Beruflich Dokumente

Kultur Dokumente

Performance Evaluation and Emission Analysis of Variable Compression Ratio Direct Injection Diesel Engine

Hochgeladen von

Global Research and Development ServicesCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Performance Evaluation and Emission Analysis of Variable Compression Ratio Direct Injection Diesel Engine

Hochgeladen von

Global Research and Development ServicesCopyright:

Verfügbare Formate

MATTER: International Journal of Science and Technology

ISSN 2454-5880

Narender Kumar et al.

Matter Vol. 2 Issue 2, pp. 32-47

DOI - http://dx.doi.org/10.20319/mijst.2016.22.3247

PERFORMANCE EVALUATION AND EMISSION ANALYSIS

OF VARIABLE COMPRESSION RATIO DIRECT INJECTION

DIESEL ENGINE

Narender Kumar

M.Tech student, Malaviya National Institute of Technology (MNIT), Jaipur, India,

narenderchoudhary2014@gmail.com

Shyam Lal Soni

Professor, Malaviya National Institute of Technology (MNIT), Jaipur, India,

shyamlalsoni@gmail.com

Dilip Sharma

Professor, Malaviya National Institute of Technology (MNIT), Jaipur, India,

dsharma.mech@mnit.ac.in

Anmesh Kumar Srivastava

PhD scholar, Malaviya National Institute of Technology (MNIT), Jaipur, India,

2012rme9038@mnit.ac.in

Abstract

With the advent of enhancing environmental and fossil energy concerns, sustainability that can

be done with the effective utilization of presently used energy sources, is of major concern. The

world of today is working hard to solve energy related problems, such as, energy supply security,

emission control, economy and conservation of energy etc. A great potential lies in the hand of

automotive engineers and scientists to use these exhisting reserves of petrolium products

2016 The author and GRDS Publishing. All rights reserved.

Available Online at: http://grdspublishing.org/journals-MATTER-home

32

MATTER: International Journal of Science and Technology

ISSN 2454-5880

effectively. In this present study, effect of compression ratio on the performance and emissions of

the diesel engine at various loads is done. While conducting the experiment compresssion ratio

range is kept from 18 to 22. It is observed that compression ratio 21 is giving maximum Brake

thermal efficiency at part as well as full load. Brake specific fuel consumption and Brake specific

energy consumption is found minimum at compression ratio 21.

Keywords

VCR, Brake Thermal Efficiency, BSFC, BSEC, Smoke

1. Introduction

Energy is most important entity for the economic development of any country in the

world especially in large and developing country such as India where a high fraction of the

worlds population is in need of satisfying their energy need. These large populations have

increased the demand of energy rapidly in the recent years due to accelerated pace of industrial

and economic growth. Considering the environmental protection and in the context of great

uncertainty in future energy supplies, awareness is concentrated on the sustainable utilization of

energy sources and the energy conservation methodologies.

Diesel engines are widely used for satisfying energy demand of vehicles, power

generation units in many industries, hospitals, CHP, residential sectors, commercial and

institutional facilities. Main advantages of these are quick startups, have good part load

efficiencies, and highly reliable. However, diesel is a non-renewable energy source and takes

millions of years for its formation. Indiscriminate extraction of fossil fuels and lavish

consumption of them have led to mitigation of conventional reserves. The world is confronted

with the twin crisis of fossil fuel depletion and environmental degradation and the situation is

expected to exfoliate more in the coming years.

One way to solve this problem is to use Alternate fuels and another one is, to use existing

fuels effectively. In this research paper second method is focused. It is well known that

2016 The author and GRDS Publishing. All rights reserved.

Available Online at: http://grdspublishing.org/journals-MATTER-home

33

MATTER: International Journal of Science and Technology

ISSN 2454-5880

efficiency of a diesel engine is increased by increasing compression ratio (Ganesan, 2015),

(Mathur,2015). A VCR diesel engine is used to find the optimum compression ratio for a diesel

engine.

