Beruflich Dokumente

Kultur Dokumente

3 - SFQ Corrosion Resistant Sump Pumps

Hochgeladen von

thomasoburOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

3 - SFQ Corrosion Resistant Sump Pumps

Hochgeladen von

thomasoburCopyright:

Verfügbare Formate

CORROSIVE LIQUID SEMI-OPEN IMPELLER

SFQ

80

Chemical Wastewater

0 to 40

Semi-open Impeller

Double Mechanical Seal with Oil Lifter

Double-shielded Ball Bearing

Impeller

316 Stainless Steel Casting

Casing

316 Stainless Steel Casting

Suction Cover 316 Stainless Steel Casting

Type, Pole

Motor

50

Bearing

Shaft Seal

SiC

Dry Type Submersible Induction Motor

2-pole

Class of Insulation

Class E (0.75kW and below)

Class F (1.5kW and above)

Phase

Single-phase (suffix S)

Three-phase

Starting Method

Capacitor Start (single-phase only)

Direct on Line

Star-delta (11kW only)

Protection Device

(built-in)

Lubricant

Circle Thermal Protector

Miniature Thermal Protector (11kW only)

Turbine Oil (ISO VG32)

Frame

Materials Shaft

Cable

Discharge Connection

1.2

1.4

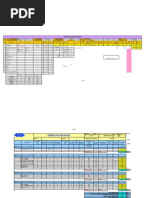

Total Head (m)

Total Head (m)

0.4

0.8

Capacity (m3/min)

10

5

1.

Q2

SF

.75

2.4

Q2 50SFQ

/

SF

Materials

80

Pump

.7

SF

23

.7

S

2.4

FQ

0S

Structure Shaft Seal

23

80

20

50

10

2.4

FQ

Impeller

SF

20

5

1.

Q2

5

SF

.7

80

2.4

Q2

SFQ

SF S / 50

Pumping Type of Fluid

Fluid

Fluid Temperature

80

0S

mm

S.S. 3000min-1

45

40

80

30

80

SF

SF

20

SF

80

Q2

Q2

25

11

7.5

.5

10

0.4

0.8

Capacity (m3/min)

1.2

1.4

S.S. 3600min-1

45

30

80

80

80

SF

SF

20

SF

25

27

21

1

.5

.5

10

1.0

Capacity (m3/min)

0

0

2.0 2.2

1.0

Capacity (m3/min)

2.0 2.2

Guide Rail Fitting

Standard Specifications

Discharge Bore

S.S. 3600min-1

30

40

50

gMajor

S.S. 3000min-1

30

Free Standing

Curves

Total Head (m)

gPerformance

Total Head (m)

The SFQ-series is made of austenitic cast

stainless steel, ideal for draining corrosive

liquid in chemical plant or other industrial

plant. The pump is a highly specialist pump

in term of design and materials.

316 Stainless Steel Casting

316 Stainless Steel

PVC (3.7kW and below)

Chloroprene Rubber (5.5kW and above)

Screwed Flange (3.7kW and below)

JIS 10K Flange (5.5kW and above)

gApplications

Draining wastewater from chemical plant, plastic plant, etc

Draining effluent from hospital and laboratory, etc

gStandard

Specifications

Model

Discharge

Bore

Guide Rail

Fitting

Motor

Starting

Output

Method

kW

Speed

(S.S.)

50Hz/60Hz

min 1

Cabtyre Cable

Dry Weight *

Impeller

kgs

200 ~ 240 V

380 ~ 575 V

Passage

Length

No. of

Outer

50Hz/60Hz

Material

Free Guide Rail

Cores Dia. Cores Outer

Dia.

