoidable, the growing film is subject to bombardment of

high-energy (> 100 eV) negative ions, causing ion damage

[4], which is highly undesirable for some crystalline films such

as TCOs.

A magnetron produces plasma of gas (and in the case of

HIPIMS also of the target metal). A portion of the plasma can

escape from the magnetron depending on the unbalancing of

the magnetic field. Stronger unbalancing is used to intentionally

assist film growth by (positive) ions of relative low energy

(mostly < 20 eV).

Manuscript received November 25, 2010; accepted May 5, 2011. Date of

publication June 27, 2011; date of current version November 9, 2011. This work

was supported by the U.S. Department of Energy under Contract DE-AC0205CH11231.

A. Anders is with the Lawrence Berkeley National Laboratory, University of

California, Berkeley, CA 94720 USA (e-mail: aanders@lbl.gov).

J. Brown is with Acree Technologies, Inc., Concord, CA 94520 USA (e-mail:

jbrown@acreetech.com).

Digital Object Identifier 10.1109/TPS.2011.2157172

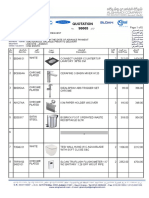

Fig. 1 shows an interesting approach to plasma utilization in

magnetron sputtering. Here, a solenoid generates an essentially

axial magnetic field which influences the degree of unbalancing

the magnetron, promoting the escape of plasma. Apart from

affecting the magnetic field near the target zone, the solenoid

also aids the excitation and ionization of material and guides

the plasma to the substrate. That is, while electrons and positive

ions are confined and transported, negative ions are actually

pushed out of the plasma stream: In this sense, the solenoid

acts as a plasma lens with focusing properties for positive

ions and defocusing properties for negative ions [5][7]. The

guiding of plasma by solenoids has been much studied for

filtered cathodic arc plasma deposition [8], [9], and the field of

research has been dubbed plasma optics [10]. An image of arc

plasma transport in a curved solenoid filter has been shown in

one of the previous Special Issues on Images in Plasma Science

[11]. In cathodic arcs, the motivation was to rid the plasma of

the undesired so-called macroparticles. In HIPIMS, an axial

magnetic field was shown to locally enhance the deposition

rate [12]. Here, however, the main goal is to affect the ratio of

positive and negative ions arriving on the substrate. The plasma

lensing effect is based on the radial electric field that builds

when electrons are magnetized and ions are not magnetized.

One can go one step further and introduce ring electrodes near

the solenoids entrance and exit to aid in establishing a desired

potential gradient. A curved version of such plasma lens has

the advantage of also addressing macroparticle issues in case

arcing occurs although the deposition rate is reduced.

The photo in Fig. 1 was taken through a window of the

vacuum processing chamber using a Canon EOS Rebel T1i

SRL camera with a 15 megapixel CMOS detector. The exposure time was 1/30 s, with f /5 aperture, at a sensitivity

of ISO 1600. In the center part of the figure, we see a coil

made of 1/4-in copper tubing, which is water cooled. Biasable

electrode rings are placed near the entrance and exit of the

solenoid. The 2-in (5 cm) diameter planar magnetron, shown

on the right, with a 2-in (5 cm) diameter Zn4at%Al target

was connected to a Pinnacle Plus magnetron supply (Advanced

Energy). The medium-frequency discharge was run with 300 W

average power, at 315 V and 0.95 A, 150 kHz, with a

0.5 s reverse phase. The gas flow ratio of argon and oxygen

was 30 : 9 resulting in a pressure of 0.53 Pa during deposition.

The solenoid carried 400 A of current. The AZO films made

at 200 C were of good quality with a transmission of about

85% in the visible spectrum and an electrical conductivity in

the high 104 cm. Using HIPIMS and a 90 filter delivered

even better films with 3.5 104 cm at a reduced substrate temperature of only 160 C, to be reported elsewhere.

Research in the lensing effect and film optimization is still

ongoing.

