Beruflich Dokumente

Kultur Dokumente

Ijebea13 262 PDF

Hochgeladen von

islaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ijebea13 262 PDF

Hochgeladen von

islaCopyright:

Verfügbare Formate

International Association of Scientific Innovation and Research (IASIR)

(An Association Unifying the Sciences, Engineering, and Applied Research)

ISSN (Print): 2279-0020

ISSN (Online): 2279-0039

International Journal of Engineering, Business and Enterprise

Applications (IJEBEA)

www.iasir.net

Effect of Fiber length on the Tensile Properties of PALF Reinforced

Bisphenol Composites

Vinod B1, Dr. Sudev L J 2

Department of Mechanical Engg, Vidyavardhaka College of Engg, Mysore, INDIA.

2

Department of Mechanical Engg, Vidyavardhaka College of Engg, Mysore, INDIA.

Abstract: In recent years natural fibers appear to be the outstanding materials which come as the viable and

abundant substitute for the expensive and non-renewable synthetic fiber. Natural fibers like sisal, banana, jute,

oil palm, kenaf and coir has been used as reinforcement in thermoset composite for applications in consumer

goods, furniture, low cost housing and civil structures. Pineapple leaf fiber (PALF) is one of them that have also

good potential as reinforcement in thermoset composite. The objective of the present work is to explore the

potential of using PALF as reinforcement and investigate the effect of fiber length on tensile properties of PALF

reinforced Bisphenol composite. From this experimental study, it was observed that the fiber length greatly

influences the tensile properties of reinforced composites. A higher tensile strength of 36.36Mpa was obtained

for the fiber length of 9mm compared to the fiber length of 3, 6 and 12mm.

Keywords: Pineapple leaf fiber, Bisphenol, anaerobic extraction, mechanical properties, tensile strength.

I.

Introduction

Recently, composite materials have successfully substituted the traditional materials in several light weight and

high strength applications. The reasons why composites are selected for such applications are mainly their high

strength-to-weight ratio, high tensile strength at elevated temperatures, high creep resistance and high

toughness. By definition, composites are materials consisting of two or more chemically distinct constituents on

a macro scale having a distinct interface separating them and having bulk behavior which is considerably

different from those of any of the constituents[1].

Two types of fibers can be used for reinforcing in the composite materials:

1. Synthetic Fibers

2. Natural Fibers

Synthetic fibers are the most widely used to reinforce plastics due to their low cost and fairly good mechanical

properties. However, these fibers have serious drawbacks as high density, non-renewability, nonbiodegradability, high energy consumption etc. Growing environmental awareness and societal concern, a high

rate of depletion of petroleum resources, the concept of sustainability, and new environmental regulations have

triggered the search for new products that are compatible with the environment. Sustainability, cradle to grave

design, industrial ecology, eco-friendly and bio-compatibility are the guiding principles of development of new

generation materials. Lignocellulosic reinforced composites are the materials of the new paradigm. The use of

biodegradable and environment friendly plant-based fibers in the composites reduces waste disposal problems,

environment pollution and ecological concerns.

India, endowed with an abundant availability of natural fibers such as jute, coir, sisal, pineapple, ramie, bamboo,

banana etc., has focused on the development of natural fiber composites primarily to explore value-added

application avenue. Due to an occurrence of a wide variety of natural fibers in the country, Indian researchers

have directed efforts for quite some time in developing innovative natural fiber composites for various

applications. While the national research agencies in India have excellent scientific achievements to their credit

for development of natural fiber composites, efforts on their commercialization have been limited so far. The

natural fiber composites can be very cost-effective material especially for building & construction industry

(panels, false ceilings, partition boards etc.), packaging, automobile & railway coach interiors and storage

devices[2].

