Beruflich Dokumente

Kultur Dokumente

Project Equipment Numbering Procedure

Hochgeladen von

BiginchOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Project Equipment Numbering Procedure

Hochgeladen von

BiginchCopyright:

Verfügbare Formate

Project:

Client:

Sub-contractor:

Azar Oil Field Development

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

91014

Sub-contractor Document

No :

ARFD-GGNRPR-PMPM-PRPM0002

Rev:

D02

Page 1 of 48

Project Equipment Identification Procedure

D0

2

D0

1

D0

0

Rev

.

Issued for Design

N. Bigdeli

Issued for Design

N. Bigdeli

Issued for Approval

N. Bigdeli

Description

Prepared

M.

Mortazavi

M.

Mortazavi

M.

Mortazavi

E.

Behbahani

E.

Behbahani

E.

Behbahani

Checked

Approved

06.Aug.13

28.Oct.12

14.Agu.12

Date

Project:

Client:

Subcontractor:

Azar Oil Field Development

Doc. Title:

Project Equipment Identification

NIOC

Procedure

Contract No.:

Document Number

91014

Subcontractor Document

No :

ARFD-GGNRPR-PMPM-PRPM0002

Page 2 of 48

Rev.

D02

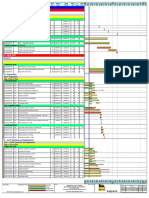

TABULATION OF REVISED PAGES

Page

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

D00

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

D01 D02 D03

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

D04

Page

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

59.

60.

61.

62.

63.

D00 D01 D02 D03 D04

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

Project Equipment Identification

NIOC

Procedure

Contract No.:

Document Number

30.

31.

32.

33.

34.

X

X

X

X

X

X

X

X

X

X

ARFD-GGNRPR-PMPM-PRPM0002

64.

65.

66.

67.

68.

91014

Subcontractor Document

No :

Page 3 of 48

Rev.

D02

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

91014

Subcontractor Document

No :

Page 4 of 48

Rev.

D02

Table of Content

1.

GENERAL................................................................................................5

1.1. Scope.......................................................................................................5

1.2. Definition of Terms..................................................................................5

1.3. Project Overview.....................................................................................6

1.4. Applicable Codes and Standards.............................................................6

1.5. Reference Documents..............................................................................6

1.6. Abbreviations...........................................................................................6

1.7. Conflict Requirements.............................................................................6

1.8. Units........................................................................................................6

2.

Equipment Numbering System...............................................................7

2.1. Main Equipment & Package Unit............................................................7

2.2. Equipment of Package Units...................................................................7

3.

Instrument Equipment identification......................................................8

3.1. Instrument Tag No...................................................................................8

3.2. Junction Box.............................................................................................9

3.3. I & C Cable No.........................................................................................9

3.4. Emergency Shutdown/ Depressurizing Interlock..................................10

3.5. Process Interlock...................................................................................11

3.6. F&G Device Tag No.............................................................................11

4.

Electrical Equipment Numbering System.............................................12

4.1. Numbering For Main Electrical Equipment..........................................12

4.2. Numbering For Other Electrical Equipment.........................................12

4.3. Numbering For Electrical Cables..........................................................13

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

5.

ARFD-GGNRPR-PMPM-PRPM0002

91014

Subcontractor Document

No :

Page 5 of 48

Rev.

D02

Communication Equipment Numbering System...................................13

5.1. Telecommunication Junction Box And Multicore Cable No...................14

6.

Piping Line Numbering System.............................................................15

7.

Building And Structure Numbering System..........................................16

7.1. Numbering For Buildings......................................................................16

7.2. Numbering For HVAC Equipments........................................................17

7.3. Numbering For Structure......................................................................17

8.

Special Item Numbering........................................................................18

8.1.

Indication on P&ID......................................................................................18

8.2.

Indication on Data Sheet................................................................................18

8.3.

Short Code and Serial Number........................................................................19

APPENDIXES..................................................................................................21

APPENDIX A...................................................................................................22

APPENDIX B.................................................................................................24

APPENDIX C...................................................................................................27

APPENDIX D...................................................................................................32

APPENDIX E...................................................................................................34

APPENDIX F...................................................................................................35

APPENDIX G...................................................................................................37

APPENDIX H...................................................................................................39

APPENDIX I....................................................................................................41

APPENDIX J....................................................................................................42

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

91014

Subcontractor Document

No :

Page 6 of 48

Rev.

D02

1. GENERAL

1.1. Scope

This procedure, prescribes equipment numbering system including

numbering for mechanical equipments, instrument, electrical equipment,

piping, piping line, building and structure used in engineering documents

in Azar Oil Field Development Project.

1.2. Definition of Terms

The following defines the meaning of specific words used in this

document (if applicable):

CLIENT

SARVAK of AZAR Engineering & Development

Company (SAED)

SUBCONTRACT

OR

Tehran Raymand Consultant

PROJECT

Azar Oil Field Development

LOCATION

South of Mehran City ; Ilam Province

IRAN

EPCC

The CONTRACTOR who is responsible

for providing any service and material

with respect to detailed engineering,

procurement ,construction and

commissioning of all items and material

in accordance with the contract

between the CLIENT and him

PURCHASER

Any firm who buy services, material

and/or equipment for execution of the

project within a dedicated contract.

SUPPLIER

Any vendor, manufacturer who supply

any Service , Material or Equipment for

the project

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

Project Equipment Identification

NIOC

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

91014

Subcontractor Document

No :

Page 7 of 48

Rev.

D02

SHALL

Refer to a mandatory requirement.

SHOULD

Refer to a recommendation

MAY

Refer to one acceptable course of action

1.3. Project Overview

Oil Industries Engineering and Construction (OIEC) and Oil Pension Fund

Investment Company (OPIC) under the terms and conditions of a buy-back

contract; intend to develop AZAR oil field including a Central Processing

Facilities (CPF) which is an oil production unit. The operating capacity of

the CPF is 30000 STB/D in early production stage and 65000 STB/D in

final production stage respectively.

Reservoir fluid from each well of the AZAR oil field will be routed to the

inlet manifold of the CPF via a separate flowline. In the early production

stage, crude oil is separated from oil associated sour gas within the CPF

and transferred to Dehloran facilities. In the final production stage, on

arrival into the CPF the crude oil, oil associated sour gases and water will

be separated and processed to meet the product specifications. The

treated crude and associated sour gases will be exported via separate

buried pipelines respectively to the Cheshmeh Khosh and Dehloran

facilities. The separated and produced waste water after treating will be

disposed of by injection into the reservoir via an underground pipeline.

1.4. Applicable Codes and Standards

IPS-E-PR-308

NUMBERING SYSTEM

ISA S.5.1

1992)

Instrumentation symbol and identification formerly (Edition

ISO

International organization for standardization

1.5. Reference Documents

Not Applicable

Project:

Client:

Subcontractor:

Azar Oil Field Development

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

1.6. Abbreviations

91014

Subcontractor Document

No :

ARFD-GGNRPR-PMPM-PRPM0002

Rev.

D02

Page 8 of 48

Not Applicable

1.7. Conflict Requirements

In the event of conflict between this document and other applicable

contractual documents, the issue shall be referred to CLIENT for

approval. However, in general any other necessary additional

requirements shall be applied.

1.8. Units

Not applicable

2. EQUIPMENT NUMBERING SYSTEM

2.1. Main Equipment & Package Unit

Main Equipment and Package Unit shall be numbered in the following

manner.

Unit Number

(As Per Appendix A)

Train Number / Well Number

(As Per Appendix J)

Equipment Category Symbol

(2 to 3 Alphabet Symbol As Per

Appendix B)

Serial Number

(From 001 To 999)

Alphabet Symbol

(From A To Z For Duplicate /

Triplicate Etc.)

XX

X

ZZZ

Project:

Client:

Subcontractor:

Azar Oil Field Development

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

91014

Subcontractor Document

No :

ARFD-GGNRPR-PMPM-PRPM0002

Rev.