2. Literature Review

Raut et al (2014) in this paper studied the impact of blend, load, speed, injection timing,

brake power etc on thermal performance and emission characteristics by performing the

experiment on a four stroke variable compression ratio diesel engine using Jatropha blends. This

paper aims to optimize the engine exhaust emission based on compression ratio, load, and blend

to find the optimum operating conditions. It has been found that with increasing compression

ratio, the performance of Jatropha oil blends is similar to that of diesel operated engine operating

at full loads especially at compression ratios of 17 and 18. But at higher compression ratios,

NOx emission increases remarkably. He had suggested to find out the optimum blend using GA

(Genetic Algorithm). SayiLikhitha et al (2014) conducted experiments on a single cylinder, four

stroke, variable compression ratio diesel engine connected with eddy current dynamometer. The

compression ratio was varied from 14 to 18 and different blends (5%, 7.5% and 10%) of DEE

were made. By introduction of DEE blend, BTE increases and specific fuel consumption

decreases. Best efficiency was obtained at 18 CR and with 5% DEE blend. The author observed

that when DEE increased beyond 15%, high knocking sound were used and also as the

concentration of DEE was increased viscosity of fuel decreased. K. Muralidharan et al

(2011)conducted experiments on a single cylinder four stroke VCR multi fuel engine when

fuelled with waste cooking oil methyl ester and 20%, 40%, 60% and 80% blends with were

investigated. The compression ratio was varied from 18:1 to 22:1 and the analysis was done at

50% load. The author observed that performance of B40 blend was superior when compared

with neat diesel at CR 21. NOx emissions were comparable with that of neat diesel, by

increasing the compression ratio HC emissions were increased and also CO emissions were

comparable.

2016 The author and GRDS Publishing. All rights reserved.

Available Online at: http://grdspublishing.org/journals-MATTER-home

34

MATTER: International Journal of Science and Technology

ISSN 2454-5880

3. Experimental Set-up

3.1 Engine

A single cylinder, four stroke, water cooled, DI, variable compression ratio diesel engine

designed to develop a rated power of 3.5 kW at 1500 rpm was used to carry out the present

research work.Specifications of the engine are enlisted below:

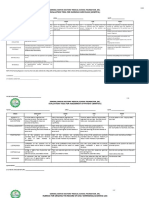

Table 1: Engine Specifications

Sr. No.

Specifications

Rating

1.

No. of cylinder

1 (single)

2.

Bore x Stroke

87.5 X 110 (mm)

3.

Capacity

661 cc

4.

Diesel mode (Rated Output)

3.5 kW

5.

Compression Ratio range

18-22

6.

Rated Speed (constant)

1500 rpm

7.

Injection Timing Variations

00-250 BTDC

8.

Valve timing

IVO 4.50 BTDC

IVC 35.50 ABDC

EVO 35.50 BBDC

EVC 4.50 ATDC

2016 The author and GRDS Publishing. All rights reserved.

Available Online at: http://grdspublishing.org/journals-MATTER-home

35

MATTER: International Journal of Science and Technology

ISSN 2454-5880

Figure 1: Engine

3.2 Gas AnalyzerTo measure the engine exhaust emissions two analysers were used

3.2.1 AVL Digas 444 Exhaust Gas Analyser

It is used to measure the emissions like carbon monoxide, carbon dioxide, hydro carbons,

oxygen and oxides of nitrogen.

