Beruflich Dokumente

Kultur Dokumente

Asphalt Lab Report - Lab Form Example

Hochgeladen von

PedjaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Asphalt Lab Report - Lab Form Example

Hochgeladen von

PedjaCopyright:

Verfügbare Formate

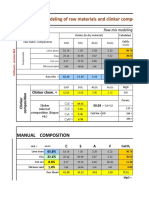

SUMMARY REPORT

BINDER COURSE

Asphalt layer

ID:

916

km 71+300

Date:

12/26/2010

Source:

SUMMARY REPORT

Properties

Test results

Bulk density of Marshall specimen

Specified

(g/cm3)

Stability of Marshall specimen

(kN)

min 6 kN

Flow of Marshall specimen

(mm)

max 4 mm

Air Voids in Total Mix

Percent Voids Filled

with Bitumen

Bitumen content in Asphalt mix

(%)

3-8%

(%)

5.3

Thickness of Core specimen

(cm)

6.2

(%)

Bulk density of Core specimen

(g/cm3)

Compaction of asphalt layer

100

5.30.3%

(%)

min 97 %

100.0

93.6

90

Aggregate Mix

80

Average

70

57.8

60

Passing (%)

50

42.2

40

27.9

30

20

13.6

7.8

10

0

25.0

19.0

9.5

4.8

2.4

0.6

0.3

5.3

0.2

2.1

0.1

Sieve (mm)

REMARKS:

Tested by Lab - technician

(Contractor)

Checked by M.E.

(Contractor)

xxx

xxx

QR 457-1

Witness by M.I.

(Consultant)

QUANTITATIVE EXTRACTION OF BITUMEN

AND SIEVE ANALYSIS OF AGGREGATE OF BITUMINOUS PAVING

MIXTURES

BINDER COURSE

EXTRACTION 1

Source:

Asphalt layer

ID:

916

km 71+300

Date:

12/26/2010

BITUMEN EXTRACTION

1213.4

199.2

209.7

1139.8

0.0

1150.3

63.1

A : Wt of Mix (g)

B : Bowl empty (g)

C : Bowl with sediment (g)

D : Wt of Aggregate after test (g)

S : Sediment fines (rest)

E (D+C-B+S) : Total Wt of Aggregate (g)

F (A-E) : Loss of Wt (g)

5.2

G (100xF/A) : Bitumen Percentage by Wt of Mix (%)

PARTICLE SIZE ANALYSIS OF AGGREGATE

BS

(mm)

25.0

19.0

9.5

4.75

2.36

0.600

0.300

0.150

0.075

ASTM

(in)

1

3/4

3/8

No. 4

No. 8

No. 30

No. 50

No. 100

No. 200

PAN

loss

TOTAL

100

Retained Weight

cum. (g)

0

59

411

195

141

183

63

39

37

4

18.3

1150.3

Retained

(%)

0.0

5.1

35.7

17.0

12.3

15.9

5.5

3.4

3.2

Passing

(%)

100

94.9

59.1

42.2

29.9

14.0

8.5

5.2

1.9

REMARKS:

1.9

Tolerance

grading

100

89.9 - 99.9

52.9 - 62.9

39.6 - 47.6

25.4 - 33.4

9.6 - 17.6

5.6 - 11.6

3.9 - 7.9

0.9 - 3.9

Specification limits

100

75-100

45-70

30-50

20-35

5-20

3-12

2-8

0-4

100.0

100.0

94.9

90

Aggregate Mix

80

3.2

3.2

3.2

70

Sample

59.1

60

Passing (%)

50

42.2

40

29.9

30

20

14.0

8.5

10

0

25.0

19.0

9.5

4.8

2.4

0.6

0.3

5.2

0.2

Sieve (mm)

Tested by Lab - technician

(Contractor)

Checked by M.E.

(Contractor)

xxx

xxx

QR 457-2a

Witness by M.I.

(Consultant)

1.9

0.1

QUANTITATIVE EXTRACTION OF BITUMEN

AND SIEVE ANALYSIS OF AGGREGATE OF BITUMINOUS PAVING

MIXTURES

BINDER COURSE

EXTRACTION 2

Source:

Asphalt layer

ID:

916

km 71+300

Date:

12/26/2010

BITUMEN EXTRACTION

1224.7

234.2

262.4

1131.6

0.0

1159.8

64.9

A : Wt of Mix (g)

B : Bowl empty (g)

C : Bowl with sediment (g)

D : Wt of Aggregate after test (g)

S : Sediment fines (rest)

E (D+C-B+S) : Total Wt of Aggregate (g)

F (A-E) : Loss of Wt (g)

5.3

G (100xF/A) : Bitumen Percentage by Wt of Mix (%)

PARTICLE SIZE ANALYSIS OF AGGREGATE

BS

(mm)