D02

Page 9 of 48

2.2. Equipment of Package Units

XXXTYZZZ

A

ZZZ

Package Unit Number

(Refer To Part 2.1)

Auxiliary Equipment Category Code

(2 to 3 Alphabet Symbol As Per

Appendix B)

Serial Number

(From 001 To 999)

Alphabet Symbol

(From A To Z For Duplicate /

Triplicate etc.

3. INSTRUMENT EQUIPMENT IDENTIFICATION

3.1. Instrument Tag No.

Instrument equipment shall be identified by an instrument tag number

formed as follows:

Unit Number For Field

Instrument / ITR Number or CR

For Control Equipment

(As Per Appendix A)

YY

Y

Train Number / Well Number

(As Per Appendix J)

Item Indicative

(Two Or More Letters In Accordance With ISA

Symbol Standards (ISA S.5.1), e.g. PI, PT, PV, LSH,

etc. Refer To Appendix C, D)

ZZ

Z

XXX

X

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

Sequence Number

(From 0001 To 9999)

ARFD-GGNRPR-PMPM-PRPM0002

Alphabet Symbol

(From A To Z For Duplicate / Triplicate

etc)

91014

Subcontractor Document

No :

Page 10 of

48

Rev.

D02

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

91014

Subcontractor Document

No :

Page 11 of

48

ARFD-GGNRPR-PMPM-PRPM0002

Rev.

D02

3.2. Junction Box

Junction Boxes shall be identified by a tag number formed as follows:

Unit Number

(As Per Appendix A)

XX

X

JB

ZZ

Z

Train Number / Well

Number

(As Per Appendix J)

Type of System:

(E: ESD, D: DCS, P: Package Unit System ,

G: Fire/ Gas Detection, L: PLDMS, T: TGS,

H: HIPPS, W: WHCP, R: RTU )

Junction Box

D0

2

Instrumentation

Type of Signals:

(A: Analog , D: Discrete , P: Power)

Sequence Number

(from 001 to 999)

Signal Certification:

(i: Intrinsically Safe ,n: Non-Intrinsically Safe)

Example: Junction box No. for Intrinsically Safe Analog Signals from ESD

system in unit 100 is: 1000-EJBIA-001i.

3.3. I & C Cable No.

Field cables from instruments to junction boxes shall be identified with

Tag No. of connected instrument.

Project:

Client:

Subcontractor:

Azar Oil Field Development

Doc. Title:

Project Equipment Identification

NIOC

Procedure

Contract No.:

Document Number

91014

Subcontractor Document

No :

Page 12 of

48

ARFD-GGNRPR-PMPM-PRPM0002

Multi-pair/core cables from junction boxes to control building shall be

identified with associated junction box, with C instead of JB.

Rev.

D02

Example: 1000-ECIA-001i

Earthing cables shall be numbered as follow:

PE: Protective Earth. (plant earth)

IE: Instrument Earth.

ISE: Intrinsic Safe Earth.

3.4. Emergency Shutdown/ Depressurizing Interlock

Emergency Shutdown/ Depressurizing Interlock shall be identified by a

tag number formed as follows:

Unit Number

(As Per Appendix A)

YY

Y

ZZ

Z

Train Number / Well Number

(As Per Appendix J)

Item Indicative

(ESD: Emergency Shutdown, EDP:

Depressurizing/Blow Down)

Shutdown/Depressurizing Level

(0: Level 0, 1: Level 1, 2: Level 2, 3: Level 3 )

D0

Sequence Number

2

(From 01 To 99)

Alphabet Symbol

(A To Z)

Example: ESD level 1 interlock for unit 120 train 1:

1201-ESD-124

X

X

Project:

Client:

Subcontractor:

Azar Oil Field Development

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

91014

Subcontractor Document

No :

Page 13 of

48

ARFD-GGNRPR-PMPM-PRPM0002

Rev.

D02

3.5. Process Interlock

Process Interlock shall be identified by a tag number formed as follows:

Unit Number

(As Per Appendix A)

YY

Y

XX

Train Number / Well Number

(As Per Appendix J)

Item Indicative

(I: Process Interlock)

Sequence Number

(From 01 To 99)

Alphabet Symbol

(From A To Z )

3.6. F&G Device Tag No.

D0

2

F&G devices shall be identified by a tag number formed as follows:

Unit Number For Field

Instrument / ITR Number or

CR For Control Equipment

Unit Number (As Per

Appendix A)

For Buildings: B01~B16

XX

X

Train Number / Well Number

(As Per Appendix J)

Item Indicative

(Two Or More Letters For Function Code, e.g.

IRGD, FD)

Fire Zone Number

ZZZ

Z

- XX

X

X

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

91014

Subcontractor Document

No :

Page 14 of

48

ARFD-GGNRPR-PMPM-PRPM0002

(From 01 To 99)

Sequence Number

(From 01 To 99)

Alphabet Symbol

(From A To Z For Duplicate / Triplicate etc)

Rev.

D02

4. ELECTRICAL EQUIPMENT NUMBERING SYSTEM

4.1. Numbering For Main Electrical Equipment

Main Electrical Equipment which composes primary power distribution

system, power supply to process equipment, instrument power supply and

supervisory system shall be numbered in the following manner:

Unit /Building Number

(As Per Appendix A)

XX

X

- 01

YY

ZZ

Train Number / Well Number

(As Per Appendix J)

(01 And Up ) , Use 00 For Power Plant And 90

For All Others Not Within Sub Station

Equipment Category Code

(1 to 4 Alphabet Symbol As Per Appendix F)

Equipment Sequence Number

(01 And Up)

Alphabet Symbol

(A To Z For Duplicate / Triplicate etc)

4.2. Numbering For Other Electrical Equipment

Panel boards and other electrical equipment shall be numbered in the

following manner:

Unit /Building Number

(As Per Appendix A)

Train Number / Well Number

(As Per Appendix J)

XX

X

- YY

Z

Z

Project:

Client:

Subcontractor:

Azar Oil Field Development

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

91014

Subcontractor Document

No :

Page 15 of

48

ARFD-GGNRPR-PMPM-PRPM0002

Rev.

D02

Equipment Category Code

(1 to 4 Alphabet Symbol As Per Appendix

F)

Serial Number

(01 And Up)

4.3. Numbering For Electrical Cables

Power and control electrical cables shall be numbered in the following

manner:

Destination equipment Code

(Refer to Section 2)

YYY

Y

Z

Z

Train Number / Well Number

(Refer to Section 2)

Type of cable

Power (P), Control (C), Space Heater

(H), RTD or PTC (T)

Circuit Number

(01 And Up only for more than one

circuit)

ELECTRICAL cables to consumers shall be identified with Tag No. of

connected equipment / cubicle.

5. COMMUNICATION EQUIPMENT NUMBERING SYSTEM

Communication equipment shall be numbered in the following manner:

System Designation

(As Per Appendix G , Item

A)

A

A

XX

X

YY

ZZ

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

91014

Subcontractor Document

No :

Page 16 of

48

ARFD-GGNRPR-PMPM-PRPM0002

Unit /Building Number

(As Per Appendix A)

Rev.

D02

Train Number and Well Number

(As Per Appendix J)

Equipment Category Code

(As Per Appendix G . Item B)

Serial Number

(01 And Up)

5.1. Telecommunication Junction Box And Multicore Cable No.

Junction Boxes shall be identified by a tag number formed as follows:

Unit /Building

Number

(As Per Appendix A)

XXX

Train Number / Well Number

(As Per Appendix J)

Type of System:

(As per App. G P: Paging, R: Radio, T:

Telephone,)

Junction Box/ Cable

Telecommunication

Type of Signals:

(S: Signal, P: Power)

Sequence Number

(from 001 to 999)

JB/

C

ZZ

Z

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

91014

Subcontractor Document

No :

Page 17 of

48

ARFD-GGNRPR-PMPM-PRPM0002

Rev.

D02

Example: Signal Junction box No. 001 for Paging System in unit 100 is:

100T (Refer to appendix J)- PCJBTES-001.

Field cables from equipment to junction boxes shall be identified with Tag

No. of connected equipment.

