Beruflich Dokumente

Kultur Dokumente

Linden c360 c400

Hochgeladen von

Nuñez JesusCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Linden c360 c400

Hochgeladen von

Nuñez JesusCopyright:

Verfügbare Formate

Engine-powered

Laden Container Handler

36000 kg and 40000 kg

C 360

C 400

356

Introduction

The development of the Container Handling

Forklift Trucks, models C 360 and C 400, is

based on a thorough analysis of the handling

requirements typical for container terminals,

followed by extensive trials on Lindes own

testing ground as well as in severe, practical

applications. The result is a new range of

high-performance container handling forklift

trucks suitable for a great variety of application

characteristics, guaranteeing reliable operation

and long service life.

The major characteristics at a glance

Ultra-wide lift mast combining excellent

rigidity with optimum visibility

Capability of transporting and stacking

all containers compatible with ISO

standards (with optional lock stops)

Ergonomically optimised drivers compartment

Powerful, modern diesel engine combining

low fuel consumption with excellent

exhaust emission characteristics fully

satisfying the latest standards TIER 2

High engine torque at low rpm, facilitating

fast as well as accurate manoeuvring

On-demand working hydraulics:

Hydraulic power output always

corresponds to actual demand

Automatic four-speed transmission incorporating a reverse interlock, enabling safe,

efficient working and providing high rates

of acceleration and slowdown

Drivers compartment

with optimised ergonomics

Steps on either side of the vehicle provide

access to the centralised drivers compartment. A comfortable suspension-type drivers

seat is standard with full adjustment for

weight and size of the operator. Operator

controls satisfy the ergonomic standards defined by ISO 6682, and have all been further

optimised for easy, effortless operation. A multifunction single hydraulic control lever provides

all load control movements, facilitating smooth

easy load handling. Control and supervision

instruments installed below the lower front

cross member of the overhead guard. Major

components constantly monitored, malfunctions are signalled through a central warning

light the driver is able to concentrate fully

on the job in hand, in the safe knowledge

that all important truck functions are subject

to permanent, automatic supervision.

Stable, robust chassis

The chassis frame incorporates two large I

section side members. Front and rear cross

chassis load plates; ensures excellent rigidity

and stress handling. All mechanical and

hydraulic components are located well inside

the chassis structure where they are perfectly

protected from outside damage.

High-tech diesel engine

Cummins 6-cylinder diesel engine of 11 litres

cubic capacity, equipped with turbocharger

and intercooler. Rated output 246 kW. Maximum engine torque of 1674 Nm is attained at

1100 rpm. This modern propulsion unit is

notable particularly smooth running with low

noise emissions and outstandingly clean

exhaust.

The automatic transmission and drive axle

Torque converter-coupled automatic fourspeed

powershift transmission. Reversing interlock.

Speed-controlled downshift protection. For

accurate lower-speed handling and positioning, a brake plate pressure switch is coupled

to the accelerator pedal to enable transmission disconnect whilst maintaining high engine

speed for hydraulic operations. Wide-track front

drive axle incorporates two-stage reduction

gearboxes. High-quality steel plate construction optimised for heavy-load handling.

Powerful brakes

Oil-actuated, hub-mounted wet disc brake units.

Fail-safe oil-actuated brake system. Input shaft,

disc mounted hand brake unit. Foot brake

application by applied pressure to the centralised brake plate. Parking brake application

electrical switch situated on the operators

console.

Smooth power steering

Hydrostatic power steering allows full steering

lock to be attained even at standstill. Accurate

manoeuvrability with minimum effort. Linemounted anti-shock valve. Cab-mounted antikick valve. Heavy-duty steer axle is mounted to

the chassis via spherelastic bushes allowing

axle articulation over uneven ground. Steering

lock stops preventing cylinder overstroke.

Working hydraulics

with on-demand characteristics

On-demand working hydraulic system. Multipump installation always supplying hydraulic

power in proportion to actual demand. This

innovative arrangement leads to reduced fuel

consumption, minimises wear of all hydraulic

components and also reduces the frequency of

the oil change.

