Beruflich Dokumente

Kultur Dokumente

15 May 33

Hochgeladen von

suraj dhulannavarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

15 May 33

Hochgeladen von

suraj dhulannavarCopyright:

Verfügbare Formate

International Journall of Research In Science & Engineering

Volume: 1 Issue: 3

e

e-ISSN:

2394-8299

pp-ISSN: 2394-8280

SOLAR POWERED SPRAYER FOR AGRICULTURAL USES

Sagar P. Yadav1, Pooja M. Kakad2, Anushree V. Bhujade3

1

B.E. Final Year, Mechanical Engineering Department, J.D.I.E.T. Yavatmal,(M.S.), India,

Sagaryadav1999@gmail.com

2

B.E. Final Year, Mechanical Engineering Department, J.D.I.E.T. Yavatmal, (M.S.), India,

kakadpooja2@gmail.com

3

B.E. Final Year, Mechanical Engineering Department, J.D.I.E.T. Yavatmal, (M.S.), India,

anushreeb92@gmail.com

_________________________________________________________________________________

ABSTRACT

Energy - demand is one of the major threads for our country. Finding solutions, to meet the Energy demand is the great challenge for Social Scientist, Engineers, Entrepreneurs and Industrialist of our

Country. According to them, Applications of Non conventional energy is the only alternate solution for

conventional energy demand. Now-a--days the Concept and Technology employing this Non

Non-conventional

energy becomes very popular for all kinds of development activities. One of the major area, which finds

number applications are in Agriculture Sectors. Solar energy plays an important role in drying agriculture

products and for irrigation purpose for pumping the well water in remote villages without electricity. This

Technology on solar energy can be extended for spraying pesticides, Fungicides and Fertilizers etc., using

Solar Sprayers. This paper deals how a Power Sprayer

Sprayer which is already in use and works with fossil fuel

can be converted into solar sprayers works without any fossil fuel.

Keywords: Spray Pump, Agriculture Spraying Equipment.

Equipment

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. INTRODUCTION

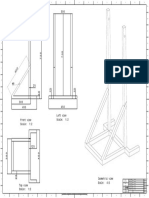

In this project an aluminum frame is constructed using aluminum bars to keep the weight of the frame low. In

this frame a retractable link is fixed to the top end of which a solar photovoltaic panel is fixed that converts solar

power into electricity. This electricity is then provided to battery via a charging circuit and is used for charging

the battery. Electric power from this battery is given to an electric motor via control switches,

switches, by controlling

which entire device can be operated. To the shaft of this electric motor a blower fan is connected. This blower

blows high speed air into the blower pipe.

Fig. 1 Solar sprayer

IJRISE| www.ijrise.org|editor@ijrise.org [182-186]

International Journall of Research In Science & Engineering

Volume: 1 Issue: 3

e

e-ISSN:

2394-8299

pp-ISSN: 2394-8280

This blower pipe is held with hand by the device operator and is directed onto the area where he wishes to spray

the pesticides / insecticides. The insecticide reservoir is connected to the blower pipe. By continuously feeding

this insecticide to the blower pipe the same is spread or sprinkled

sprinkled where wished. Liquid insecticide is sprayed on

the crops using Spray pipe, which receives liquid from a reservoir with the help of a pump. This pump is driven

by another DC motor that receives power from the same battery. Thus insecticide in liquid

liquid form is sprayed

where wished. The project can also run emergency lamp using battery power thus this project can be of very

much use and can be very beneficial for farmers. The running cost of project is nil.

2. EQUIPMENT USES

Spraying fluid tank

Spraying pipe.

Solar panel.

Battery.

Charger.

Pump.

Motor, Etc.

3. SPECIFICATION

3.1 According to Spraying Capacity & Discharge Capacity Of Spray Motor Is Selected

Weight of the motor

: 1kg (approx)

Current

:7Amp

mp

Operating power required : 84 watt

Operating Voltage

: 12V

Motor Speed

: 1,600 rpm.

Discharge Capacity

Flow rate

Fluid pressure

: 0-12

12 Lit/min

: >560ml / 10 seconds

: 1.6kgf/cm2

6kgf/cm2

3.2 According To Motor Operating Power Battery Is Selected

Weight of the battery : 2 kg.