6. PIPING LINE NUMBERING SYSTEM

Piping lines shall be numbered in the following manner: AAAA

Size Service Unit No.-(Train No.+ Serial No.) Class Insulation Type

Numbering Of All Lines Excluding Steam Tracing Spools

X

Nominal Pipe size

(As Per Appendix I)

(Note: For trim line

TR shall be used

instead of Line Size)

Fluid code

(2 or 3 Alphabet Symbol As Per

Appendix H)

Unit Number

- XXX -

TWZZ

Z

AAA

A

III

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

91014

Subcontractor Document

No :

Page 18 of

48

Rev.

D02

(As Per Appendix A)

Train No / Well No. (As per Appendix J)+Serial No

(001 And Up See Note 1)

Piping Class Code

(See Note 2)

Insulation Or Tracing Symbol

(1 to 3 alphabet symbol As Per Appendix

E)

Notes:

1)

For assigning the piping serial number, the following items should be

taken into consideration:

a)

Pipe line numbers shall be prefixed, from source to unit battery limit

with the unit number of the unit of origin.

b)

The individual line number shall be held up to the point where the

line ends at the inlet of equipment such as a vessel, exchanger, pump,

etc., another number is required for the line downstream of the

equipment.

c)

A new line number is required when the pipe design condition can

vary (e.g., downstream of the control valve assembly) or when a new

piping class is to be specified.

d)

Line number shall be held up to the point where the line ends to the

header or unit battery limit block valve. All branches to and from

header shall have an individual line number.

e) All utility headers (systems) shall be numbered with their respective

units. All branches serving a specific unit will be numbered with that

unit.

f)

All firewater and sewer branches serving a specific unit shall be

numbered in accordance with note number (e) above.

Project:

Client:

Subcontractor:

Azar Oil Field Development

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

91014

Subcontractor Document

No :

Page 19 of

48

ARFD-GGNRPR-PMPM-PRPM0002

Rev.

D02

g) Start point and end point of lines shall be unique.(From

individual equipment item to individual equipment item From

D0

line to individual equipment item and vice versa.). It's mean

2

that the one line cannot be connected to two equipment.

2)

Piping class code shall be in accordance with the line classes utilized

in project piping material specification.

3)

Piping components not identified by instrument or mechanical

equipment numbers, etc., and not covered by the piping material

specification, are identified by a special item number.

7. BUILDING AND STRUCTURE NUMBERING SYSTEM

7.1. Numbering For Buildings

YY - XXX - ZZ

Building code

(See Note 1)

Unit Number

(As Per Appendix A)

Serial Number

(01 And Up)

Notes:

1) Use "BD" for buildings.

7.2. Numbering For HVAC Equipments

Building code

(See Note 1)

B

B

UU

U

YY

XX

X

ZZZ

Project:

Client:

Subcontractor:

Azar Oil Field Development

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

91014

Subcontractor Document

No :

Page 20 of

48

ARFD-GGNRPR-PMPM-PRPM0002

Unit Number

(As Per Appendix A)

Building Serial Number

(01 And Up)

HVAC Equipment Category

Symbol

(2 to 3 Alphabet Symbol As Per

Appendix B)

Serial Number

(From 001 To 999)

Alphabet Symbol

(From A To Z For Duplicate /

Triplicate Etc.)

Notes:

1) Use "BD" for buildings.

7.3. Numbering For Structure

Structure and pipe rack shall be numbered in the following manner:

Unit Number

(As Per Appendix A)

Train Number / Well Number

(As Per Appendix J)

STRUCTURE IDENTIFICATION

(See Note 1)

Serial Number

XX

X

YY

- 01

Rev.

D02

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

91014

Subcontractor Document

No :

ARFD-GGNRPR-PMPM-PRPM0002

Page 21 of

48

(01 And Up) (See Note 2)

Notes:

1) Structure Identification

AT = Antenna Tower

SH= Shelter

CB = Catch Basin

CPS = Concrete Pipe Sleeper

MH = Sewer Manhole

MP = Miscellaneous Platform

PB = Pull Box

PBC = Pipe Box Culvert

PS = Pipe Support

SL = Stiles

SS = Steel Structure

PR = Pipe Rack

ST = Equipment Structure

2) Structure numbering shall be South to North and West to East.

8. SPECIAL ITEM NUMBERING

Special Item Numbering Procedure is as the followings:

(Unit + Train No. / Well No.) (SHORT CODE) (SERIAL NUMBER)

8.1. Indication on P&ID

Short Code and Serial Number only

STR

0001

Rev.

D02

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

91014

Subcontractor Document

No :

ARFD-GGNRPR-PMPM-PRPM0002

(Unit + Train No. are not required on P&ID) Ex.:

Page 22 of

48

Rev.

D02

8.2. Indication on Data Sheet

(Unit + Train No. / Well No.) - (Short Code) (Serial Number)

8.3. Short Code and Serial Number

For the Short Code and Serial Number of each Special Item refer table below:

TYPE

Strainer

SPECIAL ITEM NO

STR-101A

STR-104B

STR-0001

NOTES

SUCT. STR FOR PUMP 101A

SUCT. STR FOR PUMP 104B

Stone Trap

STT-0001

For Well No.: AZAR-P-1

Quick CPLG

SQC-2401

Utility Station/AIR/MALE

SQC-2802

Utility Station/WATER/MALE

SQC-3303

Utility Station/Nitrogen/MALE

SFH-2401

Utility Station/AIR

SFH-2802

Utility Station/WATER

SFH-3303

Utility Station/Nitrogen

Flex Hose Metal

SXH-0001

Serial No. From 0001

Sample Cooler

SSC-0001

Serial No. From 0001

Injection Nozzle

SNZ-0001

Serial No. From 0001

Piping POT

SPP-0001

Serial No. From 0001

Special Bend

SBD-0001

Serial No. From 0001

Insulating Joint

SIJ-0001

Serial No. From 0001

Special Valve

SPV-0001

Non Return Valve

Non Slam Dual Plate Type

Flex Hose-Non Metal

OTHER STRAINERS

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

91014

Subcontractor Document

No :

ARFD-GGNRPR-PMPM-PRPM0002

Page 23 of

48

Non Slam Venturi Type

Mokveld Check Valve

Non Slam Tilted Disc Type

Mech Interlock

SMI-0001

Serial No. From 0001

Key Interlock

SKL-0001

Serial No. From 0001

Insulation Kit

IKT-0001

Serial No. From 0001

Special Flange

SFG-0001

Serial No. From 0001

Transition Piece

STP-0001

Serial No. From 0001

Extended Stem Valve

SEV-0001

Serial No. From 0001

D0

2

D0

2

Rev.

D02

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

APPENDIXES

91014

Subcontractor Document

No :

Page 24 of

48

Rev.

D02

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

Subcontractor Document

No :

ARFD-GGNRPR-PMPM-PRPM0002

APPENDIX A

UNIT IDENTIFICATION NUMBER

AZAR OIL FIELD DEVELOPMENT

Unit No

Unit Name

000

Common

OFF-PLOT

100

91014

Well Head Facilities &

Flow Lines and burn pit

CPF PROCESS

110

Oil Inlet Manifold

120

Separation (Separators,

Desalter, Stabilizer)

130

Oil Storage ,Delivery and

Metering

140

Oil Export Pipeline &

Related Launcher,

Receiver

150

Gas Compression

Page 25 of

48

Rev.

D02

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

Subcontractor Document

No :

ARFD-GGNRPR-PMPM-PRPM0002

Unit No

Unit Name

160

Gas Dehydration

170

Gas compression and

Export and metering

Gas Export Pipe Line

180

& Related Launcher,

Receiver

CPF UTILITY

210

Fuel Gas

220

Emergency Power

Generation

230

Fuel Oil

240

Compressed Air

250

Chemical Injection

260

Flare & Burn Pit

270

Fire Water

Potable Water

280

and Water Supply Lines

290

Dilution Water System

300

Waste water Treatment

and injection pump and

injection pump and

pipeline facilities

310

Closed Drain

320

Open Drain

330

Nitrogen System

340

350

D0

2

91014

Heating Medium System &

Fresh Glycol Storage

Raw water Supply System

Page 26 of

48

Rev.

