Beruflich Dokumente

Kultur Dokumente

Corrosion of Steel in Embedded Concrete With Volcanic Aggregates Due To Sulfate Attack

Hochgeladen von

IAEME PublicationOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Corrosion of Steel in Embedded Concrete With Volcanic Aggregates Due To Sulfate Attack

Hochgeladen von

IAEME PublicationCopyright:

Verfügbare Formate

International Journal of Civil Engineering and Technology (IJCIET)

Volume 7, Issue 2, March-April 2016, pp. 328340, Article ID: IJCIET_07_02_029

Available online at

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=7&IType=2

Journal Impact Factor (2016): 9.7820 (Calculated by GISI) www.jifactor.com

ISSN Print: 0976-6308 and ISSN Online: 0976-6316

IAEME Publication

CORROSION OF STEEL IN EMBEDDED

CONCRETE WITH VOLCANIC

AGGREGATES DUE TO SULFATE ATTACK

Abaho. G

Research Scholar, Department of Civil Engineering,

School of Engineering and Technology,Jain University, Bangalore

M. R. Prenesh

Professor, Department of Civil Engineering Engineering,

School of Engineering and Technology,Jain University, Bangalore

ABSTRACT

The experimental tests conducted helps to study the concrete properties of

volcanic concrete systems with granite replacement of river sand. The test

results show that granite rock aggregates is an alternative construction

material to river sand with a beneficial effect of reduced permeability

properties. Compression strength, Corrosion potential and polarization

resistance test results give an impression that 30% river sand replacement in

volcanic concrete system is more resistant to sulfate attack as compared to

same systems with no replacement. The reduced permeability property of

concrete system could lead to reduced chances of corrosion of steel in

reinforced concrete structures hence to increased durability of structures.

Key word: Sulfate Attack, Volcanic Concrete System, Granite Rock Powder,

River Sand, Corrosion of Reinforcement

Cite this Article: Abaho. G and M. R. Prenesh. Corrosion of Steel In

Embedded Concrete with Volcanic Aggregates Due To Sulfate Attack,

International Journal of Civil Engineering and Technology, 7(2), 2016, pp.

328340.

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=7&IType=2

1. INTRODUCTION

Industrialization and urbanization development in Rwanda involves constructions of

different types of infrastructure hence consuming large quantities of building raw

materials like aggregates. The environmental impact associated with this development

is high due to extraction of raw materials in quarries and carbon dioxide emissions

released in the production and transport processes (Schneider et al. 2011; Shi et al.

2011; Jungle et al.2011) [1, 2, 3,]. Waste industrial materials can be used as an

http://www.iaeme.com/IJCIET/index.asp 328

editor@iaeme.com

Corrosion of Steel In Embedded Concrete with Volcanic Aggregates Due To Sulfate Attack

alternative to natural fine aggregates in concrete mixes (Halifax AL-Jabra et al. 2009)

[4]. Fly ash, siliceous stone powder, lime stone rock dust and quarry waste are

examples of reported used raw materials in place of natural river sand Red DURAR

(1998) [5].SciTech (2012), [6] reported the use of volcanic rock aggregates in local

construction industry. This work is suspicious to the durability of the structures

constructed with volcanic rock aggregates due to its porosity. Rasheeduzzafar et al.

1990) [7] found the effect of porous concrete system to cause concrete cover

deterioration and the reinforcement corrosion. Reinforced concrete deterioration by

sulfate attack causes the reinforcing steel exposed to aggressive agents initiate

corrosion of the reinforcement and shortens its designed service life. The sulfate

permeation can be controlled by: increasing compactness, lowering water-to-cement

ratio, proper curing, surface treatment, and use precast concrete in place of cast-in-situ

concrete (ACI Committee, 1991;Hossain, 2004; Kalousek et al., 1972; Al-Amoudi et

al., 1994;Young et al. ,1998) [8,9, 10, 11,15] .

Research in cement chemistry over the past two decades resulted in cements with

a high C3S/C2S content(Rasheeduzzafar,1990).This increase in C3S/C2S ratio results

in increased calcium hydroxide content in the hardened cement concrete, thereby

enhancing the susceptibility to such cements to softening type of sulfate attack

(Rasheeduzzafar, 1990; ACI Committee, 1991). Irassar et al. (2000) [12] reported that

a low C3S/C2S ratio is a significant positive cause in the choice of cement for good

sulfate resistance. However, Kalousek et al. 1972; Rasheeduzzafar, 1990; Lawrence,

1990 [13] reported that the limitation on C3A content is not the last answer to the

problem of sulfate attack. Mehta (1993) [14] said that Type V cement addresses only

the problem of sulfate expansion associated with the ettringite formation. Therefore,

Type V cement is particularly efficacious when calcium sulfate is the attacking

medium, although it could be beneficial with respect to the prevention of gypsum

owing sodium sulfate attack. Thus, Type V cement is of no avail in the attack of

calcium hydroxide and C-S-H and the next loss of strength (Mehta, 1993). Neville,

2004 [16] said that although significant progress has been made on the understanding

of the mechanism of sulfate attack in concrete, knowledge and understanding remains

inadequate. Accordingly, the role of C3A, cement content, water to binder ratio, and

the role of pozzolanic materials remain controversial. Hence, the effect of ingredient

materials used in the concrete material to sulfate attack and their interaction to cause

corrosion of steel in concrete remains an interesting area to research.

