Beruflich Dokumente

Kultur Dokumente

02 MaintInspecForm Scissors

Hochgeladen von

dediranduCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

02 MaintInspecForm Scissors

Hochgeladen von

dediranduCopyright:

Verfügbare Formate

March 2016

Maintenance Manual

Maintenance Procedures

Maintenanc e Schedul e

Maintenance Schedule

Programmed Example (under 1000 HRS):

The maintenance procedures have been divided

into subsections that include: Commissioning,

Quarterly, Annually and Programmed maintenance

intervals. The maintenance inspection report has

been divided into general areas of the machine

that include: Drive Chassis, Platform, Functions

and Controls, Engine and Electrical.

Failure to perform these procedures may result in

poor performance, component damage and unsafe

operating conditions. They are essential to safe

operation, machine performance and service life.

Commissioning: A series of required one time

maintenance procedures to be performed at

50 and 150 hour intervals.

Quarterly and Annually: A series of maintenance

procedures to be performed quarterly or annually.

Programmed Example:

Instructions Legend

Use the following detailed descriptions to identify

the intended use of the maintenance inspection

reports.

Programmed: A series of maintenance

procedures to be performed during a Pre-Delivery

Preparation or based on machine operating hours.

Specific Interval: blank box is the interval

to be completed and the marks the

interval as not required.

Maintenance Inspection Report

The description of the procedure or

checklist to be completed.

The maintenance inspection report contains

checklists for each type of scheduled inspection.

Make copies of the Maintenance Inspection Report

to use for each inspection. Maintain completed

forms for a minimum of 4 years or in compliance

with your employer, jobsite and governmental

regulations and requirements.

Instruction Examples

Check box to indicate status of

inspection.

Specific interval is not required for this

procedure.

General area of the machine to complete

the procedure.

Commissioning Example:

If this box has a designated time interval:

this is the specific time interval to

complete the procedure or checklist.

Quarterly and Annually Example:

Part No. 1272215

The procedure number or checklist to be

completed.

If this box is empty: the maintenance

checklist will include multiple time

intervals, use this box to write in the

specific interval for the inspection

completed.

Scissor Lifts

19

Maintenance Manual

March 2016

Pre-Delivery Preparation Report

Pre-Deliv ery Prepar ati on Repor t

Fundamentals

Instructions

It is the responsibility of the owner or dealer to

perform the Pre-delivery Preparation.

Use the operators manual on your machine.

The Pre-delivery Preparation is performed prior to

each delivery. The inspection is designed to

discover if anything is apparently wrong with a

machine before it is put into service.

A damaged or modified machine must never be

used. If damage or any variation from factory

delivered condition is discovered, the machine

must be tagged and removed from service.

Repairs to the machine may only be made by a

qualified service technician, according to the

manufacturer's specifications.

Scheduled maintenance inspections shall be

performed by qualified service technicians,

according to the manufacturer's specifications and

the requirements listed in the responsibilities

manual.

The Pre-delivery Preparation consists of

completing the Pre-operation Inspection, the

Maintenance items and the Function Tests.

Use this form to record the results. Place a check

in the appropriate box after each part is completed.

Follow the instructions in the operators manual.

If any inspection receives an N, remove the

machine from service, repair and re-inspect it.

After repair, place a check in the R box.

Legend

Y = yes, acceptable

N = no, remove from service

R = repaired

Comments

Pre-delivery Preparation

Pre-operation inspection

completed

Maintenance items completed

Function tests completed

Model

Serial number

Date

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

Scheduled

March 2016

Maintenance Inspection Report Scissor Lifts

Schedul ed Mai ntenance Inspec tion R eport - Sciss or Lifts

Model

Hour meter

Date

Serial number

Inspector company

Machine owner

Inspected by (print)

Inspector signature

Inspection Type

Q = quarterly or frequent inspections

A = annual inspections

Legend

Y = yes, acceptable

N = no, remove from service

R = repaired

= not applicable

Make copies of this report to use for each inspection.