D02

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

Project Equipment Identification

NIOC

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

91014

Subcontractor Document

No :

Page 27 of

48

Note: For Outdoor substation, B01 and B02 will be used as unit

number of equipments in first and second bays, respectively.

Rev.

D02

D0

2

APPENDIX B

EQUIPMENT CATEGORY SYMBOL

EQUIPMENT ITEMS

CODE

Air Handling Unit

EQUIPMENT

AHU

Air-Cooled Condensing Unit

BUILDING

ACCU

BD

COALESCER VESSEL TYPE (SEE VESSEL)

VS

CENTRIFUGAL COMPRESSOR

CC

SCREW COMPRESSOR

SC

CONTROL PANEL

CONVEYOR, MECHANICAL OR PNEUMATIC

CPL

CV

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

COLUMN (SEE TOWER)

91014

Subcontractor Document

No :

Page 28 of

48

Rev.

D02

CL

CRANE

CN

CYCLONE AND HYDROCLONE

CY

DAMPER

DP

DEAERATOR

DA

DESALTER

DE

DIVERTER VALVE

DV

DRUM (SEE VESSEL)

VS

DISTRIBUTOR

DB

INDUCED GAS FLOATATION

IGF

CORROGATED PLATE INTERCEPTOR

CPI

EQUIPMENT ITEMS

CODE

EQUIPMENT

EXCHANGER, SHELL-AND TUBE, DOUBLE PIPE,

EX

COILS, AIR COOLED, REBOILER, COLD BOX,

CASCADE COOLER, SURFACE CONDENSER, PLATE AND FRAME,

BAROMETRIC CONDENSER, WASTE-HEAT BOILER

Exhaust Fan

EF

Electrical Water Heater

EWH

FAN

FA

FEEDER

FE

FILTER

FT

FIRE WATER HYDRANTS

FH

FIXED WATER MONITORS

WM

FLAKIER

FK

FLARE STACK

FOAM GENERATORS

FL

FG

FURNACE (SEE HEATER)

FR

FLOW METERING SYSTEM

FMC

Fire Damper

FD

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

GENERATOR, ELECTRIC

HEATER, FIRED

91014

Subcontractor Document

No :

Page 29 of

48

GN

FR

HOIST

HI

HOPPER (SEE TANK)

HP

HOSE REEL

HR

MECHANICAL EQUIPMENT, MISC.

ME

MIXER, SOLID, LIQUID OR IN-LINE, STATIC MIXER

MX

MOTOR, ELECTRIC

MR

Motorized Damper

MD

OIL SKIMMER

OS

PACKAGING UNIT, BAG, BOTTLE OR CAN, METERING

PK

PIG LAUNCHER

PL

EQUIPMENT ITEMS

CODE

EQUIPMENT

PIG RECEIVER

PR

PULSATION DAMPENER

PUMP

PD

PU

RECLAIMER

RC

SEPARATOR, ATMOSPHERIC (SEE VESSEL)

SILENCER, MUFFLER

VS

SI

STACK, CHIMNEY

SK

STRAINER

STR

SUMP

SU

Split Unit

SP

TANK, STORGE TANK; API,

TRANSFORMER

TK

TR

TOWER (COLUMN)

CL

VALVE, SLIDE (SEE GATE, SLIDE)

SG

VALVE, ROTARY

Rev.

D02

RV

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

VALVE, MOTORIZED

ARFD-GGNRPR-PMPM-PRPM0002

91014

Subcontractor Document

No :

Page 30 of

48

MOV

VESSEL, PRESSURE (ACCUMULATOR, K.O. DRUM

Rev.

D02

VS

SPHERE, BULLET)

WASHER

WA

SURFACE SAFETY VALVES

SSV

SUB SURFACE SAFETY VALVES

SSSV

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

91014

Subcontractor Document

No :

ARFD-GGNRPR-PMPM-PRPM0002

Page 31 of

48

Rev.

D02

APPENDIX C

INSTRUMENTATION IDENTIFICATION LETTERS ACCORDING TO ISA S.5.1

C

D

E

FIRST-LETTER (4)

MEASURED

OR

MODIFIER

INITIATING

VARIABLE

Analysis (5,19)

Burner,

Combustion

Conductivity

Density

Differential (4)

Voltage

Flow Rate

Gaging

(Dimensional)

Hand

Current

(Electrical)

Power

Time, Time

Schedule

Level

A

B

J

K

L

M

N

O

P

Moisture/Humi

dity

User's Choice

(1)

User's Choice

(1)

Pressure,

SUCCEEDING-LETTERS (3)

READ-OUT

OR

OUTPUT

MODIFIER

PASSIVE

FUNCTION

FUNCTION

Alarm

User's Choice

User's

User's

(1)

Choice (1)

Choice (1)

Control (13)

Sensor

(Primary

Element)

Ratio

(Fraction) (4)

Glass, Viewing

Device (9)

Gauge

High

(7,15,16)

Indicate (10)

Scan (7)

Time Rate of

Change (4,21)

Control

Station (22)

Light (11)

Low

(7,15,16)

Middle,

Momentary (4)

User's Choice

(1)

Orifice,

Restriction

Point (Test)

User's

Choice (1)

Intermediat

e (7,15)

User's

Choice (1)

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

Q

R

S

T

U

V

W

X

Y

91014

Subcontractor Document

No :

Page 32 of

Rev.

ARFD-GGNRPR-PMPM-PRPM48

D02

0002

FIRST-LETTER (4)

SUCCEEDING-LETTERS (3)

MEASURED

READ-OUT

OR

OR

OUTPUT

MODIFIER

MODIFIER

INITIATING

PASSIVE

FUNCTION

VARIABLE

FUNCTION

Vacuum

Connection

Quantity

Integrate,

Totalize (4)

Radiation

Record (17)

Speed,

Safety (8)

Switch (13)

Frequency

Temperature

Transmit

(18)

Multivariable

Multifunction

Multifunctio Multifuncti

(6)

(12)

n (12)

on (12)

Vibration,

Valve,

Mechanical

Damper,

Analysis (19)

Louver (13)

Viscosity

Weight, Force

Well

Unclassified

X Axis

Unclassified (2) Unclassified Unclassifie

(2)

(2)

d (2)

Event, State or Y Axis

Relay,

Presence (20)

Compute,

Convert

(13,14,18)

Position,

Z Axis

Driver,

Dimension

Actuator,

Unclassified

Final

Control

Element

Note:

Numbers in parentheses refer to specific explanatory notes on the

following pages.

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

91014

Subcontractor Document

No :

Page 33 of

48

Rev.

D02

1)

A "users choice" letter is intended to cover unlisted meanings that

will be used repetitively in a particular project. If used, the letter may

have one meaning as a first-letter and another meaning as a

succeeding-letter. The meanings need to be defined only once in a

legend, or other place, for that project. For example, the letter N may

be defined as "modulus of elasticity" as a first-letter and

"oscilloscope" as a succeeding-letter.

2)

The unclassified letter X is intended to cover unlisted meanings that

will be used only once or used to a limited extent. If used, the letter

may have any number of meanings as a first-letter and any number of

meanings as a succeeding-letter. Except for its use with distinctive

symbols, it is expected that the meanings will be defined outside a

tagging bubble on a flow diagram. For example, XR-2 may be a stress

recorder and XX-4 may be a stress oscilloscope.

3)

The grammatical form of the succeeding-letter meanings may be

modified as required. For example, "indicate" may be applied as

"indicator" or "indicating," "transmit" as "transmitter" or

"transmitting," etc.

4)

Any first-letter, if used in combination with modifying letters D

(differential), F (ratio), M (momentary), K (time rate of change), Q

(integrate or totalize), or any combination of these is intended to

represent a new and separate measured variable, and the

combination is treated as a first-letter entity. Thus, instruments TDI

and TI indicate two different variables namely, differentialtemperature and temperature. Modifying letters are used when

applicable.

5)

First-letter A (analysis) covers all analyses not described by a "users

choice" letter. It is expected that the type of analysis will be defined

outside a tagging bubble.

6)

Use of first-letter U for "multivariable" in lieu of a combination of first

letters is optional. It is recommended that nonspecific variable

designators such as U be used sparingly.

