Beruflich Dokumente

Kultur Dokumente

ASME 2A - 2B - Inch Thread Calculator

Hochgeladen von

Bruno GondimOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ASME 2A - 2B - Inch Thread Calculator

Hochgeladen von

Bruno GondimCopyright:

Verfügbare Formate

ReadMe

ReadMe - Page 1

All calculations are performed via the tabs on the bottom. You may have to

scroll the tabs to see each one.

I've tried to keep each of the tabs fitted to a single letter sized sheet of paper.

So, due to the lack of space on the various tabs, special instructions for each of

the tabs are noted below.

All Sheets:

To calculate Pitch Diameter from Measurement over Wires:

d2 = Mw+(0.866025*P)-(3*W)

To calculate Measurement over Wires from Pitch Diameter:

Mw = d2-(0.866025*P)+(3*W)

If you are cutting a thread to fit a high quality nut/bolt, give yourself about a

0.001 to 0.002 allowance on all dimensions, otherwise the fit of the nut/bolt will

be extremely tight. Store Bought nuts/bolts, are hit and miss. I've found some

cheap nuts/bolts that even cutting to the minimum size for nuts, or maximum size

for bolts, they were still loose, because their tolerances were already maxed out.

Your experience may be different, but measuring with a good set of thread wires

will give you a good idea what's going on.

ASME-2A and 2B Threads sheet:

The value for UNC, UNF, UNEF, or UN needs to be set, because this affects

how the External Pitch Diameter Tolerance is set. If unknown, use UN, as you

won't be off more than a couple of tenths.

* External cutter tip width rounded to external thread root (Frs). Internal cutter

tip width rounded to internal thread root (Frn).

ASME 2A and 2B Machine Screw Threads sheet:

* External cutter tip width rounded to external thread root (Frs). Internal cutter

tip width rounded to internal thread root (Frn).

USS and SAE Threads sheet:

** External, and Internal cutter tip width rounded to flat (Fc/Fr)

Page 1

ReadMe

20131221

ReadMe - Page 2

The information in this spreadsheet came from many sources. The bulk of the informatio

The information on using the 3-wire measuring system, came from the Machineries Hand

So far, all of the threads that I've calculated for the ASME threads, were within

0.0002 of the actual measurements listed in the Machineries Handbook, 27 th ed..

The Pitch Diameter Tolerance for the USS/SAE threads were a pain to get right.

Anyway, they seem to be good now. I had to Adjust a couple of formulas, so

that they followed the thread specs. All of the threads are within 0.0003 of the

Actual measurements listed in the Screw Thread Production for Close Limits

PDF.

All of the threads, both ASME, and USS/SAE, that have subsequently been cut,

were well within 0.001 of the actual standards. More than adequate for my use.

This spreadsheet has protection turned on for everything but the light gray

boxes at the top of each sheet. There is no password for the protection, so you

can modify it as you see fit. It's only there to prevent accidental changes

occurring to the math calculations, which, were difficult enough to do the first

time.

If you do modify this spreadsheet, let me know. My email is: farmerboy1967@yahoo.com

Page 2

ReadMe

NOTE: I removed the specs for creating a machine screw tap, due to using two

conflicting standards. I will add it back again, when I can get hold of a copy of

ASME B94.9

20131221

ChangeLog

20120516 Why, oh why, did I not put this in earlier?

20120516 Modified the Thread_Passes tab. It now looks, and functions much

better.

20120519 Minor Cleanup.

20131221 Modified scripts to use ^1/3 instead of ^0.333. This is to conform

with cube root standard. Minor text changes / cleanup

Page 3

ReadMe

20131221

Page 4

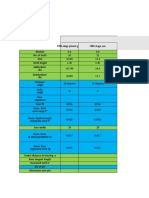

ASME-2A_and_2B_Threads

ASME B1.1 Inch Threads

Basic (Nominal) Diameter (dbsc/Dbsc) =

Threads per Inch (TPI) =

Coarse=UNC, Fine=UNF, Extra Fine=UNEF. Everything else=UN =

1.2361

20.000

UNC

Basic Information

Thread Pitch (P) = 0.0500

Thread Height (H) = 0.0433

Internal Minimum Diameter Tolerance (TD1) = 0.011500

External Pitch Diameter Tolerance (Td2) = 0.005313

Single Depth of Thread * (hn) = 0.0271

Double Depth of Thread (hn2) = 0.0541

Single Depth of Thread In-feed @ 29.5 Degrees = 0.0311

Double Depth of Thread In-feed @ 29.5 Degrees = 0.0622

Flat on External Thread Root and Internal Thread Crest (Frs/Fcn) = 0.0125

Flat on External Thread Crest and Internal Thread Root (Fcs/Frn) = 0.0063

External Threads (2A)