2016 The author and GRDS Publishing. All rights reserved.

Available Online at: http://grdspublishing.org/journals-MATTER-home

36

MATTER: International Journal of Science and Technology

ISSN 2454-5880

Figure 2: AVL Gas Analyser (DIGAS 444)

3.2.2 AVL DITEST CDS 450

It is used to measure smoke density of the smoke. It measures the smoke opacity in %

HSU (Hartridge Smoke Unit). It can also be used to measure exhaust emissions of carbon

monoxide, carbon dioxide, oxides of nitrogen, hydrocarbons and oxygen. It has following

components:

AVL DITEST CDS main unit with integrated engine speed recording

Fuel Module AVL DITEST Gas 1000

Diesel module AVL DISMOKE 480 with wireless link

EOBD interface AVL DITEST OBD 1000 with Bluetooth connectivity

Laser printer s/w

Frame mount

2016 The author and GRDS Publishing. All rights reserved.

Available Online at: http://grdspublishing.org/journals-MATTER-home

37

MATTER: International Journal of Science and Technology

ISSN 2454-5880

Figure 3: AVL Gas Analyser (DITEST CDS 450)

3.3 Compression ratio Adjustment

This modified engine can be operated in Diesel as well as in gasoline mode. For Diesel

mode compression ratio can be varied from 18-22. For Gasoline mode compression ratio can be

varied from 6-10. To change the compression ratio of the engine, first of all allen bolts were

loosen with the help of allen key. Compression ratio adjustor (CR adjustor) is provided on one

side of the engine. Predefined grading is marked on the CR adjustor. CR adjustor is used to

change the compression ration by rotating the locknut clockwise and anti-clockwise. Anticlockwise rotation of the locknut increases the compression ratio and Clockwise rotation

decreases the compression ratio. This method of changing compression ratio is based on tilting

the cylinder block of the engine.

2016 The author and GRDS Publishing. All rights reserved.

Available Online at: http://grdspublishing.org/journals-MATTER-home

38

MATTER: International Journal of Science and Technology

ISSN 2454-5880

Figure 4: Compression ratio adjustment

4. Results and Discussions

Engine performance parameters which include Brake Thermal Efficiency (BTE), Brake

Specific Fuel Consumption (BSFC) and Brake Specific Energy Consumption (BSEC) were

analyzed. Exhaust gas Emissions were also recorded during the experiment to study the effect of

variation of compression ratio.

2016 The author and GRDS Publishing. All rights reserved.

Available Online at: http://grdspublishing.org/journals-MATTER-home

39

MATTER: International Journal of Science and Technology

ISSN 2454-5880

4.1 Brake Thermal Efficiency

Brake thermal efficiency increases with the increase in load. Also BTE increases with

increase in compression ratio for a CI engine, as there is no restriction of knocking (unlike SI

engine) caused by very high increase in temperature while high inlet temperature is desirable for

CI engine. Highest BTE was achieved at compression ratio 21 and it was found to be 25.84544 at

full load.On further increasing compression ratio BTE decreases as heat generated is not

dissipated properly.

30

25

20

BTE%

CR18

CR19

CR20

15

CR21

CR22

10

5

0

0.5

1.5

2.5

3.5

LOAD

Figure 5: Variation of BTE with load at different compression ratio

2016 The author and GRDS Publishing. All rights reserved.

Available Online at: http://grdspublishing.org/journals-MATTER-home

40

MATTER: International Journal of Science and Technology

ISSN 2454-5880

4.2 Brake Specific Fuel Consumption (BSFC)

Brake specific fuel consumption decreases with increase in load initially but at full load,

it increases slightly. At CR18 minimum BSFC is found to be 0.357 kg/kW-hr at 3.35 kW. At

CR21 BSFC is minimum, which is 0.335 kg/kW-hr. BSFC, decreased with increase in

compression ratio, reached minimum at CR 21 but it slightly increased for CR22.

1.2

BSFC vs Load

1

BSFC (kg/kWh)

0.8

CR 18

0.6

CR 19

CR 20

0.4

CR 21

0.2

CR 22

0.5

1.5

2.5

3.5

Load (kW)

Figure 6: Variation of BSFC with load at different compression ratio

4.3 Brake Specific Energy Consumption (BSEC)

Brake specific energy consumption decreases with increase in load initially but at full

load, it increases slightly. At CR21 BSEC is minimum, which is 13853.73 kJ/kW-hr. BSEC

decreased with increase in compression ratio, reached minimum at CR 21 but it slightly

increased for CR22. Figure 4.3 shows variation of BSEC with respect to compression ratio at

different loads.