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

91014

Subcontractor Document

No :

Page 34 of

48

Rev.

D02

7)

The use of modifying terms "high," "low," "middle" or "intermediate,"

and "scan" is optional.

8)

The term "safety" applies to emergency protective primary elements

and emergency protective final control elements only. Thus, a selfactuated valve that prevents operation of a fluid system at a higherthan-desired pressure by bleeding fluid from the system is a backpressure-type PCV, even if the valve is not intended to be used

normally. However, this valve is designated as a PSV if it is intended

to protect against emergency conditions, i.e., conditions that are

hazardous to personnel and/or equipment and that are not expected

to arise normally.

The designation PSV applies to all valves intended to protect against

emergency pressure conditions regardless of whether the valve

construction and mode of operation place them in the category of the

safety valve, relief valve, or safety relief valve. A rupture disc is

designated PSE.

9)

The passive function G applies to instruments or devices that provide

an uncalibrated view, such as sight glasses and television monitors.

10) "Indicate" normally applies to the read-out-analog or digital-of an

actual measurement. In the case of a manual loader, it may be used

for the dial or setting indication. i.e., for the value of the initiating

variable.

11) A pilot light that is part of an instrument loop should be designated

by a first-letter followed by the succeeding-letter L. For example, a

pilot light that indicates an expired time period should be tagged

KQL. If it is desired to tag a pilot light that is not part of an

instrument loop, the light is designated in the same way. For

example, a running light for an electric motor may be tagged EL,

assuming voltage to be the appropriate measured variable, or YL,

assuming the operating status is being monitored. The unclassified

variable X should be used only for applications which are limited in

extent. The designation XL should not be used for motor running

lights, as these are commonly numerous. It is permissible to use the

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

91014

Subcontractor Document

No :

Page 35 of

48

Rev.

D02

users choice letters M, N or O for a motor running light when the

meaning is previously defined. If M is used, it must be clear that the

letter does not stand for the word "motor," but for a monitored state.

12) Use of a succeeding-letter U for "multifunction" instead of a

combination of other functional letters is optional. This nonspecific

function designator should be used sparingly.

13) A device that connects, disconnects, or transfers one or more circuits

may be either a switch, a relay, as ON-OFF controller, or a control

valve, depending on the application.

If the device manipulates a fluid process stream and is not a handactuated ON-OFF block valve, it is designated as a control valve. It is

incorrect to use the succeeding-letters CV for anything other than a

self actuated control valve. For all applications other than fluid

process streams, the device is designated as follows:

A switch, if it is actuated by hand.

A switch or an ON-OFF controller, if it is automatic and is the first

such device in a loop. The term "switch" is generally used if the

device is used for alarm, pilot light, selection, interlock, or safety.

The term "controller" is generally used if the device is used for

normal operating control.

A relay, if it is automatic and is not the first such device in a loop, i.e.,

it is actuated by a switch or an ON-OFF controller.

14) It is expected that the functions associated with the use of

succeeding-letter Y will be defined outside a bubble on a diagram

when further definition is considered necessary. This definition need

not be made when the function is self-evident, as for a solenoid valve

in a fluid signal line.

15) The modifying terms "high," and "low," and "middle" or

"intermediate" correspond to values of the measured variable, not to

values of the signal, unless otherwise noted. For example, a highlevel alarm derived from a reverse-acting level transmitter signal

should be an LAH, even though the alarm is actuated when the signal

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

91014

Subcontractor Document

No :

Page 36 of

48

Rev.

D02

falls to a low value. The terms may be used in combinations as

appropriate. (See Section 6.9 A of ISA).

16) The terms "high" and "low," when applied to positions of valves and

other open-close devices, are defined as follows:

"high" denotes that the valve is in or approaching the fully open

position, and "low" denotes that it is in or approaching the fully

closed position.

17) The word "record" applies to any form of permanent storage of

information that permits retrieval by any means.

18) For use of the term "transmitter" versus "converter", see the

definitions in Section 3 of ISA.

19) First-letter V, "vibration or mechanical analysis," is intended to

perform the duties in machinery monitoring that the letter A

performs in more general analysis. Except for vibration, it is expected

that the variable of interest will be defined outside the tagging

bubble.

20) First-letter Y is intended for use when control or monitoring

responses are event-driven as opposed to time or time schedule

driven. The letter Y, in this position, can also signify presence or

state.

21) Modifying-letter K, in combination with a first-letter such as L, T, or

W, signifies a time rate of change of the measured or initiating

variable. The variable WKIC, for instance, may represent a rate-ofweight-loss controller.

22) Succeeding-letter K is a users option for designating a control

station, while the succeeding-letter C is used for describing

automatic or manual controllers. (See Section 3, "Definitions" of ISA).

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

Project Equipment Identification

NIOC

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

91014

Subcontractor Document

No :

Page 37 of

48

Rev.

D02

APPENDIX D

CONTROL & SAFETY EQUIPMENT CODE

Equipment Code

ADU

CVT

CPU

EWS

FOC

FRW

FTA

LSC

MCB

OCD

OWS

PAP

PRT

SER

SVR

SWB

LP

AP

C

ANC

CC

Description

Alarm Display Unit.

Converter.

Central Processing Unit.

Engineering Workstation.

Fibre Optic Converter.

Fire Wall.

Field Terminal Assembly.

Large Screen.

Miniature Circuit Breaker.

Operator Console Desk.

Operator Workstation.

Patch Panel.

Printer.

Sequential Event Recorder computer.

Server.

Switches and Lamps Board.

Local Panel.

Alarm panel

Cabinet.

Analyser Cabinet

Converter Cabinet

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

Project Equipment Identification

NIOC

Procedure

Contract No.:

Document Number

CCT

CIC

DCS

ESD

FFC

F&G

FMS

IC

Subcontractor Document

No :

ARFD-GGNRPR-PMPM-PRPM0002

Equipment Code

91014

Page 38 of

48

Rev.

D02

Closed Circuit Television System.

Computer Interface Cabinet

DCS System.

ESD System.

Fire Fighting Cabinet

Description

F&G System.

Fiscal Metering System

Instrument Console

MMS

Machinery Monitoring System.

MRD

Marshalling for DCS.

MRE

Marshalling for ESD System.

MRF

Marshalling for F&G System.

MRS

MRY

PCS

PDB

Marshalling Cabinet ESD / F&G (ESD

and F&G are combined in the same

marshalling cabinet)

Marshalling - general purpose.

Process Control System

Power Distribution Board.

PA

Public Address Cabinet.

PNL

Package Cabinet

SEF

ESD / F&G System Cabinet (ESD and

F&G are combined in the same system

cabinet)

SSC

Safeguarding System Cabinet

TEC

Telemetering Cabinet

TEL

Telephone Cabinet.

TLC

Telecommunication Cabinet.

UDP

Utility Display Panel

UPS

UPS Cabinet.

WHCP

Well Head Control Panel

YC

General purpose Cabinet.

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

Project Equipment Identification

NIOC

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

PLDS

Monitoring

91014

Subcontractor Document

No :

Page 39 of

48

Rev.

D02

Pipeline Leak detection and

System

TGS

Tank Gauging System

HIPPS

Protection System

WELLHEAD CONTROL

High Integrity Pressure

WHCP

PANEL

LINE BREAK VALVE

LBV

CORROSION COUPON CC

CORROSION PROBE

CP

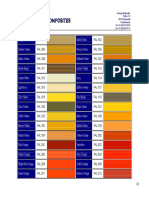

APPENDIX E

PAINTING, INSULATION AND HEAT TRACING DESIGNATION

INSULATION OR HEAT

TRACING TYPE

ET (1)

ETT (1)

insulated

SERVICE

Electrical Traced and Insulated

Electrical Traced with Heat Transfer Cement and

CI

Cold Insulation

HI

Hot Insulation

PP

Insulation for Personnel Protection

SJ (1)

Steam Jacketed and Insulated

ST (1)

Steam Traced and Insulated

STS (1)

Steam Traced With Spacers and Insulated

STT (1)

Steam Traced with Heat Transfer Cement and Insulated

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

Project Equipment Identification

NIOC

Procedure

Contract No.:

Document Number

Subcontractor Document

No :

ARFD-GGNRPR-PMPM-PRPM0002

PT

Painting

NO Painting, No Insulation

UW

Underground Wrapping

TB

Trace Body and Insulate

TBB

Trace Body and Bonnet and Insulate

91014

Page 40 of

48

Note:

1)

Use (H) for Heat Conservation as a suffix after the above symbols.