Maximum Major Diameter (dmax) =

Minimum Major Diameter (dmin) =

Maximum Minor Diameter (d1max) =

Basic Pitch Diameter (d2) =

Maximum Pitch Diameter (d2max) =

Minimum Pitch Diameter (d2min) =

Best Wire Size (W) =

Pee Dee Wire Size (Wpd) =

Maximum Measurement over Pee Dee Wires (Mwmax) =

Minimum Measurement over Pee Dee Wires (Mwmin) =

Internal Threads (2B)

Minimum Minor Diameter (D1min)=

Maximum Minor Diameter (D1max) =

Minimum Pitch Diameter (D2min) =

Basic Pitch Diameter (D2) =

Maximum Pitch Diameter (D2max) =

Minimum Major Diameter (Dmin) =

See ReadMe for additional instructions.

Page 5

1.2345

1.2264

1.1804

1.2036

1.2020

1.1967

0.0289

0.0290

1.2457

1.2404

1.1820

1.1935

1.2036

1.2071

1.2105

1.2361

20131221

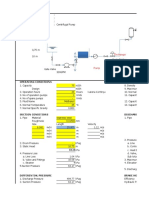

ASME 2A and 2B Machine Screw Th

ASME B1.1 Machine Screw Threads

Screw Number (Sn) =

Threads per Inch (TPI) =

10

32.000

Basic Information

Basic (Nominal) Diameter (dbsc/Dbsc) = 0.1900

Thread Pitch (P) = 0.0313

Thread Height (H) = 0.0271

Internal Minimum Diameter Tolerance (TD1) = 0.007906

External Pitch Diameter Tolerance (Td2) = 0.003008

Single Depth of Thread * (hn) = 0.0169

Double Depth of Thread (hn2) = 0.0338

Single Depth of Thread In-feed @ 29.5 Degrees = 0.0194

Double Depth of Thread In-feed @ 29.5 Degrees = 0.0389

Flat on External Thread Root and Internal Thread Crest (Frs/Fcn) = 0.0078

Flat on External Thread Crest and Internal Thread Root (Fcs/Frn) = 0.0039

External Threads (2A)

Maximum Major Diameter (dmax) =

Minimum Major Diameter (dmin) =

Maximum Minor Diameter (d1max) =

Basic Pitch Diameter (d2) =

Maximum Pitch Diameter (d2max) =

Minimum Pitch Diameter (d2min) =

Best Wire Size (W) =

Pee Dee Wire Size (Wpd) =

Maximum Measurement over Pee Dee Wires (Mwmax) =

Minimum Measurement over Pee Dee Wires (Mwmin) =

Internal Threads (2B)

Minimum Minor Diameter (D1min)=

Maximum Minor Diameter (D1max) =

Minimum Pitch Diameter (D2min) =

Basic Pitch Diameter (D2) =

Maximum Pitch Diameter (D2max) =

Minimum Major Diameter (Dmin) =

See ReadMe for additional instructions.

