Beruflich Dokumente

Kultur Dokumente

Moduflow Series

Hochgeladen von

fernandoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Moduflow Series

Hochgeladen von

fernandoCopyright:

Verfügbare Formate

Moduflow Series

IL2 /RF2/CF2 Low Pressure Filters

35

Low Pressure Filters

Moduflow Series

Applications for

Moduflow Filters

Power Unit Fabrication

Off-line Filter Loops

minimizes turbulence and pressure

loss through the filter, improving

system performance.

Mobile Equipment

The Moduflow filter is widely

considered the most versatile filter

available on the market. The unique

diverter valve assembly, and inside

to outside flow through the element,

allows the Moduflow to be configured for in-line, in-tank or suction

filtration. The flow diverter

The newly designed closed bottom

elements for the RF2 and IL2 models

insures all contamination remains

trapped within the element as the

filter is serviced.

A wide variety of visual and

electrical indicators allows you to

know exactly when the element

needs to be serviced. There is even a

no element indicator that can

sense when there is not an element

installed in the filter.

From top to bottom, the Moduflow

filter series provides the high

level of filtration and long term

dependability so vital to todays

hydraulic systems.

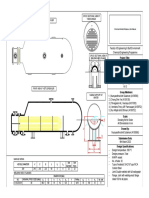

Mounting / Porting Styles

CF2

Suction Filter

PUMP

RF2

Return Filter

IL2

In-Line Filter

FILTER

HEAD

FLANGE

925167

RETURN

OUT

IN

BRACKET

924904

TANK

BOWL

TANK

BOWL

OUTLET

PORT

INLET

36

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

Low Pressure Filters

Moduflow Series

Features

Flanges

Cover

SAE to 2

Lightweight

aluminum

Lightweight

NPT or

Slotted for

quick release

aluminum

Bowl

Indicators

Single or

Visual or electrical

Mounted on either side

Optional no element

double length

Durable steel

construction

indication

Bypass/Diverter

Element

(not visible)

5 different

(not visible)

Available in

pressure settings

cellulose, wire

mesh or high

performance

Microglass II media

Single or

double length

No bypass option

available

Feature

Advantage

Benefit

Top access element service

Oil remains in housing

Quicker element change

No spills

Reduced maintenance costs

Slotted cover

Quick release cover

Cap screws remain in housing

Reduced maintenance costs

No loose parts to lose

Closed bottom elements

(RF2 and IL2 only)

Removes all contaminant

during element service

No downstream

contamination from servicing

Visual or electrical indicators

Know exactly when to service

elements

Helps prevent bypass condition

No premature disposal

Flange face ports

Flexible mounting (3/4 to 2)

Easy plumbing to your system

37

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

Low Pressure Filters

Moduflow Series

CF2-1, RF2-1 & IL2-1 Element Performance

Efficiency

Beta Rating

10,000

Efficiency %

Capacity

PSID

50

BAR

02Q

10Q

05Q

05Q

1,000

3.0

40

99.9

10Q

200

99.5

99.0

20Q

100

2.5

30

2.0

1.5

20

20

95.0

20

1.0

10

2

1

0.5

02Q

50.0

0

10

15

20

25

10

20

Particle Size (Micrometre)