APPENDIX F

ELECTRICAL EQUIPMENT CATEGORY CODE

EQUIPMENT

ELECTRICAL EQUIPMENT ITEMS

CODE

AN

BB

BC

CB

ANNUNCIATOR/ALARM PANEL

BATTERY BANKS

BATTERY CHARGERS/RECTIFIERS

POWER FACTOR CORRECTION

CPR

CAPACITOR BANK

CATHODIC PROTECTION

DC

NDP

EDP

TRANSFORMER RECTIFIER

DIRECT CURRENT DISTRIBUTION

PANEL

NORMAL DISTRIBUTION PANEL

EMERGENCY DISTRIBUTION PANEL

Rev.

D02

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

EQUIPMENT

91014

Subcontractor Document

No :

ARFD-GGNRPR-PMPM-PRPM0002

Page 41 of

48

ELECTRICAL EQUIPMENT ITEMS

CODE

BD

GR

IRP

DG

LCP

TG

MLP

MCC

MP

PMCC

PMS

RMU

SWG

TR

BUS DUCT

GROUNDING RESISTOR

INTERPOSING RELAYS PANEL

DIESEL GENERATOR

LOCAL CONTROL PANEL

TURBO GENERATOR

MAIN LIGHTING PANEL (For indoor

and outdoor lighting panel)

400 V MOTOR CONTROL CENTER

MARSHALLING PANEL

POWER & MOTOR CONTROL CENTER

PANEL

POWER MANAGEMENT SYSTEM

PANEL

RING MAIN UNITS

33 kV, 11 kV, 6 kV & 400 V

SWITCHGEAR

TRANSFORMER

UPS

UNINTERRUPTIBLE POWER SUPPLY

MSS

MOTOR SOFT STARTER

VFD

VARIABLE FREQUENCY DRIVE

ELP

EMERGENCY LIGHTING PANEL

NLP

NORMAL LIGHTING PANEL

WO - WS

PDCS

WELDING OUTLET - SOCKET

Power Distribution Control System

JB

Junction Box

LF

Lighting Fixture

Rev.

D02

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

91014

Subcontractor Document

No :

Page 42 of

48

Rev.

D02

APPENDIX G

SYSTEM DISTINCTION AND EQUIPMENT CATEGORY CODE FOR

COMMUNICATION EQUIPMENT

A. Each communication system shall have the following character for system

distinction:

TL: Telephone System

RA: Radio communication System

PC: Intra Plant Communication System

HT: Hotline Telephone System

D0

CT: CCTV System

SC: SCADA System

LN: LAN System

B.

Equipment category code

1. Telephone System

EX: Automatic Telephone Exchanger

TH: Telephone Hand-set (Outdoor use)

TB: Telephone Terminal Board

MD: Main Distribution Frame

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

Project Equipment Identification

NIOC

Procedure

Contract No.:

Document Number

OC: Operator Console

ARFD-GGNRPR-PMPM-PRPM0002

Subcontractor Document

No :

Page 43 of

48

FP: Fiber Optic Patch Panel

SW: Switch

SC: Socket

D0

2

2. Radio communication System

BS: Radio Base Station

RD: Radio Remote Desk Set

RC: Radio Multi Coupler

TT: Telecom Tower

D0

2

3. Intra Plant Communication System

PB: Paging Base Station

AMP: Amplifier Panel

D0

2

EP: Exchanger Panel

DP: AC/DC Distribution Panel

TB: Paging Terminal Board

LD: Load Speaker

IS: Intercom Station

VC: Volume Controller

CD: CD Player

MC: Microphone

D0

2

FL: Flash Light for alarm system

4. Hotline System

HX: Telephone Exchange

TH: Telephone Hand-Set for Fire Alarm System

HP: Paging Equipment

HS: Fire Loudspeaker D0

HC: Fire Console

91014

HS: OUTDOOR TELEPHONE SET FOR HOTLINE SYSTEM

Rev.

D02

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

5. CCTV System

CA: Camera

CC: CCTV Console

CX: CCTV Exchange

6. SCADA System

RT: Remote Terminal Unit

MT: Master Terminal Unit

7. LAN System

FP: Fiber Optic Patch Panel

LC: Local Area Network Cabinet

SW: Switch

D0

SC: Socket 2

APPENDIX H

FLUID ABBREVIATION SYMBOLS

a) Air Systems

ISA

Instrument Air

PLA

Plant Air

b) Drain (Sewer) Systems

CDH

Closed Drain Header

CSW

Chemical Sewer

NSW

Non Oily Sewer

OSW

Oily Sewer Water

SSW

Sanitary Sewer

D0

2

GD

Glycol Drain

HMD

Heating Medium Drain

91014

Subcontractor Document

No :

Page 44 of

48

Rev.

D02

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

Project Equipment Identification

NIOC

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

c) Flare Systems

FL

Flare (Normal)

HFL

High Pressure Flare

LFL

Low Pressure Flare

d) Fuels

FLG

Fuel Gas

FLO

Fuel Oil

e) Special Gas Systems

ACG

Acid Gas

NIT

Nitrogen

f) Special Chemical and Solvent Systems

AMN

Amine

CHM

Chemicals

DEA

di-Ethanol Amine

DGA

di-Glycole Amine

MDEA

Metyl di-Ethanol Amine

TEG

Three Ethylene Glycol

MEG

Mono Ethylene Glycol

DTM

Dowtherm

g) Oil Utility Systems

LBO

Lubricating Oil

h) Water Systems

AFW

Air Foam Water Solution

FWA

Fire Water

D0

2

91014

Subcontractor Document

No :

Page 45 of

48

Rev.

D02

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

Project Equipment Identification

NIOC

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

OWA

Sour Oily Water

PRW

Process (Dilution) Water

PTW

Potable Water

RWA

Raw Water

TWA

91014

Subcontractor Document

No :

Page 46 of

48

Rev.

D02

Treated Water

i) Process Services

CRD

Crude

GAS

Gas

HMT

Heating Medium

D0

2

APPENDIX I

DEFINITION OF NOMINAL SIZE

1) Definition

Nominal size (DN): A numerical designation of size which is common to all components in a

piping system other than components designed by outside diameters or by thread size. It is a

convenient round number for reference purposes and is only loosely related to manufacturing

dimensions.

Notes:

1) It is designated by DN followed by a number.

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

ARFD-GGNRPR-PMPM-PRPM0002

91014

Subcontractor Document

No :

Page 47 of

48

Rev.

D02

2) It should be noted that not all piping components are designated by nominal

size, for example steel tubes are designated and ordered by outside diameter

and thickness.

3) The nominal size DN cannot be subject to measurement and shall not be

used for purposes of calculation.

APPENDIX J

TRAIN AND WELL NUMBER

Train No.:

0: Common unit and facilities

1: Facilities of Train-1

2: Facilities of Train-2

Project:

Client:

Azar Oil Field Development

Subcontractor:

Doc. Title:

NIOC

Project Equipment Identification

Procedure

Contract No.:

Document Number

Well No.:

ARFD-GGNRPR-PMPM-PRPM0002

0: AZAR-WI-1

1~17: From AZAR-P-1 TO AZAR-P-17

91014

Subcontractor Document

No :

Page 48 of

48

Rev.