Page 6

0.1891

0.1831

0.1553

0.1697

0.1688

0.1658

0.0180

0.0180

0.1957

0.1927

0.1562

0.1641

0.1697

0.1799

0.1736

0.1900

20131221

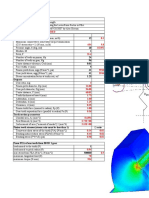

USS and SAE Threads

USS (Coarse) and SAE (Fine) Inch Threads

Major Diameter (d/D) =

Threads per Inch (TPI) =

Basic Information

Thread Pitch (P) =

Thread Height (H) =

Single Depth of Thread ** (hn) =

Double Depth of Thread (hn2) =

Single Depth of Thread In-feed @ 29.5 Degrees =

Double Depth of Thread In-feed @ 29.5 Degrees =

Flat on Crest and Root of Threads (Fc/Fr) =

External Threads

Maximum Major Diameter (dmax) =

Minimum Major Diameter (dmin) =

Maximum Pitch Diameter (d2max) =

Minimum Pitch Diameter(d2min) =

Maximum Minor Diameter (d1max) =

Minimum Minor Diameter (d1min) =

Best Wire Size (W) =

Pee Dee Wire Size (Wpd) =

Maximum Measurement over Pee Dee Wires (Mwmax) =

Minimum Measurement over Pee Dee Wires (Mwmin) =

Internal Threads

Maximum Minor Diameter (D1max) =

Minimum Minor Diameter (D1min) =

Maximum Pitch Diameter (D2max) =

Minimum Pitch Diameter(D2min) =

Maximum Major Diameter (Dmax) =

Minimum Major Diameter (Dmin) =

See ReadMe for additional instructions.

0.2500

20.000

0.0500

0.0433

0.0325

0.0650

0.0373

0.0746

0.0063

0.2500

0.2440

0.2175

0.2155

0.1850

0.1792

0.0289

0.0290

0.2612

0.2592

0.1909

0.1860

0.2195

0.2180

0.2557

0.2519

20131221

Page 7

Thread_Passes

Thread Cutting Passes.

Threads per Inch (TPI)

Iron/Steel = I, Cast Iron = C, Non Ferrous = N

Thread Pitch (P)

Single Depth of Thread (hn)

Last Path Depth (L)

Thread Depth minus Last Path Depth (D)

Tangent (T)

Area (A)

Number of Passes (N)

Area Ratio (a)

Depth of Thread per Pass

0.0500

0.0271

0.0010

0.0261

0.5774

0.0005

4

0.0004

Single Double

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

Pass

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Spring means to run another threading pass without moving the compound.

Page 8

20

I

0.0106

0.0184

0.0261

0.0271

Spring

0.0213

0.0369

0.0521

0.0541

Spring

20131221

Das könnte Ihnen auch gefallen

- Proper Bolt Axial Tightening ForceDokument1 SeiteProper Bolt Axial Tightening ForcePrabhu SelvaRajNoch keine Bewertungen

- ASTM Tables ConvertersDokument314 SeitenASTM Tables ConvertersVasileios PantouvakisNoch keine Bewertungen

- Helical Compressing Spring Calculation PDFDokument4 SeitenHelical Compressing Spring Calculation PDFViktor KovtunNoch keine Bewertungen

- Catalogo New PrecisionDrill ML HB r2 PDFDokument214 SeitenCatalogo New PrecisionDrill ML HB r2 PDFDei AdrianzaNoch keine Bewertungen

- Fits BoreDokument1 SeiteFits BorezzzNoch keine Bewertungen

- Complete Rim and Face Using One DialDokument7 SeitenComplete Rim and Face Using One DialAzani NoorNoch keine Bewertungen

- Mode Shape Frequency (HZ.) Speed (RPM)Dokument3 SeitenMode Shape Frequency (HZ.) Speed (RPM)tooocooolNoch keine Bewertungen

- Activity 2Dokument16 SeitenActivity 2Kate Joshua A. MinguitoNoch keine Bewertungen

- Galling 2Dokument6 SeitenGalling 2Ricardo MartinsNoch keine Bewertungen

- Pressing Force Calculator UpdatedDokument25 SeitenPressing Force Calculator Updatedanush_swaminathanNoch keine Bewertungen

- h06974 MC Series IcvDokument2 Seitenh06974 MC Series IcvLoganBohannonNoch keine Bewertungen

- h06971 HV Series IcvDokument3 Seitenh06971 HV Series IcvLoganBohannonNoch keine Bewertungen

- SHAFT GoodSod Deriv07Dokument11 SeitenSHAFT GoodSod Deriv07Leonidas FritzNoch keine Bewertungen

- Hydraulic Seals - Rod SealsDokument176 SeitenHydraulic Seals - Rod SealsRoberto HipólitoNoch keine Bewertungen

- Excel Project ManagerDokument30 SeitenExcel Project ManagerFika JeNoch keine Bewertungen

- Tolerance SheetDokument76 SeitenTolerance SheetprasannaNoch keine Bewertungen

- Bearing Stress AnalysisDokument7 SeitenBearing Stress Analysisrahulmenon995030Noch keine Bewertungen