Cables

Standing Fitting

mm

mm2

mm2

m

mm

mm

mm

Free

Standing

50

50SFQ2.4S

0.4

Capacitor 3000/3600

22

3 1.25 10.1 3 1.25 10.1

PVC

50

50SFQ2.4

0.4

D.O.L. 3000/3600

20

4 1.25 11.1 4 1.25 11.1

PVC

50

50SFQ2.75

0.75

D.O.L. 3000/3600 cur_SFQ.ai

6

22

4 1.25 11.1 4 1.25 11.1

PVC

80

80SFQ21.5

1.5

D.O.L. 3000/3600

38

4 1.25 11.1 4 1.25 11.1

PVC

80

80SFQ23.7

3.7

D.O.L. 3000/3600

15

52

4 3.5

13.9 4 2.0

11.8

PVC

80

80SFQ25.5

TOS80SFQ25.5

5.5

D.O.L. 3000/3600

18

124

113

4 3.5

14.1 4 3.5

14.1

80

80SFQ27.5

TOS80SFQ27.5

7.5

D.O.L. 3000/3600

23/20

123

112

4 5.5

16.8 4 5.5

16.8

4 3.5

3 3.5

2 1.25

14.1

12.9

9.8

14.1

12.9

9.8

80

80SFQ211

TOS80SFQ211

11

Star-Delta 3000/3600

23

143

132

110 ~ 120 V

220 ~ 240 V

4 3.5

3 3.5

2 1.25

Chloroprene

Rubber

Chloroprene

Rubber

Chloroprene

Rubber

* Dry weight

All weights excluding cable

Weights of guide rail fitting excluding duckfoot bend

gModel

Number Designation

50 SFQ 2 .4 S

Discharge bore in millimeters

Name of the Series

Number of poles of the motor

Rated motor output in kilowatts

Phase

None : Three-phase

S : Single-phase

gStandard Accessories

Free Standing

Guide Rail Fitting - TOS

Screwed Flange

-3.7kW andspec_SFQ.ai

below

JIS 10kg/cm2 Flange (with Packing, Bolts & Nuts)

-5.5kW and above

Lifting Chain 5m, (with Shackles)

Guide Support (with Bolts & Nuts)

Guide Hook (with Bolts)

Duckfoot Bend

Guide Connector (with Bolts)

JIS 10kg/cm2 Flange (with Packing, Bolts & Nuts)

Foundation Bolts (with Nuts)

Distributed by Australian Pump Industries (02) 8865 3500

Das könnte Ihnen auch gefallen

- Manual Aire Acondiciona SamsungDokument46 SeitenManual Aire Acondiciona Samsung5deivid5Noch keine Bewertungen

- Omega Injection Moulding MachineDokument9 SeitenOmega Injection Moulding Machinerajpujara50% (2)

- 40SS Series: High Pressure Stainless Steel FilterDokument8 Seiten40SS Series: High Pressure Stainless Steel FilterYair Alexis Muñoz RojasNoch keine Bewertungen

- 06 SCT Extended PDFDokument40 Seiten06 SCT Extended PDFSlobodan Antic100% (2)

- Slurry Pumps WH Agitator - Models - HSD, KTV, KRS, NKZ, GPN, Gsz-6Dokument5 SeitenSlurry Pumps WH Agitator - Models - HSD, KTV, KRS, NKZ, GPN, Gsz-6Guilherme CamposNoch keine Bewertungen

- Goulds AF: Axial Flow PumpsDokument11 SeitenGoulds AF: Axial Flow PumpsKarthick VenkateshNoch keine Bewertungen

- Centrifugal PumpDokument32 SeitenCentrifugal PumpAhmadMoaazNoch keine Bewertungen

- E-Self Priming PumpsDokument27 SeitenE-Self Priming PumpsTeguh SetionoNoch keine Bewertungen

- Ap TTF BGTS 3Dokument12 SeitenAp TTF BGTS 3Madhu RajagopalanNoch keine Bewertungen

- Ex Junction BoxDokument26 SeitenEx Junction BoxMiky MooseNoch keine Bewertungen

- MPVN BrochureDokument32 SeitenMPVN Brochurefernando_naciamentNoch keine Bewertungen

- HP 5890 Parts BreakdownsDokument129 SeitenHP 5890 Parts BreakdownszeppelinboyNoch keine Bewertungen

- ARO Flo 1500 SeriesDokument11 SeitenARO Flo 1500 SeriesEliasNoch keine Bewertungen

- Cu PVC Swa PVC (Nyrgby)Dokument6 SeitenCu PVC Swa PVC (Nyrgby)Fani Dwi Putra50% (2)

- Centrifugal PumpDokument32 SeitenCentrifugal PumpAshok SrivatsanNoch keine Bewertungen

- 3 - KRS-Slurry 4 Pole Agitator PumpDokument1 Seite3 - KRS-Slurry 4 Pole Agitator PumpStefan ConstantinNoch keine Bewertungen

- Lennox G26Dokument53 SeitenLennox G26Kyle ZielinskiNoch keine Bewertungen

- Mixer Flowmaker AMG AMD AFG Low PDFDokument28 SeitenMixer Flowmaker AMG AMD AFG Low PDFpaulinhacoruNoch keine Bewertungen

