Beruflich Dokumente

Kultur Dokumente

Benefits of Vfds in Cooling Towers

Hochgeladen von

Anand NambiarCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Benefits of Vfds in Cooling Towers

Hochgeladen von

Anand NambiarCopyright:

Verfügbare Formate

The Benefits of VFDs on Cooling Towers | Motors / Drives content from HPAC Engineer...

Page 1 of 4

REGISTER

Subscribe

Air Conditioning

Building Controls

Fire / Smoke

Heating

Humidity Control

Contact Us

IAQ & Ventilation

Newsletters

Advertise With Us

Motors / Drives

About Us

Piping / Pumping

LOG IN

Info-Dex

RSS

Resources

HOME > MOTORS / DRIVES > THE BENEFITS OF VFDS ON COOLING TOWERS

The Benefits of VFDs on Cooling Towers

Advertisement

Variable-frequency drives can adjust fan speed, reverse fan rotation

JOE KOEPKE Yaskawa Electric America Inc. Waukegan, Ill.

TWEET

Advertisement

Aug. 1, 2009

COMMENTS 0

Used on large industrial projects, such as nuclear power

plants, and countless HVAC applications ranging from 15 to

700,000 gpm, cooling towers are everywhere. Because of

their increasing popularity and considerable number of

applications, cooling towers are available in many different

sizes and designs. This is especially true in the HVAC

industry, in which the demand to increase efficiency and

lower energy costs is great.

One of the most beneficial ways to increase efficiency and lower energy costs in a coolingtower design is to utilize a variable-frequency drive (VFD). This article will discuss the

different aspects of designs in which VFDs are used to improve performance and how this

performance differs from conventional cooling-tower designs.

Featured Authors

Boiler Maximum Available Control

Technology (MACT) Standards Are In

Effect: Now What?

by Michael Weil

Published on Jun. 7, 2013

in Mike Weil

Integrated Project Delivery: A Return to

Teamwork

by Dan Bulley

Published on Dec. 7, 2012

in Engineering Green Buildings

O&M the Key to Keeping Green Buildings

Optimized

by James Workman

Published on Aug. 1, 2012

in Managing Facilities

Figure 1. A mechanical forced-draft cooling tower.

Rules for Challenging LEED Certifications

Changed

by Timothy Hughes, Esq.

Published on Nov. 1, 2010

in Liability & Litigation

http://hpac.com/motors-drives/benefits-vfds-cooling-towers

6/20/2013

The Benefits of VFDs on Cooling Towers | Motors / Drives content from HPAC Engineer... Page 2 of 4

COOLING-TOWER TYPES

Upcoming Webinar

Commentaries and Blogs

Dreaming of a Pashmina-Free World

by Ron Rajecki

Posted 8 weeks ago

in Ron's Ramblings

Would You Want Your Child To Be an

HVAC Engineer?

by Ron Rajecki

FIGURE 2. A mechanical induced-draft cooling tower.

A mechanical-draft tower is a common type of cooling tower used in HVAC applications.

Mechanical-draft towers can be broken into two main categories: forced draft and

induced draft. A forced-draft tower has a fan mounted on its side, located in the path of

entering ambient air (Figure 1). The fan draws ambient air in, pushing/forcing it through

the tower and out of the top. Forced-draft towers generally have high air-entrance

velocities and low air-exit velocities. An induced-draft tower has a fan mounted on its top,

located in the path of exiting air (Figure 2). The fan draws ambient air in from the sides

and blows it out of the top. Both designs use one or more fans to provide the flow required

to extract heat from process cooling water. VFDs have proved to be beneficial on these

fans.

VFD BENEFITS

Fans regulate airflow to compensate for changes in ambient air and load conditions. In

the past, this was achieved by cycling fans on and off, manipulating fan capacity by

varying the pitch of fan blades, or using two-speed motors. These methods can have

considerable drawbacks and do not leave much room for error.

Across-the-line motor operation can be efficient if a system is designed for a fan to

operate at full speed 100 percent of the time. However, that rarely is the case. As

conditions change, flow needs to change as well. As a fan cycles on and off, its speed alters

dramatically, causing leaving-water temperature to fluctuate, leading to inefficiency and

control difficulty.