25.0

19.0

9.5

4.75

2.36

0.600

0.300

0.150

0.075

ASTM

(in)

1

3/4

3/8

No. 4

No. 8

No. 30

No. 50

No. 100

No. 200

PAN

loss

TOTAL

100

Retained Weight

cum. (g)

0

88

418

165

189

148

70

19

36

1

25.8

1159.8

Retained

(%)

0.0

7.6

36.0

14.2

16.3

12.8

6.0

1.6

3.1

2.3

Passing

(%)

100

92.4

56.4

42.1

25.8

13.1

7.0

5.4

2.3

REMARKS:

Tolerance grading

Specification limits

100

89.9 - 99.9

52.9 - 62.9

39.6 - 47.6

25.4 - 33.4

9.6 - 17.6

5.6 - 11.6

3.9 - 7.9

0.9 - 3.9

100

75-100

45-70

30-50

20-35

5-20

3-12

2-8

0-4

100.0

100.0

Aggregate Mix

92.4

90

80

Sample

70

56.4

60

Passing (%)

50

42.1

40

25.8

30

20

13.1

10

7.0

5.4

2.3

0

1

Sieve (mm)

Tested by Lab - technician

(Contractor)

Checked by M.E.

(Contractor)

xxx

xxx

QR 457-2b

Witness by M.I.

(Consultant)

LABORATORY DENSITY , PERCENT AIR VOIDS ,

RESISTANCE TO PLASTIC FLOW AND STABILITY OF BITUMINOUS

MIXTURES USING MARSHALL APPARATUS

BINDER COURSE

MARSHALL

Marshall Specimen No

Asphalt layer

ID:

916

km 71+300

Date:

12/26/2010

Source:

LABORATORY DENSITY (Bulk Specific Gravity) OF SPECIMEN prepared by 2x75 blows

A : Wt of Dry Specimen in Air

(g)

B : Wt of SSD Specimen in Air

(g)

C : Wt of SSD Specimen in Water

(g)

D = (B-C) : Volume of Specimen

(cm3)

E = (A/D) : Laboratory Density of Specimen

(g/cm3)

F: AVERAGE LABORATORY DENSITY

(g/cm3)

AVG=

Gmm (AASHTO T 209)

G1: Asphalt dry mass

(g)

G2: Weight In water

(g)

G3 : Flask callibration weight

(g)

G4 = [G1/(G1-G2+G3)] : Max Density (Gmm)

(g/cm3)

G: AVG (Gmm)

(g/cm3)

8405

AVG=

AIR VOIDS IN SPECIMEN

(g/cm3)

1.01

1.01

L : Bitumen Content

(%)

5.3

5.3

M = [100x(1-F/G)] : Air Voids in Total Mix

(%)

AVG=

O = [LxF/H] : Percent Voids in Mineral

Aggregate (VMA)

(%)

AVG=

P (100xM/O) :Percent Voids Filled

with Bitumen (VFB)

(%)

AVG=

H : Specific Gravity of Bitumen

STABILITY AND FLOW OF SPECIMENs

Q1 : Height of Specimen

(mm)

Q2 : Dial Reading

(mm)

Q3 : Converter Factor of Load Ring

Q4 = (Q2xQ3) : Converted Measured Stability

(kN/mm)

(kN)

Q5 : Stability Correlation Ratio (as per Thickn.)

Q6 = (Q4xQ5) : Corrected Stability

(kN)

Q7 : Flow

(mm)

AVERAGE STABILITY OF SPECIMENS

(kN)

AVG=

AVERAGE FLOW OF SPECIMENS

(mm)

AVG=

Tested by Lab - Engineer

(Contractor)

QR 457-3/1

Checked by M.E.(Contractor)

Witness by M.I. (Consultant)

COMPACTION TESTING OF ASPHALT

LAYER

BINDER COURSE

CORE

1

CH:

km 70+040

CORE Specimen No

Location:

RHS

(cm)

6.2

CORE Specimen position

Thickness

Asphalt layer

ID:

916

km 71+300

Date:

12/26/2010

Source:

LHS

CL

AVG.=

6.2

AVG.=

2.296

(cm)

LABORATORY DENSITY (Bulk Specific Gravity) OF SPECIMEN

A : Wt of Dry Specimen in Air

(g)

B : Wt of Specimen with parafine

(g)

B : Wt of SSD Specimen in Air

(g)

1124.0

C : Wt of SSD Specimen in Water

(g)

645.0

C : Parafine density

(g/cm3)

0.908

C : Parafine volume

(cm3)

D (B-C) : Volume of Specimen

(cm3)

479.0

E (A/D) : Density of Specimen

(g/cm3)

2.296

AVERAGE

Density of Core specimen

(g/cm3)

1100.0

(g/cm3)

2.296

COMPACTION

G : Bulk Specific Gravity of

Marshall specimen

(g/cm3)