- AVT Ball & Butterfly Brochure 05 Latest 12 PageDokument12 SeitenAVT Ball & Butterfly Brochure 05 Latest 12 PageshalbyNoch keine Bewertungen

- Arlon TTF BgtsDokument11 SeitenArlon TTF BgtsSamad A BakarNoch keine Bewertungen

- CW Hydro Pump PDFDokument56 SeitenCW Hydro Pump PDFashim_scribdNoch keine Bewertungen

- Cu-PVC-CTS-PVC (NYSY)Dokument6 SeitenCu-PVC-CTS-PVC (NYSY)Fani Dwi PutraNoch keine Bewertungen

- LS RF Catalogue-2016Dokument68 SeitenLS RF Catalogue-2016nikhom_dk1565Noch keine Bewertungen

- Válvulas Bola SegmentadaDokument12 SeitenVálvulas Bola SegmentadarehynaldoNoch keine Bewertungen

- FS120-FS200-FS300-FS350-FS400-FS450-FR350-FR450 Service ManualDokument63 SeitenFS120-FS200-FS300-FS350-FS400-FS450-FR350-FR450 Service Manualnik_nicholson_189% (18)

- Catalogo HydacDokument392 SeitenCatalogo HydacFrancisco Hernandez0% (1)

- NOVA Servo CatalogueDokument7 SeitenNOVA Servo CatalogueDip Narayan BiswasNoch keine Bewertungen

- Ebara Pumps Catalog DVS CatalogueDokument30 SeitenEbara Pumps Catalog DVS CataloguePutry Tria ChristyNoch keine Bewertungen

- Masoneilan - 37002 Series Spec DataDokument8 SeitenMasoneilan - 37002 Series Spec Datayasararafat12010Noch keine Bewertungen

- 1guia para Válvulas de ControlDokument25 Seiten1guia para Válvulas de ControlLindsey PatrickNoch keine Bewertungen

- Caracteristicas Motores PDFDokument60 SeitenCaracteristicas Motores PDF0ZKRCITHONoch keine Bewertungen

- Internal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00Dokument2 SeitenInternal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00ramabhplNoch keine Bewertungen

- Movex 2016USALDokument332 SeitenMovex 2016USALserenetaNoch keine Bewertungen

- Datasheet Relay Finder40.31Dokument16 SeitenDatasheet Relay Finder40.31Jader Lucas PerezNoch keine Bewertungen

- Technical Specifications For Centrifugal Pumps PDFDokument12 SeitenTechnical Specifications For Centrifugal Pumps PDFVicky GautamNoch keine Bewertungen

- Ebara FssDokument19 SeitenEbara FssHardi YantoNoch keine Bewertungen

- STEEL Filters: Durable High Quality Steel Filters For Wide Range of Filtration ApplicationsDokument14 SeitenSTEEL Filters: Durable High Quality Steel Filters For Wide Range of Filtration ApplicationsJos AcadNoch keine Bewertungen

- 0200 DSZ BrochureDokument6 Seiten0200 DSZ Brochurenezz_nezzNoch keine Bewertungen

- 9836 3064 04 e Hydric LF423,647,430,660 2011-02Dokument6 Seiten9836 3064 04 e Hydric LF423,647,430,660 2011-02UbanAirlanggaNoch keine Bewertungen

- Grundfos MTS Screw Spindle PumpDokument68 SeitenGrundfos MTS Screw Spindle PumpAnonymous lswzqlo100% (1)

- 650 SchematicDokument4 Seiten650 Schematicab5951Noch keine Bewertungen

- Chief TC3Dokument1 SeiteChief TC3roberto carlos ortizNoch keine Bewertungen

- WOT - Tech Data Sheets PDFDokument43 SeitenWOT - Tech Data Sheets PDFAmbroise RICHARDNoch keine Bewertungen

- AJ401Dokument36 SeitenAJ401Richar Manuel Simanca FontalvoNoch keine Bewertungen

- Sae 6000 PsiDokument41 SeitenSae 6000 PsiEricNoch keine Bewertungen

- H1000e K FJDokument8 SeitenH1000e K FJSyarif HidayatullahNoch keine Bewertungen

- Amiad Plastic FiltersDokument11 SeitenAmiad Plastic FiltersWayne SeamanNoch keine Bewertungen