Fan speed

Posted 14 weeks ago

in Ron's Ramblings

Are Energy-Efficient Buildings the

Superheroes That Will Save Humanity?

by Ron Rajecki

Posted 16 weeks ago

in Ron's Ramblings

Sign-up to receive our free newsletters

HPAC Engineering Fastrack - (Bi-Weekly)

Engineering Green Buildings - (Monthly)

Networked Controls Plus - (Monthly)

Product Spotlight - (Monthly)

HPAC Show Product News - (Monthly)

* E-MAIL:

* COUNTRY:

Please select one

Submit Query

Connect With Us

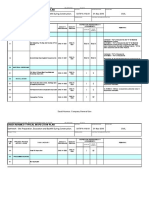

FIGURE 3. Affinity laws.

VFDs are able to adjust fan speed as conditions change while maintaining the exact flow

required. They also are able to increase fan speed above 60 Hz to provide additional

cooling capacity should the need arise. VFDs have built-in proportional-integral

capabilities to automatically adjust fan speed to maintain a given set point, eliminating

http://hpac.com/motors-drives/benefits-vfds-cooling-towers

6/20/2013

The Benefits of VFDs on Cooling Towers | Motors / Drives content from HPAC Engineer... Page 3 of 4

the need for an external set-point controller or variable-pitch fan. VFDs can reduce the

energy consumed by a fan just by slowing the motor. As shown in Figure 3, a fan's power

varies proportionally with the cube of its speed, so a small speed reduction causes a large

power reduction. For example, if a fan motor runs at 80-percent speed, its energy

consumption decreases by 50 percent.

Fan motors consume a large amount of energy because a high inrush of current is

required to start the motor every time it is cycled. VFDs eliminate this problem by acting

as soft starters, increasing/decreasing speed at a programmable rate. This feature reduces

mechanical wear by eliminating stress on the power train caused by across-the-line motor

starting. This can increase system life and save maintenance costs.

Fan rotation

VFDs not only save on energy and increase system efficiency, they perform numerous

other functions that eliminate the need for additional equipment. For example, VFDs can

sense fan rotation. If a fan is rotating in reverse because of windmilling, a VFD can catch

it, slow it down, and ramp it back up in the correct rotation. A VFD's ability to reverse fan

rotation can be beneficial in cold-weather conditions. Reversing a fan can cause warm air

to be blown back into a tower, melting any ice that has developed. These VFD functions

typically are performed using mechanical brakes or reversing contactors, which can

increase costs and wear while adding mechanical components that can fail.

Automation and motor protection

Using a VFD on a cooling-tower fan also is valuable for automation and motor protection.

VFDs have digital and analog inputs, outputs, programmable relays, and numerous serialcommunication options that allow for flexibility in tower automation and performance

monitoring.

Retrofits

Although it is best to consider VFD capabilities during a tower's initial design, VFDs can

be implemented into existing applications effectively. Many, if not all, of the benefits

mentioned previously can be utilized; however, there are some considerations to note in

retrofit applications. Because many parameters are fixed, there may be tower-design

characteristics that need to be worked around rather than avoided completely.

For example, cooling towers have fixed locations, and fan motors may not include

inverter-duty features. Depending on where a VFD can be mounted, long lead lengths can

be a problem and could damage motor insulation. To protect the motor, an output load

reactor or a dv/dt filter can be added to the VFD output. However, it may be more costeffective to mount the VFD to the side of the cooling tower in an outdoor-duty enclosure.

This can solve the long-lead-length issue, making it possible to use the existing motor for

the remainder of its life.

Gearboxes also can be considered. Many times a gearbox requires a minimum speed to

stay effectively lubricated. If this is the case, a VFD can be programmed with a minimum

speed, thus protecting the gearbox.

Because these are just a few of the considerations that may arise in a typical retrofit

application, it is best to consult the VFD manufacturer for assistance.