30

40

50

60

0.0

Grams

Multipass tests run @ 40 gpm to 50 psid terminal - 5mg/L BUGL

Flow vs. Pressure Loss

0

20

LPM

50 100 150 200 250 300 350

LPM

50 100 150 200 250 300 350

20

150SUS

150SUS

Empty Housing

1.2

02Q

05Q

0.5

1.0

PSID

0.4

0.3

10Q

1 SAE

0.4

20Q

0.2

4

0.2

0

BAR

0.6

12

BAR

0.8

PSID

12

0.6

16

16

20

40

60

GPM

80

100

2 SAE flange

0.0

38

20

40

60

GPM

80

100

0.1

0.0

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

Low Pressure Filters

Moduflow Series

CF2-1, RF2-1 & IL2-1 Element Performance

Flow vs. Pressure Loss

0

10

LPM

50 100 150 200 250 300 350

0

10

150SUS

LPM

50 100 150 200 250 300 350

150SUS

0.6

0.6

8

0.5

PSID

0.3

0.4

03C

0.3

0.2

40SA

0.2

2

0.1

BAR

10C

6

BAR

0.4

PSID

0.5

20

40

60

GPM

80

100

0.1

74W

0.0

20

40

60

GPM

80

100

0.0

Flow vs. Pressure Loss

0

10

LPM

50 100 150 200 250 300 350

0

10

150SUS

LPM

50 100 150 200 250 300 350

150SUS

0.6

0.6

8

0.5

PSID

0.4

0.3

0.2

20C

BAR

0.3

6

BAR

0.4

PSID

0.5

0.2

2

0.1

0.1

40W

20

40

60

GPM

80

100

0.0

39

20

40

60

GPM

80

100

0.0

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

Low Pressure Filters

Moduflow Series

CF2-2, RF2-2 & IL2-2 Element Performance

Efficiency

Efficiency %

02Q

BAR

3.0

40

05Q

1,000

Capacity

PSID

50

99.9

10Q

05Q

Beta Rating

10,000

10Q

200

99.5

99.0

20Q

100

2.5

30

2.0

1.5

20

20

95.0

20

1.0

10

2

1

0.5

02Q

50.0

0

10

15

20

25

20

40

Particle Size (Micrometre)

60

80

100

400

500

120

0.0

Grams

Multipass tests run @ 80 gpm to 50 psid terminal - 5mg/L BUGL

Flow vs. Pressure Loss

0

20

100

200

LPM

300

400

500

100

LPM

200

300

10

150SUS

150SUS

Empty Housing

1.2

16

0.6

8

1.0

PSID

05Q

0.6

10Q

20Q

0.4

1 SAE

0.3

0.4

2 SAE flange

0.2

2

0.2

BAR

02Q

6

BAR

0.8

PSID

12

0.5

25

50

75 100

GPM

125

150

0.1

0.0

40

25

50

75 100

GPM

125

150

0.0

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

Low Pressure Filters

Moduflow Series

CF2-2, RF2-2 & IL2-2 Element Performance

Flow vs. Pressure Loss

0

100

LPM

200

300

400

500

10

100

LPM

200

300

400

500

10

150SUS

150SUS

0.6

0.6

8

0.5

PSID

0.4

0.3

0.2

0.2

2

0.1

74W

BAR

0.3

6

BAR

0.4

PSID

0.5

25

50

75 100

GPM

125 150

0.1

40W

0.0

25

50

75 100

GPM

125 150

0.0

Flow vs. Pressure Loss

0

100

LPM

200

300

400

500

10

100

LPM

200

300

400

500

10

150SUS

0.6

0.6

8

0.5

10C

03C

PSID

40SA

0.4

0.3

0.2

20C

0.2

2

0.1

BAR

0.3

6

BAR

0.4

PSID

0.5

25

50

75 100

GPM

125 150

0.1

0

0.0

41

25

50

75 100

GPM

125 150

0.0

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

Low Pressure Filters

Moduflow Series

Specifications: CF2, RF2, IL2

mm

Dimensions: inch

Pressure Ratings:

Maximum Allowable Operating Pressure

(MAOP): 200 psi (13.8 bar)

Design Safety Factor: 2:1

Rated Fatigue Pressure: 150 psi (10.3 bar)

Element Burst Rating: 70 psid (4.8 bar)

Filter Materials:

Head, Cover, Flanges: die cast aluminum

Bowl: steel

Operating Temperatures:

Buna: -40F to 225F (-40C to 107C)

Fluorocarbon: -15F to 275F (-26C to 135C)

Weight (approximate):

Single: 20 lbs. (9.1 kg)

Double: 25 lbs. (11.3 kg)

Indicators:

Visual (optional)