2016 The author and GRDS Publishing. All rights reserved.

Available Online at: http://grdspublishing.org/journals-MATTER-home

41

MATTER: International Journal of Science and Technology

ISSN 2454-5880

Diesel

1500 RPM

CR- Compression

Ratio

BSEC (kJ/kWh)

CR18

CR19

CR20

CR21

CR22

0.5

1.5

2.5

3.5

LOAD (kW)

Figure 7: Variation of BSEC with load at different compression ratio

4.4 CO emissions

CO emissions decreases with increase in load for diesel engine, it is due to the proper

combustion of fuel at high loads. In the experiment it is found that CO emissions are decreasing

by increasing compression ratio from 18-22.

2016 The author and GRDS Publishing. All rights reserved.

Available Online at: http://grdspublishing.org/journals-MATTER-home

42

MATTER: International Journal of Science and Technology

ISSN 2454-5880

Diesel, 1500 RPM

CR-Compression Ratio

0.2

0.18

0.16

CO (%v/v)

0.14

0.12

CR18

0.1

CR19

0.08

CR20

0.06

CR21

0.04

CR22

0.02

0

0

0.5

1.5

2.5

3.5

LOAD (kW)

Figure 8: Variation of CO emissions with Load at different compression ratio

4.5 HC emissions

HC emissions decrease with increase in load for diesel engine. As by increasing load,

turbulence increases, which results in proper mixing of the fuel mixture and hence lowers the HC

emissions. In the experiment it is found that HC emissions are decreasing by increasing

compression ratio from 18-22. As by increasing the compression ratio, the temperature of the

cylinder wall increases, which burns the HC present in crevicesof the engine. It is found

minimum for CR22 and it is found maximum for CR18.

2016 The author and GRDS Publishing. All rights reserved.

Available Online at: http://grdspublishing.org/journals-MATTER-home

43

MATTER: International Journal of Science and Technology

ISSN 2454-5880

Diesel, 1500 RPM

CR-Compression Ratio

35

HC (ppm vol. Hex.)

30

25

CR18

20

CR19

15

CR20

10

CR21

CR22

5

0

0

0.5

1.5

2.5

3.5

LOAD (kW)

Figure 9: Variation of HC emissions with Load at different compression ratio

4.6 Nox emissions

Nitrogen and Oxygen reacts at comparatively high temperature. NOx formation in an

engine depends on many factors which are temperature during reaction, Oxygen availability in

the reaction and time period for which oxygen is available. NOx emissions are increased by

increasing load as by increasing load rich mixture of fuel will enter into the combustion chamber

due to this more NOx emissions will be formed. At full load it is slightly decreased.

2016 The author and GRDS Publishing. All rights reserved.

Available Online at: http://grdspublishing.org/journals-MATTER-home

44

MATTER: International Journal of Science and Technology

ISSN 2454-5880

Diesel, 1500 RPM

CR-Compression Ratio

700

600

NOx (ppm)

500

CR18

400

CR19

300

CR20

200

CR21

CR22

100

0

LOAD (kW)

Figure 10:Variation of NOx emissions with Load at different compression ratio

4.7 Smoke

Smoke is measured in % Hartridge Smoke Unit (HSU). Smoke opacity increases with

increase in load as by increasing load high in-cylinder temperature is obtained due to rich fuel

mixture and that will ultimately increase pyrolysis of hydrocarbon which is the main cause of

smoke formation. Smoke opacity decreased by increasing compression ratio.