Cost of the battery : Rs.1200

Output power

Operating voltage : 12v

: 144 watt.

3.3 According to Battery Output Power Solar Panel Is Selected

Power

: 10 watt

Dimension

: 397*278*25 mm

IJRISE| www.ijrise.org|editor@ijrise.org [182-186]

International Journall of Research In Science & Engineering

Volume: 1 Issue: 3

Weight

Open Circuit Voltage : 21.5 volt

Short Circuit Current : 0.65Amp

Operating Current : 12 Amp.

e

e-ISSN:

2394-8299

pp-ISSN: 2394-8280

: 1.6 kg

4. WORKING OF SOLAR SPRAYER

4.1 Working Principle and Operation

Solar radiation can be converted directly into electricity using semiconductor devices, which are known

as Photovoltaic (PV) cells. When Sunlight falls upon the Solar cell a part of the light is absorbed and it is

converted into Electrical Energy by means of Electron Movements. This Solar Panel is connected to 12V lead

acid battery for storing the electrical energy. A 12V DC motor is connected to these lead acid battery to convert

the electrical energy into mechanical energy.

4.2 Operating System of Solar Panel

Charging can be done using a solar Panel. Battery can be charged continuously during discharge itself,

by attaching the Panel on the sprayers. Without Panel on the sprayers, discharge can be done for a minimum

period of 4 to 5 hours. By changing thee battery, discharge can be continued for further more hours. Charging can

be done by separate Solar Panel attachment.

4.3 Working of solar sprayer

The solar agro sprayer consist of three main parts namely,

Solar panel unit

Storage battery unit and

Rotating motor.

In the solar agro sprayer the two stroke petrol engine component of the power sprayer has been

replaced with a combination of storage battery and rotating motor. The action of the rotating motor could be

controlled by a switch attached withh it in the assembly. Solar panel arrangement has been provided at the top of

the unit to charge the storage battery. The units of solar panel, storage battery and a rotating DC motor were

mutually attached with one another. A solar panel of size of 1m2 area

area with an output power of 75 watt has been

mounted on a circular metal frame which is enclosed over the cylindrical chemical tank of capacity of 10 l. The

solar panel arrangement was made at an angle of 45 to the vertical so that it should not create any trouble to the

person who is loading the unit on his back. Moreover it is able to receive maximum solar radiations

continuously from the sun during the operation of the unit in the field. The output of the panel is connected in

parallel with the 12 V storage

age battery to store the electrical energy from the panel. The 12 V battery is properly

connected with a 12 V DC motor attachment on the frame. The operation of the motor is controlled by a press

type switch attached on the assembly. energy received from the solar cell is stored in a storage battery unit for

application. This stored electrical energy can be converted in to mechanical energy by rotating the motor. For

this mechanical operation there is no need of conventional fuel like petrol and oil. The Per

IJRISE| www.ijrise.org|editor@ijrise.org [182-186]

International Journall of Research In Science & Engineering

Volume: 1 Issue: 3

e

e-ISSN:

2394-8299

pp-ISSN: 2394-8280

Fig.2: Solar Panel Unit

Working of this pump is simple. Solar panel collects the solar energy into electricity and supplies it to

battery. Battery uses this electricity to charge itself. This battery next is used to operate motor and lighting

system. Motor attached at the bottom of tank sucks the liquid from tank and deliver it. The ON and OFF of

motor is controlled with handle attached to spray gun. A switch is given there to operate its function. As the

handle is pushed, the valve of gun is released and at the same time the switch is pushed which supplies the

current to motor. Thus motor sucks liquid and deliver it through delivery pipe.

5. CALCULATION

5.1 Analytical calculation of current & charging time of the battery

The current produced by the solar panel (I) was calculated

calculated by knowing the maximum power (P) of the

solar panel and the voltage rating (V) of the battery that is given by

I=P/V

Therefore, I=10/12 = 0.83 Ampere

Charging time (T) was computed by taking the ratio rating of battery in ampere hour (Ah) to the total

current consumed by the solar panel.

