Beruflich Dokumente

Kultur Dokumente

Assessing Economizer Performance

Hochgeladen von

Dedi YushardiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Assessing Economizer Performance

Hochgeladen von

Dedi YushardiCopyright:

Verfügbare Formate

Assessing Economizer Performance

Air-side economizers are control devices that open and close dampers to bring in outside

air for cooling and ventilation. They save energy by using outside air for cooling when the

outdoor air is cooler than the return air. Unfortunately, improper operation of economizers

is quite common and often goes unnoticed, resulting in increased energy use. This

application note describes a relatively simple procedure used to assess an economizers

performance.

Economizers are required by Title 24, Section 144(e) 1 for cooling fans with a capacity over

2500 CFM and a cooling capacity over 75,000 Btu/hr.

Equipment Needed

4 Hobo XT (or Stowaway XT) dataloggers

1 HOBO software and communication cable

NOTE:

When measuring air temperatures, sensor tips must be shielded from sources of

radiation such as the sun or cooling coils. Is a sensor able to "see" the source of radiation?

If it can, it should be shielded with a reflective material such as aluminum foil. The foil

should not be in contact with the sensor, nor constrict air flow around it.

Procedure

Step 1: Launch the Hobo XT dataloggers. (See Onset Software application note for

instructions.) In most cases, we recommend configuring the loggers to operate

for a period of two weeks. Make sure that the overwrite data box is selected (in

the Hobo software) to insure that you are collecting the most recent data.

PEC Tool Lending Library Application Note:

Assessing Economizer Performance

http://www.pge.com/pec

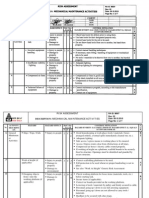

Figure 1 Diagram of a rooftop AC unit

Step 2: Place the Hobo XT thermistor tips in different air chambers (Figure 1). The

loggers should be fastened securely with duct tape as the air at high speeds

within the unit can lift the loggers away. Insure that the thermistor is suspended

in the air chamber and not touching heating/cooling coil or other surfaces. If you

are conducting long-term studies, consider securing the logger in such a way

that provides easy access to the cable port.

Supply Air Temperature [SAT] (1). Place a HOBO downstream of the cooling

coil.

Mixed Air Temperature [MAT] (2). Place a logger in the mixed air stream. It is

important that the sensor is in a well-mixed location as far downstream from the

mixing dampers as possible without being too close to the cooling coil.

Return Air Temperature [RAT] (3). Place a HOBO in the return air upstream of

the mixed air dampers.

Outside Air Temperature [OAT] (4). Place a logger in a protected location near

the outside air grill. Avoid a location where the sensor will receive direct sun. If

you cannot find an ideal location, shield the sensor with aluminum foil to block

direct sun allowing air to flow around the sensor while making no contact with it.

Step 3: After the data collection period has expired, retrieve the loggers from the field

and download the data.

Step 4: Transfer data to a spreadsheet with the time for each sensor coincident. Graph

all four data series on one chart to assess performance. The Energy Center

developed a spreadsheet automating the graphing processes. Click here to

download a copy of this spreadsheet, Econ.exe [self-extracting zip file 564k]

PEC Tool Lending Library Application Note:

Assessing Economizer Performance

http://www.pge.com/pec

Looking at the Data

Figure 2: Graph of ideal economizer operation

The mixed air temperature and the outside air temperature should track closely when the

outside air temperature is above the minimum supply air setpoint. This condition should

persist until either; a) the outside air temperature exceeds the return air temperature, or b)

the outside air temperature is below the minimum supply air temperature setpoint. Under

these conditions the percentage of outside air brought in is reduced and the mixed air

temperature and supply air temperature drift apart. For ventilation purposes, the outside

air is never reduced to 0%.

Fi gure 3: Typical data from an economizer with a stuck damper

Compare fig. 2 with fig. 3. Fig 3 shows that the mixed air temperature is not tracking

outside air temperature even though the outside air is cooler than the return air. The most

likely scenario is that the outside air damper is stuck in a closed or nearly closed position.