LINDE

Data sheet for material

handling equipment

Container Trucks

Designation to VDI 3586

Other

Engine

Performance

Dimensions

Wheels and tyres

Weight

Characteristics

December 2003

1.1

1.2

1.3

1.4

1.5

1.6

1.8

1.9

2.1

2.2

2.3

3.1

3.2

3.3

3.5

3.6

3.7

4.1

4.2

4.4

4.5

4.7

4.8

4.12

4.15

4.19

4.20

4.21

4.24

4.28

4.31

4.32

4.33

4.34

4.35

4.36

5.1

5.2

5.3

5.5

5.6

5.7

5.9

5.10

6.4

7.1

7.2

7.3

7.4

7.5

8.1

8.2

8.3

8.4

8.5

Manufacturer

Model designation

Power unit: battery, diesel, LP gas, mains power

Operation: manual, pedestrian, stand-on, seated, order picker

Load capacity

Load centre

Axle centre to fork face

Wheelbase

Service weight

Axle load with load, front/rear

Axle load without load, front/rear

Tyres, front/rear (SE = superelastic, P = pneumatic)

Tyre size, front

Tyre size, rear

Wheels, number, front/rear (x=driven)

Track width, front

Track width, rear

Mast/fork carriage/truck tilt, forward/backward

Heigth of mast, lowered

Lift

Height of mast, extended

Height of overhead guard (cabin)

Height, operators seat/stand-on platform

Towing coupling height

Twistlock height lowered

Overall length

Length to fork face

Overall width

Width of attachment 20 / 40

Reach travel

Ground clearance, mast

Ground clearance, centre of wheelbase

Aisle width with 20 container

Aisle width with 40 container

Turning radius

Minimum pivoting point distance

Travel speed, with/without load

Lift speed, with/without load

Lowering speed, with/without load

Tractive force, with/without load

Maximum tractive force, with/without load

Climbing ability, with/without load

1 kph

Acceleration time, with/without load

Service brake

Battery voltage, rated capacity

Engine manufacturer/type

Engine performance according to ISO 1585

Rated speed

Maximum engine torque/speed

Number of cylinders/displacement

Fuel consumption according to VDI cycle

Type of drive control

Working pressure for attachments

Oil flow for attachments

Noise level, at operators ear, overhead guard/cab

Trailer coupling, design/type DIN

Q (kg)

C (mm)

x (mm)

y (mm)

kg

kg

kg

b10 (mm)

b11 (mm)

a/b ()

h1 (mm)

h3 (mm)

h4 (mm)

h6 (mm)

h7 (mm)

h10 (mm)

h13 (mm)

l1 (mm)

l2 (mm)

b1/b2 (mm)

b3 (mm)

l4 (mm)

m1 (mm)

m2 (mm)

Ast (mm)

Ast (mm)

Wa (mm)

b13 (mm)

km/h

m/s

m/s

N

N

%

s

V/Ah

kW

1/min

Nm/rpm

/cm3

l/h

bar

l/min

dB (A)

l (mm)