- Specs of Ducted UnitsDokument2 SeitenSpecs of Ducted UnitsAdil MohdNoch keine Bewertungen

- Datasheet Phe OnwjDokument1 SeiteDatasheet Phe OnwjMamank Ira Sudrajat100% (1)

- 1091 Bombas CentrifugasDokument17 Seiten1091 Bombas CentrifugasEugenio GomezNoch keine Bewertungen

- Electronic Parts Catalog - Option DetailDokument3 SeitenElectronic Parts Catalog - Option Detailnaya aninditaNoch keine Bewertungen

- 198 Faf2500 Flanged y Type StrainerDokument4 Seiten198 Faf2500 Flanged y Type Strainerinfo8176Noch keine Bewertungen

- Air Cylinder TPCDokument9 SeitenAir Cylinder TPCDwi AbdullahNoch keine Bewertungen

- Il2 RF2 CF2 PDFDokument14 SeitenIl2 RF2 CF2 PDFjuliocanel2009Noch keine Bewertungen

- Contact orDokument13 SeitenContact orVictor ToledanoNoch keine Bewertungen

- Optima CatalogueDokument32 SeitenOptima Cataloguemanoj6189Noch keine Bewertungen

- Advances in Solid Oxide Fuel Cells XVon EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNoch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Design Calc Saud It SampleDokument25 SeitenDesign Calc Saud It SampleglazetmNoch keine Bewertungen

- FX 3900 PVDokument194 SeitenFX 3900 PVthomasoburNoch keine Bewertungen

- Military Standard: WL-S 2155 (A@Dokument18 SeitenMilitary Standard: WL-S 2155 (A@thomasoburNoch keine Bewertungen

- Auto Drain 70APADH4000Dokument3 SeitenAuto Drain 70APADH4000thomasoburNoch keine Bewertungen

- Steel Onesteel HandbookDokument34 SeitenSteel Onesteel HandbookjlolhnpNoch keine Bewertungen

- Varec 3650B 33-11518Dokument15 SeitenVarec 3650B 33-11518thomasoburNoch keine Bewertungen

- Bolting Torques - Spiral Wound GasketsDokument1 SeiteBolting Torques - Spiral Wound GasketsthomasoburNoch keine Bewertungen

- 3% Rule Sizing For PSV-Compressible FlowDokument1 Seite3% Rule Sizing For PSV-Compressible FlowthomasoburNoch keine Bewertungen

- Mack Ball ValvesDokument10 SeitenMack Ball ValvesthomasoburNoch keine Bewertungen

- Engineering Competency StandardsDokument11 SeitenEngineering Competency StandardsRobbie van LeeuwenNoch keine Bewertungen

- Type A Pressure Relief Valve: Standard Features Parts List (Sizes 1/2" - 2")Dokument2 SeitenType A Pressure Relief Valve: Standard Features Parts List (Sizes 1/2" - 2")thomasoburNoch keine Bewertungen

- Parker 72 00DDokument2 SeitenParker 72 00DthomasoburNoch keine Bewertungen

- Metaland KYS CatalogueDokument96 SeitenMetaland KYS CataloguethomasoburNoch keine Bewertungen

- Air Test Gun For Tube BundlesDokument7 SeitenAir Test Gun For Tube BundlesthomasoburNoch keine Bewertungen

- Bond Ek Design and Construction Manual June 2012Dokument56 SeitenBond Ek Design and Construction Manual June 2012rocketNoch keine Bewertungen

- Heat Transfer - Transient Hyperbolic Conduction in Hollow CylinderDokument6 SeitenHeat Transfer - Transient Hyperbolic Conduction in Hollow CylinderthomasoburNoch keine Bewertungen

- Atlas Metals - Carbon Steel Pipe Pressure Rating ChartDokument4 SeitenAtlas Metals - Carbon Steel Pipe Pressure Rating ChartthomasoburNoch keine Bewertungen

- Eaton Hydraulic Power PackDokument6 SeitenEaton Hydraulic Power PackthomasoburNoch keine Bewertungen

- SCC Containing Coal Fly Ash and Bottom AshDokument9 SeitenSCC Containing Coal Fly Ash and Bottom AshGeorgeEdwardNoch keine Bewertungen

- Dco MaterialDokument35 SeitenDco MaterialAlakesh PhukanNoch keine Bewertungen

- Types of DamsDokument8 SeitenTypes of DamsNoeBonga100% (1)