The most economic strategy, environmental friendly for sustainable development

in the construction industry in Rwanda is to use the locally available construction raw

materials. The abundances of volcanic rocks in northwestern part and granite rock

aggregates industrial waste in the eastern part of Rwanda have motivated the conduct

of this research.

2. CONCRETE MATERIALS

One of the important aims of this work was to find out and compare the permeability

properties of two concrete systems with granite rock aggregates and river sand fine

aggregates. Some countries like Rwanda still use concrete with no admixtures.

Concrete is normally a mixture of well-proportioned ingredients of cement, water,

fine and coarse aggregates sometimes with chemical and mineral admixtures. Cement

acts as a binding material, aggregates in general, are inert granular materials

which give to 60 to 70 percent of the volume of concrete. Fine aggregates are filler

materials and work as workability agent because coarse aggregates contribute to the

http://www.iaeme.com/IJCIET/index.asp 329

editor@iaeme.com

Abaho. G and M. R. Prenesh

volume of concrete. In this study, the materials used were, grade 43 Portland cement

(cement RW), purified drinking water, volcanic rock coarse aggregates from

Ruhengeri, Kaguguriver sand and granite rock powder from East Africa granite plant

at Nyagatare used as fine aggregates. The size of crushed volcanic rock coarse

aggregates used ranged between (20-6.3) mm while fine aggregates ranged between

4.75mm and 150micro. Table1and Table2 below give more details on materials,

sieves analysis results, grading and grading limits for all aggregates used.

Table 1 shows some of the physical-chemical properties of materials.

Materials

cement

Description

Type Opc 43grade , Specific gravity - 3.15, Standard consistency32%, Fine setting time- 300 minutes, Compressive strength- 7th

day- 41N/mm2 - 28thN/mm2- 62 N/mm2 , Specific surface Average

size - ( m) 15-25, Specific surface, BET (m2/kg) - 1400

Specific gravity-2.42,

Fine modulus- 2.93,

Mamum size-20 mm

Bulk Density(Kg/lit)- Loose - 1.216,

- rounded - 1.360

Specific gravity-2.58,

Fine modulus- 2.43,

Volcanic rock

aggregate

River sand

Granite powder

AlO3

12.36

Fe2O3

5.99

4.40

2.97

Specific gravity-2.69,

Fine modulus- 2.43

Chemical properties

CaO

SO3

4.63

0.007

63.50

3.08

K2O

-

Na2O

-

MgO

1.81

0.42

0.12

The most proportioned fine aggregates to coarse aggregates ratio depend upon

actual grading, particle shape and surface texture of both fine and coarse aggregates.

For conformity with grading limit (IS: 383-197), the granite aggregate fall in zone II

of crushed aggregate and river sand aggregates fall in zone II grading limit of fine

aggregates Table.2. Sieve analysis carried out on granite aggregates compared to river

sand gives the results as presented in Table2. The surface index method was used to

find out easily the proportion of fine to coarse aggregates (Murdock, L. J, 19 60) [31].

Figure1 Sieve analysis of fine aggregates for different sieve sizes

http://www.iaeme.com/IJCIET/index.asp 330

editor@iaeme.com

Corrosion of Steel In Embedded Concrete with Volcanic Aggregates Due To Sulfate Attack

Fig 1 shows that the amount of fine particles present in granite powder is

considerably higher when compared to the river sand. Water plays a critical role in the

green concrete mixture, particularly in the amount used. Workability of concrete

usually increases with increased water in the concrete system. Water requirement for

workability of concrete increases with increase of fine aggregates but this is only true

above 300micro particle size of aggregates otherwise for 300micro and below particle

size the phenomena is vice versa.

Table 2 Sieve Analysis results, grading limits and surface Index for coarse and fine and

aggregates.

Percentage

Passing of

the granite

fine

Aggregates

(GP)

Grading

limit of

crushed

aggregate

zone II

%passing

by weight

Percentage

Passing of

the River

sand

Aggregates

(RS)

Grading

limit of fine

aggregate

zone II

% passing by

weight

Sieve Size

(mm)

Percentage

Passing of

the volcanic

coarse

aggregates

25

20

16

12.5

10

6.3

100

98

87

64

26

03

100

-

4.75

2.36

1.18

100

98

89.9

90-100

75-100

55-90

99.5

98

80

90-100

75-100

55-90

600

micron

300

micron

150

micron

75 micron

58.9

35-59

50

35-59

40-20mm

20-10 mm

10-4.75 mm

4.75-2.36 mm

2.36-1.18 mm

1.18-600

micron

600-300 micro

300-150 micron

Smaller than

150 micron

-

29.9

8-30

24

8-30

18.9

0-20

0-10

Max 15

100

-

Sieve size

within which

particle lie

For surface

Index [31]

Surface

Index for

particles

[31]