D02

Das könnte Ihnen auch gefallen

- Elm 02 JGC PM SPC 0008Dokument25 SeitenElm 02 JGC PM SPC 0008Amine GuedjibaNoch keine Bewertungen

- Installation Procedure.Dokument11 SeitenInstallation Procedure.er_paramjeetgillNoch keine Bewertungen

- Supplier Documentation Instructions: Kashagan Development Experimental ProgramDokument22 SeitenSupplier Documentation Instructions: Kashagan Development Experimental ProgramMaffone Numerouno100% (2)

- KE01!00!000 AK A PR 0001 000 AGIP Document NumberingDokument30 SeitenKE01!00!000 AK A PR 0001 000 AGIP Document NumberingmasahinNoch keine Bewertungen

- Document Numbering Procedure (20.10.14)Dokument7 SeitenDocument Numbering Procedure (20.10.14)whmughal00100% (2)

- Engineering numbering system guideDokument81 SeitenEngineering numbering system guideguru4lifegmailcomNoch keine Bewertungen

- Mechanical CompletionDokument6 SeitenMechanical CompletionYosses Sang NahkodaNoch keine Bewertungen

- MS For Hydro Test ModDokument7 SeitenMS For Hydro Test ModIbrahim KhanNoch keine Bewertungen

- Manpower Calculation Speed Sheet - BcesDokument3 SeitenManpower Calculation Speed Sheet - BcesAMMAR MAWNoch keine Bewertungen

- Installation of Rotating Equipment ITPDokument3 SeitenInstallation of Rotating Equipment ITPMari Belajar100% (1)

- Agip KCO: Kashagan Field Development Project Experimental ProgrammeDokument27 SeitenAgip KCO: Kashagan Field Development Project Experimental ProgrammeMaffone NumerounoNoch keine Bewertungen

- Job Number and Title Master Document RegisterDokument81 SeitenJob Number and Title Master Document RegisterFerdie OS100% (3)

- Project Numbering ProcedureDokument23 SeitenProject Numbering ProcedureHamid Mansouri100% (2)

- FPM-PSG-GEN-GEN-001-A4 Procedure of Numbering System Rev. ADokument7 SeitenFPM-PSG-GEN-GEN-001-A4 Procedure of Numbering System Rev. Adeion29100% (1)

- ITP-SV-M-FAN-CENTRIFUGAL&AXIALDokument7 SeitenITP-SV-M-FAN-CENTRIFUGAL&AXIALgauravamberkarNoch keine Bewertungen

- Uzu With CPF Upgrade - Interface Management PlanDokument20 SeitenUzu With CPF Upgrade - Interface Management PlanOkeymanNoch keine Bewertungen

- EDO-PLN-QAC-GNR-INT-XXX-013-110-111-Rev-A.SAMPLE PROJECT QUALITY MANAGEMENT FOR STORAGE TANK PDFDokument31 SeitenEDO-PLN-QAC-GNR-INT-XXX-013-110-111-Rev-A.SAMPLE PROJECT QUALITY MANAGEMENT FOR STORAGE TANK PDFErol DAĞNoch keine Bewertungen

- ITP's and ITR's A Necessary - Monster - PDFDokument5 SeitenITP's and ITR's A Necessary - Monster - PDFshastri85Noch keine Bewertungen

- Z 007 5913722 PDFDokument56 SeitenZ 007 5913722 PDFLegend AnbuNoch keine Bewertungen

- Vendor Document Index & Submittal ScheduleDokument43 SeitenVendor Document Index & Submittal SchedulesanjeevchhabraNoch keine Bewertungen

- Supplier Document Requirements SDR GDFDokument14 SeitenSupplier Document Requirements SDR GDFFahd Bin Riasat100% (1)

- SBU1 TLD G PR 002 Rev.B Document Control ProcedureDokument56 SeitenSBU1 TLD G PR 002 Rev.B Document Control ProcedureAndreas SchlagerNoch keine Bewertungen

- Field Inspection & Test Plan (F-Itp) : DOC. NO.: I-T3108-QAQC-018Dokument8 SeitenField Inspection & Test Plan (F-Itp) : DOC. NO.: I-T3108-QAQC-018bernard100% (1)

- 05 00 TTP - Technical Document Numbering System - FDokument15 Seiten05 00 TTP - Technical Document Numbering System - FNigelllewellyn1Noch keine Bewertungen

- 076551C 000D Sow 9000 001 - R0Dokument37 Seiten076551C 000D Sow 9000 001 - R0ikenn100% (1)

- MAJOR EQUIPMENT LIST FOR CILACAP LNG TERMINALDokument2 SeitenMAJOR EQUIPMENT LIST FOR CILACAP LNG TERMINALwong_949618676Noch keine Bewertungen

- Piping Fabrication and Installation Functional SpecificationDokument30 SeitenPiping Fabrication and Installation Functional SpecificationVijay Mohan100% (3)

- 8015-0151-ENTR-41-411-EL-MS-41205 - A0 Method Statement For Cathodic Protection PDFDokument9 Seiten8015-0151-ENTR-41-411-EL-MS-41205 - A0 Method Statement For Cathodic Protection PDFCripoNoch keine Bewertungen

- Quality Surveillance ReportDokument1 SeiteQuality Surveillance Reportsiva8000Noch keine Bewertungen

- Piping System Project ChecklistDokument2 SeitenPiping System Project ChecklistMohsen KeramatiNoch keine Bewertungen

- Construction Checklist for Rabab Flow Line InstallationDokument3 SeitenConstruction Checklist for Rabab Flow Line InstallationDaniel MartinezNoch keine Bewertungen

- D-Erection Manual MAGHREB-SP-SMPDokument357 SeitenD-Erection Manual MAGHREB-SP-SMPYoussef EL HamraouiNoch keine Bewertungen

- RFQ For Pressure TransmitterDokument21 SeitenRFQ For Pressure Transmittersugeng wahyudiNoch keine Bewertungen

- Zawtika Project ITP for Electrical, Instrumentation and Telecom InspectionDokument13 SeitenZawtika Project ITP for Electrical, Instrumentation and Telecom Inspectionsfd640Noch keine Bewertungen

- 1.9 Engineering PlanDokument9 Seiten1.9 Engineering PlanaswarNoch keine Bewertungen

- 4 NTP Document Numbering ProcedureDokument11 Seiten4 NTP Document Numbering Procedurenaser hasan fauzi100% (1)

- Material inspection checklist for purchase ordersDokument2 SeitenMaterial inspection checklist for purchase ordersmanisami7036Noch keine Bewertungen

- MVEP-1-CE-602 Project Document ManagementDokument22 SeitenMVEP-1-CE-602 Project Document ManagementsindalisindiNoch keine Bewertungen

- Project Standards and Specifications Numbering Systems Rev01Dokument23 SeitenProject Standards and Specifications Numbering Systems Rev01Arini RizalNoch keine Bewertungen

- S-000-5131-301 - 0 Project Excution PlanDokument35 SeitenS-000-5131-301 - 0 Project Excution PlanMahadevan Mahalingam100% (2)

- MEENAKSHI ENERGY PRIVATE LIMITED WORK INSTRUCTION FOR DOCUMENT NUMBERING SYSTEMDokument135 SeitenMEENAKSHI ENERGY PRIVATE LIMITED WORK INSTRUCTION FOR DOCUMENT NUMBERING SYSTEMGiri Kiran Bikkina67% (3)

- Hydrotest Procedure For HVAC PKG#2 (Incl. Fire Fighting) WorkDokument8 SeitenHydrotest Procedure For HVAC PKG#2 (Incl. Fire Fighting) WorkCipta Adikarya100% (1)

- Sample MRB Index For ENIDokument1 SeiteSample MRB Index For ENIAnanthu Krishnan100% (1)

- Management Documents for Refinery ProjectDokument1 SeiteManagement Documents for Refinery ProjectMasoud MirshekarNoch keine Bewertungen

- 10016-COM-020 Rev0 Procedure For Commissioning of MBF UnitDokument15 Seiten10016-COM-020 Rev0 Procedure For Commissioning of MBF UnitsithulibraNoch keine Bewertungen

- Weld Map of Well 32 FLDokument13 SeitenWeld Map of Well 32 FLArfanAliNoch keine Bewertungen

- MLE System SubSystem SheduleDokument29 SeitenMLE System SubSystem Shedulealinor_tnNoch keine Bewertungen

- Topsides 1 - Equipment ListDokument22 SeitenTopsides 1 - Equipment ListMathias OnosemuodeNoch keine Bewertungen

- Dimentional ControlDokument3 SeitenDimentional ControlObiuto Okey OnyiriohaNoch keine Bewertungen