- GEN-071 MoS Booster Pump InstallationDokument10 SeitenGEN-071 MoS Booster Pump InstallationFrancisco M. RamosNoch keine Bewertungen

- Introduction To Well IntegrityDokument154 SeitenIntroduction To Well Integrityb4rf100% (2)

- Dynamic Study of Step Back and Set Back Building: ResearchDokument7 SeitenDynamic Study of Step Back and Set Back Building: ResearchSristi GuptaNoch keine Bewertungen

- Front Elevation Side Elevation: E.W.S. HousingDokument1 SeiteFront Elevation Side Elevation: E.W.S. HousingsahilNoch keine Bewertungen

- PVM Su 4750 GDokument30 SeitenPVM Su 4750 GJEEVITHANoch keine Bewertungen

- 34.51.01.33 P6000CFP 000 PV - A DEP Tanks VariationDokument22 Seiten34.51.01.33 P6000CFP 000 PV - A DEP Tanks VariationNaser Alshraim100% (1)

- Cecw-Eg Engineer Manual 1110-2-2102 U.S. Army Corps of Engineers EM 1110-2-2102 30 September 1995Dokument23 SeitenCecw-Eg Engineer Manual 1110-2-2102 U.S. Army Corps of Engineers EM 1110-2-2102 30 September 1995cp yangNoch keine Bewertungen

- Peppers A2LCF GlandDokument2 SeitenPeppers A2LCF GlandBob JohnsonNoch keine Bewertungen

- (2020) Experimental Comparisons of Repairable Precast Concrete Shear Walls With ADokument16 Seiten(2020) Experimental Comparisons of Repairable Precast Concrete Shear Walls With ASofía Córdoba SáenzNoch keine Bewertungen

- Time ScheduleDokument2 SeitenTime ScheduleSanggalangi LatinroNoch keine Bewertungen

- RubberDokument11 SeitenRubberpkbhat100% (1)

- Effect of Cement Stabilization On Geotechnical Properties of Sandy Soils PDFDokument16 SeitenEffect of Cement Stabilization On Geotechnical Properties of Sandy Soils PDFFahim KhanNoch keine Bewertungen

- Business Profile: B&J Civil WorksDokument11 SeitenBusiness Profile: B&J Civil WorksJosephine TappNoch keine Bewertungen

- ASME B 31.3 2016 Process PipingDokument30 SeitenASME B 31.3 2016 Process Pipingr.devendran25% (4)

- Course Outline UpdatedDokument1 SeiteCourse Outline UpdatedAddisu AyeleNoch keine Bewertungen

- 54450b13e6c55 Dutypoint Dosing Pots DetailsDokument2 Seiten54450b13e6c55 Dutypoint Dosing Pots DetailsMohammed KhaledNoch keine Bewertungen

- Mad Dog Primer BrochureDokument2 SeitenMad Dog Primer BrochureMad Dog Paint ProductsNoch keine Bewertungen

- Medium-Hard-Drawn Copper Wire: Standard Specification ForDokument4 SeitenMedium-Hard-Drawn Copper Wire: Standard Specification ForRizwanNoch keine Bewertungen

- ELECTRICAL WIRING PLAN DemoDokument24 SeitenELECTRICAL WIRING PLAN DemoTommy Dela CruzNoch keine Bewertungen

- MK4 Posttensioning SpecificationsDokument28 SeitenMK4 Posttensioning SpecificationsshashireshNoch keine Bewertungen

- Primary SchoolDokument57 SeitenPrimary SchoolMUUTHUKRISHNAN100% (1)

- Group 4 Members:: Adjustable Nib Technical PenDokument3 SeitenGroup 4 Members:: Adjustable Nib Technical PenLaiRicoNoch keine Bewertungen

- Pump - Tpe3000 Thermal Oil HeaterDokument57 SeitenPump - Tpe3000 Thermal Oil Heaterjadetorres100% (1)

- Weekly Progress Report No 9 (SSO)Dokument95 SeitenWeekly Progress Report No 9 (SSO)JohnnyNoch keine Bewertungen

- Technical Instruction Manual: Meva Formset MfsDokument20 SeitenTechnical Instruction Manual: Meva Formset MfspablopelaNoch keine Bewertungen

- On Fly Ash ConDokument46 SeitenOn Fly Ash ConSantosh Kumar MNoch keine Bewertungen

- Bolt and Stud DimentionDokument1 SeiteBolt and Stud DimentionwhngomjNoch keine Bewertungen