If the damper was stuck open we would expect to see the mixed air temperature track

outside air even when the outside air temperature is hotter than the return air or cooler

than the supply air setpoint.

PEC Tool Lending Library Application Note:

Assessing Economizer Performance

http://www.pge.com/pec

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Power Generation From CoalDokument114 SeitenPower Generation From CoalOral KarahanNoch keine Bewertungen

- Hot-Dip Galvanizing Service: BS 729:1971 Hot-Dip Galvanized Coatings On Iron & Steel ArticlesDokument2 SeitenHot-Dip Galvanizing Service: BS 729:1971 Hot-Dip Galvanized Coatings On Iron & Steel ArticleshbookNoch keine Bewertungen

- HDGDokument16 SeitenHDGharry0% (1)

- It0704 29Dokument3 SeitenIt0704 29Anonymous avGU1iNoch keine Bewertungen

- Fuji ReviewDokument38 SeitenFuji ReviewaakashtrivediNoch keine Bewertungen

- It0704 29Dokument3 SeitenIt0704 29Anonymous avGU1iNoch keine Bewertungen

- Sgre20120300010 72212999Dokument7 SeitenSgre20120300010 72212999Dedi YushardiNoch keine Bewertungen

- BR 1884Dokument9 SeitenBR 1884Dedi YushardiNoch keine Bewertungen

- Of 72 Duplex Steam Tubes That Became Unbonded IDokument6 SeitenOf 72 Duplex Steam Tubes That Became Unbonded IDedi YushardiNoch keine Bewertungen

- Sgre 2014012211540501Dokument7 SeitenSgre 2014012211540501Dedi YushardiNoch keine Bewertungen

- A Twin Unidirectional Impulse Turbine For Wave Energy ConversionDokument5 SeitenA Twin Unidirectional Impulse Turbine For Wave Energy ConversionDedi YushardiNoch keine Bewertungen

- Higher Algebra - Hall & KnightDokument593 SeitenHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- The Density and Momentum Distributions of 2-Dimensional Transonic Flow in An LP-Steam TurbineDokument7 SeitenThe Density and Momentum Distributions of 2-Dimensional Transonic Flow in An LP-Steam TurbineDedi YushardiNoch keine Bewertungen

- Ojfd 2013072417112487Dokument6 SeitenOjfd 2013072417112487Revan TaeNoch keine Bewertungen

- Roller ChainsDokument2 SeitenRoller ChainsDedi YushardiNoch keine Bewertungen

- Electromagnetic Study of MW-Class HTS Wind Turbine GeneratorsDokument4 SeitenElectromagnetic Study of MW-Class HTS Wind Turbine GeneratorsDedi YushardiNoch keine Bewertungen

- Epe 2013101515521844Dokument5 SeitenEpe 2013101515521844Dedi YushardiNoch keine Bewertungen

- Teknologi Pengolahan Hasil PerkebunanDokument8 SeitenTeknologi Pengolahan Hasil PerkebunanDedi YushardiNoch keine Bewertungen

- AADPL CNC Manual 2010 PDFDokument57 SeitenAADPL CNC Manual 2010 PDFsssf-dobojNoch keine Bewertungen

- Higher Algebra - Hall & KnightDokument593 SeitenHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Higher Algebra - Hall & KnightDokument593 SeitenHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Ed Bus inDokument132 SeitenEd Bus inmihaelaNoch keine Bewertungen

- Clean Room PDFDokument62 SeitenClean Room PDFcaporegime01100% (2)

- Brc1e61 Navigator Ed72-975Dokument50 SeitenBrc1e61 Navigator Ed72-975Ernesto GarzaNoch keine Bewertungen

- ANSI Science Festival Slide ShowDokument193 SeitenANSI Science Festival Slide ShowAnonymous AA30q4Noch keine Bewertungen

- M&E Room DimensionsDokument3 SeitenM&E Room Dimensionsjamescad425990% (10)

- Ampelair Stainless VentsDokument4 SeitenAmpelair Stainless VentsJasper MojiunNoch keine Bewertungen