Linde

Linde

Linde

C 360 / 3

C 360 / 4

C 360 / 5

Diesel

Diesel

Diesel

Rider seated

Rider seated

Rider seated

36000

36000

36000

1220 /1460

1220 /1460

1220 /1460

1030

1030

1030

5500

5500

5500

65660

67970

70280

90240 /11420

92750 /11220

95350 /11030

39420 /26240

41920 /26050

44420 /25860

P/P

P/P

P/P

18.00 x 25 /40 pr

18.00 x 25 /40 pr

18.00 x 25 /40 pr

18.00 x 25 /40 pr

18.00 x 25 /40 pr

18.00 x 25 /40 pr

4x /2

4x /2

4x /2

3030

3030

3030

2786

2786

2786

2 /5

2 /5

2 /5

7665

9165

10665

7000

10000

13000

11000

14000

17000

4690

4690

4690

3500

3500

3500

600

600

600

2300

2300

2300

10168

10168

10168

7730

7730

7730

4180 / 3400

4180 / 3400

4180 / 3400

6050 /12150

6050 /12150

6050 /12150

240

240

240

445

445

445

500

500

500

11500

11500

11500

14500

14500

14500

7600

7600

7600

2925

2925

2925

23.3 / 24.9

23.3 / 24.9

23.3 / 24.9

0.30 / 0.40

0.30 / 0.40

0.30 / 0.40

0.50 / 0.50

0.50 / 0.50

0.50 / 0.50

234 /

234 /

234 /

290 /

290 /

290 /

30.9

30.9

30.9

Wet disc

Wet disc

Wet disc

2x 12 /128

2x 12 /128

2x 12 /128

Cummins QSM 11 Cummins QSM 11 Cummins QSM 11

246

246

246

2100

2100

2100

1674 /1100

1674 /1100

1674 /1100

6 /10820

6 /10820

6 /10820

Torque converter 4 /4 Torque converter 4 /4 Torque converter 4 /4

240

240

240

74

74

74

50

50

50

Container load weight

C 360 / 3

8 Container

Height

Q

(mm)

36 t

36 t

36 t

7314

4876

2438

86 Container

Height

Q

(mm)

36 t

36 t

36 t

7773

5182

2591

to c = 1220 /1460 mm

C 360 / 4

96 Container

Height

Q

(mm)

36 t

36 t

36 t

8688

5792

2896

8 Container

Height

Q

(mm)

36 t

36 t

36 t

36 t

9752

7314

4876

2438

86 Container

Height

Q

(mm)

36 t

36 t

36 t

36 t

10364

7773

5182

2591

to c = 1220 /1460 mm

C 36

96 Container

Height

Q

(mm)

36 t

36 t

36 t

36 t

11584

8688

5792

2896

8 Container

Height

Q

(mm)

14628

36 t

12190

36 t

9752

36 t

7314

36 t

4876

36 t

2438

36 t

86 Co

Q

36 t

36 t

36 t

36 t

36 t

to c = 1220

DFG

VDI 2198

Registration note

Linde

Linde

C 400 / 3

C 400 / 4

Diesel

Diesel

Rider seated

Rider seated

40000

40000

1220 /1460

1220 /1460

1030

1030

5500

5500

67660

69970

95835 /11825

98385 /11585

39410 /28250

41920 /28050

P/P

P/P

18.00 x 25 /40 pr

18.00 x 25 /40 pr

18.00 x 25 /40 pr

18.00 x 25 /40 pr

4x /2

4x /2

3030

3030

2786

2786

2 /5

2 /5

7665

9165

7000

10000

11000

14000

4690

4690

3500

3500

600

600

2300

2300

10168

10168

7730

7730

4180 / 3400

4180 / 3400

6050 /12150

6050 /12150

240

240

445

445

500

500

11500

11500

14500

14500

7600

7600

2925

2925

23.3 / 24.9

23.3 / 24.9

0.30 / 0.40

0.30 / 0.40

0.50 / 0.50

0.50 / 0.50

234 /

234 /

290 /

290 /

30.9

30.9

Wet disc

Wet disc

2x 12 /128

2x 12 /128

Cummins QSM 11 Cummins QSM 11

246

246

2100

2100

1674 /1100

1674 /1100

6 /10820

6 /10820

Torque converter 4 /4 Torque converter 4 /4

240

240

74

74

50

50

60 / 5

ontainer

Height

(mm)

12955

10364

7773

5182

2591

0 /1460 mm

C 400 / 3

96 Container

Height

Q

(mm)

36 t

36 t

36 t

36 t

36 t

14480

11584

8688

5792

2896

8 Container

Height

Q

(mm)

40 t

40 t

40 t

7314

4876

2438

86 Container

Height

Q

(mm)

40 t

40 t

40 t

7773

5182

2591

to c = 1220 /1460 mm

C 400 / 4

96 Container

Height

Q

(mm)