Electrical (optional) 15A@250VAC / .5A@125 VDC

Electrical (D option) 5A@250VAC / 3A@28 VDC

MODEL

CF2-1

65.0

2.56

N/A

RF2-1 without

optional 2 fitting

65.0

2.56

330.2

13.0

IL2-1

65.0

2.56

330.2

13.0

RF2-1 with

optional 2 fitting

68.3

2.69

CF2-2

68.3

2.69

RF2-2

IL2-2

352.3

13.87

110.0

4.3

110.0

4.3

N/A

110.0

4.3

383.4

15.07

114.0

4.5

N/A

623.8

24.56

114.0

4.5

68.3

2.69

617.5

24.31

623.8

24.56

114.0

4.5

68.3

2.69

617.5

24.31

N/A

114.0

4.5

Color Coding:

White (normally closed)

Red (normally open)

Black (common)

IL & CF OUTLET

OPTIONAL 3-PIN

MALE RECEPTACLE

MINIMUM ELEMENT

REMOVAL CLEARANCE

Single: 345.9

13.62

Double: 482.6

19.00

108.5

4.27

228.6

9.0

168.0

6.6

A

168.0

6.7

78.7

3.1

OPTIONAL

TANK

FLANGE

IL & RF INLET

196.3

7.7

OPTIONAL PORT FLANGE

77.8

3.062

38.9

1.53

30.2

1.19

OPTIONAL

BMOUNTING

BRACKET

Linear Measure: millimeter

inch

12.7

0.50

(99 OPTION)

RF2-1 OUTLET

4 1 HOLES

CF INLET

RF OUTLET

42.9

1.68

21.3

0.84

69.9

2.75

2-11 NPTF

OPTIONAL

FITTING

42

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

Low Pressure Filters

Moduflow Series

Specifications: DIL2

3.3

.013

Pressure Ratings:

Maximum Allowable Operating Pressure

(MAOP): 200 psi (13.8 bar)

Design Safety Factor: 2:1

Rated Fatigue Pressure: 150 psi (10.3 bar)

116.8

4.60

79.0

3.11

76.2

3.00

Element Burst Rating: 70 psid (4.8 bar)

Filter Materials:

Diverter Valve Assembly: die cast aluminum

Check Valve Assembly: die cast aluminum

Filter Assembly: see IL2 specifications

-13 SHCS

TORQUE

32-38 FT-LB

-18 NPT

DRAIN VENT

CONNECT

TO TANK

173.0

6.81

330.2 SINGLE

13.0

Operating Temperatures:

Buna: -40F to 225F (-40C to 107C)

Fluorocarbon: -15F to 275F (-26C to 135C)

617.5

DOUBLE

24.31

Weight (approximate):

Single: 55 lbs. (24.9 kg) / Double: 65 lbs. (29.5 kg)

110.5

4.35

Indicators:

Visual (optional)

Electrical (optional) 15A@250VAC / .5A@125 VDC

Electrical (D option) 5A@250VAC / 3A@28 VDC

Linear Measure: millimeter

inch

479.3

18.87

Color Coding:

White (normally closed)

Red (normally open)

Black (common)

AIR BLEED

EACH FILTER

30.2

1.19

FILTER SCHEMATIC

OPTIONAL

FLANGE

OUTLET

FILTER

FILTER

177.8

7.00

INLET

BYPASS

INLET

402.8

15.86

OUTLET

345.9

13.62

BYPASS

DRAIN

VENT

OPTIONAL MECHANICAL INDICATOR

BOTH CHECK VALVES

MOVE SAME DIRECTION

Approximate handle torque required for changeover.

Typical Flow/Pressure Curves For Duplex Valves

1.75

1.5

25

LPM

30

(Add to differential pressure of

filter assembly for total duplex

pressure differential)

20

0.75

10

DIFF. PRESSURE

*Diverter/check valves combined

S

SU S

00 SU

0

3 0

20

15

10

0.5

5

0.25

100

200

300

GPM

Torque (Ft-Lbs)

1.25

20

System Pressure (psi)

43

10

GPM

25

20

50

30

40

50

FLOW

60

70

80

90

100

LPM

75 100 125 150 175 200 225 250 275 300 325 375

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

Low Pressure Filters

Moduflow Series

Submersible Option

Check Valve Flow/Pressure Drop

3.0

When there is a limited amount of space on the

top of the reservoir, the Moduflow filter can be

mounted in the side of a reservoir.