- Ashrae Comm BLDG Std-211p Draft 2015-09-21 - CleanDokument64 SeitenAshrae Comm BLDG Std-211p Draft 2015-09-21 - CleanAndy Paul67% (3)

- TM 5-4210-249-13P-1Dokument1.188 SeitenTM 5-4210-249-13P-1AdvocateNoch keine Bewertungen

- Guidelines For Poultry FarmingDokument7 SeitenGuidelines For Poultry Farmingkayjaycee13Noch keine Bewertungen

- Arup JournalDokument52 SeitenArup JournaldamindaNoch keine Bewertungen

- 15780Dokument16 Seiten15780uddinnadeemNoch keine Bewertungen

- 3 Non-Residential V4Dokument49 Seiten3 Non-Residential V4Ah LoutNoch keine Bewertungen

- Oberon A620: 1. Product IdentificationDokument7 SeitenOberon A620: 1. Product Identificationmdlc6878Noch keine Bewertungen

- CPC 2Dokument113 SeitenCPC 2Gaber AlliNoch keine Bewertungen

- Hempel - High Temperature Paint - PDS - 85671-AiDokument6 SeitenHempel - High Temperature Paint - PDS - 85671-AiRoger ChetcutiNoch keine Bewertungen

- FBI and Fire DevelopmentDokument15 SeitenFBI and Fire Developmentagung100% (1)

- Passive and Active Design - 121010Dokument33 SeitenPassive and Active Design - 121010Buddhanandhan SigaNoch keine Bewertungen

- Performance of Chinese (Wok) Ranges: Standard Test Method ForDokument10 SeitenPerformance of Chinese (Wok) Ranges: Standard Test Method ForFrancisco GuerraNoch keine Bewertungen

- AFA Animal Production 7 8 Quarter 1 Module 4 FINALDokument30 SeitenAFA Animal Production 7 8 Quarter 1 Module 4 FINALELMERNoch keine Bewertungen

- Attachment 16. Site HSSE PlanDokument79 SeitenAttachment 16. Site HSSE PlanCristianMontoyaMujica100% (1)

- Mechanical Maintenance ActivitesDokument7 SeitenMechanical Maintenance ActivitesJhun Aquino50% (2)

- Lab DesignDokument49 SeitenLab DesignRaveen Matugama100% (1)

- Apartment Design Guide: Guidelines For The Design of Multi-Storey Apartment Buildings in New ZealandDokument52 SeitenApartment Design Guide: Guidelines For The Design of Multi-Storey Apartment Buildings in New ZealandYeabtsega ZelalemNoch keine Bewertungen

- Systems Design Report From HapDokument5 SeitenSystems Design Report From HapRoberto TraspalacioNoch keine Bewertungen

- UVGI DISINFECTION OF ROOM AIR. An Evidence Based Guideline For Desing, Implementation and MaintenanceDokument36 SeitenUVGI DISINFECTION OF ROOM AIR. An Evidence Based Guideline For Desing, Implementation and MaintenanceMedu100% (1)

- CO2 Flooding System or Central Bank CO2 System Is One of The Common Fixed Fire Fighting System Installed On Most of The ShipsDokument15 SeitenCO2 Flooding System or Central Bank CO2 System Is One of The Common Fixed Fire Fighting System Installed On Most of The ShipsSuresh JangidNoch keine Bewertungen

- SSP 104 Skoda Fabia III Vehicle Introduction Part IIDokument64 SeitenSSP 104 Skoda Fabia III Vehicle Introduction Part IITahaNoch keine Bewertungen

- SH 09 12 BPH X Service ManualDokument52 SeitenSH 09 12 BPH X Service ManualBobi GorgievskiNoch keine Bewertungen

- NITE Heaters Espar Operation Manual Airtronic Mini Controller InstructionsDokument2 SeitenNITE Heaters Espar Operation Manual Airtronic Mini Controller InstructionsRob GustNoch keine Bewertungen

- Module 15 EditionDokument92 SeitenModule 15 EditionAngel Sergio Perez CastilloNoch keine Bewertungen