-2

-1

+1

4

7

9

9

7

2

-

3. EXPERIMENTATION

The proposed study conducted tests and their experimental setups in series to find

steel corrosion behavior due to sulfate attack on a new concrete system mixture. The

study utilized crushed volcanic rock aggregates as coarse aggregates and granite rock

powder partly as well as full replacement. The laboratory program conducted in this

investigation focused on six basic mixes. The mix designations according to the grade

of concrete and the fine aggregates type used are: Mixes incorporating 0% river sand

(100% granite powder), 10% granite powder (90% river sand), 30% granite powder

(70% river sand), 50% granite powder (50% river sand), 70% granite powder (30%

river sand), 100% granite powder (0% river sand), with no admixtures for RS100

or GP0, GP10, GP30, GP50, GP70and GP100respectively. This work adapted the

Bureau of Indian Standards IS 10262:2009; 456:200 [27, 29] guidance for

making M40 grade concrete specimens. Table 3 shows the resultant mixture

compositions.

http://www.iaeme.com/IJCIET/index.asp 331

editor@iaeme.com

Abaho. G and M. R. Prenesh

Table 3Mix design with mixture compositions

NO

1

2

3

4

5

6

Designation of

Mix

(%)

GP0

GP10

GP30

GP50

GP75

G100

River Sand

(%)

100

10

30

50

70

0

Replacement of

sand with granite

aggregates (%)

0

90

70

50

30

100

Volcanic

Coarse

aggregates

100

100

100

100

100

100

Cement

(%)

100

100

100

100

100

100

This study comprised of six experimental tests which are explain independently

here below.

3.1. Workability

The strength of concrete is much dependent upon water cement ratio (w/c). Leaving

other factors constant, the lower the w/c ratio higher compressive strength of concrete

will be. Workability of concrete with low w/cis obtained by good gradation of

aggregates as it helps to reduce voids in the paste. Good gradation here means that

concrete sample contains all standard fractions of aggregate in required portion to

minimize voids. This study adopted the use of surface index which is an empirical

number related to specific surface of the particle with more weightage given to the

finer fractions (Murdock, L. J, 19 60).

3.2. Compressive strength

One of the most important properties of concrete is its compressive strength. The

other characteristics of concrete are closely related to its compressive strength. It is

one of the factors that affect the durability of the concrete structures. In this study,

compressive strength test was conducted on 150mm x 150mm x150mm cube

specimens using compression testing machine (CTM) of 3000kN capacity. On the

specimen prepared under same condition but with different w/c ratio of 0.35, 0.4 and

0.45, the compressive strength was tested at different curing age of (1, 3, 7 and 28)

days and the average test results were considered for analysis and comparison.

3.3 Weight loss

In order to study the effect of sulfate environment on the weight loss of concrete

and rebar corrosion of reinforcing steel, the six set up of concrete cylinder of 15 cm in

diameter and 30 cm in height, with the two centrally embedded reinforcing bars, was

arranged. Specimens were immersed in a 3.5% of NaSO4 aqueous solution after dried

in air for one day in a laboratory temperature (21 2C) and weighed. The reduction

or increase in weight of the reinforced concrete specimens was evaluated and

recorded periodically. The results for weight loss (WL) were calculated using the

equation 1,

% =

http://www.iaeme.com/IJCIET/index.asp 332

editor@iaeme.com

Corrosion of Steel In Embedded Concrete with Volcanic Aggregates Due To Sulfate Attack

Where Wi = average initial weight of triplicate specimens (g); and Wt.= average

weight of triplicate specimens after a prescribed exposure period (g).

3.4. Corrosion potential

Reinforcement corrosion of the embedded steel was monitored by measuring the

corrosion potentials and polarization resistance at regular intervals. The corrosion

potentials (Ecorr) were measured using a high impedance voltmeter and recording the

potentials with respect to a copper/copper sulfate (Cu/CuSO4) reference electrode.

3.5. Linear polarization resistance

The linear polarization resistance (LPR) technique measures the polarization

resistance (R) of the concrete specimen in a Potentiostat/Galvanostat of ACM

Instruments. The work (Song and Saraswathy, 2007) [17] has details

of electrochemical techniques. The test scan of 20 mV to a scan speed of mV/min

gave the polarization resistance of the concrete specimen tested. The basic principle

of electrochemical corrosion of reinforced concrete is well-known (Dao et al

2010; Bentur et al.1998) [18, 19] and the experimental testing is shown in Figure 2

shown below.

Figure 2Experimental schemes for testing LPR

With the curves for the potential against current density the Rp of the systems in

study was obtained and hence the basis to calculate the corrosion current density

(icorr) of the systems using Equation 2 (stern and Geary, 1957) [20], where B

is Tafel constant with recommended value (Dhir et al.1993; Gonzlez et al.1996;

Gowers and Millard, 1993; Mangat and Mollay, 1992)[21, 22, 23, 24] of 0.052 V for

the passive corrosion of steel in concrete.