F : (E/G*100): Compaction

(%)

AVERAGE COMPACTION

AVG.=

(%)

REMARKS:

QR 457-4

Tested by Lab - Engineer

(Contractor)

Checked by M.E.(Contractor)

xxx

xxx

Witness by M.I. (Consultant)

(%)

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- PrEN 13043 - Aggregates For Bituminous Mixtures and SurfaceDokument45 SeitenPrEN 13043 - Aggregates For Bituminous Mixtures and SurfacePedja100% (1)

- ASTM D6938-08aDokument11 SeitenASTM D6938-08ainspmtto100% (1)

- Chapter 11 Grade 5 Scott Foresman ScienceDokument3 SeitenChapter 11 Grade 5 Scott Foresman ScienceasaleemnaNoch keine Bewertungen

- 6129-202 Key Plumbing Principles Version ADokument10 Seiten6129-202 Key Plumbing Principles Version AP_DaviesNoch keine Bewertungen

- Calculation Cover SheetDokument10 SeitenCalculation Cover SheetMurali MuthuNoch keine Bewertungen

- Petar Subotic - Prirucnik Za Asfalt I DeoDokument308 SeitenPetar Subotic - Prirucnik Za Asfalt I DeoPedjaNoch keine Bewertungen

- PrEN 12273 - Slurry Surfacing - Product StandardDokument25 SeitenPrEN 12273 - Slurry Surfacing - Product StandardPedjaNoch keine Bewertungen

- Cement Calculus 28Dokument2 SeitenCement Calculus 28PedjaNoch keine Bewertungen

- PrEN 13020 - Road Surface Treatment MachinesDokument20 SeitenPrEN 13020 - Road Surface Treatment MachinesPedjaNoch keine Bewertungen

- Klinker Composition CalculationProt 231bDokument28 SeitenKlinker Composition CalculationProt 231bPedjaNoch keine Bewertungen

- Aggregate Pop OutDokument0 SeitenAggregate Pop Outتوان امتياس سامسدينNoch keine Bewertungen

- Matematika Jedan Nikic Comic RP22Dokument152 SeitenMatematika Jedan Nikic Comic RP22PedjaNoch keine Bewertungen

- PrEN 12271-10 - Factory Production ControlDokument17 SeitenPrEN 12271-10 - Factory Production ControlPedjaNoch keine Bewertungen

- NRMC CIP 44prDokument2 SeitenNRMC CIP 44prPedjaNoch keine Bewertungen

- Maturity Method To Estimate Concrete StrengthDokument2 SeitenMaturity Method To Estimate Concrete StrengthRV Vimal100% (1)

- NRMC CIP 13pDokument2 SeitenNRMC CIP 13pPedjaNoch keine Bewertungen

- PrEN 12271 - Surface DressingDokument54 SeitenPrEN 12271 - Surface DressingPedjaNoch keine Bewertungen

- NRMC CIP 32pDokument2 SeitenNRMC CIP 32pPedjaNoch keine Bewertungen

- NRMC CIP 26pDokument2 SeitenNRMC CIP 26pPedjaNoch keine Bewertungen

- NRMC CIP 28pDokument2 SeitenNRMC CIP 28pPedjaNoch keine Bewertungen

- CIP35 - Testing Compressive Strength of ConcreteDokument2 SeitenCIP35 - Testing Compressive Strength of ConcreteGerardo BeckerNoch keine Bewertungen

- GuidelinesDokument2 SeitenGuidelinesMike2322Noch keine Bewertungen

- Cold Weather ConcretingDokument2 SeitenCold Weather ConcretingBoris DikovNoch keine Bewertungen

- NRMC CIP 43pDokument2 SeitenNRMC CIP 43pPedjaNoch keine Bewertungen

- NRMC CIP 23pDokument2 SeitenNRMC CIP 23pPedjaNoch keine Bewertungen

- NRMC CIP 20pDokument2 SeitenNRMC CIP 20pPedjaNoch keine Bewertungen

- NRMC CIP 17pDokument2 SeitenNRMC CIP 17pPedjaNoch keine Bewertungen

- NRMC CIP 29pDokument2 SeitenNRMC CIP 29pPedjaNoch keine Bewertungen

- High Strength ConcreteDokument0 SeitenHigh Strength ConcreteAris Co AbergosNoch keine Bewertungen

- STANDARD SPECIFICATIONS For HIGHWAY BRIDGESDokument0 SeitenSTANDARD SPECIFICATIONS For HIGHWAY BRIDGESتوان امتياس سامسدينNoch keine Bewertungen

- NRMC CIP 18pDokument2 SeitenNRMC CIP 18pPedjaNoch keine Bewertungen

- CIP 19 - Curling of Concrete SlabsDokument2 SeitenCIP 19 - Curling of Concrete SlabsMaestroColicus100% (1)