CONCLUSION

VFDs not only can save money, they can make money. Some utilities offer rebates for

installing VFDs in new or retrofit work. In many cases, a VFD can pay for itself in less

than a year. Upgrading with VFDs is a major part of the U.S. Environmental Protection

Agency's effort to improve energy efficiency. Many resources offer comprehensive

information on state, local, utility, and federal incentives that promote renewable energy

and energy efficiency. Whether in a new design or an existing application, VFDs offer

numerous advantages when used on cooling towers.

For past HPAC Engineering feature articles, visit www.hpac.com.

http://hpac.com/motors-drives/benefits-vfds-cooling-towers

6/20/2013

The Benefits of VFDs on Cooling Towers | Motors / Drives content from HPAC Engineer... Page 4 of 4

A building-automation application engineer for Yaskawa Electric America Inc., Joe

Koepke has a bachelor's degree in mechanical engineering from the Milwaukee School of

Engineering. He has a decade of experience in variable-frequency-drive technical

support and application engineering.

TWEET

Newsletter Signup

Sign-up to receive our free newsletters

E-MAIL:

COUNTRY:

UNITED STATES

SUBSCRIBE

Please Log In or Register to post comments.

Related Articles

Applying VFDs to Refrigeration Systems

Calculating Benefits of VFD Performance

Extending Motor Life With Sustainable Shaft Grounding

NEW EQUIPMENT

Harmonic Distortion: Reality vs. Perception

HPAC.com

Air Conditioning Building Controls Fire / Smoke Heating Humidity Control IAQ & Ventilation Motors / Drives Piping / Pumping

Site Features

HPAC Engineering Corporate

Media Center

Privacy Statement

RSS

Terms of Use

Sitemap

Contact

Site Archive

Search HPAC.com

Follow Us

Newsletters

View Mobile Site

Mechanical Systems Sites

Contracting Business Contractor HVAC-Talk Comfortech 2013 Show HVACR Distribution Business Radiant Living

Fire Protection Engineering

Copyright 2013 Penton

http://hpac.com/motors-drives/benefits-vfds-cooling-towers

6/20/2013

Das könnte Ihnen auch gefallen

- T3LN Digital PDFDokument4 SeitenT3LN Digital PDFAnand NambiarNoch keine Bewertungen

- Pay and Allowances For September 2020 - RTI ActDokument13 SeitenPay and Allowances For September 2020 - RTI ActAnand NambiarNoch keine Bewertungen

- Lbs End Suction Pump PDFDokument4 SeitenLbs End Suction Pump PDFAndrew StanleyNoch keine Bewertungen

- LBS Technical Data 50Hz DimensionsDokument10 SeitenLBS Technical Data 50Hz DimensionsAnand NambiarNoch keine Bewertungen

- Lbs End Suction Pump PDFDokument4 SeitenLbs End Suction Pump PDFAndrew StanleyNoch keine Bewertungen

- LBS Technical Data 50Hz DimensionsDokument10 SeitenLBS Technical Data 50Hz DimensionsAnand NambiarNoch keine Bewertungen

- Budget Should Not Only Repair, But Reboot EconomyDokument4 SeitenBudget Should Not Only Repair, But Reboot EconomyAnand NambiarNoch keine Bewertungen

- 9786 Posts So Far: #India-PhotosDokument8 Seiten9786 Posts So Far: #India-PhotosAnand NambiarNoch keine Bewertungen

- At Rs 1700 Crore, Jhunjunwala Takes His Biggest Hit in 10 QuartersDokument4 SeitenAt Rs 1700 Crore, Jhunjunwala Takes His Biggest Hit in 10 QuartersAnand NambiarNoch keine Bewertungen

- Polycarbonate Testing ChartDokument1 SeitePolycarbonate Testing ChartAnand NambiarNoch keine Bewertungen

- 10 Smallcaps That Logged Up To 1,000% Rise in 2017, Can Click in 2018 AgainDokument22 Seiten10 Smallcaps That Logged Up To 1,000% Rise in 2017, Can Click in 2018 AgainAnand NambiarNoch keine Bewertungen