0093-3813/$26.00 2011 IEEE

ANDERS AND BROWN: PLASMA LENS FOR MAGNETRON SPUTTERING

2529

Fig. 1. Plasma lens placed between (right) magnetron and (left) substrate. The magnetron has a 2-in (5 cm) diameter aluminum-doped zinc target, operating in an

argonoxygen gas mixture. Microscope slide substrates are mounted on a heater; the goal is to deposit high-quality AZO films, a low-cost transparent conductor.

ACKNOWLEDGMENT

The authors would like to thank J. Wallig for the technical

support.

R EFERENCES

[1] P. Martin, Ed., Handbook of Deposition Technologies for Films and Coatings. Norwich, NY: William Andrew, 2009.

[2] K. Sarakinos, J. Alami, and S. Konstantinidis, High power pulsed magnetron sputtering: Scientific and engineering state of the art, Surf. Coat.

Technol., vol. 204, pp. 16611684, 2010.

[3] K. Ellmer, A. Klein, and B. Rech, Eds., Transparent Conductive Zinc

Oxide: Basics and Applications in Thin Film Solar Cells. New York:

Springer, 2008.

[4] S. Mrz and J. M. Schneider, Influence of the negative oxygen ions on

the structure evolution of transition metal oxide thin films, J. Appl. Phys.,

vol. 100, no. 2, pp. 023503-1023503-6, Jul. 2006.

[5] A. Anders, LBNL patent disclosure IB-2473, July 13, 2007: Method

and apparatus for improved high power impulse magnetron sputtering,

unpublished.

[6] A. Anders and J. Brown, LBNL patent disclosure IB-2712, Method and

apparatus for filtered high power impulse magnetron sputtering, Mar. 13,

2009, unpublished.

[7] A. Anders, LBNL patent disclosure IB-2803: Method and apparatus for

sputtering with a plasma lens, Dec. 7, 2009, unpublished.

[8] I. I. Aksenov, V. G. Padalka, V. T. Tolok, and V. M. Khoroshikh, Motion

of plasma streams from a vacuum arc in a long, straight plasma optics

system, Sov. J. Plasma Phys., vol. 6, pp. 504507, 1980.

[9] A. Anders, Cathodic Arcs: From Fractal Spots to Energetic Condensation.

New York: Springer, 2008.

[10] A. I. Morozov and S. V. Lebedev, Plasma optics, in Reviews of Plasma

Physics, vol. 8, M. A. Leontovich, Ed. New York: Consultants Bureau,

1980, pp. 301460.

[11] A. Anders, Imaging the separation of cathodic arc plasma and macroparticles in curved magnetic filters, IEEE Trans. Plasma Sci., vol. 30, no. 1,

pp. 108109, Feb. 2002.

[12] J. Bohlmark, M. Ostbye, M. Lattemann, H. Ljungcrantz, T. Rosell, and

U. Helmersson, Guiding the deposition flux in an ionized magnetron

discharge, Thin Solid Films, vol. 515, no. 4, pp. 19281931, Dec. 2006.

Das könnte Ihnen auch gefallen

- Damon Stages of FriendshipDokument2 SeitenDamon Stages of FriendshipRamani ChandranNoch keine Bewertungen

- Final Upcat Mock ExamDokument24 SeitenFinal Upcat Mock Examjbgonzales8Noch keine Bewertungen

- Astm F 30 - 96 R02 - RJMWDokument5 SeitenAstm F 30 - 96 R02 - RJMWphaindikaNoch keine Bewertungen

- Operate A Personal Computer PDFDokument56 SeitenOperate A Personal Computer PDFBirhanu Girmay100% (8)

- 2012 D61ex-15e0Dokument1.239 Seiten2012 D61ex-15e0Alex San Tana100% (3)

- 02-Dr Ooi-Design of Jacked-In Piles & Case Studies in SingaporeDokument39 Seiten02-Dr Ooi-Design of Jacked-In Piles & Case Studies in SingaporefreezefreezeNoch keine Bewertungen

- Silicon Solar Cell Enhancement by Using Au NanoparticlesDokument8 SeitenSilicon Solar Cell Enhancement by Using Au NanoparticlesInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Geometry Dependence of Coercivity in Ni Nanowire Arrays: Home Search Collections Journals About Contact Us My IopscienceDokument7 SeitenGeometry Dependence of Coercivity in Ni Nanowire Arrays: Home Search Collections Journals About Contact Us My IopscienceANU SAJINoch keine Bewertungen