Select the appropriate procedures for the type of

inspection(s) to perform.

If any inspection receives an "N," tag and remove the machine from service, repair and re-inspect it. After repair, place a "R" in the box.

Drive Chassis

Intervals

Inspect Electrical Contactors - GS-30, GS-32,

GS-46, GS-47, GS-69 DC and GS-69 BE

Q-6

Inspect the Fuel Tank Check Valve Venting

System - GS-69 RT Gas Models

Q-12

Inspect the Tires, Wheels and Lug Nut Torque

Q-15

Confirm the Proper Brake Configuration - GS-69,

GS-84 and GS-90

Q-16

Check Drive Hub Oil Level and Fastener Torque

A-1

Test the Oscillate Axle - GS-90

A-3

Chassis Mechanicals and Hydraulics

Intervals

Check the Module Tray Latch Components

Q-3

Visual Inspection of the Hydraulic Oil

Q-9

Inspect the Hydraulic Filters

Q-10

Test the Function Pump GS-69 BE and GS-69 DC

A-2

Electrical

Intervals

Battery Inspection

Q-2

Inspect the Battery Balancer - GS-69 DC

Q-4

Inspect the Electrical Wiring

Q-5

Inspect the Voltage Inverter - (if equipped)

Q-7

Engine

Intervals

Check the Exhaust System

Q-11

Check and Adjust Engine RPM

Q-14

Part No. 1272215

Platform

Intervals

Test the Platform Overload Pressure Transducer

and Platform Height Sensor - GS-30, GS-32,

GS-46 and GS-47 (if equipped)

A-5

Test the Platform Overload System - GS-30,

GS-32, GS-46 and GS-47 (if equipped)

A-6

Test the Platform Overload System GS-69 (if equipped)

A-7

Test the Platform Overload System - GS-84 and

GS-90 (if equipped)

A-8

Functions and Controls

Intervals

Check for Open Bulletins and Owner Registration

Q-1

Test the Flashing Beacons (if equipped)

Q-8

Test Fuel Select Operation - Gas/LPG Models

Q-13

Test the Drive Brakes

Q-17

Test Drive Speed Stowed Position

Q-18

Test Drive Speed Raised Position

Q-19

Test the Down Limit Switch, Level Sensor and

Pothole Limit Switches - GS-30, GS-32,

GS-46 and GS-47

Q-20

Test the Platform Gate Proximity Switches and the Q-21

Extension Deck Limit Switch - GS-2646 AV,

GS-2646 AV35

Q

Test the Down Limit Switch Descent Delay GS-69, GS-84 and GS-90 (if equipped)

Scissor Lifts Maintenance Manual

A-4

21

Programmed

March 2016

Maintenance Inspection Report Scissor Lifts

Programm ed M ai ntenance Inspecti on Report - Sciss or Li fts

Model

Hour meter

Date

Serial number

Inspector company

Machine owner

Inspected by (print)

Inspector signature

Programmed maintenance will be completed based on machine

hours. This program includes the onetime or commissioning

procedures for new products.

The onetime procedures will be completed at 50 or 150 hours.

Legend

Y = yes, acceptable

N = no, remove from service

R = repaired

= not applicable

Make copies of this report to use for each

inspection.

Select the appropriate procedures for the type of

inspection(s) to perform.

If any inspection receives an "N," tag and remove the machine from service, repair and re-inspect it. After repair, place a "R" in the box.