One such fiber source known for a long time is pineapple leaves from which pineapple leaf fibers (PALF) may

be extracted. Pineapple (Ananas comosus) is the third most important tropical fruit in the world after banana and

citrus. S.M.Sapuan et.al [3] reviewed the importance of pineapple leaf fiber by stating that PALF is the least

studied natural fiber, especially for reinforcing composites. The article presented a survey of research works

carried out on PALF and PALF-reinforced composites. Noor Sabah Sadeq [4] made experimental studies on

Influence of Natural Fiber on the Mechanical Properties of Epoxy Composites. The study deals with the effects

of natural fibers on some mechanical properties of the Epoxy composite. Jayamol George [5] made

IJEBEA 13-262; 2013, IJEBEA All Rights Reserved

Page 158

Vinod B et al., International Journal of Engineering, Business and Enterprise Applications, 5(2), June-August, 2013, pp. 158-162

experimental studies on Short Pineapple-Leaf-Fiber-Reinforced Low-Density Polyethylene Composites. The

influence of fiber length, fiber loading, and orientation on the mechanical properties has also been evaluated.

The objective of the present work is to investigate the effect of fiber length on tensile strength of the PALF

reinforced polymer composite.

II.

Materials and Methodology

PALF is one such fiber source known from a long time obtained from the leaves of pineapple plant

(Ananascomosus) from the family of Bromeliaceae. The Food and Agriculture Organization (FAO) has reported

that most of the world pineapple fruit production in 2001 amounting to about 13.7 million tons of fresh fruits are

produced in Asia [6]. Pineapple leaves from the plantations are being wasted as they are cut after the fruits are

harvested before being either composted or burnt. Additionally, burning of these beneficial agricultural wastes

causes environmental pollution. Table 2.1 shows some of the physical and mechanical properties of pineapple

leaf fiber.

Table 2.1 Properties of pineapple leaf fiber:

Property

Value

Density (g/cm3)

1.526

Softening Point (C)

104

Tensile Strength (MPa)

170

Youngs Modulus (MPa)

6260

Specific Modulus (MPa)

4070

Elongation at Break (%)

Moisture regain (%)

12

Bisphenol-A (BPA) is an organic compound which belongs to the group of diphenyl methane derivatives and

Bisphenol. The chemical formula is (CH3)2C (C6H4OH)2. BPA is used to make certain plastics and epoxy resins;

it has been in commercial use since 1957. Table 2.2 shows some of the properties of Bisphenol resin.

Table 2.2 Properties of Bisphenol resin:

Tensile strength

30Mpa

Tensile modulus

3300 Mpa

Elongation at break

2%

Flexure strength

80Mpa

Flexure modulus

3100 Mpa

Melting point

156 - 159 0C

Specific gravity

1.19 - 1.20

Impact strength

2.0-2.2 kJ/m2

Poissons ratio

0.37

A. Extraction of fibers

PALF were extracted from the leaf of pineapple plant by biological method. The conventional extraction

processes like retting leads to serious problems like methane and sulphide emission, water contamination and

other environmental pollutions. Owing to the above factors, biological method is preferred to mechanical and

chemical routes for extracting fibers of good quality from embedding matrix. It is in this context that National

Institute of Interdisciplinary Science and Technology (NIIST), Trivandrum, Kerala devised a clean anaerobic

process to yield superior quality fibers while shortening the processing time substantially. Here separation of

fibers from their matrices is achieved by enzymatic cleaving of cementing compounds with in situ microbial

growth and enzyme production. The organic residue generated by the process is converted to methane that can

be recovered for fuel.

B. Chemical treatment

Alkali treatment or mercerization using sodium hydroxide (NaOH) is the most commonly used treatment for

bleaching and cleaning the surface of natural fibers to produce high-quality fibers. Modifying natural fibers with

alkali has greatly improved the mechanical properties of the resultant composites.

The following steps were carried out during chemical treatment:

IJEBEA 13-262; 2013, IJEBEA All Rights Reserved

Page 159

Vinod B et al., International Journal of Engineering, Business and Enterprise Applications, 5(2), June-August, 2013, pp. 158-162

5% NaOH solution was prepared using sodium hydroxide pellets and distilled water.

Pineapple leaf fibers were then dipped in the solution for 1hour.

After 1 hour fibers were washed with 1% HCl solution to neutralize the fibers.