40 t

40 t

40 t

8688

5792

2896

8 Container

Height

Q

(mm)

40 t

40 t

40 t

40 t

9752

7314

4876

2438

86 Container

Height

Q

(mm)

40 t

40 t

40 t

40 t

10364

7773

5182

2591

to c = 1220 /1460 mm

96 Container

Height

Q

(mm)

40 t

40 t

40 t

40 t

11584

8688

5792

2896

Subject to modification in the interests of progress.

lllustrations and technical details not binding for actual construction. All dimensions subject to customary tolerances.

Equipment

Telescopic spreader

Telescopic spreader 20ft to 40ft. Incorporates

self-levelling suspension cylinders. 240 mm outreach. 3 degrees slew. 200 mm sideshift.

The toplift assembly is mounted directly onto

the outside of the wide telescoping lift mast.

Safety

Transmission integrated forward/reverse

interlock and downshift protection

Engine neutral start transmission safety

interlock

Power unit integrated safety monitors

Steering control integrated anti-kick valve

Steering axle proximity mounted shock valve

Twistlock position indicators, lights and

safety interlock

Safe load lowering valve

High-mounted cabin

excellent all-round visibility

Low noise emissions

Central warning lamp

(instrument monitoring)

Horn

Standard equipment

Fully equipped centrally located drivers

cab with hinged doors, sliding window on

left side, wipers and washers for windscreen,

rear screen and overhead guard screen,

heater and demister

Adjustable steering column

Fully adjustable suspension-type seat

Comprehensive instrumentation

Cummins diesel engine with turbocharger

and intercooler

Safety monitors for engine oil pressure,

and temperature

Clark 4-speed powershift transmission with

integrated forward/reverse safety interlock;

automatic transmission ratio selection

Heavy-duty double hub reduction drive

axle, incorporating oil bath-type multi-disc

brakes with zero maintenance requirements

Anti-stall engine speed-up device

for all working hydraulics

Linde AG, Linde Material Handling Division

Postfach 10 0136, 63701 Aschaffenburg, Germany

Phone +49-60 21- 99-0, Fax +49-60 21-99 -1570

www.linde-forklifts.com, info@linde-forklifts.com

On-demand working hydraulics,

oil supply by multi-pump installation

Power-assisted hydraulic controls

High lift and lowering speeds

Hydrostatic power steering

Telescopic spreader with integrated

outreach, slew and sideshift

Unique reverse section mast

Road lighting

Pneumatic tyres

Optional equipment

Central greasing system

Spreader stops 30ft and 24ft

Cabin pre-heat system

Climate control

Automatic reversing light

Working lights on spreader

Working lights on mast

Rotating beacon

Load weight indicator

Cold climate specification to 25 C

Radio/CD player

Reverse driving mirrors

Dry-type fire extinguisher 2.5 kg

Alternative colour schemes

Printed in Germany 114 e 4 1203 A & P Ind. D

Innovative lift mast

The design of the ultra-wide clearview lift mast

qualifies as revolutionary: in contrast to established fork truck design principles, the inner

mast is pivoted on the chassis whereas it is the

outer mast that telescopes. Increased forward

visibility. Mast construction extremely stiff in

torsion, guaranteeing perfect load elevation

up to maximum lift. The transmission of torsional

stresses from mast to chassis is minimised by

a special valve controlling the tilt jacks.