For return line applications(RF2), the fluid

returning to the reservoir holds the check valve

open. When the system is shut down, the

check valve closes automatically. In suction

applications (CF2), the check valve is held

open by a check rod assembly extending from

the cover to the check valve at the base of the

filter bowl. When the cover is in place, fluid

enters the filter. When the cover is removed

for servicing, the check valve closes.

2.5

Pressure Loss (psid)

A check valve mounted on the filter bowl

prevents the reservoir from being drained

during servicing of the element. The only fluid

drained is from the inside of the filter housing.

*Check valve pressure drop must be added

to assembly pressure drop to get total

2.0

1.5

1.0

0.5

0.0

0

10

20 30

40

50

60 70

80

90 100

Flow (GPM)

Linear Measure: millimeter

inch

Check valve rod assy.

Single length: P/N 926954

Double length: P/N 925140

(Used on submersible

CF2 only. Submersible RF2

uses only the check valve assy.)

CF2

SINGLE ELEMENT

391.3

15.4

RF2

SINGLE ELEMENT

452.1

17.8

CF2/RF2

DOUBLE ELEMENT

688.3

27.1

Note: Cover Seal Engages

Before CF Rod

Assembly Opens

Check Valve

CHECK VALVE ASSY.

P/N 925120

117.1 MAX. O.D.

4.61 OVER WELD

(RF2 & DOUBLE LENGTH)

44

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

Low Pressure Filters

Moduflow Series

Accessories

M OPTION-VISUAL INDICATOR,

NO ELEMENT WARNING

Linear Measure: millimeter

inch

OPTIONAL MOUNTING BRACKET (924904)

161.5

6.5

8.7

0.344

DIA. THRU

PLACES

122.9

4.84

60

TYP

7.9

0.31

114.3

4.500

R

114.3

4.500

6.44

0.25

V OPTION-VISUAL INDICATOR

13.5

0.531

DIA. THRU

4 PLACES

114.3

4.500

57.2

2.25

13.5

.531 DIA. THRU TYP.

41.1

1.62

25.4

1.00

OPTIONAL TANK FLANGE (925167)

10.3

0.406

DIA. THRU

8 PLACES

235.0

9.25

E OPTION-ELECTRICAL INDICATOR

122.9

4.84

98.4

3.875

TYPICAL

8.7

0.344

DIA. THRU

6 PLACES

196.9

7.750

TYPICAL

MATERIAL

THICKNESS

4.60

.18

149.2

5.875

DIA. B.C.

45

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

Low Pressure Filters

Moduflow Series

Parts List

Index Description

1

2

3

4

5

6

8

9

10

11

12

13

14

15

16

17

18

19

20

Screws, Nameplate ..............................

Name Plate, Unstamped ......................

Cover Screws, 5/16-18 UNC x 1 ........

Bowl Screws, 5/16-18 UNC x 1 ..........

Cover, Without nameplate ....................

O-Ring, cover, bowl and diverter

Buna .................................................

Fluorocarbon .....................................

Diverter/Bypass Valve Assembly .......

35 psid, Purple ..................................

25 psid, Metalic Aluminum ................

15 psid, Light Blue ............................

3 psid, Yellow ....................................

2 psid, Pink .......................................

No Bypass ........................................

Head, Machined only ............................

Flange Kits

Grommet (Buna) ..................................

Grommet, (Fluorocarbon) ....................

Single Elements, RF, IL

Bowl, Select desired model ..................

IL2-1 ..................................................

IL2-2 ..................................................

RF2-1 ................................................

RF2-1 with 2 inch NPTF fitting ..........

RF2-2 ................................................

RF2-2 with 2 inch NPTF fitting ..........

CF1-1 with 2 inch NPTF fitting ..........

CF2-2 with 2 inch NPTF fitting ..........