T= (battery rating in ampere hour)/(total current consumed by the solar panel)

Therefore, T=12/0.83=14.45 hours

6. ADVANTAGE

Easy in construction

More economical

Easy to clean and maintain

It is a renewable energy source

It does not create air pollutant & noise

Easy to handle

Do not required fuel hence cost reduce for spraying

IJRISE| www.ijrise.org|editor@ijrise.org [182-186]

International Journall of Research In Science & Engineering

Volume: 1 Issue: 3

e

e-ISSN:

2394-8299

pp-ISSN: 2394-8280

7. RESULT

The proposed system was tested with AC charging as well as solar charging. From the results it was

found that the current and time required for charging the full battery capacity of 12V, 12Ah by practically is

14.45 hours and hours. The fully charged batte

battery

ry can be used to spray 580 liters of fertilizer, which

approximately spray 5-6

6 acres of land. It was also found that, if we charge the battery in a day it can be used to

spray 200 liters of fertilizer. The initial cost of the proposed system is little more

more as compared to conventional

sprayer but the running cost of the system is very less. The developed system used for spraying the fertilizer,

pesticides, fungicides and painting.

8. CONCLUSION

As we know 70% of population of our country lives in villages & their main occupation is agriculture. The

prominent aim of this project is to fulfil the tasks like hand spraying, IC engine spraying, and leg pump spraying

etc. using non-conventional energyy sources. Thus solar operated spray pump will help the farmers of those

remote areas of country where fuel is not available easily. They can perform their regular work as well as saves

fuel up to large extent. At the same time they reduces environment pollution.

pollution. Thus saving revenue of

government & also most demanded fuel.

REFERENCES

[1] Sootha, G.D. and S.K. Gupta, 1991. Jugal Kishor (Ed.); Solar Energy Centre. Proceedings of the

Workshop on Technology Transfer.

[2 ] Rao, G.D., 0000. Solar Energy, Sol

Solar Photo-Voltaic:

Voltaic: Electric Power Generation, 15: 434-484.

434

[3] Rajesh, Kumar and O.S. Sastry, 1998. Proceedings of 2nd World Conference on Photovoltaic Solar

Energy Conversion held at Vienna, Austria, pp: 6-10.

6 10. Performance, evaluation and development of S

Solar

Photovoltaic Lighting Systems in India.

[4] Sastry, O.S., Rajesh Kumar and P.C. Pant, 1999. Indo-Japan

Indo

Co-operation

operation on Science&Technology

Seminar Photovoltaic Technology in India & Japan, 2 New Delhi.

[5] Sharma, R.S., 1995. Environmental Economics

Economics and Design Consideration to commercialize Solar

Thermal Power Generation in Megawatt(MW) Range, Published in the transactions of International

organized by the University of Melbourne, Australia.

IJRISE| www.ijrise.org|editor@ijrise.org [182-186]

Das könnte Ihnen auch gefallen

- 2 Suku - Mar o Automatic PDFDokument4 Seiten2 Suku - Mar o Automatic PDFsuraj dhulannavarNoch keine Bewertungen

- 44 Tapsa Mech 006Dokument9 Seiten44 Tapsa Mech 006suraj dhulannavarNoch keine Bewertungen

- E RationingDokument3 SeitenE Rationingsuraj dhulannavarNoch keine Bewertungen

- Analysis of Vibration Damping in Machine ToolsDokument6 SeitenAnalysis of Vibration Damping in Machine Toolssuraj dhulannavarNoch keine Bewertungen

- 199 Iphv7i3008xDokument7 Seiten199 Iphv7i3008xsuraj dhulannavarNoch keine Bewertungen

- 1:1 XXX A1: Designed By: DateDokument1 Seite1:1 XXX A1: Designed By: Datesuraj dhulannavarNoch keine Bewertungen

- 03 e Pipetube en WebDokument18 Seiten03 e Pipetube en Websuraj dhulannavarNoch keine Bewertungen

- 1:1 XXX A1: Toshavi PCDokument1 Seite1:1 XXX A1: Toshavi PCsuraj dhulannavarNoch keine Bewertungen

- (IJCST-V4I4P3) :reema Patel, A.N.Shewale, C.S.PatilDokument3 Seiten(IJCST-V4I4P3) :reema Patel, A.N.Shewale, C.S.PatilEighthSenseGroupNoch keine Bewertungen