Das könnte Ihnen auch gefallen

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusVon EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNoch keine Bewertungen

- QSK38 MCRSDokument2 SeitenQSK38 MCRSsomplaklgNoch keine Bewertungen

- QSK 45Dokument107 SeitenQSK 45VinhNoch keine Bewertungen

- Injection Timing BTDCDokument4 SeitenInjection Timing BTDCFilipposNoch keine Bewertungen

- Fuel Injection Pump - Install - With Electronic GovernorDokument5 SeitenFuel Injection Pump - Install - With Electronic Governoreshopmanual limaNoch keine Bewertungen

- Cat® Engine Specifications: C18 Acert Industrial EngineDokument5 SeitenCat® Engine Specifications: C18 Acert Industrial EngineAsif MehmoodNoch keine Bewertungen

- Annaite Tyres GR Truck Tyres TBR Tech InfoDokument5 SeitenAnnaite Tyres GR Truck Tyres TBR Tech Infoapi-314751517Noch keine Bewertungen

- Tad 722 GeDokument2 SeitenTad 722 GePaulo César Managó100% (1)

- Emissions Data For Cat EngineDokument4 SeitenEmissions Data For Cat EngineRajan SharmaNoch keine Bewertungen

- 800kva CaterpillerDokument6 Seiten800kva CaterpillerSureshkumar Kulanthai VeluNoch keine Bewertungen

- Msi Ms-7120 Rev 1b SCHDokument28 SeitenMsi Ms-7120 Rev 1b SCHalexgrtNoch keine Bewertungen

- Hydreco V3A4013 Brochure 2014Dokument8 SeitenHydreco V3A4013 Brochure 2014Montes JorgeNoch keine Bewertungen

- Cummins Gta1710g Natural Gas EngineDokument2 SeitenCummins Gta1710g Natural Gas EngineAbhi Karmyal100% (1)

- Call 800-DIESELS (343-7357) : 3164131 Terminal Elec. Repair 3164292 Terminal Elec. RepairDokument5 SeitenCall 800-DIESELS (343-7357) : 3164131 Terminal Elec. Repair 3164292 Terminal Elec. RepairreycoeleNoch keine Bewertungen

- rqvwuxfwlrq, Qgxvwuldo Dqg3HwurohxppowerDokument19 Seitenrqvwuxfwlrq, Qgxvwuldo Dqg3Hwurohxppower李春杰Noch keine Bewertungen

- Fuel Supply Pump Inner Parts PDFDokument2 SeitenFuel Supply Pump Inner Parts PDFMilorad ZelenovicNoch keine Bewertungen

- Diesel Generator Set QSX15 Series Engine: Power GenerationDokument4 SeitenDiesel Generator Set QSX15 Series Engine: Power GenerationsdasdNoch keine Bewertungen

- Volvo Engine RangeDokument2 SeitenVolvo Engine Range3efooNoch keine Bewertungen

- SD 11 eDokument12 SeitenSD 11 eseaqu3stNoch keine Bewertungen

- 6BT5.9-DM Non-Certified Ratings SSDokument2 Seiten6BT5.9-DM Non-Certified Ratings SStempro100% (1)

- Gensets CatlogueDokument10 SeitenGensets CatloguejengandxbNoch keine Bewertungen

- CAN Data Link (RENR5059)Dokument3 SeitenCAN Data Link (RENR5059)PramodNoch keine Bewertungen

- 8281 SRi27 DS P4A048014E Jan04 PDFDokument2 Seiten8281 SRi27 DS P4A048014E Jan04 PDFSamuel CanelónNoch keine Bewertungen

- Kioti Daedong CK2610 (H), CK3510 (H), CK4010 (H) Tractors Service ManualDokument19 SeitenKioti Daedong CK2610 (H), CK3510 (H), CK4010 (H) Tractors Service ManualLisakolyNoch keine Bewertungen

- QuickServe Online - (3666003) C Series Troubleshooting and Repair Manual LINERDokument14 SeitenQuickServe Online - (3666003) C Series Troubleshooting and Repair Manual LINERKrisman SimanjuntakNoch keine Bewertungen

- C1376Dokument6 SeitenC1376Harry Wart WartNoch keine Bewertungen

- ZF85A Marine Propulsion SystemDokument9 SeitenZF85A Marine Propulsion SystemJun AballeNoch keine Bewertungen

- ID FLX Lite 1.9 Reference GuideDokument149 SeitenID FLX Lite 1.9 Reference Guideluisgomezpasion1Noch keine Bewertungen