Then it is washed with distilled water.

It was then kept in hot air oven for 3hours at 65-70C.

C. Manufacturing of composite

A polypropylene (PP) mould having dimensions of 150 X 100 X 4 mm is used for composite fabrication. The

mould was first cleaned with wax so that the laminate easily comes out of the die after hardening. Then around

15 to 20 ml of promoter and accelerator are added to Bisphenol and the color of the resin changes from pale

yellow to dark yellow with the addition of these two agents. The laminates of three different fibers orientations

mats of unidirectional, bidirectional and inclined are prepared using hand layup method. This method of

manufacturing is a relatively simple method compared to other methods like vacuum bag molding, resin transfer

molding, autoclave molding etc. Figure 2.1 shows the PALF reinforced laminated composites with fiber length

of 3, 6, 9 and 12mm respectively.

Figure 2.1 The PALF reinforced laminated composites with fiber length of 3, 6, 9 and 12mm respectively.

III.

Results and Discussion

The tensile property of the PALF reinforced laminated composites with fiber length of 3, 6, 9 and 12mm was

studied and compared. ASTM D638 is one of the most common plastic strength specifications and covers the

tensile properties of unreinforced and reinforced plastics. The tensile test were conducted following the standard

of ASTM D638 (115*19*4mm) is type IV using JJ Lloyd universal testing machine with load cell of 1kN and

using crosshead speed of 5 mm/min. The test was performed until the tensile failure occurred.

Figure 3.1 Specimen undergoing tensile test

IJEBEA 13-262; 2013, IJEBEA All Rights Reserved

Page 160

Vinod B et al., International Journal of Engineering, Business and Enterprise Applications, 5(2), June-August, 2013, pp. 158-162

The results of the tensile test are put forth in the form of stress-strain curves. Figures 3.2(a), 3.2(b), 3.2(c) and

3.2(d) show the stress-strain curve for the PALF reinforced laminated composites with fiber length of 3, 6, 9 and

12mm respectively. The maximum load, Youngs modulus and tensile stress obtained from the experimental

study are given in Table 3.1. Figure 3.3 shows the variation of tensile stress for different fiber lengths in the

laminated composite.

Figure 3.1(a) Stress-strain curve of 3mm length PALF composite

Figure 3.1(c) Stress-strain curve of 9mm length PALF composite

Figure 3.1(b) Stress-strain curve of 3mm length PALF composite

Figure 3.1(d) Stress-strain curve of 12mm length PALF composite

Table 3.2 shows the maximum load, Youngs modulus and tensile stress obtained from the experimental study for

the PALF reinforced laminated composites with fiber length of 3, 6, 9 and 12mm.

Table 3.1 Maximum load, Youngs Modulus and Stress at Maximum load

Fiber length (mm)

Maximum load(kN)

Youngs Modulus(MPa)

Stress at maximum load (Mpa)

0.365888355

3266.22926

15.24534815

0.740519816

4267.980312

30.85499234

0.872640056

4536.495564

36.36000235

12

0.871208972

4399.825824

36.30037385

IJEBEA 13-262; 2013, IJEBEA All Rights Reserved

Page 161

Vinod B et al., International Journal of Engineering, Business and Enterprise Applications, 5(2), June-August, 2013, pp. 158-162

Figure 3.3.The variation of tensile stress for different fiber lengths.

The tensile strength of the matrix material Bisphenol alone is 30 Mpa (Table 2.2). Initially for fiber length of

3mm, Youngs modulus value is slightly lesser than the matrix material. But as the length of the fiber increased,

the value increased by 22.68% for 6mm and further increased by 27.26% for 9mm with respect to that of matrix

material. Tensile stress also shows the same variation as that of Youngs modulus. From the table 3.1 it can be

observed that a slight increase of 2.75% for 6mm fiber length. But the value increased significantly by 17.49%

for 9mm fiber length and it was the highest and then it remained constant for 12mm fiber length. The highest

value of tensile strength is 36.36Mpa is obtained for laminated composite of fiber length of 9mm.