=

3.6. Slabs for water Absorption Test

In general, water absorption in the concrete causes durability problems due to

migration of water. In this experiment, the measurements of water rise in the slabs

were performed at the age of 1 and 2 hours. The slabs were cured at 38OC water

ponding temperature for 28 days; air dried for 2 days and finally placed in a basin

10mm soaking in water, the water level was monitored to keep the water height at

10mm height. Measurements were taken using an ordinary inch tape over a cross

http://www.iaeme.com/IJCIET/index.asp 333

editor@iaeme.com

Abaho. G and M. R. Prenesh

section of the slab to determine the depth of water rise. This test measures the rate of

absorption of water by capillary suction of unsaturated concrete placed in contact with

water. The photographic view of the measurements of water absorption in slab

specimen is shown in Fig. 3 adopted from Felix Kala (2013) [25].

Figure3Measurements of water absorption in slab specimen

4. RESULTS AND DISCUSSION

4.1. Workability

Concrete workability for six mixes studied and had slump values; 70, 70, 75, 73, 71

and 70 for RS, GP10, GP30, GP50, GP70 and GP100 respectively. It shows that

concrete mixes with 30% granite powder produced higher slump compared to other

the mixes. This improved workability for the mix might be due

to the more amounts of fine particles in granite aggregates. The very fine particle in

granite aggregates i.e., 300 micron and 150 micron particles, being so fine, contribute

more towards workability by acting like ball bearings to reduce the internal friction

between coarse particles. However more than 30% replacement of river sand (50, 70

and 100) % by more fines made the concrete leaner which restrained the mobility of

aggregates as less paste was there to provide lubrication. Other factors considered

constant, it shows that a good grading was reached with 30% replacement of rivers

and. It led to less total voids in concrete which caused excess paste available that

effected better lubrication hence caused higher workability of concrete.

4.2. Compressive strength test

Compressive strength test was considered important in this work because other

desirable characteristic properties concrete directly or indirectly depend on its

compressive strength. The effect of granite aggregates in partial and fully replacement

of river sand fine aggregates is shown in Fig. 4 a), b) and c).The data show that 30%

river sand replacement with granite aggregates gives the highest compressive strength

in all curing days. The increased compressive strength was due to finer particles of

granite aggregates that filled the pores in concrete in general which increased its

density and compactness of concrete system. It is seen from the figures that the lower

the w/c the more the compressive strength the concrete gained in early curing age.

This possibly is due to decreased aggregate cement transition zone which increases

with increase in water cement ratio. This is more likely because the cement particles

are held at a closer interval in case of lower w/c ratio than higher w/c ratio. 10% of

river sand replacement showed insignificant change in compressive strength. Above

30% replacement (50, 70, and 100) %, both workability and compressive strength

http://www.iaeme.com/IJCIET/index.asp 334

editor@iaeme.com

Corrosion of Steel In Embedded Concrete with Volcanic Aggregates Due To Sulfate Attack

have a trend of decrease due to more water requirement of fine aggregates for better

workability. It means that inadequate water to hydrate cement particles as well as fine

aggregates left pores in concrete system. This is a line of weakness for cracking in

case of compression force applied on this concrete. Also it is observed that the more

the curing age, the more the compressive strength as a result of increased binding

together of aggregates due to continued hydration process.

a)

b)

c)

Figure 4 a, b and c Compressive strength of 0.35, 0.4 and 0.45w/c ratio at different age of

curing respectively.

http://www.iaeme.com/IJCIET/index.asp 335

editor@iaeme.com

Abaho. G and M. R. Prenesh

4.2. Concrete weight loss

Experimental results for weight loss of reinforced concrete specimens exposed to

sulfate solution are schematically presented as a function of the exposure time in

Figure 5. The data show that the concrete specimen lost weight. This was when the

weight of specimens immersed in test solution was compared with their weights

before immersion. It shows that the specimen gained weight on their immersion to

solution. Weight loss increased considerably after three months in the RS (0% granite

replacement) concrete. In comparison to others, specimens designated GP 30, the

increase of weight loss was not so big and it appears after three months. This could be

due to capillary pore system filled by little expansive reaction products compact the

concrete matrix system and increasing the weight. Then, the expansion of these

products is increased to a great extent generating fractures in the concrete matrix

system, loosening of material and therefore, the weight of specimen decreased.

Figure5Weight loss of concrete in sulfate environment

The maximum weight loss was 2.1% in duration of six months of exposure in the

RS (0% GP) volcanic concrete specimens and the minimum weight loss (0.2 %) was

in GP30 concrete system. From these results, it is clear that the contribution of granite

powder inporefilling of the concrete system is significant and prevents the easy

penetration of sulfate ions towards and within the concrete. Again the trend in water

loss in volcanic concrete system shows that the concrete becomes porous and

permeable above 30% river sand replacement by granite aggregates due absorption of

water by increased fines in the mix. Possibly also, 30% river sand replacement

consumes some calcium hydroxide during poazzolanic reaction which reduces the amount

of gypsum in the mixture. This would be the same case for mixtures more above 30% but

it might be overcome by its porosity that permit the ingress of more water to concrete.

4.3. Corrosion potentials

Figure 5 the results of corrosion potentials of evaluated test specimens. The horizontal

broken lines show the limits corresponding to the corrosion probability criterion

suggested in the norm ASTM C876 [26].