- Bending PaperDokument6 SeitenBending PaperDr-Mandeep SinghNoch keine Bewertungen

- Experimental Determination of The Principal Dielectric Functions in Silver Nanowire MetamaterialsDokument4 SeitenExperimental Determination of The Principal Dielectric Functions in Silver Nanowire MetamaterialsMuhammad YunusNoch keine Bewertungen

- Catchpole-Red Shifting The Surface Plasmon Resonance of Silver Nanoparticles For Light Trapping in Solar CellsDokument9 SeitenCatchpole-Red Shifting The Surface Plasmon Resonance of Silver Nanoparticles For Light Trapping in Solar CellsVenus DilluNoch keine Bewertungen

- Extraordinary Optical Transmission in A Hybrid Plasmonic WaveguideDokument8 SeitenExtraordinary Optical Transmission in A Hybrid Plasmonic WaveguideRami WahshehNoch keine Bewertungen

- Nanomaterials: Origin and Future of Plasmonic Optical TweezersDokument18 SeitenNanomaterials: Origin and Future of Plasmonic Optical TweezersShailendra SinghNoch keine Bewertungen

- Lithography-Advanced MaterialsDokument15 SeitenLithography-Advanced MaterialsJaya LohaniNoch keine Bewertungen

- Klaui MagneticAnisotropyEngineeringYhinFilm PhysRevApplied2014Dokument6 SeitenKlaui MagneticAnisotropyEngineeringYhinFilm PhysRevApplied2014astro123321Noch keine Bewertungen

- RomJPhys 66 606Dokument10 SeitenRomJPhys 66 606Madhiyah YahayaNoch keine Bewertungen

- Magnetically-Induced Flow During ElectropolishingDokument6 SeitenMagnetically-Induced Flow During Electropolishingmohammadreza hajialiNoch keine Bewertungen

- TMP 5 DDCDokument7 SeitenTMP 5 DDCFrontiersNoch keine Bewertungen

- Finalised Report111 Appu NewDokument20 SeitenFinalised Report111 Appu NewAparna RamakrishnanNoch keine Bewertungen

- Fusion Engineering and DesignDokument10 SeitenFusion Engineering and DesignMahdi EslamiNoch keine Bewertungen

- Confinement and Dynamics of Laser Produced Plasma Expanding Across A Transverse Magnetic FieldDokument38 SeitenConfinement and Dynamics of Laser Produced Plasma Expanding Across A Transverse Magnetic Fieldimtiaz.ahmed611499Noch keine Bewertungen

- Piezoelectric Properties of AlnDokument6 SeitenPiezoelectric Properties of AlnErnest Ting-Ta YenNoch keine Bewertungen

- Webb CHPT 2s5Dokument8 SeitenWebb CHPT 2s5aloove66Noch keine Bewertungen

- Unit-5 Radiography: AdvantagesDokument23 SeitenUnit-5 Radiography: AdvantagescandypranavNoch keine Bewertungen

- Nano 2003 1231772Dokument4 SeitenNano 2003 1231772GoxseNoch keine Bewertungen

- July 14, 2005 10:3 WSPC/175-IJN 00313: Ion Beam Lithography and Nanofabrication: A ReviewDokument18 SeitenJuly 14, 2005 10:3 WSPC/175-IJN 00313: Ion Beam Lithography and Nanofabrication: A Reviewmoviemac7Noch keine Bewertungen

- Hot Electrons in Microscale Thin-Film Schottky Barriers For Enhancing Near-Infrared DetectionDokument4 SeitenHot Electrons in Microscale Thin-Film Schottky Barriers For Enhancing Near-Infrared DetectionAvery HillNoch keine Bewertungen

- Gao 2016Dokument6 SeitenGao 2016Jorge Daniel Torres AlvarezNoch keine Bewertungen

- Plasmonics Redefined SlidesDokument23 SeitenPlasmonics Redefined SlidesUmesh Bhagat100% (1)