2016 The author and GRDS Publishing. All rights reserved.

Available Online at: http://grdspublishing.org/journals-MATTER-home

45

MATTER: International Journal of Science and Technology

ISSN 2454-5880

60

Diesel, 1500 RPM

CR-Compression Ratio

50

SMOKE (HSU%)

40

CR18

CR19

30

CR20

20

CR21

10

CR22

0

0

0.5

1.5

2.5

3.5

LOAD (kW)

Figure 11: Variation of Smoke emissions with Load at different compression ratio

5. Conclusion

In the present research work it is obtained that CR21 is the nest for present engine from

Brake thermal efficiency, BSFC and BSEC point of view. Emissions are also reduced by

increasing compression ratio. Generally it is found minimum for CR22 but it is almost similar to

CR21 it can be concluded that CR21 is the optimum for the presently used VCR diesel engine.

BTE is 24.46 % at CR18 which increases to 25.85% at CR21 so it is clear that 1.39% efficiency

increase is obtained in BTE. Minimum BSEC is 14709.6 kJ/kW-hr at CR18, which decreases to

13928.96 kJ/kW-hr at CR21 so it can be understood that BSEC is decreased by 5.30%.

REFERENCES

Ganesan, V. (2015). Internal Combustion Engines. New Delhi: McGraw Hill Education.

K. Muralidharan, D. V. (2011). Performance, emission and combustion characteristics of a

variable compression ratio engine using methyl esters of waste cooking oil and diesel

blends. Applied Energy , 39593968.http://dx.doi.org/10.1016/j.apenergy.2011.04.014

2016 The author and GRDS Publishing. All rights reserved.

Available Online at: http://grdspublishing.org/journals-MATTER-home

46

MATTER: International Journal of Science and Technology

ISSN 2454-5880

L. Prabhu, S. S. (2013). Combustion, Performance and Emission Characteristics of Diesel

Engine with Neem Oil Methyl Ester and its Diesel Blends. American Journal of Applied

Sciences , 1546-9239.http://dx.doi.org/10.3844/ajassp.2013.810.818

M. L. Mathur, R. P. (2015). Internal Combustion Engine. New Delhi: Dhanpat Rai Publications.

Murat Karabektas, M. H. (2009). Performance and emission characteristics of a diesel engine

using isobutanoldiesel fuel blends. Renewable Energy 34 , 1554

1559.http://dx.doi.org/10.1016/j.renene.2008.11.003

Raut Rupesh L., N. B. (2014). Emission analysis of biodiesel blends on VCR engine.

International Journal of Research in Engineering and Technology , 2321-7308.

Sayi Likhitha S S, B. D. (2014). Investigation on the Effect of Diethyl Ether Additive on the

Performance of Variable Compression Ratio Diesel Engine. International Journal of

Engineering , 11-15.

T. Elango, T. S. (2011). Performance And Emission Characteristics Of Ci Engine Fuelled with

Non Edible Vegetable Oil And Diesel Blends. Journal of Engineering Science and

Technology , 240 - 250.

2016 The author and GRDS Publishing. All rights reserved.

Available Online at: http://grdspublishing.org/journals-MATTER-home

47

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Dialogue About Handling ComplaintDokument3 SeitenDialogue About Handling ComplaintKarimah Rameli100% (4)

- Mutants & Masterminds 3e - Power Profile - Death PowersDokument6 SeitenMutants & Masterminds 3e - Power Profile - Death PowersMichael MorganNoch keine Bewertungen

- Things in The Classroom WorksheetDokument2 SeitenThings in The Classroom WorksheetElizabeth AstaizaNoch keine Bewertungen

- Waldorf Curriculum ChartDokument1 SeiteWaldorf Curriculum Chartplanetalingua2020100% (1)

- Resolving A Realistic Middle Ground Towards The Sustainability Transition in The Global Political and Economic Landscape: A Comprehensive Review On Green CapitalismDokument29 SeitenResolving A Realistic Middle Ground Towards The Sustainability Transition in The Global Political and Economic Landscape: A Comprehensive Review On Green CapitalismGlobal Research and Development ServicesNoch keine Bewertungen

- Interpretation and Justification of Rules For Managers in Business Organizations: A Professional Ethics PerspectiveDokument10 SeitenInterpretation and Justification of Rules For Managers in Business Organizations: A Professional Ethics PerspectiveGlobal Research and Development ServicesNoch keine Bewertungen