- Child Marriages in IndiaDokument4 SeitenChild Marriages in IndiaAnand NambiarNoch keine Bewertungen

- India GDP Grows 7.7% in Q4, Remains Ahead of China As Fastest Growing EconomyDokument5 SeitenIndia GDP Grows 7.7% in Q4, Remains Ahead of China As Fastest Growing EconomyAnand NambiarNoch keine Bewertungen

- High Performance Glass PDFDokument4 SeitenHigh Performance Glass PDFBrajesh MishraNoch keine Bewertungen

- The Ashokan Rock Edicts Are A Marvel of HistoryDokument4 SeitenThe Ashokan Rock Edicts Are A Marvel of HistoryAnand NambiarNoch keine Bewertungen

- Is The Taj SafeDokument3 SeitenIs The Taj SafeAnand NambiarNoch keine Bewertungen

- 11% Rise in Rural Incomes But Migration Continues UnabatedDokument2 Seiten11% Rise in Rural Incomes But Migration Continues UnabatedAnand NambiarNoch keine Bewertungen

- A Prince Who Walked On The Wild SideDokument5 SeitenA Prince Who Walked On The Wild SideAnand NambiarNoch keine Bewertungen

- IT Firms Cut Flab, Sack 3,000 in Q1Dokument4 SeitenIT Firms Cut Flab, Sack 3,000 in Q1Anand NambiarNoch keine Bewertungen

- 3-Sizing 08 06Dokument14 Seiten3-Sizing 08 06paijo_konatNoch keine Bewertungen

- An Energy Superpower - Not India!Dokument4 SeitenAn Energy Superpower - Not India!Anand NambiarNoch keine Bewertungen

- Find Out - How Happy and Peaceful Is Your CountryDokument3 SeitenFind Out - How Happy and Peaceful Is Your CountryAnand NambiarNoch keine Bewertungen

- Kashmiris Are Going NowhereDokument8 SeitenKashmiris Are Going NowhereAnand NambiarNoch keine Bewertungen

- Determining Required Valve Pressure RatingsDokument3 SeitenDetermining Required Valve Pressure RatingsAnand NambiarNoch keine Bewertungen

- Approved Engine Oils by Maruti SuzukiDokument18 SeitenApproved Engine Oils by Maruti SuzukiAnand NambiarNoch keine Bewertungen

- Can Brisk Walking Help You Lose WeightDokument3 SeitenCan Brisk Walking Help You Lose WeightAnand NambiarNoch keine Bewertungen

- Why Liquid Funds Are Better Than Savings Accounts For Idle CashDokument3 SeitenWhy Liquid Funds Are Better Than Savings Accounts For Idle CashAnand NambiarNoch keine Bewertungen

- We Cannot Keep Ignoring What Is Happening To Our ChildrenDokument7 SeitenWe Cannot Keep Ignoring What Is Happening To Our ChildrenAnand NambiarNoch keine Bewertungen

- 10 Silly Grammar Mistakes Smart People Make!Dokument4 Seiten10 Silly Grammar Mistakes Smart People Make!Anand NambiarNoch keine Bewertungen

- Smart India Hackathon 2017 - How We Created The World's Biggest Hackathon!Dokument4 SeitenSmart India Hackathon 2017 - How We Created The World's Biggest Hackathon!Anand NambiarNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- GMP WHO For Hormone Product PDFDokument17 SeitenGMP WHO For Hormone Product PDFphamuyenthuNoch keine Bewertungen

- LA9P307 TelemecaniqueDokument36 SeitenLA9P307 TelemecaniqueEder JoelNoch keine Bewertungen

- UbiCom NotesDokument3 SeitenUbiCom NotesJohn CenaNoch keine Bewertungen

- AWTG BenchmarkingDokument27 SeitenAWTG BenchmarkingJayant VaishyaNoch keine Bewertungen

- 12 Ip Camera ManualDokument64 Seiten12 Ip Camera Manualpaninaro2011Noch keine Bewertungen

- Quotation-Standard Items (Internal Use) 20180706r1Dokument1 SeiteQuotation-Standard Items (Internal Use) 20180706r1Aisha KhatibiNoch keine Bewertungen