Double Elements, CF

Plug Kit, Fastener, self-sealing,

o-ring seal included with fastener .........

Indicator Electrical ..............................

35 psid ..............................................

25 psid ..............................................

15 psid ..............................................

3 psid ................................................

2 psid ................................................

Indicator Visual ...................................

35 psid 4-band ..................................

25 psid 4-band ..................................

15 psid 4-band ..................................

3 psid 4-band ....................................

2 psid 4-band ....................................

35 psid 3-band ..................................

25 psid 3-band ..................................

15 psid 3-band ..................................

3 psid 3-band ....................................

2 psid 3-band ....................................

Flange, In-tank mounting .....................

Bracket, Inline mounting ......................

Indicator Kit Remote mount ................

Check Valve Assy. (Submersible) ........

Check Rod Assy. .................................

2 - 1 CF ............................................

2 - 2 CF ............................................

Changeover Valve Assy., Duplex ........

Check Valve Assy., Duplex ..................

Flange Kits (flange, 4 bolts, o-ring)

Part

Quanity

No.

900028

2

924928

1

926633

6

926633

6

924634

1

N72350

V72350

926783

926582

926581

926580

926579

926578

925972

Refer

to Table

924433

925026

Refer to

Table

925916

924816

925917

924676

924815

924818

926207

924817

Refer to

Table

925974

3

3

1

Fluorocarbon

inch NPTF

YB

924788

926013

1 inch NPTF

YC

924787

926012

1 inch NPTF

YD

924912

926004

1 inch NPTF

YE

924786

926011

2 inch NPTF

YF

924785

926010

SAE - 12

YM

924784

926009

SAE - 16

YN

924783

926008

SAE - 20

YO

924913

926005

SAE - 24

YP

924782

926007

BLANK FLANGE

924781

926006

1

2

2

1

RF2 / IL2 / DIL2 Replacement Elements

BUNA

Single

Double

932686Q

932692Q

Fluorocarbon

Single

Double

932689Q 932695Q

05Q

932687Q

932693Q

932690Q

932696Q

10Q

932688Q

932694Q

932691Q

932697Q

20Q

933116Q

933117Q

933118Q

933119Q

03C

932361

932567

932367

932574

10C

932360

932467

932366

932473

20C

932359

932469

932365

932474

40SA

932358

932468

932364

932475

25W

932563

932566

932570

932573

40W

932562

932565

932569

932572

74W

932561

932564

932568

932571

WR

932363

932476

932370

932575

MEDIA

02Q

2

Optional

CF2 Replacement Elements

Optional

926954

925140

926758

926757

Buna

926643

924964

924965

924966

924967

926748

924776

924777

924778

924779

926750

924929

924824

924927

924926

925167

924904

924894

925120

Part Number

Code

Size

BUNA

Single

Double

924452Q

934264Q

Fluorocarbon

Single

Double

925039Q 935534Q

10Q

924453Q

934265Q

925040Q

935535Q

03C

924449

924791

925036

925046

10C

924450

924792

925037

925047

MEDIA

05Q

Optional

Optional

Optional

Optional

Optional

20C

924451

924793

925038

925048

40SA

924448

924790

925035

925045

25W

924454

924796

925041

925051

40W

924455

924797

925042

925052

74W

924456

924798

925043

925053

WR

927584

927585

928908

928925

Optional

Optional

*Two kits required for differential indication

46

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

Low Pressure Filters

Moduflow Series

Filter Assembly Exploded View

12

10

13

10

12

4

11

6

10

17

8

6

5

3

19

20

14

15

16

18

47

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

Low Pressure Filters

Moduflow Series

HOW TO ORDER: Select the desired symbol (in the correct position) to construct a model code.

Example:

BOX 1

BOX 2

BOX 3

BOX 4

BOX 5

BOX 6

BOX 7

BOX 8

BOX 9

IL2

10Q

MP

35

Y9Y9

Design number

assigned

by Parker

BOX 5: Indicators (See Note A)

BOX 1: Seals

Symbol

Description

Symbol

None

F3

E8

Buna

Fluorocarbon

EPR

M

Description

CF2

Suction filter,

inlet on bottom;

outlet on side

Return-line filter,

inlet on side;

outlet on bottom

In-line filter

In-line duplex

RF2

IL2

DIL2

V

D

S

Note: Add W after 2 for HWCF modification.