- Examine The Effects of Goods and Services Tax (GST) and Its Compliance: Reference To Sierra LeoneDokument18 SeitenExamine The Effects of Goods and Services Tax (GST) and Its Compliance: Reference To Sierra LeoneGlobal Research and Development ServicesNoch keine Bewertungen

- Teacher Educators' Perceptions of Utilizing Mobile Apps For English Learning in Secondary EducationDokument28 SeitenTeacher Educators' Perceptions of Utilizing Mobile Apps For English Learning in Secondary EducationGlobal Research and Development ServicesNoch keine Bewertungen

- Perceived Self-Efficacy and Academic Performance of Stem Senior High School StudentsDokument13 SeitenPerceived Self-Efficacy and Academic Performance of Stem Senior High School StudentsGlobal Research and Development ServicesNoch keine Bewertungen

- Analyzing The Relationship Between Industrial Policy and Entrepreneurial EcosystemDokument13 SeitenAnalyzing The Relationship Between Industrial Policy and Entrepreneurial EcosystemGlobal Research and Development ServicesNoch keine Bewertungen

- The Ethical Perception On Utang Na Loob As Basis of Voter's ChoiceDokument18 SeitenThe Ethical Perception On Utang Na Loob As Basis of Voter's ChoiceGlobal Research and Development Services100% (1)

- Using Collaborative Web-Based Maps To Promote Geography Teaching and LearningDokument13 SeitenUsing Collaborative Web-Based Maps To Promote Geography Teaching and LearningGlobal Research and Development ServicesNoch keine Bewertungen

- Potential Factors Influence Failure of The Village-Owned Business: The Entity Village Autonomy of Indonesian Government's ProgramDokument12 SeitenPotential Factors Influence Failure of The Village-Owned Business: The Entity Village Autonomy of Indonesian Government's ProgramGlobal Research and Development ServicesNoch keine Bewertungen

- Design and Implementation of An Arabic Braille Self-Learning WebsiteDokument17 SeitenDesign and Implementation of An Arabic Braille Self-Learning WebsiteGlobal Research and Development ServicesNoch keine Bewertungen

- Influence of Iot On Smart LogisticsDokument12 SeitenInfluence of Iot On Smart LogisticsGlobal Research and Development ServicesNoch keine Bewertungen

- Loss Analysis in Bread Production Process Using Material Flow Cost Accounting TechniqueDokument16 SeitenLoss Analysis in Bread Production Process Using Material Flow Cost Accounting TechniqueGlobal Research and Development ServicesNoch keine Bewertungen

- Challenges in The Implementation of Schoolbased Management of Developing Schools: Basis For A Compliance FrameworkDokument14 SeitenChallenges in The Implementation of Schoolbased Management of Developing Schools: Basis For A Compliance FrameworkGlobal Research and Development ServicesNoch keine Bewertungen

- Effect of Metacognitive Intervention Strategies in Enhancing Resilience Among Pre-Service TeachersDokument12 SeitenEffect of Metacognitive Intervention Strategies in Enhancing Resilience Among Pre-Service TeachersGlobal Research and Development ServicesNoch keine Bewertungen

- Global E-Learning and Experiential Opportunities For Programs and StudentsDokument12 SeitenGlobal E-Learning and Experiential Opportunities For Programs and StudentsGlobal Research and Development ServicesNoch keine Bewertungen

- Study of Urban Heat Island in Yogyakarta City Using Local Climate Zone ApproachDokument17 SeitenStudy of Urban Heat Island in Yogyakarta City Using Local Climate Zone ApproachGlobal Research and Development ServicesNoch keine Bewertungen

- The Development of Nursing Care Model in Patients With Total Knee Replacement Reconstructive SurgeryDokument17 SeitenThe Development of Nursing Care Model in Patients With Total Knee Replacement Reconstructive SurgeryGlobal Research and Development ServicesNoch keine Bewertungen