- Pump Save 4401Dokument31 SeitenPump Save 4401quyenducqdcNoch keine Bewertungen

- Tugas MekfluDokument21 SeitenTugas MekfluriloaddNoch keine Bewertungen

- How To Manually Delete An Enterprise PDM File Vault (Archives and Database) PDFDokument7 SeitenHow To Manually Delete An Enterprise PDM File Vault (Archives and Database) PDFrachamreddyrNoch keine Bewertungen

- Solidworks Routing - Piping and TubingDokument3 SeitenSolidworks Routing - Piping and TubingLuis Rodrigo SanchezNoch keine Bewertungen

- FWEFJLNIY4QKLQXDokument13 SeitenFWEFJLNIY4QKLQXSoldan MihaiNoch keine Bewertungen

- Acme Thread External 29Dokument16 SeitenAcme Thread External 29Dhanraj VasanthNoch keine Bewertungen

- SandHug BailerDokument2 SeitenSandHug BailerAhmedMohsenNoch keine Bewertungen

- PressFitPressureCalculator English UnitsDokument5 SeitenPressFitPressureCalculator English UnitsFelipeNoch keine Bewertungen

- Acme & Stub Acme LoadDokument4 SeitenAcme & Stub Acme Loadraseen pNoch keine Bewertungen

- Problem 877 - Continuous Beam by Moment Distribution MethodDokument5 SeitenProblem 877 - Continuous Beam by Moment Distribution MethodRod PariñoNoch keine Bewertungen

- Shaft - Axial - Xls Radius Transition or Undercut Between Diameters?Dokument2 SeitenShaft - Axial - Xls Radius Transition or Undercut Between Diameters?Pradeep SarodeNoch keine Bewertungen

- Stress DesignDokument11 SeitenStress DesignKarthikeyan SankarrajanNoch keine Bewertungen

- O-RING Cross Section in MMDokument10 SeitenO-RING Cross Section in MMSuresh Kumar MittapalliNoch keine Bewertungen

- Af KSB 049-1504103-045Dokument3 SeitenAf KSB 049-1504103-045johannes angga panjaitanNoch keine Bewertungen

- Shaft StabilityDokument2 SeitenShaft Stabilitythulasi_krishnaNoch keine Bewertungen

- Solidworks Workgroup PDM InstallationDokument7 SeitenSolidworks Workgroup PDM InstallationmecanicajcNoch keine Bewertungen

- Double Suction Impeller Axial Suction Inlet: Pump Flowrate (USGPM)Dokument3 SeitenDouble Suction Impeller Axial Suction Inlet: Pump Flowrate (USGPM)ctorresmghNoch keine Bewertungen

- Manual - Bba SP 750Dokument32 SeitenManual - Bba SP 750Leopoldo Wille100% (1)

- FCC Pump SizingDokument13 SeitenFCC Pump Sizingcoolth2Noch keine Bewertungen

- Tap Drill CalculatorDokument1 SeiteTap Drill CalculatorSasan AbbasiNoch keine Bewertungen

- Shell Minimum Thickness Calculations: D (FT) G E Fill Height (FT)Dokument2 SeitenShell Minimum Thickness Calculations: D (FT) G E Fill Height (FT)trijaya landscapeNoch keine Bewertungen

- Business Intelligence DashboardDokument12 SeitenBusiness Intelligence Dashboardabi habudinNoch keine Bewertungen

- Limited End Float Couplings: CautionDokument2 SeitenLimited End Float Couplings: CautionsanthoshNoch keine Bewertungen

- Design Calculation of Worm and Worm Gear Endurance StrengthDokument9 SeitenDesign Calculation of Worm and Worm Gear Endurance StrengthVenkateswaran venkateswaranNoch keine Bewertungen

- Peract Pi Q23 DW 0004 PDFDokument5 SeitenPeract Pi Q23 DW 0004 PDFGNoch keine Bewertungen

- Tolerances Fit CalculatorDokument33 SeitenTolerances Fit CalculatorVasi ValiNoch keine Bewertungen

- Anderson Seal: Radial Seal O-Ring Application GuideDokument2 SeitenAnderson Seal: Radial Seal O-Ring Application GuideSaurabh KaushikNoch keine Bewertungen