BOX 3: Length

Symbol

Description

1

2

Single element

Double element

Description

Pressure ports

drilled and

plugged; no

indicator

Visual indicator

w/ no element

warning

Electrical indicator;

no visual

Visual indicator

Electrical indicator;

3-pin male quick

disconnect

Pressure or

vacuum switch

(Selected based on

bypass setting.)

BOX 2: Basic Assembly

Symbol

(Two

Required)

Note A: (First letter of indicator code =

left side of filter head when looking

into inlet with bowl down; second

letter = right side of filter head

when looking into inlet with

bowl down.)

BOX 6: Bypass & Indicator Setting

BOX 4: Filter Media

Symbol

Description

74W

40W

25W

40SA

20C

10C

03C

02Q

05Q

10Q

20Q

WR

74-micron wire mesh

40-micron wire mesh

25-micron wire mesh

40-micron synthetic

20-micron cellulose

10-micron cellulose

3-micron cellulose

Microglass III

Microglass III

Microglass III

Microglass III

Water removal

Symbol

Pressure Setting

2

3

15

25

35

2 psid

3 psid

15 psid

25 psid

35 psid

BOX 7: Port Options

Filter Inlet

Model Symbol/Description

F9 2 NPTF

CF2

RF2

IL2

DIL2

F8 External

check valve

Y9 2 flange face

P9 SAE-24

integral threads

E9 1 NPTF

integral threads

*See table below

Y9 2 flange face

P9 SAE-24

integral threads

E9 1 NPTF

integral threads

*See table below

Y9 2 flange face

*See table below

Outlet

Symbol/Description

Y9 2 flange face

P9 SAE-24

integral threads

E9 1 NPTF

integral threads

*See table below

99 No fitting

F9 2 NPTF

F8 External

check value

Y9 2 flange face

P9 SAE-24

integral threads

E9 1 NPTF

integral threads

*See table below

Y9 2 flange face

*See table below

1)First pair of symbols denotes inlet for all filter styles;

second pair of symbols denotes outlet.

2)Four symbols required: two for inlet, two for outlet.

3)Unused ports in CF2 and RF2 filters come plugged

with a blank flange.

4)On CF2, F8 option includes internal rod assembly.

* Available Port Flange Options For Filter Head

Note: Indicators installed on filters will

be matched to the bypass valve.

YB

NPTF flange

YC

1 NPTF flange

YD

1 NPTF flange

YE

1 NPTF flange

YF

2 NPTF flange

YM

SAE-12 flange

YN

SAE-16 flange

YO

SAE-20 flange

YP

SAE-24 flange

BOX 8: Modifications

Symbol

Description

1

3

11

12

Please note the bolded options reflect

standard options with a reduced

lead-time. Consult factory on all

other lead-time options.

None

Magnets

No-bypass

No-bypass with magnets

BOX 9: Design Number

Applied to the filter by Parker Hydraulic Filter

Division. Use the full model code, including the

design number when ordering replacement parts.

48

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Designing Hydraulic Elevators PDFDokument73 SeitenDesigning Hydraulic Elevators PDFFelipeVelasquezZapataNoch keine Bewertungen

- Lab Manual 3.1 - LEVEL 1 - Determination of Head Loss in Pipes Due To Friction, Fittings, Sudden Expansion and Contraction.Dokument4 SeitenLab Manual 3.1 - LEVEL 1 - Determination of Head Loss in Pipes Due To Friction, Fittings, Sudden Expansion and Contraction.Coi50% (2)

- Brayton CycleDokument6 SeitenBrayton CycleNavnina Bhatia100% (1)

- Rupture Disk - Application and InspectionDokument33 SeitenRupture Disk - Application and InspectionLudi D. LunarNoch keine Bewertungen