- Fabricating A Nano-Labyrinth On Silicon Wafer: Project ReportDokument15 SeitenFabricating A Nano-Labyrinth On Silicon Wafer: Project ReportEthan HuntNoch keine Bewertungen

- Matrix-Assisted Laser Desorption/Ionization in Transmission Geometry: Instrumental Implementation and Mechanistic ImplicationsDokument8 SeitenMatrix-Assisted Laser Desorption/Ionization in Transmission Geometry: Instrumental Implementation and Mechanistic ImplicationsLata DeshmukhNoch keine Bewertungen

- SaaDokument41 SeitenSaaAbdur RahmanNoch keine Bewertungen

- tmpA4E7 TMPDokument9 SeitentmpA4E7 TMPFrontiersNoch keine Bewertungen

- Ion Beam Lithogrpaphy Seminar NewDokument55 SeitenIon Beam Lithogrpaphy Seminar NewMohammad RameezNoch keine Bewertungen

- Wavelength Dependence of Laser-Induced Nanowelded Microstructures Assembled From Metal NanoparticlesDokument15 SeitenWavelength Dependence of Laser-Induced Nanowelded Microstructures Assembled From Metal NanoparticlesTa BarNoch keine Bewertungen

- Photovoltaic Effect of Copper Photovoltaic Cells: Catibog, J.M.R., Mercado, A.R.T., See, A.J.GDokument3 SeitenPhotovoltaic Effect of Copper Photovoltaic Cells: Catibog, J.M.R., Mercado, A.R.T., See, A.J.GRomina MercadoNoch keine Bewertungen

- Formation of Conductive Copper Lines by Femtosecond Laser Irradiation of Copper Nitride Film On Plastic Substrates Xu2015 PDFDokument5 SeitenFormation of Conductive Copper Lines by Femtosecond Laser Irradiation of Copper Nitride Film On Plastic Substrates Xu2015 PDFSundry 1000Noch keine Bewertungen

- Controlled Electrodeposition of Nanoparticulate Tungsten OxideDokument4 SeitenControlled Electrodeposition of Nanoparticulate Tungsten OxideemediageNoch keine Bewertungen

- Metal Nanoparticles For Light Trapping ApplicationsDokument13 SeitenMetal Nanoparticles For Light Trapping ApplicationsHimanshu GuptaNoch keine Bewertungen

- Role of The Cesium Antimonide Layer in The Na 2 Ksb/Cs 3 SB PhotocathodeDokument7 SeitenRole of The Cesium Antimonide Layer in The Na 2 Ksb/Cs 3 SB PhotocathodeDayti JuniorNoch keine Bewertungen

- Nano Material CharacterisationDokument14 SeitenNano Material CharacterisationRama SamyNoch keine Bewertungen

- Lasing in Metal-Insulator-Metal Subwavelength Plasmonic WaveguideDokument6 SeitenLasing in Metal-Insulator-Metal Subwavelength Plasmonic WaveguideMichele CelliNoch keine Bewertungen

- Simon C. Bott Et Al - Quantitative Measurements of Wire Ablation in Tungsten X-Pinches at 80 KaDokument6 SeitenSimon C. Bott Et Al - Quantitative Measurements of Wire Ablation in Tungsten X-Pinches at 80 KaCola7890Noch keine Bewertungen

- Synthesis and Deposition of Ag Nanoparticles by CoDokument9 SeitenSynthesis and Deposition of Ag Nanoparticles by Comonikasharma1604Noch keine Bewertungen

- Fei 2018Dokument38 SeitenFei 2018PN VinodNoch keine Bewertungen

- Experimental Confirmation at Visible Light Wavelengths of The Backscattering Enhancement Phenomenon of The Photonic NanojetDokument10 SeitenExperimental Confirmation at Visible Light Wavelengths of The Backscattering Enhancement Phenomenon of The Photonic NanojetFrontiersNoch keine Bewertungen

- Multi-Junction Solar Cell: From Wikipedia, The Free EncyclopediaDokument13 SeitenMulti-Junction Solar Cell: From Wikipedia, The Free EncyclopediaAryan KhannaNoch keine Bewertungen