- 3b. Powertrain Cont PDFDokument921 Seiten3b. Powertrain Cont PDFDejan StojanovskiNoch keine Bewertungen

- Cat c15 Cylinder Head RemovalDokument6 SeitenCat c15 Cylinder Head RemovalMUHSIN MTNoch keine Bewertungen

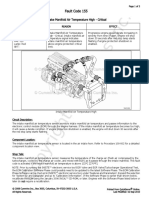

- Fault Code 155: Intake Manifold Air Temperature High - CriticalDokument3 SeitenFault Code 155: Intake Manifold Air Temperature High - Criticalhamilton miranda100% (1)

- QSK19 M 660hkDokument2 SeitenQSK19 M 660hkAinur Bamol Namsembilan100% (1)

- Southeast Diesel Collaborative Clean Diesel Initiatives: Kirk Gavaghan 27-Jun-07Dokument21 SeitenSoutheast Diesel Collaborative Clean Diesel Initiatives: Kirk Gavaghan 27-Jun-07DIEGONoch keine Bewertungen

- MJB639 L4aDokument4 SeitenMJB639 L4aAshfaq Ahmed Khawer bhattiNoch keine Bewertungen

- Data Download HGM1770 V1.6 enDokument19 SeitenData Download HGM1770 V1.6 enJohn GarnetNoch keine Bewertungen

- Inyector E7 PDFDokument5 SeitenInyector E7 PDFBryan TulpaNoch keine Bewertungen

- Overall Requirements 1. Scope: Applicable Gazette Notification Under CMVRDokument23 SeitenOverall Requirements 1. Scope: Applicable Gazette Notification Under CMVRsingh_ranveerNoch keine Bewertungen

- Geni CrennDokument253 SeitenGeni CrennRoyenNoch keine Bewertungen

- Collant CumminsDokument7 SeitenCollant Cumminsalbertinus pangngaroanNoch keine Bewertungen

- Harvest Set UpDokument117 SeitenHarvest Set UpMihály KucserkaNoch keine Bewertungen

- FPT Energy GBDokument16 SeitenFPT Energy GBAsif Shah100% (1)

- QuickServe Online - (3666087) A B3.9, B4.5, B4.5 RGT, and B5.9 Service ManualDokument7 SeitenQuickServe Online - (3666087) A B3.9, B4.5, B4.5 RGT, and B5.9 Service ManualshashirajNoch keine Bewertungen

- Air Brake System TroubleshootingDokument5 SeitenAir Brake System Troubleshootingbhanuka2009Noch keine Bewertungen

- Pump Goveror Class OneDokument38 SeitenPump Goveror Class OneEolo RojasNoch keine Bewertungen

- QSK19 DM PDFDokument2 SeitenQSK19 DM PDFSoumya Ranjan Nayak100% (2)

- Jacobs Brake 310 312 Parts Book On Caterpillar C10 C12 022040BDokument4 SeitenJacobs Brake 310 312 Parts Book On Caterpillar C10 C12 022040Bvasanth kumar100% (1)

- Valve Lash C15 AccertDokument5 SeitenValve Lash C15 AccertDominick TalaricoNoch keine Bewertungen

- Hydraulic Excavator: Engine WeightsDokument24 SeitenHydraulic Excavator: Engine WeightsRoberto HernandezNoch keine Bewertungen

- Metro-Liner: Specifications Mid Axle Forward 6x4 8x4 10x4Dokument2 SeitenMetro-Liner: Specifications Mid Axle Forward 6x4 8x4 10x4Ricardo CastroNoch keine Bewertungen

- Engine Overhaul - Bs-Iii Cummins EngineDokument28 SeitenEngine Overhaul - Bs-Iii Cummins EngineAshesh BhattaraiNoch keine Bewertungen

- Torque Specifications: Engine Mechanical (4Hk1, 6Hk1) 1A-113Dokument1 SeiteTorque Specifications: Engine Mechanical (4Hk1, 6Hk1) 1A-113Владимир ШведNoch keine Bewertungen