Figure 6

http://www.iaeme.com/IJCIET/index.asp 336

editor@iaeme.com

Corrosion of Steel In Embedded Concrete with Volcanic Aggregates Due To Sulfate Attack

Fig 7

Figure 6and 7 Variation of Ecorr and iccorrof the reinforcement steel as a function of the

exposure time respectively

In the five months of specimen exposure, the corrosion potentials, of all the

reinforced concrete systems, show fluctuation ranging from -696 to -380 mV/ CuCuSO4 with a slight decrease during the month, towards more noble values.

According to ASTM C 876, these Ecorr values show that there exists a 90% chance of

active corrosion during all the exposure time; but, the criterion is for partly saturated

not totally saturated specimens. ASTM C 876 criterion is applied in fully merged

structures or specimen environment reinforcement corrosion tests. Therefore,

probably all embedded steel were in a passive state during the six months of specimen

immersion in the sulfate solution. Otherwise, GP30 could have performed better in as

far as resisting corrosion of steel reinforcement as shown in fig.6. Since the system

with the granite rock powder presented the more noble corrosion potentials during the

exposure time. The GP70 concrete samples presented corrosion potentials between 520 to -380 mV /Cu-CuSO4 compared -696 to -518.7mV/ CuSO4 for RS

(GP0) concrete systems. This shows that granite powder contribution to the inhibition

of corrosion of the reinforcement has limit with percentage replacement. This testing

technique provides qualitative information on reinforcement corrosion. Therefore,

quantitative information on reinforcement corrosion could be developed by

employing the linear polarization resistance technique presented in fig.7 shown above.

4.4. Polarization resistance

From the curves potential against current density Rp was obtained for all the systems

in study and icorr was calculated representing the results in Figure 7; the horizontal

broken line point out the threshold of active to passive corrosion (Andrade and

Alonso, 1996) [28].

In Figure 7; it can be observed that the system steel-concrete that presents a

highest corrosion resistance induced by sulfates is GP30, because its corrosive activity

was the lowest in the exposure time and decreased significantly until it reached a low

level of corrosion (0.003A/cm2) at the end of the period. The GP 70 system showed

levels of corrosion between 0.03 and 0.008 A/cm2, and RS (GP0) showed levels of

corrosion between 0.06 and 0.0035A/cm2 which means that GP 30 significantly

inhibit the corrosion of the reinforcement in the initial six months. The significant

effect of GP 30 to inhabit corrosion current density is due to reduction of pores size

and pore distribution in concrete system that makes the possible dense structure of

pores formed. Because of that, it is deduced that the microstructure of concrete with

GP30 becomes denser than the rest of the system. Therefore, it reports a decrease in

http://www.iaeme.com/IJCIET/index.asp 337

editor@iaeme.com

Abaho. G and M. R. Prenesh

both sulfate ion penetrability and corrosion current density. According to Powers

1958 [30], several mineral additions have also been shown to improve the resistance

of concrete materials to the penetration of aggressive ions. So the research in this field

may produce interesting results also regarding the durability of reinforced concrete

structures.

4.5. Water Absorption

Table 4Effect of granite powder on water absorption

Hours of

curing

1 hr.

2 hr.

1hr

2 hr.

1 hr.

2 hr.

Water penetration (mm) at

320c water Ponding

Temperature

Mix Designation

W/C

Ratio

0.35

0.40

0.45

GP 100

17.5

21.1

16.3

21.1

16.2

21.5

GP 70

14.3

18.2

15.0

21.1

16.1

21.1

GP 50

16.0

21.0

16.0

21.4

16.3

22.1

GP30

14.2

18.0

15.2

20.2

16.0

21.2

GP 10

17.2

21

16.4

21.3

16.1

21.7

GP 0

17.4

21.5

16.8

21.8

16.5

22.5

The test results are presented in table 4 above. The absorption of the slabs 100 mm

x 500 mm x500 mm containing granite powder are lower than that of RS (GP0) as

presented in table 4. In the case of concrete mix GP30 the average absorption for 1

and 2 hours is 15.2 mm and 20 mm respectively. The average absorption of concrete

mix RS for 1 and 2 hours is 16.9 mm and 22 mm. It is observed that the reduction in

water absorption for GP30 is 5% compared to conventional concrete RS (GP0) mix

presented table 4. It could be noted that the variation in absorption for different

concrete mixes was found to be normal for 2 hours of curing when compared to 1

hour of curing. The interaction between permeability, volume change and micro

cracking here is a challenge to the discussant, heat of hydration and internal

manifestation can cause micro cracks and increase permeability of concrete system.

However, based on the analysis made on the previous tests and on the water

penetration comparison of GP30 and RS, the high the porosity of the specimen the

higher was the water penetration in concrete. Hence, G30 was impermeable compared

to RS concrete mixtures.