- Electric Contacts For ZnODokument5 SeitenElectric Contacts For ZnOjmcorreahNoch keine Bewertungen

- PHD Thesis Surface Plasmon ResonanceDokument4 SeitenPHD Thesis Surface Plasmon Resonancevetepuwej1z3100% (1)

- A Nanoparticle Formation Model Considering Layered Motion Based On An Electrical Explosion Experiment With AI WiresDokument12 SeitenA Nanoparticle Formation Model Considering Layered Motion Based On An Electrical Explosion Experiment With AI Wires胡浩Noch keine Bewertungen

- Optical Properties WC PDFDokument7 SeitenOptical Properties WC PDFamol476853Noch keine Bewertungen

- Electrodeposition: A Technology For The Future: by Walther SchwarzacherDokument4 SeitenElectrodeposition: A Technology For The Future: by Walther Schwarzachervivalavida31Noch keine Bewertungen

- Dynamics of Guided Post-Acceleration of Protons in A Laser-Driven Travelling-Field AcceleratorDokument9 SeitenDynamics of Guided Post-Acceleration of Protons in A Laser-Driven Travelling-Field AcceleratorSkel IngtonNoch keine Bewertungen

- NOV161376Dokument4 SeitenNOV161376K.H. TanNoch keine Bewertungen

- 9 Focused Ion Beam MicrosDokument28 Seiten9 Focused Ion Beam MicrosPrashant VermaNoch keine Bewertungen

- Manuscript FinalDokument11 SeitenManuscript Finalsifat2070Noch keine Bewertungen

- Energy-Dispersive X-Ray SpectrosDokument9 SeitenEnergy-Dispersive X-Ray SpectrosJuan CogolludoNoch keine Bewertungen

- Plasmonic Lenses With Long Focal Lengths PDFDokument4 SeitenPlasmonic Lenses With Long Focal Lengths PDFgNoch keine Bewertungen

- Enhanced Light Absorption in Thin Film Solar Cells With Embedded Dielectric Nanoparticles: Induced Texture Dominates Mie ScatteringDokument4 SeitenEnhanced Light Absorption in Thin Film Solar Cells With Embedded Dielectric Nanoparticles: Induced Texture Dominates Mie Scatteringbaljit6111Noch keine Bewertungen

- Min Qiu - Basics of Plasmonics-2 PDFDokument38 SeitenMin Qiu - Basics of Plasmonics-2 PDFJitendraBehera100% (1)

- Dependence of The Electrical and Optical Properties On The Bias Voltage For Zno:Al Films Deposited by R.F. Magnetron SputteringDokument5 SeitenDependence of The Electrical and Optical Properties On The Bias Voltage For Zno:Al Films Deposited by R.F. Magnetron SputteringGeetha Sokkian RammanoharNoch keine Bewertungen

- RomJPhys 66 602Dokument17 SeitenRomJPhys 66 602Madhiyah YahayaNoch keine Bewertungen

- J Phys D 2018Dokument8 SeitenJ Phys D 2018Samit PaulNoch keine Bewertungen

- 1 5120037Dokument14 Seiten1 5120037AbdelhameD AlINoch keine Bewertungen

- Nanoantennas For Visible and Infrared RadiationDokument41 SeitenNanoantennas For Visible and Infrared RadiationMichele CelliNoch keine Bewertungen

- Applied Surface Science: Yuan Tao, Genshui Ke, Yan Xie, Yigang Chen, Siqi Shi, Haibo GuoDokument6 SeitenApplied Surface Science: Yuan Tao, Genshui Ke, Yan Xie, Yigang Chen, Siqi Shi, Haibo GuoRamani ChandranNoch keine Bewertungen

- Surface WettingDokument169 SeitenSurface WettingRamani ChandranNoch keine Bewertungen

- High Power Impulse Magnetron SputteringDokument36 SeitenHigh Power Impulse Magnetron SputteringRamani ChandranNoch keine Bewertungen

- Surface WettingDokument169 SeitenSurface WettingRamani ChandranNoch keine Bewertungen

- Introduction To Chemical EquationsDokument21 SeitenIntroduction To Chemical EquationsRamani ChandranNoch keine Bewertungen