- Bore & Key SheetsDokument2 SeitenBore & Key Sheetsalexandre_motta_3Noch keine Bewertungen

- GB SpringDokument69 SeitenGB Springshivkumar1587100% (1)

- Bearings Simply Supported ShaftDokument8 SeitenBearings Simply Supported ShaftRiyazuddin MahamadNoch keine Bewertungen

- FITSDokument11 SeitenFITSArun51092Noch keine Bewertungen

- Threads and ChangegearsDokument36 SeitenThreads and ChangegearsRC VilledaNoch keine Bewertungen

- Galling InformationDokument3 SeitenGalling Informationvp989Noch keine Bewertungen

- Torsion Springs CALCULATIONDokument14 SeitenTorsion Springs CALCULATIONnarshihNoch keine Bewertungen

- T Stack Rev00 CDRDokument47 SeitenT Stack Rev00 CDRBabu RajamanickamNoch keine Bewertungen

- Bladedesign CalcDokument55 SeitenBladedesign CalcMeiring PretoriusNoch keine Bewertungen

- Spur - Gears - Metric - XLS: Tooth Normal ForceDokument5 SeitenSpur - Gears - Metric - XLS: Tooth Normal ForceTigistuNoch keine Bewertungen

- Pressure DropDokument4 SeitenPressure Dropsrishanthi82Noch keine Bewertungen

- Rosca Acme 3-2 MasmecánicaDokument6 SeitenRosca Acme 3-2 MasmecánicaBachoNoch keine Bewertungen

- Bolts TheoryDokument30 SeitenBolts TheoryIbrahim Mesfin100% (1)

- Complete EDM Handbook - 3Dokument16 SeitenComplete EDM Handbook - 3Neil BotesNoch keine Bewertungen

- MITER BEND Formula To Calculate Length Angle of Cut Weight and Cut-Back of The Miters With PDFiftypeoDokument9 SeitenMITER BEND Formula To Calculate Length Angle of Cut Weight and Cut-Back of The Miters With PDFiftypeoamlanfacebookNoch keine Bewertungen

- Plantilla para Cortar La Sim Card A Nanosim o Microsim PDFDokument1 SeitePlantilla para Cortar La Sim Card A Nanosim o Microsim PDFJuniorBasquezNoch keine Bewertungen

- Gearbox: Keeping The World FlowingDokument2 SeitenGearbox: Keeping The World FlowingBruno GondimNoch keine Bewertungen

- F14/FA14 INPUT F10/FA10 OUTPUT Ib4 Gearbox: Drawing NoDokument1 SeiteF14/FA14 INPUT F10/FA10 OUTPUT Ib4 Gearbox: Drawing NoBruno GondimNoch keine Bewertungen

- Ordering Code:: Line Mount Bodies Standard ManifoldDokument1 SeiteOrdering Code:: Line Mount Bodies Standard ManifoldBruno GondimNoch keine Bewertungen

- Technical Data: Orifice Pressure Drop DataDokument1 SeiteTechnical Data: Orifice Pressure Drop DataBruno GondimNoch keine Bewertungen

- Katalog Bloki Liniowe HydropressDokument149 SeitenKatalog Bloki Liniowe HydropressBruno GondimNoch keine Bewertungen

- Materials Properties DatabaseDokument36 SeitenMaterials Properties DatabaseBruno GondimNoch keine Bewertungen

- Orcaflex 11.0D: Passo01 - Sparbuoy - Sim (Modified 09:45 On 13/08/2021 by Orcaflex 11.0D) Replay Section 1, Static StateDokument16 SeitenOrcaflex 11.0D: Passo01 - Sparbuoy - Sim (Modified 09:45 On 13/08/2021 by Orcaflex 11.0D) Replay Section 1, Static StateBruno GondimNoch keine Bewertungen

- Tap Drill ChartDokument1 SeiteTap Drill ChartBruno GondimNoch keine Bewertungen

- Bolted Joint CalculatorDokument12 SeitenBolted Joint Calculatorharoub_nasNoch keine Bewertungen

- Quantity Units Symbol ValueDokument2 SeitenQuantity Units Symbol ValueBruno GondimNoch keine Bewertungen