4. CONCLUSIONS

The experimental study on steel reinforcement corrosion due to sulfate attack in

concrete with volcanic rock coarse aggregates and granite aggregates to replace river

sand fine aggregates is the specialty of this paper. Experimental results analysis for

workability, compressive strength, weight loss, corrosion potentials, polarization

resistance and water absorption characteristics of concrete systems are the basis for

conclusion enclosed. It has been found that granite aggregate is an alternate

construction material in volcanic concrete system with even some beneficial effects of

improved workability, compression strength etc. but within certain limit. The test

results show that granite powder in 30% partial replacement of river sand has an

advantage of reduced permeability properties on hardened concrete over the river

sand. With the results obtained in conducted test, specimens made with 30% granite

rock powder (GP 30) as fine aggregates give 8% absorption decrease in the hardened

http://www.iaeme.com/IJCIET/index.asp 338

editor@iaeme.com

Corrosion of Steel In Embedded Concrete with Volcanic Aggregates Due To Sulfate Attack

concrete system compared to river sand aggregates. Polarization resistance test has

proved that volcanic concrete system with 30 % granite rock powder replacement is

more resistant to corrosion of steel reinforcement compared to 100 % volcanic river

sand system. The addition of 30% of granite rock powder as partial replacement river

sand reduced weight loss by around 1.9%. Granite rock powder

increases densification of the concrete system and reduces pore size as well as poredistribution in volcanic concrete systems as justified by an average of 14.75MPa

difference in compressive strength GP30 as compared to RS. Therefore, corrosion of

steel reinforcement due to sulfate attack in volcanic concrete systems could be

reduced with the use of GP30 granite rock powder fine aggregates than using RS

(GPO). This work opens for more research to find out the exact limit for river sand

replacement which lies between (10-50) percent as per present finding.

ACKNOWLEDGEMENT

The authors thank Jain University for its support in the Ph.D. Program with its

scholarship. Thanks for the government of Rwanda to the support extended to the

research scholar through His Excellency president Kagame scholarship. Thanks for

the University of Rwanda for the study leave given to the research scholar. Authors

are also thankful to support given by Civil-Aid Techno clinic P.V.T. Ltd in

conducting experiments and other laboratory tests.

REFERENCE

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

Schneider, M, Romer, M, Tschudin, M, Bolio. H. Sustainable cement production:

Present and future. Cem. Concr. Res, 41, 2011, pp. 642650.

Shi, C, Fernandez-Jimnez, A, Palomo, A. New cements for the 21st century: The

pursuit of an alternative to Portland cement. Cem.Concr.Re s., 41, 2011, pp. 750

763.

Juenger, M.C.G.; Winfield, F.; Provis, J.L.; Ideker, J.H. Advances in alternative

cementitiousbinders.Cem.Concr. Res, 41, 2011, pp. 12321243.

Khalifa Al-Jabri, S; Makoto Hisada, K. Salem Al-Oraimi and H. Abdullah AlSaidy, Copper slag as the sand replacement for high-performance concrete,

Cement &Concrete Composites, 31,2009, pp. 483-488.

Red DURAR, Manual de Inspeccin, Evaluacin y Diagnostico de

Corrosinenestructuras de HormignArmado, CYTED, Espaa, 1998.

Schittich, C, Building simply two: Sustainable, cost-efficient, local, Walter de

Gruyter, Architecture, 2012.

Rasheeduzzafar, Dakhil F. H, Al-GahtaniA. S, Al-Saadoun S.S, Bader M. A.

Influence of cement composition on corrosion of reinforcement and sulfate

resistance of concrete. ACI Mater J, 87(2), 1990, pp. 11422.

ACI committee 201, proposed revision of: Guide to durable concrete, ACI Mater.

J. 88(2): 1991, pp. 544-582.

Hossain K .M. A Properties of volcanic scoria based lightweight concrete. Mag.

Concr. Res.56 (2), 2004, pp. 111-120.

Kalousek GL, Porter LC, Benton EJ Concrete for long-time service in sulfate

environment.Cem.Concr. Res. 2(1), 1972, pp.79- 89.

Al-Amoudi OSB, Maslehuddin RM, Abduljauwad SN, Influence of chloride ions

on sulphate deterioration in plain and blended cement, Mag.Concr. Res. 46(167),

1994, pp. 113-123.

http://www.iaeme.com/IJCIET/index.asp 339

editor@iaeme.com

Abaho. G and M. R. Prenesh

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

[22]

[23]

[24]

[25]

[26]

[27]

[28]

[29]

[30]

[31]

[32]

[33]

Irassar EF, Gonzalez M, Rahhal V (2000). Sulphate resistance of Type cements

with limestone filler and natural pozzolana. Cem.Concr.Compos. 22(5), 2000, pp.

361368.

Lawrence C. D, Sulphate attack on concrete, Mag. Concr. Res.4 (153), 1990, pp.

249- 264.

Mehta PK, Sulfate attack on concrete: a critical review, Materials Science of

Concrete, Ohio. Am. Ceram. Soc. 3, 1993, pp. 105130.

Young J. F, Mindess S, Gray R. J, BenturA, The Science and Technology of Civil

Engineering Materials, Prentice-Hall, New Jersey, 1998.

Neville, The confused world of sulfate attack on concrete, Cem.Concr.Res.34 (8),

2004, 1275-1296.