- CIP 12 Hot Weather ConcretingDokument2 SeitenCIP 12 Hot Weather ConcretingTim_CNoch keine Bewertungen

- Finishing Concrete FlatworkDokument0 SeitenFinishing Concrete Flatworkتوان امتياس سامسدينNoch keine Bewertungen

- BS 3958-5 PDFDokument10 SeitenBS 3958-5 PDFAnitha MjNoch keine Bewertungen

- Evaluation of Real Yarn Diameter - Processing, Dyeing & Finishing - FeaturesDokument7 SeitenEvaluation of Real Yarn Diameter - Processing, Dyeing & Finishing - FeaturesTrinhTruongNoch keine Bewertungen

- Term Exam Me2aDokument3 SeitenTerm Exam Me2aJonathan Ampis67% (3)

- 6th Grade - Mixture Test ReviewDokument21 Seiten6th Grade - Mixture Test Reviewleojohn2Noch keine Bewertungen

- Food Compendium 2013 VolumeDokument498 SeitenFood Compendium 2013 VolumeAgeng Wahyu PatrianitaNoch keine Bewertungen

- Astm D 1217Dokument5 SeitenAstm D 1217DeniseeMO100% (1)

- Anomalous Properties of WaterDokument5 SeitenAnomalous Properties of Watertulinne100% (1)

- Lecture 3: Exercise On Measurement of QuantitiesDokument3 SeitenLecture 3: Exercise On Measurement of Quantitiesjr_satishNoch keine Bewertungen

- fle, Tii,:v,' Jy ' TR Ijf, Q D, 4cto'r:.,ma, Ri:al' :1j::"""Dokument4 Seitenfle, Tii,:v,' Jy ' TR Ijf, Q D, 4cto'r:.,ma, Ri:al' :1j::"""Ovidijus RučinskasNoch keine Bewertungen

- Soil Mechanics and Foundation Engineering Question (Qwa) PDFDokument18 SeitenSoil Mechanics and Foundation Engineering Question (Qwa) PDFMohammed AnwhazNoch keine Bewertungen

- HPC-02 Catalyst HandlingDokument7 SeitenHPC-02 Catalyst HandlingCarolina Cortes VazquezNoch keine Bewertungen

- Prakash Shrinkage Wax MethodDokument5 SeitenPrakash Shrinkage Wax MethodCj SumilangNoch keine Bewertungen

- Was vs. Were: What's The Difference? HomeDokument16 SeitenWas vs. Were: What's The Difference? HomeMervin Kristian FetalveroNoch keine Bewertungen

- Density of Soil in Place by The Drive-Cylinder Method: Standard Test Method ForDokument5 SeitenDensity of Soil in Place by The Drive-Cylinder Method: Standard Test Method ForAssfachew BeleteNoch keine Bewertungen

- Tpo 0030 RTP 4920 1620 Uv IsoDokument2 SeitenTpo 0030 RTP 4920 1620 Uv IsoVenkata ChadaNoch keine Bewertungen

- Technological Institute of The PhilippinesDokument10 SeitenTechnological Institute of The PhilippinesJeremiah ComingNoch keine Bewertungen

- DPL - EnsaioDokument14 SeitenDPL - EnsaioTimothy CaldwellNoch keine Bewertungen

- AS NotesDokument222 SeitenAS NotesRayyan HashmiNoch keine Bewertungen

- Non-Ferrous Metals: From Last LectureDokument18 SeitenNon-Ferrous Metals: From Last LectureNooruddin SheikNoch keine Bewertungen

- Gas Dehydration: Part of The Petroleum Processing Technology SeriesDokument714 SeitenGas Dehydration: Part of The Petroleum Processing Technology SeriesImad AghilaNoch keine Bewertungen

- June 2021 (v2) QP - Paper 2 CIE Physics IGCSEDokument16 SeitenJune 2021 (v2) QP - Paper 2 CIE Physics IGCSEMonoNoch keine Bewertungen

- Density of ChocolateDokument4 SeitenDensity of Chocolategwinnru100% (1)

- Aashto T 310 - In-Place Density and Moisture Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth)Dokument6 SeitenAashto T 310 - In-Place Density and Moisture Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth)Aldrin SantosNoch keine Bewertungen

- Breakage and Fragmentation Modelling For Underground (Onederra-Extemin05)Dokument24 SeitenBreakage and Fragmentation Modelling For Underground (Onederra-Extemin05)Kevin EduardoNoch keine Bewertungen

- Mste Online Preboard Mste Online Preboard: InstructionDokument10 SeitenMste Online Preboard Mste Online Preboard: InstructionJoshua John JulioNoch keine Bewertungen

- Agarwal-Int J Heat Mass Transfer-2021Dokument11 SeitenAgarwal-Int J Heat Mass Transfer-2021TOufiqueNoch keine Bewertungen