- Bank-Specific and Macroeconomic Determinants of Banks Liquidity in Southeast AsiaDokument18 SeitenBank-Specific and Macroeconomic Determinants of Banks Liquidity in Southeast AsiaGlobal Research and Development ServicesNoch keine Bewertungen

- Investigating The Effects of Social Media On The Well-Being of TeenagersDokument18 SeitenInvestigating The Effects of Social Media On The Well-Being of TeenagersGlobal Research and Development ServicesNoch keine Bewertungen

- Implementation of Biorhythm Graph With Trigonometric Functions Using PythonDokument8 SeitenImplementation of Biorhythm Graph With Trigonometric Functions Using PythonGlobal Research and Development ServicesNoch keine Bewertungen

- Thai and Non-Thai Instructors' Perspectives On Peer Feedback Activities in English Oral PresentationsDokument22 SeitenThai and Non-Thai Instructors' Perspectives On Peer Feedback Activities in English Oral PresentationsGlobal Research and Development ServicesNoch keine Bewertungen

- Refining The English Syntax Course For Undergraduate English Language Students With Digital TechnologiesDokument19 SeitenRefining The English Syntax Course For Undergraduate English Language Students With Digital TechnologiesGlobal Research and Development ServicesNoch keine Bewertungen

- "Higher, Faster, Stronger": Championing Classroom TeachingDokument13 Seiten"Higher, Faster, Stronger": Championing Classroom TeachingGlobal Research and Development ServicesNoch keine Bewertungen

- Review of Vibration-Based Surface & Terrain Classification For Wheel-Based Robot in Palm Oil PlantationDokument14 SeitenReview of Vibration-Based Surface & Terrain Classification For Wheel-Based Robot in Palm Oil PlantationGlobal Research and Development ServicesNoch keine Bewertungen

- Development of A Topical Gel Containing A Dipeptidyl Peptidase-4 Inhibitor For Wound Healing ApplicationsDokument15 SeitenDevelopment of A Topical Gel Containing A Dipeptidyl Peptidase-4 Inhibitor For Wound Healing ApplicationsGlobal Research and Development ServicesNoch keine Bewertungen

- The Relationship of Teaching Clarity and Student Academic Motivation in Online ClassesDokument9 SeitenThe Relationship of Teaching Clarity and Student Academic Motivation in Online ClassesGlobal Research and Development ServicesNoch keine Bewertungen

- How Bi-Lingual Fathers Support Their Children To Learn Languages at HomeDokument35 SeitenHow Bi-Lingual Fathers Support Their Children To Learn Languages at HomeGlobal Research and Development ServicesNoch keine Bewertungen

- Work-Related Problems and Performance Level of Senior High School TeachersDokument22 SeitenWork-Related Problems and Performance Level of Senior High School TeachersGlobal Research and Development ServicesNoch keine Bewertungen

- The Hijiri Calendar and Its Conformance With The Gregorain Calendar by Mathematical CalculationsDokument19 SeitenThe Hijiri Calendar and Its Conformance With The Gregorain Calendar by Mathematical CalculationsGlobal Research and Development ServicesNoch keine Bewertungen

- Building A Scale of Competence To Apply Interdisciplinary Integrated Knowledge Into Practice For StudentDokument10 SeitenBuilding A Scale of Competence To Apply Interdisciplinary Integrated Knowledge Into Practice For StudentGlobal Research and Development ServicesNoch keine Bewertungen

- Grammar: English - Form 3Dokument39 SeitenGrammar: English - Form 3bellbeh1988Noch keine Bewertungen

- Fireware EssentialsDokument499 SeitenFireware EssentialsEmmanuel RodríguezNoch keine Bewertungen

- University of Engineering & Management, Jaipur: (A) Production (B) Quality (C) Product Planning (D) All of The AboveDokument4 SeitenUniversity of Engineering & Management, Jaipur: (A) Production (B) Quality (C) Product Planning (D) All of The AboveSupriyo BiswasNoch keine Bewertungen