IV.

Conclusion

The results of the present study revealed that a useful composite with good properties could be successfully

developed using treated PALF as reinforcing agent for the Bisphenol matrix. It can be seen that fiber length of

9mm show better tensile strength (36.36 MPa) than fiber length of 3, 6 and 12mm respectively. Hence fiber

length greatly influences the tensile strength of the PALF reinforced Bisphenol composite.

V.

References

[1]

D. W. Clegg and A. A. Collyer, Mechanical Properties of reinforced thermoplastics, Elsevier Applied Science Publishers, London and

New York, 1986.

[2] P. K. Mallick, Fibre Reinforced Composites, Marcel Dekker. Inc., New York, 1988.

[3] Arib, R.M.N., Sapuan, S.M., Hamdan, M.A.M.M., Paridah, M.T. and Zaman, H.M.D.K. (2004). A Literature Review of Pineapple

Fiber Reinforced Polymer Composites. Polymer and Polymer Composites. 12(4): 341-348.

[4] Noor Sabah Sadeq. Influence of Natural Fiber on the Mechanical Properties of Epoxy Composites. Eng. & Tech. Journal, Vol.28,

No.17, 2010.

[5] Sabu Thomas. Short Pineapple-Leaf-Fiber-Reinforced Low-Density Polyethylene Composites. Journal of Applied Polymer Science.

vol. 57. 841-864 11996).

[6] Drzal, L.T., Mohanty, A.K., Burgueo, R. and Misra, M. (2003). Biobased Structural Composite Materials for Housing and

Infrastructure Applications: Opportunities and Challenges. Composite Science and Technology. 63: 129-140.

[7] Ramakrishna Malkapuram, Vivek Kumar, and Yuvraj Singh NegiRecent Development in Natural Fiber Reinforced Polypropylene

Composites Journal of Reinforced Plastics and Composites 2009 28:1169-1189:10.1177/0731684407087759

[8] Munirahmokhtar, Abdul Rrazakrahmat, Azman Hassan (2007) Characterization and treatments of pineapple leaf fiber thermoplastic

composite for construction applications volume 75147

[9] Uma Devi, L., Bhagawan, S.S. and Thomas, S. (1997). Mechanical Properties of Pineapple Leaf Fiber-Reinforced Polyester

Composites. Journal of Applied Polymer Science. 64: 1739-1748.

[10] Arib, R.M.N. (2003). Mechanical Properties of Pineapple Leaf Fiber Reinforced Polypropylene Laminated Composites. University

Putra Malaysia. Masters Thesis.

[11] American Standard of Testing and Materials-ASTM International (2003). Standard Test Method for Tensile Properties of Plastics.

United State, ASTM 638-03.

[12] American Standard of Testing and Materials-ASTM International (2003). Standard Test Methods for Flexural Properties of

Unreinforced and Reinforced Plastics and Electrical Insulating Materials. United State, ASTM D790-03

IJEBEA 13-262; 2013, IJEBEA All Rights Reserved

Page 162

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- VPEG System OverviewDokument26 SeitenVPEG System OverviewdgfggfhghgdfhtNoch keine Bewertungen

- CH 02Dokument16 SeitenCH 02hamedNoch keine Bewertungen

- 0123Dokument12 Seiten0123islaNoch keine Bewertungen

- 0621 HandsOn LadderDokument35 Seiten0621 HandsOn LadderislaNoch keine Bewertungen

- UiraDokument60 SeitenUiraisla100% (1)

- Derivation and Analysis of Some Wave EquationsDokument19 SeitenDerivation and Analysis of Some Wave EquationsAxad Ali ChaudharyNoch keine Bewertungen

- Comparison of Numerical Simulation and Experiment of A Flexible Composite Connecting RodDokument6 SeitenComparison of Numerical Simulation and Experiment of A Flexible Composite Connecting RodislaNoch keine Bewertungen

- Ch3 - 3 - 3D Forces PDFDokument19 SeitenCh3 - 3 - 3D Forces PDFislaNoch keine Bewertungen