- Bolts PreloadDokument7 SeitenBolts PreloadBruno GondimNoch keine Bewertungen

- Temper Designations of Magnesium Alloys, Cast and Wrought: Standard Practice ForDokument3 SeitenTemper Designations of Magnesium Alloys, Cast and Wrought: Standard Practice FormahfuzNoch keine Bewertungen

- Asme 2017 Sa 312Dokument1 SeiteAsme 2017 Sa 312Kathir VelNoch keine Bewertungen

- CBLM PipeDokument44 SeitenCBLM PipeAko Lang Poh100% (5)

- PVC Sheet Working TechDokument5 SeitenPVC Sheet Working Techlipi8100% (1)

- DJF21012 Sand Casting 1006Dokument15 SeitenDJF21012 Sand Casting 1006Sakinah KamalNoch keine Bewertungen

- W10x22 Beam To W10x22 BeamDokument2 SeitenW10x22 Beam To W10x22 Beamsurbanoj_79Noch keine Bewertungen

- SET-2 Brazing - SolderingDokument8 SeitenSET-2 Brazing - SolderingSyed TanveerNoch keine Bewertungen

- ,,knkjkjk1 s2.0 S0924013605004000 Main PDFDokument7 Seiten,,knkjkjk1 s2.0 S0924013605004000 Main PDFKarissa ElvinaNoch keine Bewertungen

- CNCpart ADokument110 SeitenCNCpart AAnish ShuklaNoch keine Bewertungen

- Internal Hex ImplantDokument8 SeitenInternal Hex ImplanthvcgNoch keine Bewertungen

- Tilt TableDokument2 SeitenTilt TablenikhilNoch keine Bewertungen

- Thread Pitch ChartDokument2 SeitenThread Pitch ChartChoon Wei WongNoch keine Bewertungen

- HW-emoto Rotary Table High QualityDokument14 SeitenHW-emoto Rotary Table High QualityDenis TkachukNoch keine Bewertungen

- BG42 Data SheetDokument0 SeitenBG42 Data SheetTroy AshcraftNoch keine Bewertungen

- Determining Decarburization and Carburization F2328Dokument2 SeitenDetermining Decarburization and Carburization F2328Ali MohsinNoch keine Bewertungen

- NC Tool StorageDokument6 SeitenNC Tool StorageabhayiimcNoch keine Bewertungen

- Types of DiesDokument99 SeitenTypes of DiesMadhav ChaudharyNoch keine Bewertungen

- CNC Milling G+M Code ListDokument4 SeitenCNC Milling G+M Code ListSilvia_282008roNoch keine Bewertungen

- The Figure Below Shows The First Conceptual Design by Der Zhi Jeremy SowDokument6 SeitenThe Figure Below Shows The First Conceptual Design by Der Zhi Jeremy SowJer SowNoch keine Bewertungen

- Manufacturing Engineering 2Dokument7 SeitenManufacturing Engineering 2Study SuccessNoch keine Bewertungen

- W.G.rathmann ClampsDokument2 SeitenW.G.rathmann ClampsjbertralNoch keine Bewertungen

- Track Components Summer TrainingDokument13 SeitenTrack Components Summer TrainingSourabh GuptaNoch keine Bewertungen

- ST40Dokument2 SeitenST40Abhishek VelagaNoch keine Bewertungen

- Welding Procedure Specification (W.P.S) According To ASME IX &ASME B31.3Dokument2 SeitenWelding Procedure Specification (W.P.S) According To ASME IX &ASME B31.3Erick HoganNoch keine Bewertungen

- Investigations On End Milling of CFRP Composite Using Router ToolsDokument14 SeitenInvestigations On End Milling of CFRP Composite Using Router Tools18M232 Nanta gopal CNoch keine Bewertungen

- XA-Series-52-53 - BODYWORK - XAS 137 - STANDARD PDFDokument2 SeitenXA-Series-52-53 - BODYWORK - XAS 137 - STANDARD PDFRICHARDNoch keine Bewertungen

- Assignment On Bulk-Forming ProcessesDokument4 SeitenAssignment On Bulk-Forming ProcessesMohammed ArishNoch keine Bewertungen

- Skytech Engg ProfileDokument20 SeitenSkytech Engg Profilesdmfm,Noch keine Bewertungen

- Haas Accessories FlyerDokument12 SeitenHaas Accessories FlyerAndrewFranciscoNoch keine Bewertungen