- Flaw Detector Sonic1200 PlusDokument2 SeitenFlaw Detector Sonic1200 PlusvrapciudorianNoch keine Bewertungen

- Kokan Mercantile Co-Operative Bank LTD.: Grievance Redressal PolicyDokument3 SeitenKokan Mercantile Co-Operative Bank LTD.: Grievance Redressal Policy077 - Ubaid dhansayNoch keine Bewertungen

- Chapter - 20: Effective ControlDokument32 SeitenChapter - 20: Effective Controlcooldude690Noch keine Bewertungen

- 21414.valvulas e Inyectores Bomba, Ajuste.. Motor Con VEBDokument2 Seiten21414.valvulas e Inyectores Bomba, Ajuste.. Motor Con VEBFrancisco Alvarado HuenquiaoNoch keine Bewertungen

- Pnational Construction-Profile - 21 2 1Dokument23 SeitenPnational Construction-Profile - 21 2 1Cold ExecuTionNoch keine Bewertungen

- 740 Architecture OverviewDokument73 Seiten740 Architecture OverviewsribNoch keine Bewertungen

- Geomembrana Agru Lldpe PDFDokument1 SeiteGeomembrana Agru Lldpe PDFJorge Luis Reyes CarmeloNoch keine Bewertungen

- Bs 7036-2Dokument18 SeitenBs 7036-2Ahmed El GendyNoch keine Bewertungen

- The Aboveground Steel Storage Tank Handbook - Brian D. Digrado, Gregory A. Thorp (Wiley, 2004)Dokument352 SeitenThe Aboveground Steel Storage Tank Handbook - Brian D. Digrado, Gregory A. Thorp (Wiley, 2004)Awan D'almighty83% (6)

- En 755-1 PDFDokument18 SeitenEn 755-1 PDFVIJAYAKUMAR T100% (1)

- BCA 4th Sem Lab ProgramsDokument25 SeitenBCA 4th Sem Lab Programsbeneefs50% (2)

- DotSpatial - 2 - Symbology e Tabela AtributoDokument14 SeitenDotSpatial - 2 - Symbology e Tabela AtributoMarco Antonio Almeida100% (1)

- Plumbing Code QuestionsDokument3 SeitenPlumbing Code QuestionsJhay DomdomNoch keine Bewertungen

- MDS SD Series: Setup GuideDokument4 SeitenMDS SD Series: Setup GuideCarlos David Ordaz JuárezNoch keine Bewertungen

- CH 13Dokument33 SeitenCH 13joyabyssNoch keine Bewertungen

- Personnel Administration PPT Chap 1Dokument16 SeitenPersonnel Administration PPT Chap 1Zanz Lee Greywolf100% (2)

- Satip A 114 01 Earth WorkDokument11 SeitenSatip A 114 01 Earth WorkZia ur RehmanNoch keine Bewertungen

- N7K NX-OS Software Upgrade and Downgrade Guide Release 5.xDokument30 SeitenN7K NX-OS Software Upgrade and Downgrade Guide Release 5.xKarthikesan IyanappanNoch keine Bewertungen

- EXJ - 19A99 Jeep XJ Service ManualDokument12 SeitenEXJ - 19A99 Jeep XJ Service ManualhottubdocNoch keine Bewertungen

- OSI ModelDokument6 SeitenOSI ModelmushahidNoch keine Bewertungen

- Maintenance Management of Electrical Equipment Condition Monitoring Based Part 1Dokument5 SeitenMaintenance Management of Electrical Equipment Condition Monitoring Based Part 1Abdan ShidqiNoch keine Bewertungen

- 3a. Loading and Hauling OperationsDokument27 Seiten3a. Loading and Hauling Operationshyari2011Noch keine Bewertungen

- Jacoby TarboxDokument7 SeitenJacoby TarboxBayu Permana RydhaNoch keine Bewertungen

- 03-401 Proceedings of ISARTDokument144 Seiten03-401 Proceedings of ISARTscott_lyeNoch keine Bewertungen