- Fina Ponya-Model PDFDokument1 SeiteFina Ponya-Model PDFNursyarafina Binti SulaimanNoch keine Bewertungen

- 5.variable Valve TimingDokument14 Seiten5.variable Valve TimingJo VialNoch keine Bewertungen

- Design and Analysis of Gear PumpDokument7 SeitenDesign and Analysis of Gear PumpMahesh KudtarkarNoch keine Bewertungen

- Book 1 PDFDokument85 SeitenBook 1 PDFAditya Mehta67% (3)

- Bombas Sumergibles Acero Inoxidable Dia. 4 Inch - 60hzDokument16 SeitenBombas Sumergibles Acero Inoxidable Dia. 4 Inch - 60hzAquilesNoch keine Bewertungen

- Flow Measuring ApparatusDokument11 SeitenFlow Measuring Apparatuschameerarandil100% (2)

- Chapter 5 Part 2Dokument13 SeitenChapter 5 Part 2Allan Gabriel LariosaNoch keine Bewertungen

- Static Pressure and Air Purge Type Level IndicatorDokument4 SeitenStatic Pressure and Air Purge Type Level IndicatorService MMINoch keine Bewertungen

- Sheet 2Dokument2 SeitenSheet 2Medo NassarNoch keine Bewertungen

- Consolidated Safety Valve Type 1510,1511 and 1811Dokument40 SeitenConsolidated Safety Valve Type 1510,1511 and 1811Marcio Silva100% (1)

- Secadores de AireDokument4 SeitenSecadores de Aireramsi17100% (1)

- New PapersDokument2 SeitenNew PapersKripan SR SukrithamNoch keine Bewertungen

- Armstrong Is 2 Stainless Steel ConnectorDokument2 SeitenArmstrong Is 2 Stainless Steel ConnectorpandahiuNoch keine Bewertungen

- Stainless Steel P10Dokument1 SeiteStainless Steel P10Lucian GrigorasNoch keine Bewertungen

- Torque Converter & Hydraulic Ratchet System - 4thDokument18 SeitenTorque Converter & Hydraulic Ratchet System - 4thfalconalnajjar0% (1)

- HdpeDokument33 SeitenHdpeThiruThirunavukkarasuNoch keine Bewertungen

- Diagrama SiennaDokument18 SeitenDiagrama SiennaAchinga AquelachingaNoch keine Bewertungen

- Standard:: ProductsDokument1 SeiteStandard:: ProductsMd. Mominul IslamNoch keine Bewertungen

- Bid Evaluation TabulationDokument1 SeiteBid Evaluation Tabulationpeach5Noch keine Bewertungen

- Ket Data SlowmovDokument42 SeitenKet Data Slowmovslamet supriyadiNoch keine Bewertungen

- Operating Instructions AND Maintenance Manual FOR HAMMONDS MODEL 800-2L-1P7-1P5 Fluid Powered Additive Injector SystemDokument33 SeitenOperating Instructions AND Maintenance Manual FOR HAMMONDS MODEL 800-2L-1P7-1P5 Fluid Powered Additive Injector SystemMushir Ul Islam67% (3)

- Kunle Models 6010, 6021, 6030, 6182, 6121, 6130, 6186, 6283, 6221, 6230, 6933, 6934 and 6935Dokument12 SeitenKunle Models 6010, 6021, 6030, 6182, 6121, 6130, 6186, 6283, 6221, 6230, 6933, 6934 and 6935TopoilServNoch keine Bewertungen

- Valvula de Control Trans. 140HDokument13 SeitenValvula de Control Trans. 140HRCA09100% (7)

- Section 221116 - Domestic Water Piping-PexDokument16 SeitenSection 221116 - Domestic Water Piping-PexChase GietterNoch keine Bewertungen

- Hydracell - d15 ManualDokument24 SeitenHydracell - d15 ManualElkan Jeveshan NaidooNoch keine Bewertungen

- REE 6031 Tutorial 1Dokument5 SeitenREE 6031 Tutorial 1Eng Maboshe Charles Namafe0% (1)