- Damon - Infancy To AdelocanceDokument25 SeitenDamon - Infancy To AdelocanceRamani ChandranNoch keine Bewertungen

- Damon Self UnderstandingDokument21 SeitenDamon Self UnderstandingRamani ChandranNoch keine Bewertungen

- Ilovepdf Merged MergedDokument209 SeitenIlovepdf Merged MergedDeepak AgrawalNoch keine Bewertungen

- Pt. Partono Fondas: Company ProfileDokument34 SeitenPt. Partono Fondas: Company Profileiqbal urbandNoch keine Bewertungen

- 1SDA066479R1 Rhe xt1 xt3 F P Stand ReturnedDokument3 Seiten1SDA066479R1 Rhe xt1 xt3 F P Stand ReturnedAndrés Muñoz PeraltaNoch keine Bewertungen

- Final App - FlsDokument9 SeitenFinal App - Flsjunebug172100% (1)

- MMD 74 XX DR PS 0020 - C03Dokument1 SeiteMMD 74 XX DR PS 0020 - C03bramexNoch keine Bewertungen

- 5 6176700143207711706Dokument198 Seiten5 6176700143207711706abc defNoch keine Bewertungen

- CambuzaDokument45 SeitenCambuzaMia Marin Pâslaru100% (2)

- 2nd Term Physics ReviewerDokument5 Seiten2nd Term Physics ReviewerAlfredo L. CariasoNoch keine Bewertungen

- 229.testing of Ycgf-11 With F6150-FieldFailureDokument13 Seiten229.testing of Ycgf-11 With F6150-FieldFailureSukant Kumar Mohanty50% (2)

- University of Mumbai: Syllabus For Sem V & VI Program: B.Sc. Course: PhysicsDokument18 SeitenUniversity of Mumbai: Syllabus For Sem V & VI Program: B.Sc. Course: Physicsdbhansali57Noch keine Bewertungen

- TabulationDokument13 SeitenTabulationWildan PushNoch keine Bewertungen

- RE 2017 EOT Brochure 4ADokument20 SeitenRE 2017 EOT Brochure 4AOrangutan SolutionsNoch keine Bewertungen

- CatalogDokument76 SeitenCatalogmkpasha55mpNoch keine Bewertungen

- By George G. Meyerhof, F. Asce: J. Geotech. Engrg., 1983, 109 (6) : 797-806Dokument10 SeitenBy George G. Meyerhof, F. Asce: J. Geotech. Engrg., 1983, 109 (6) : 797-806PoYing HuangNoch keine Bewertungen

- Alloc 150 DMDokument301 SeitenAlloc 150 DMSheik Mohamed ImranNoch keine Bewertungen

- PSP Error CodesDokument5 SeitenPSP Error CodesAd AzNoch keine Bewertungen

- Chapter 2 Magnetic Effects of Current XDokument25 SeitenChapter 2 Magnetic Effects of Current XPawan Kumar GoyalNoch keine Bewertungen

- Is 15707 2006Dokument23 SeitenIs 15707 2006anupam789Noch keine Bewertungen

- Conjoint SpssDokument28 SeitenConjoint SpssstatsoumyaNoch keine Bewertungen

- E Insurance ProjectDokument10 SeitenE Insurance ProjectChukwuebuka Oluwajuwon GodswillNoch keine Bewertungen

- The Yield Stress MythDokument5 SeitenThe Yield Stress MythRavi Kiran TađaþanenǐNoch keine Bewertungen

- Design Procedure For Journal BearingsDokument4 SeitenDesign Procedure For Journal BearingsSwaminathan100% (1)

- Quotation 98665Dokument5 SeitenQuotation 98665Reda IsmailNoch keine Bewertungen

- PDK Repair Aftersales TrainingDokument22 SeitenPDK Repair Aftersales TrainingEderson BJJNoch keine Bewertungen

- McLaren Artura Order BKZQG37 Summary 2023-12-10Dokument6 SeitenMcLaren Artura Order BKZQG37 Summary 2023-12-10Salvador BaulenasNoch keine Bewertungen