Song, H. W; Saraswathy, V. International Journal of Electrochemical Science, 2,

2007, pp.1.

L.T.N.; Dao, V.T.N; Kim, S.H; Ann, K.Y. International Journal of

Electrochemical Science, 5, 2010, pp.302.

Bentur, A; Diamond, S and Berker, N.S Steel corrosion in concrete, EFN Spon,

7, 1998.

M. Stern and A. Geary, Journal of the electrochemical society, 104, 1957, pp. 56.

Dhir, R.K; Jones, M.R.; and McCarthy, M.J. Cement and Concrete Research, 23,

1993, pp.1443.

Gonzlez, J.A; E. Ramrez, E; Bautista, A; and Feli, S; Cement and Concrete

Research, 26, 1996, pp. 501.

Gowers, K. R; and Millard, S.G; Corrosion Science, 35, 1993, pp. 1593.

Mangat, P.S; and Molloy, B.T; Materials and Structures, 25, 1992, pp. 404.

Felix Kala, T., Effect Of Granite Powder On Strength. Research Invent:

International Journal of Engineering and Science 2, 2013, Pp 36-50.

Www.Researchinventy.Com.

ASTM International, ASTM C876-09, 2009. http://www.techstreet.com/products

/1622591product_id=1622591&sid=goog&gclid=CKnLwa6H68sCFdURaAod8q

4PSA#jumps

Bureau of Indian Standards IS 10262:2009

Andrade, C and Alonso, C, Construction and Building Materials, 10 (1996) 15.

BIS (Bureau of Indian Standards), Plain and reinforcement concrete code of

practice, BIS: 456:2000, New Delhi, India

Powers, T.C., Structure and physical properties of hardened Portland cement

paste. Journal of American Ceramic Society, 41, 1958, pp. 16.

Abbas S. Al-Ameeri and Rawaa H. Issa. Effect of Sulfate on The

Properties of Self Compacting Concrete Reinforced by Steel Fiber,

International Journal of Civil Engineering and Technology, 4(2), 2013,

pp. 270287.

Behrouz Mohebimoghaddam and S.Hossein Dianat. Evaluation of The

Corrosion and Strength of Concrete Exposed To Sulfate Solution,

International Journal of Civil Engineering and Technology, 3(2), 2012,

pp. 198 - 206.

Murdock, L. J.; The workability of concrete, Magazine of concrete and concrete

research, Nov1960.

http://www.iaeme.com/IJCIET/index.asp 340

editor@iaeme.com

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Analyse The User Predilection On Gpay and Phonepe For Digital TransactionsDokument7 SeitenAnalyse The User Predilection On Gpay and Phonepe For Digital TransactionsIAEME PublicationNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDokument18 SeitenRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- A Study On The Reasons For Transgender To Become EntrepreneursDokument7 SeitenA Study On The Reasons For Transgender To Become EntrepreneursIAEME PublicationNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Determinants Affecting The User's Intention To Use Mobile Banking ApplicationsDokument8 SeitenDeterminants Affecting The User's Intention To Use Mobile Banking ApplicationsIAEME PublicationNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDokument9 SeitenEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDokument7 SeitenA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDokument10 SeitenImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Broad Unexposed Skills of Transgender EntrepreneursDokument8 SeitenBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDokument14 SeitenModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationNoch keine Bewertungen

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDokument16 SeitenInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Visualising Aging Parents & Their Close Carers Life Journey in Aging EconomyDokument4 SeitenVisualising Aging Parents & Their Close Carers Life Journey in Aging EconomyIAEME PublicationNoch keine Bewertungen

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDokument13 SeitenA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Voice Based Atm For Visually Impaired Using ArduinoDokument7 SeitenVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Gandhi On Non-Violent PoliceDokument8 SeitenGandhi On Non-Violent PoliceIAEME PublicationNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDokument9 SeitenA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDokument15 SeitenAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDokument10 SeitenA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDokument16 SeitenA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationNoch keine Bewertungen

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDokument13 SeitenAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationNoch keine Bewertungen

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDokument8 SeitenDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationNoch keine Bewertungen

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDokument19 SeitenApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationNoch keine Bewertungen

- Various Fuzzy Numbers and Their Various Ranking ApproachesDokument10 SeitenVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationNoch keine Bewertungen

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDokument13 SeitenOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDokument8 SeitenKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationNoch keine Bewertungen

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDokument7 SeitenModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationNoch keine Bewertungen

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDokument9 SeitenFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationNoch keine Bewertungen

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDokument7 SeitenQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationNoch keine Bewertungen

- A Review of Particle Swarm Optimization (Pso) AlgorithmDokument26 SeitenA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationNoch keine Bewertungen

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDokument13 SeitenPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationNoch keine Bewertungen

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDokument9 SeitenAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationNoch keine Bewertungen

- 341 BDokument4 Seiten341 BHomero Ruiz Hernandez0% (3)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Node NO Slot NO CH No. Tag Name Address Signal Description: All Valve Fault Take From LogicDokument103 SeitenNode NO Slot NO CH No. Tag Name Address Signal Description: All Valve Fault Take From Logicash_captchajobsNoch keine Bewertungen