- ES-30.99.37.0017 - External Pipeline Coatings - Part 1Dokument63 SeitenES-30.99.37.0017 - External Pipeline Coatings - Part 1maheshNoch keine Bewertungen

- TCE document review proceduresDokument15 SeitenTCE document review proceduresbandithaguru100% (1)

- Sub-Contractor Comments Response Sheet: Ain Tsila DevelopmentDokument23 SeitenSub-Contractor Comments Response Sheet: Ain Tsila DevelopmentZaidi0% (1)

- Fabrication Erection and Installation Procedure For PipingDokument60 SeitenFabrication Erection and Installation Procedure For Pipinghasan_676489616Noch keine Bewertungen

- TaggingDokument43 SeitenTaggingSterling Gordian100% (2)

- How To Write A Welding Procedure Specification (WPS)Dokument5 SeitenHow To Write A Welding Procedure Specification (WPS)Mohamed Atef100% (1)

- QMP-MOA-013 (Rev.1) Preparation of Method Statements (CSC)Dokument10 SeitenQMP-MOA-013 (Rev.1) Preparation of Method Statements (CSC)Vasilica BarbarasaNoch keine Bewertungen

- Responsibility Matrix For Shop & Site WorksDokument3 SeitenResponsibility Matrix For Shop & Site WorksRenny DevassyNoch keine Bewertungen

- Welding Surveillance ReportDokument15 SeitenWelding Surveillance ReportTuấn PhạmNoch keine Bewertungen

- Document Numbering SystemDokument3 SeitenDocument Numbering Systemnarayanan_anoobNoch keine Bewertungen

- Awwa C905-97Dokument29 SeitenAwwa C905-97BiginchNoch keine Bewertungen

- RAL Color Colour Chart PDFDokument6 SeitenRAL Color Colour Chart PDFBiginchNoch keine Bewertungen

- Avoiding Pressure Surge Damage in PipelineDokument16 SeitenAvoiding Pressure Surge Damage in PipelineFerlie IndrapatiNoch keine Bewertungen

- Marx Engels DarwinDokument28 SeitenMarx Engels DarwinJaved Saboori100% (3)

- (J.S. Milne) Fields and Galois Theory (2015)Dokument138 Seiten(J.S. Milne) Fields and Galois Theory (2015)BiginchNoch keine Bewertungen

- Wrapping Material CalculationDokument1 SeiteWrapping Material CalculationBiginchNoch keine Bewertungen

- Electrode Weight CalculationDokument1 SeiteElectrode Weight CalculationBiginchNoch keine Bewertungen

- Fluor Piping Design Layout Training Les08 - UndergroundDokument96 SeitenFluor Piping Design Layout Training Les08 - UndergroundBiginch89% (9)

- Wall Thickness Calculation MethodsDokument1 SeiteWall Thickness Calculation MethodsBiginchNoch keine Bewertungen

- Hydrogen-Induced Cracking Susceptibility in High-Strength Weld MetalDokument6 SeitenHydrogen-Induced Cracking Susceptibility in High-Strength Weld MetalgrandecaciqueNoch keine Bewertungen

- Inventory List of Pipes and FittingsDokument4 SeitenInventory List of Pipes and FittingsBiginchNoch keine Bewertungen

- Anchor Flange ForceDokument1 SeiteAnchor Flange ForceBiginchNoch keine Bewertungen

- Barred Tee DatasheetDokument3 SeitenBarred Tee DatasheetBiginch67% (3)

- Ral Colour ChartDokument3 SeitenRal Colour ChartBoer ZoltanNoch keine Bewertungen

- Ansi B1.20.1Dokument32 SeitenAnsi B1.20.1Biginch100% (2)

- Hot Tapping DatasheetDokument1 SeiteHot Tapping DatasheetBiginchNoch keine Bewertungen

- PLD-108 Anchor FlangeDokument7 SeitenPLD-108 Anchor FlangeBiginch100% (1)

- Causes of Pipeline Failure FractureDokument60 SeitenCauses of Pipeline Failure FractureBiginchNoch keine Bewertungen

- Hot BendsDokument4 SeitenHot BendsBiginchNoch keine Bewertungen

- Thermal Insulation and Pipe StressDokument3 SeitenThermal Insulation and Pipe StressDevin KendrickNoch keine Bewertungen

- ResearchDokument90 SeitenResearchST12Aulia NisaNoch keine Bewertungen

- Slip-In Cartridge Valves LunchBox SessionsDokument5 SeitenSlip-In Cartridge Valves LunchBox SessionsNguyễn ĐạtNoch keine Bewertungen

- 07 Sinamics G110D PDFDokument22 Seiten07 Sinamics G110D PDFralphholingsheadNoch keine Bewertungen

- JV300 - Maintenance Manual D500946 Ver.1.00Dokument244 SeitenJV300 - Maintenance Manual D500946 Ver.1.00Muromcev Andrey100% (1)

- K3VL Pump Power ShiftDokument2 SeitenK3VL Pump Power ShiftAB-S ELECTRO MECHANICAL INDUSTRIAL AUTOMATIONNoch keine Bewertungen

- Attachments DrawingsDokument8 SeitenAttachments DrawingsMOHNISHKUMARJHANoch keine Bewertungen

- Sale Engineer AngolaDokument2 SeitenSale Engineer AngolaMarildo Ely ElyNoch keine Bewertungen

- ME8694 HydraulicsandPneumaticsQuestionBank PDFDokument15 SeitenME8694 HydraulicsandPneumaticsQuestionBank PDFVikram mNoch keine Bewertungen

- SWS Operating Manual Rev 02Dokument73 SeitenSWS Operating Manual Rev 02Mahesh Kumar Guddeli100% (2)

- ANDRITZ Split Case Pump: Highest Efficiencies and Sturdy DesignDokument6 SeitenANDRITZ Split Case Pump: Highest Efficiencies and Sturdy Designocean220220Noch keine Bewertungen

- Centrifugal Pump Data Sheet: Operating Conditions Site and Utility Data (Cont.)Dokument1 SeiteCentrifugal Pump Data Sheet: Operating Conditions Site and Utility Data (Cont.)dante eyzaguirreNoch keine Bewertungen

- A Novel Design of The Roots BlowerDokument13 SeitenA Novel Design of The Roots BlowerAsistencia Técnica JLFNoch keine Bewertungen

- Rotary Vane Vacuum PumpsDokument8 SeitenRotary Vane Vacuum PumpsDhairyasheel BhutkarNoch keine Bewertungen

- 5-Cavitation in PumpsDokument52 Seiten5-Cavitation in PumpsFiraol DinaolNoch keine Bewertungen

- Section 7.1: Wheel Drive Circuit - General SystemDokument33 SeitenSection 7.1: Wheel Drive Circuit - General SystemАндрей ТарковскийNoch keine Bewertungen

- At 3006 BrochureDokument2 SeitenAt 3006 Brochurek BakkiarajNoch keine Bewertungen

- Ks En241hmap P Zx130 5g Sea Ver.Dokument24 SeitenKs En241hmap P Zx130 5g Sea Ver.AnggerNoch keine Bewertungen

- Strainer Screen & Mesh Selection GuideDokument4 SeitenStrainer Screen & Mesh Selection Guidelenasko0% (1)

- Accumate 2300-¿ ® Ç¿ë Í PDFDokument39 SeitenAccumate 2300-¿ ® Ç¿ë Í PDFjhoniNoch keine Bewertungen

- Project Records Index PKG-2Dokument7 SeitenProject Records Index PKG-2Dipak VaghelaNoch keine Bewertungen

- PCM and Hydration UnitsDokument64 SeitenPCM and Hydration UnitsBabak Salimifard100% (3)

- Dke672 ch2Dokument44 SeitenDke672 ch2Siraj MohammedNoch keine Bewertungen

- LKS Series Submersible Pump GuideDokument9 SeitenLKS Series Submersible Pump GuideWai TunNoch keine Bewertungen

- Chilled, Chilled-Hot and Condenser Water Piping SystemsDokument51 SeitenChilled, Chilled-Hot and Condenser Water Piping SystemsgabrielNoch keine Bewertungen