- Haryana at A Glance: Geographical AreaDokument1 SeiteHaryana at A Glance: Geographical AreasonuNoch keine Bewertungen

- The Rescue Agreement 1968 (Udara Angkasa)Dokument12 SeitenThe Rescue Agreement 1968 (Udara Angkasa)Rika Masirilla Septiari SoedarmoNoch keine Bewertungen

- Governance Whitepaper 3Dokument29 SeitenGovernance Whitepaper 3Geraldo Geraldo Jr.Noch keine Bewertungen

- ZultaniteDokument4 SeitenZultaniteAcharya BalwantNoch keine Bewertungen

- ESS Revision Session 2 - Topics 5-8 & P1 - 2Dokument54 SeitenESS Revision Session 2 - Topics 5-8 & P1 - 2jinLNoch keine Bewertungen

- Surge Protectionfor ACMachineryDokument8 SeitenSurge Protectionfor ACMachineryvyroreiNoch keine Bewertungen

- RPS Manajemen Keuangan IIDokument2 SeitenRPS Manajemen Keuangan IIaulia endiniNoch keine Bewertungen

- How To Use The ActionDokument3 SeitenHow To Use The Actioncizgiaz cizgiNoch keine Bewertungen

- The Bipolar Affective Disorder Dimension Scale (BADDS) - A Dimensional Scale For Rating Lifetime Psychopathology in Bipolar Spectrum DisordersDokument11 SeitenThe Bipolar Affective Disorder Dimension Scale (BADDS) - A Dimensional Scale For Rating Lifetime Psychopathology in Bipolar Spectrum DisordersDM YazdaniNoch keine Bewertungen

- NURS FPX 6021 Assessment 1 Concept MapDokument7 SeitenNURS FPX 6021 Assessment 1 Concept MapCarolyn HarkerNoch keine Bewertungen

- Evolution of Designed Industrial Symbiosis Networks in The Ulsan Eco-Industrial Park - Research and Development Into Business ADokument10 SeitenEvolution of Designed Industrial Symbiosis Networks in The Ulsan Eco-Industrial Park - Research and Development Into Business Asanyukta sinhaNoch keine Bewertungen

- Bus Organization of 8085 MicroprocessorDokument6 SeitenBus Organization of 8085 MicroprocessorsrikrishnathotaNoch keine Bewertungen

- Atlantean Dolphins PDFDokument40 SeitenAtlantean Dolphins PDFBethany DayNoch keine Bewertungen

- Install GuideDokument64 SeitenInstall GuideJorge Luis Yaya Cruzado67% (3)

- Problem Based LearningDokument23 SeitenProblem Based Learningapi-645777752Noch keine Bewertungen

- Cooking Oils and Smoke Points - What To Know and How To Choose The Right Cooking Oil - 2020 - MasterClassDokument7 SeitenCooking Oils and Smoke Points - What To Know and How To Choose The Right Cooking Oil - 2020 - MasterClasschumbefredNoch keine Bewertungen

- JurisprudenceDokument11 SeitenJurisprudenceTamojit DasNoch keine Bewertungen

- Value Chain AnalaysisDokument100 SeitenValue Chain AnalaysisDaguale Melaku AyeleNoch keine Bewertungen

- Robert FrostDokument15 SeitenRobert FrostRishi JainNoch keine Bewertungen

- PEDIA OPD RubricsDokument11 SeitenPEDIA OPD RubricsKylle AlimosaNoch keine Bewertungen

- PDF - Unpacking LRC and LIC Calculations For PC InsurersDokument14 SeitenPDF - Unpacking LRC and LIC Calculations For PC Insurersnod32_1206Noch keine Bewertungen

- Hoc Volume1Dokument46 SeitenHoc Volume1nordurljosNoch keine Bewertungen

- Module 5amp6 Cheerdance PDF FreeDokument27 SeitenModule 5amp6 Cheerdance PDF FreeKatNoch keine Bewertungen