- 1:1 XXX A4: Designed By: DateDokument1 Seite1:1 XXX A4: Designed By: Datesuraj dhulannavarNoch keine Bewertungen

- Mobile Wind Charger for Automobile BatteriesDokument7 SeitenMobile Wind Charger for Automobile Batteriessuraj dhulannavarNoch keine Bewertungen

- Visvesvaraya Technological University BelgaumDokument2 SeitenVisvesvaraya Technological University Belgaumsuraj dhulannavarNoch keine Bewertungen

- D e S I G N o F A N A U T o M A T e D S o R T I N G o F o B J e C T R e J e C T I o N A N D C o U N T I N G M A C H I N eDokument13 SeitenD e S I G N o F A N A U T o M A T e D S o R T I N G o F o B J e C T R e J e C T I o N A N D C o U N T I N G M A C H I N esuraj dhulannavarNoch keine Bewertungen

- FrameDokument1 SeiteFramesuraj dhulannavarNoch keine Bewertungen

- Left View Scale: 1:2: 1:1 XXX A0Dokument1 SeiteLeft View Scale: 1:2: 1:1 XXX A0suraj dhulannavarNoch keine Bewertungen

- 1:1 XXX A1: Toshavi 5/3/2016Dokument1 Seite1:1 XXX A1: Toshavi 5/3/2016suraj dhulannavarNoch keine Bewertungen

- 55Dokument3 Seiten55md junuNoch keine Bewertungen

- 437NDokument8 Seiten437Nsuraj dhulannavarNoch keine Bewertungen

- FrameDokument1 SeiteFramesuraj dhulannavarNoch keine Bewertungen

- 5Dokument4 Seiten5suraj dhulannavarNoch keine Bewertungen

- Automatic Rain Operated Wiper Group ProjectDokument5 SeitenAutomatic Rain Operated Wiper Group Projectsuraj dhulannavarNoch keine Bewertungen

- FrameDokument1 SeiteFramesuraj dhulannavarNoch keine Bewertungen

- 1:1 XXX A1: Designed By: DateDokument1 Seite1:1 XXX A1: Designed By: Datesuraj dhulannavarNoch keine Bewertungen

- 1:1 XXX A4: Designed By: DateDokument1 Seite1:1 XXX A4: Designed By: Datesuraj dhulannavarNoch keine Bewertungen

- Dam Shutter Control Using Servo MotorDokument3 SeitenDam Shutter Control Using Servo MotorkarthikNoch keine Bewertungen

- Dam Shutter Control Using Servo MotorDokument3 SeitenDam Shutter Control Using Servo MotorkarthikNoch keine Bewertungen

- WWW Mechengg Net 2015 09 Design and Fabrication of InjectionDokument17 SeitenWWW Mechengg Net 2015 09 Design and Fabrication of Injectionsuraj dhulannavarNoch keine Bewertungen

- 1:1 XXX A1: Toshavi 5/3/2016Dokument1 Seite1:1 XXX A1: Toshavi 5/3/2016suraj dhulannavarNoch keine Bewertungen

- MSHDokument20 SeitenMSHsuraj dhulannavar100% (1)

- Square Hole Drilling MachineDokument4 SeitenSquare Hole Drilling Machineedisonmech_erfNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Learn Kannada in 7 Days with Common PhrasesDokument25 SeitenLearn Kannada in 7 Days with Common PhrasesPaatima BeautymaNoch keine Bewertungen

- PepsiCo IndiaDokument6 SeitenPepsiCo Indiameghasingh_09Noch keine Bewertungen

- 49d48f60-4d15-480e-b3ce-d1d9ef8fd57eDokument12 Seiten49d48f60-4d15-480e-b3ce-d1d9ef8fd57ezahidhssn1Noch keine Bewertungen

- MP Palakkad Report PDFDokument26 SeitenMP Palakkad Report PDFRahulNoch keine Bewertungen

- History of Coffee in The CordilleraDokument3 SeitenHistory of Coffee in The CordilleraMACARTHY MALANESNoch keine Bewertungen

- Database of Restricted SuppliersDokument3 SeitenDatabase of Restricted SuppliersWhistleblowers SaNoch keine Bewertungen