- PNB V. Se, Et Al.: 18 April 1996 G.R. No. 119231 Hermosisima, JR., J.: Special Laws - Warehouse Receipts LawDokument3 SeitenPNB V. Se, Et Al.: 18 April 1996 G.R. No. 119231 Hermosisima, JR., J.: Special Laws - Warehouse Receipts LawKelvin ZabatNoch keine Bewertungen

- Best Practices For SAP-PM History DocumentationDokument8 SeitenBest Practices For SAP-PM History DocumentationLaammeem Noon100% (1)

- Flex VPNDokument3 SeitenFlex VPNAnonymous nFOywQZNoch keine Bewertungen

- The Ball Is Now in Their Hands': Lumumba Responds After City Council Rescinds Emergency DeclarationDokument2 SeitenThe Ball Is Now in Their Hands': Lumumba Responds After City Council Rescinds Emergency DeclarationWLBT NewsNoch keine Bewertungen

- Katie Todd Week 4 spd-320Dokument4 SeitenKatie Todd Week 4 spd-320api-392254752Noch keine Bewertungen

- Ab Initio Interview Questions - HTML PDFDokument131 SeitenAb Initio Interview Questions - HTML PDFdigvijay singhNoch keine Bewertungen

- Spec 2 - Activity 08Dokument6 SeitenSpec 2 - Activity 08AlvinTRectoNoch keine Bewertungen

- Delem: Installation Manual V3Dokument73 SeitenDelem: Installation Manual V3Marcus ChuaNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Philippine Mango Seed Oil: An Untapped ResourceDokument8 SeitenPhilippine Mango Seed Oil: An Untapped ResourceFrancis Peñaflor0% (1)

- PSISA Free Practice Exams TestsDokument2 SeitenPSISA Free Practice Exams TestsGoodmanBeguel50% (2)

- Daftar Pustaka Marketing ResearchDokument2 SeitenDaftar Pustaka Marketing ResearchRiyan SaputraNoch keine Bewertungen

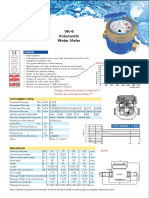

- Baylan: VK-6 Volumetric Water MeterDokument1 SeiteBaylan: VK-6 Volumetric Water MeterSanjeewa ChathurangaNoch keine Bewertungen

- Product Models Comparison: Fortigate 1100E Fortigate 1800FDokument1 SeiteProduct Models Comparison: Fortigate 1100E Fortigate 1800FAbdullah AmerNoch keine Bewertungen

- Family health assessment nursing problemsDokument8 SeitenFamily health assessment nursing problemsMari MazNoch keine Bewertungen

- Environmental Pollution and Need To Preserve EnvironmentDokument3 SeitenEnvironmental Pollution and Need To Preserve EnvironmentLakshmi Devar100% (1)

- Moi University: School of Business and EconomicsDokument5 SeitenMoi University: School of Business and EconomicsMARION KERUBONoch keine Bewertungen

- ME6019 - NON DESTRUCTIVE TESTING AND MATERIALS MCQ PadeepzDokument13 SeitenME6019 - NON DESTRUCTIVE TESTING AND MATERIALS MCQ PadeepzAjithNoch keine Bewertungen

- Personal Selling ProcessDokument21 SeitenPersonal Selling ProcessRuchika Singh MalyanNoch keine Bewertungen

- Festo Process Control - CatalogDokument3 SeitenFesto Process Control - Cataloglue-ookNoch keine Bewertungen

- Encore HR PresentationDokument8 SeitenEncore HR PresentationLatika MalhotraNoch keine Bewertungen

- Payment Solutions For Travel Platform: SabreDokument2 SeitenPayment Solutions For Travel Platform: Sabrehell nahNoch keine Bewertungen

- Deped Tacloban City 05202020 PDFDokument2 SeitenDeped Tacloban City 05202020 PDFDon MarkNoch keine Bewertungen

- Business Law and The Regulation of Business 12th Edition Mann Test BankDokument25 SeitenBusiness Law and The Regulation of Business 12th Edition Mann Test BankElizabethRuizrxka100% (60)

- TMA - ExerciseDokument3 SeitenTMA - ExercisemorrisioNoch keine Bewertungen

- Portfolio Corporate Communication AuditDokument8 SeitenPortfolio Corporate Communication Auditapi-580088958Noch keine Bewertungen

- Basic Concept of Process Validation in Solid Dosage Form (Tablet) : A ReviewDokument10 SeitenBasic Concept of Process Validation in Solid Dosage Form (Tablet) : A Reviewqc jawaNoch keine Bewertungen

- Request For Information (Rfi) : Luxury Villa at Isola Dana-09 Island - Pearl QatarDokument1 SeiteRequest For Information (Rfi) : Luxury Villa at Isola Dana-09 Island - Pearl QatarRahmat KhanNoch keine Bewertungen

- Financial Audit NotesDokument11 SeitenFinancial Audit NotesMamunoor RashidNoch keine Bewertungen