- Solving The Quadratic Assignment Problem by A Hybrid AlgorithmDokument6 SeitenSolving The Quadratic Assignment Problem by A Hybrid AlgorithmislaNoch keine Bewertungen

- 0621 HandsOn LadderDokument35 Seiten0621 HandsOn LadderislaNoch keine Bewertungen

- 10 1 1 447 2304Dokument5 Seiten10 1 1 447 2304islaNoch keine Bewertungen

- Chap. 2 Force VectorsDokument35 SeitenChap. 2 Force VectorsislaNoch keine Bewertungen

- Perpres 131 2015Dokument8 SeitenPerpres 131 2015islaNoch keine Bewertungen

- MATLAB Codes For Finite Element Analysis: Solids and StructuresDokument1 SeiteMATLAB Codes For Finite Element Analysis: Solids and Structuresisla0% (1)

- Chapter11 AdeimDokument11 SeitenChapter11 AdeimislaNoch keine Bewertungen

- Chapter11 AdeimDokument11 SeitenChapter11 AdeimislaNoch keine Bewertungen

- FT5 PDFDokument10 SeitenFT5 PDFislaNoch keine Bewertungen

- Comparison of Pareto Efficiency and Weighted Objectives Method To Solve The Multi-Criteria Vehicle Routing Problem Using The Artificial Immune SystemDokument10 SeitenComparison of Pareto Efficiency and Weighted Objectives Method To Solve The Multi-Criteria Vehicle Routing Problem Using The Artificial Immune SystemislaNoch keine Bewertungen

- DYNAMICS - Power, Input Power, Efficiency: ProduktDokument5 SeitenDYNAMICS - Power, Input Power, Efficiency: ProduktislaNoch keine Bewertungen

- SearchMH PDFDokument341 SeitenSearchMH PDFMohd NasimNoch keine Bewertungen

- 06 Linear Elasticity 01 Elastic ModelDokument9 Seiten06 Linear Elasticity 01 Elastic ModelraviNoch keine Bewertungen

- Linear Elastic Fracture MechanicsDokument19 SeitenLinear Elastic Fracture MechanicsCan Kutay TuçNoch keine Bewertungen

- DYNAMICS - Power, Input Power, Efficiency: ProduktDokument5 SeitenDYNAMICS - Power, Input Power, Efficiency: ProduktislaNoch keine Bewertungen

- Fourier Series and Integrals With Applications To Signal AnalysisDokument116 SeitenFourier Series and Integrals With Applications To Signal AnalysisislaNoch keine Bewertungen

- Type 2 FL ToolboxDokument10 SeitenType 2 FL ToolboxislaNoch keine Bewertungen

- Frequency Domain Techniques For Operational Modal AnalysisDokument10 SeitenFrequency Domain Techniques For Operational Modal AnalysisAhmed BaheiNoch keine Bewertungen

- Mot Conc2Dokument41 SeitenMot Conc2gariyakNoch keine Bewertungen

- Design of Fuzzy Logic Controller For Auto Landing ApplicationsDokument9 SeitenDesign of Fuzzy Logic Controller For Auto Landing ApplicationsislaNoch keine Bewertungen

- FT5 PDFDokument10 SeitenFT5 PDFislaNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Tomato ChutneyDokument14 SeitenTomato ChutneyDibyendu SahuNoch keine Bewertungen

- Useform 2Dokument104 SeitenUseform 2Agbede Bukola OluremiNoch keine Bewertungen

- Chapter - 6 Natural Vegetation of IndiaDokument9 SeitenChapter - 6 Natural Vegetation of IndiaMansha ChhetriNoch keine Bewertungen

- Determinationofseedmoisture Usharani 170731103129Dokument32 SeitenDeterminationofseedmoisture Usharani 170731103129Sabrina CruzNoch keine Bewertungen

- 09 - Chapter 2Dokument39 Seiten09 - Chapter 2Raj RudrapaaNoch keine Bewertungen