- Diesel Engine MitsubishiDokument4 SeitenDiesel Engine MitsubishiMarbun Benny100% (1)

- Ge W1001016 (TJK)Dokument118 SeitenGe W1001016 (TJK)Ana Hernández MonterrubioNoch keine Bewertungen

- 5 Volt Engine Pressure Sensor Supply Circuit - Test: TroubleshootingDokument7 Seiten5 Volt Engine Pressure Sensor Supply Circuit - Test: TroubleshootingsyahrilNoch keine Bewertungen

- Cat 3406C 380HP D RatingDokument4 SeitenCat 3406C 380HP D RatingDian Aprilia II100% (1)

- DATA BOOSTER 3412C Marine Engine High Performance 3JK00146-UP (SEBP2969 - 54) - Sistemas y ComponentesDokument8 SeitenDATA BOOSTER 3412C Marine Engine High Performance 3JK00146-UP (SEBP2969 - 54) - Sistemas y ComponentesmanuelNoch keine Bewertungen

- Biodiesel B20 Approval Information: Edward Lyford-Pike Michael O'DonnellDokument29 SeitenBiodiesel B20 Approval Information: Edward Lyford-Pike Michael O'DonnelltstkupdhNoch keine Bewertungen

- Underground Mining Loader: Engine Operating SpecificationsDokument20 SeitenUnderground Mining Loader: Engine Operating SpecificationsJames PaitooNoch keine Bewertungen

- E1 994D SpecalogDokument24 SeitenE1 994D SpecalogAngelo Meza Villalva100% (1)

- 966HDokument24 Seiten966Hagegnehutamirat100% (1)

- Maintenance Manual of Chery A113 - Body Accessories & DimensionsDokument169 SeitenMaintenance Manual of Chery A113 - Body Accessories & DimensionsNuñez JesusNoch keine Bewertungen

- Parker Hydraguide Steering Products PDFDokument32 SeitenParker Hydraguide Steering Products PDFJorge CabreraNoch keine Bewertungen

- Eastar ManualDokument280 SeitenEastar ManualNuñez JesusNoch keine Bewertungen

- Cvs Ferrari F 479Dokument4 SeitenCvs Ferrari F 479Nuñez JesusNoch keine Bewertungen

- Félix Rodríguez: Artist PageDokument3 SeitenFélix Rodríguez: Artist PageNuñez JesusNoch keine Bewertungen

- Joystick 1Dokument28 SeitenJoystick 1Nuñez JesusNoch keine Bewertungen

- Cvs Ferrari F 478Dokument4 SeitenCvs Ferrari F 478Nuñez JesusNoch keine Bewertungen

- HF 745 02 T eDokument4 SeitenHF 745 02 T eNuñez JesusNoch keine Bewertungen

- (Free Scores - Com) Antonio Lauro El Negrito 4136Dokument2 Seiten(Free Scores - Com) Antonio Lauro El Negrito 4136Nuñez JesusNoch keine Bewertungen

- Repair Kit Sheet Bucket Greasers (VGP) PDFDokument2 SeitenRepair Kit Sheet Bucket Greasers (VGP) PDFNuñez JesusNoch keine Bewertungen

- Filter Selection Guide-E PDFDokument78 SeitenFilter Selection Guide-E PDFNuñez JesusNoch keine Bewertungen

- 8FG25 8FD25: Main Vehicle SpecificationsDokument3 Seiten8FG25 8FD25: Main Vehicle SpecificationsNuñez JesusNoch keine Bewertungen

- HF 410 02 T eDokument2 SeitenHF 410 02 T eNuñez JesusNoch keine Bewertungen

- Diccionario Tecnico Ingles-EspañolDokument419 SeitenDiccionario Tecnico Ingles-EspañolOlga Sandoval RomeroNoch keine Bewertungen

- Automatic Transmission Manual 2 PDFDokument141 SeitenAutomatic Transmission Manual 2 PDFbobmarley20161934100% (2)