- APS Hydro Private LimitedDokument14 SeitenAPS Hydro Private LimitedHema LathaNoch keine Bewertungen

- 2012-08-09 The County TimesDokument40 Seiten2012-08-09 The County TimesSouthern Maryland OnlineNoch keine Bewertungen

- Malvern Property News 17/06/2011Dokument27 SeitenMalvern Property News 17/06/2011NQDMSNoch keine Bewertungen

- Role of AgricultureDokument13 SeitenRole of AgricultureHridoy Islam MominulNoch keine Bewertungen

- Critical Appraisal Cross-Sectional Studies Aug 2011Dokument3 SeitenCritical Appraisal Cross-Sectional Studies Aug 2011dwilico100% (1)

- Technology Profile - WavetecDokument13 SeitenTechnology Profile - WavetecanumNoch keine Bewertungen

- Volume 3, Issue 4: Agriculture, Food and HealthDokument50 SeitenVolume 3, Issue 4: Agriculture, Food and HealthWilliam Carey International University PressNoch keine Bewertungen

- Bamboo Resine BoatDokument20 SeitenBamboo Resine BoatPete CammarataNoch keine Bewertungen

- Water Resources - Exam PackDokument27 SeitenWater Resources - Exam Packdevanand.r.mahesh123Noch keine Bewertungen

- Atok Big Wedge Mining Co Vs HON IAC Et Al - G.R. No. 63528 September 9, 1996Dokument17 SeitenAtok Big Wedge Mining Co Vs HON IAC Et Al - G.R. No. 63528 September 9, 1996Jacinto Jr JameroNoch keine Bewertungen

- Acid content in fruitsDokument2 SeitenAcid content in fruitsbone fire100% (1)

- Aquaculture Health MagazineDokument36 SeitenAquaculture Health MagazinefdlabNoch keine Bewertungen

- Soil Geog NotesDokument15 SeitenSoil Geog NotesDuete Emma100% (3)

- Set A Question PaperDokument43 SeitenSet A Question PaperRahul MishraNoch keine Bewertungen

- Enrep PresentationDokument26 SeitenEnrep Presentationanon_762574056Noch keine Bewertungen

- Basic Tarantula CareDokument25 SeitenBasic Tarantula CareJen MaramionNoch keine Bewertungen

- Oriented Strand Board: Product GuideDokument12 SeitenOriented Strand Board: Product GuideDillonNoch keine Bewertungen

- B. S. Ozdemir, H. Budak (Auth.), Chittaranjan Kole (Eds.) - Wild Crop Relatives - Genomic and Breeding Resources - Millets and Grasses-Springer-Verlag Berlin Heidelberg (2011) PDFDokument344 SeitenB. S. Ozdemir, H. Budak (Auth.), Chittaranjan Kole (Eds.) - Wild Crop Relatives - Genomic and Breeding Resources - Millets and Grasses-Springer-Verlag Berlin Heidelberg (2011) PDFtejdeepaNoch keine Bewertungen

- Pest-Cure: Subject: Proposal For Renewal of Pest Management ServicesDokument6 SeitenPest-Cure: Subject: Proposal For Renewal of Pest Management Servicesvarun yadavNoch keine Bewertungen

- Meiji Japan's Agricultural and Industrial DevelopmentDokument12 SeitenMeiji Japan's Agricultural and Industrial DevelopmentSania MariamNoch keine Bewertungen

- Makueni County Integrated Development Plan 2018-2022Dokument59 SeitenMakueni County Integrated Development Plan 2018-2022Aaron MaingaNoch keine Bewertungen

- 10 Major Types of Natural Resources Found in PakistanDokument13 Seiten10 Major Types of Natural Resources Found in PakistanAbdul MajidNoch keine Bewertungen

- Modul Gerak Gempur Bahasa Inggeris Tahun 6Dokument33 SeitenModul Gerak Gempur Bahasa Inggeris Tahun 6lianaNoch keine Bewertungen

- Mishtann Foods Limited Investor Presentation Highlights Growth PlansDokument41 SeitenMishtann Foods Limited Investor Presentation Highlights Growth PlansGanesh AlamalkarNoch keine Bewertungen