- The Geopolitics of Mexico - A Mountain Fortress Besieged - StratforDokument13 SeitenThe Geopolitics of Mexico - A Mountain Fortress Besieged - StratforAbe Schreier100% (1)

- Social Development TheoryDokument15 SeitenSocial Development TheoryNikon ArbusNoch keine Bewertungen

- Cupressus SempervirensDokument2 SeitenCupressus SempervirensKelvin Llantoy VallejosNoch keine Bewertungen

- Article, JHuete Et Al-V3Dokument10 SeitenArticle, JHuete Et Al-V3J Bruno CuevasNoch keine Bewertungen

- Loan Managemetn of RAKUBDokument72 SeitenLoan Managemetn of RAKUBMonirul Islam Milon50% (4)

- About KirloskarvadiDokument4 SeitenAbout KirloskarvadiKamlesh DeorukhkarNoch keine Bewertungen

- Midwest Lesson Plan 1Dokument9 SeitenMidwest Lesson Plan 1api-269401169Noch keine Bewertungen

- Piñatex Intro Card - A5Dokument1 SeitePiñatex Intro Card - A5Samuel Arévalo GNoch keine Bewertungen

- CAE Reading DeforestationDokument4 SeitenCAE Reading DeforestationMarijana SmolčecNoch keine Bewertungen

- Fig 1.1 Rice Seed SowingDokument33 SeitenFig 1.1 Rice Seed SowingSURESH100% (1)

- Memorial and Biographical History of The Coast Counties of Central CaliforniaDokument486 SeitenMemorial and Biographical History of The Coast Counties of Central Californiapeninsulastory100% (1)

- Growing Kiwifruit: PNW 507 - Reprinted September 2000 $2.50Dokument24 SeitenGrowing Kiwifruit: PNW 507 - Reprinted September 2000 $2.50conkonagyNoch keine Bewertungen

- Narrative Report On SWCMDokument3 SeitenNarrative Report On SWCMRaymond OhNoch keine Bewertungen

- Ifea 248781Dokument31 SeitenIfea 248781ArqueologoNoch keine Bewertungen

- Informal Milk Market Desk StudyDokument22 SeitenInformal Milk Market Desk StudytanwarsachinNoch keine Bewertungen

- 887Dokument133 Seiten887bhagirath prasdaNoch keine Bewertungen

- Ojha, C.S.P. - Berndtsson, R. - Bhunya, P.-Engineering Hydrology-Oxford UniverDokument440 SeitenOjha, C.S.P. - Berndtsson, R. - Bhunya, P.-Engineering Hydrology-Oxford UniverLesly Ann Pauline Manaoat88% (8)

- Zhanxian - A CompilationDokument6.918 SeitenZhanxian - A CompilationMICKEIAS GOMES ARAUJONoch keine Bewertungen

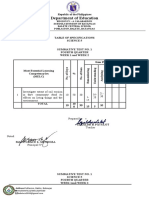

- Summative Test No. 1 in Science 5 Fourth Quarter.Dokument3 SeitenSummative Test No. 1 in Science 5 Fourth Quarter.BALETENoch keine Bewertungen

- Term Paper: On A Rising Market Giant of BangladeshDokument46 SeitenTerm Paper: On A Rising Market Giant of BangladeshSanjeed Ahamed SajeebNoch keine Bewertungen

- Managing The Philippine ForeshoreDokument24 SeitenManaging The Philippine ForeshoreAppraiser PhilippinesNoch keine Bewertungen

- Codex Standard For CornDokument4 SeitenCodex Standard For CornSalwa HamedNoch keine Bewertungen

- Samos: A Tourist Guide in EnglishDokument36 SeitenSamos: A Tourist Guide in EnglishMy Samos Blog100% (2)

- Pellet Mill Selection and Pelleting TechnologyDokument66 SeitenPellet Mill Selection and Pelleting Technologymarkodzajic100% (1)

- Biotricks Biotech, Nashik: MissionDokument5 SeitenBiotricks Biotech, Nashik: MissionSantosh TalegaonkarNoch keine Bewertungen