50

Commissioning

150

50 Hour Service - all models

C-1

Perform Engine Maintenance - 50 Hours

C-2

150 Hour Service

C-3

Programmed Maintenance - Under 1000 HRS

Status

Enter

Hours

Inspect the Engine Air Filter - GS-69 RT

P0-1

40

Grease the Steer Yokes - GS-30, GS-32,

GS-46 and GS-47

P0-2

100

Engines - Deutz Under 1000 Hours

P0-3

Engines - Ford Under 1000 Hours

P0-4

Engines - Kohler Under 1000 Hours

P0-5

Engines - Kubota Under 1000 Hours

P0-6

Engines - Perkins Under 1000 Hours

P0-7

22

Programmed Maintenance

All models

Hours are in thousands

Engines - all models, 1000 Hours

P1-1

Replace the Drive Hub Oil - GS-69,

GS-84 and GS-90

P1-2

Engines - all models, 2000 Hours

P2-1

Replace the Hydraulic Filters

P2-2

Check the Free-wheel Configuration GS-84 and GS-90

P2-3

Check the Scissor Arm Wear Pads

(and Slider Blocks, If Equipped)

P2-4

Grease Steer Axle Wheel Bearings GS-69 BE and GS-69 DC

P2-5

Test or Replace the Hydraulic Oil

P2-6

Engines - all models, 3000 Hours

P3-1

Scissor Lifts Maintenance Manual

Perform every: 1

Part No. 1272215

Das könnte Ihnen auch gefallen

- Potable Water Approvals Ansi/NsfDokument4 SeitenPotable Water Approvals Ansi/NsfdediranduNoch keine Bewertungen

- Refnet Single Line OU - 1 PDFDokument1 SeiteRefnet Single Line OU - 1 PDFdediranduNoch keine Bewertungen

- 33 01 10.13 - Pressure and Leakage TestsDokument3 Seiten33 01 10.13 - Pressure and Leakage TestsMohamed ElarabiNoch keine Bewertungen

- Vivace Brochure PDFDokument6 SeitenVivace Brochure PDFdediranduNoch keine Bewertungen

- Leciv PDFDokument1 SeiteLeciv PDFdediranduNoch keine Bewertungen

- 1243-E123 Office Power Distribution HDMI & VGA PDFDokument1 Seite1243-E123 Office Power Distribution HDMI & VGA PDFdediranduNoch keine Bewertungen

- Canalis KR Presentation V1 PDFDokument8 SeitenCanalis KR Presentation V1 PDFdediranduNoch keine Bewertungen

- ISBN Job Safety Analysis Worksheet 2004 09 PDFDokument1 SeiteISBN Job Safety Analysis Worksheet 2004 09 PDFdediranduNoch keine Bewertungen

- Indonesia Polymer Compound Shop DrawingDokument1 SeiteIndonesia Polymer Compound Shop DrawingdediranduNoch keine Bewertungen

- FM - FAB-001 Request For FabricationDokument1 SeiteFM - FAB-001 Request For FabricationdediranduNoch keine Bewertungen

- I-Line V Copper Contact Busway Launch Sep 18th PDFDokument3 SeitenI-Line V Copper Contact Busway Launch Sep 18th PDFdediranduNoch keine Bewertungen

- NFPA Fire PumpDokument12 SeitenNFPA Fire PumpSyed Faizan AliNoch keine Bewertungen

- Modif Support Screw Conv 110-665 Model PDFDokument1 SeiteModif Support Screw Conv 110-665 Model PDFdediranduNoch keine Bewertungen

- 21eb7 0 PDFDokument1 Seite21eb7 0 PDFdediranduNoch keine Bewertungen

- ASME B31.9 Building Services Piping Code (2011) ComplianceDokument3 SeitenASME B31.9 Building Services Piping Code (2011) ComplianceАнж БжлNoch keine Bewertungen

- Seismic Separation Between Storage Rack and The Building StructureDokument1 SeiteSeismic Separation Between Storage Rack and The Building StructuredediranduNoch keine Bewertungen

- Astm HDPE Pipe Testing ProcedureDokument5 SeitenAstm HDPE Pipe Testing Procedureharkanwarsingh100% (3)

- E8034 Systemair DiffusersDokument6 SeitenE8034 Systemair DiffusersdediranduNoch keine Bewertungen

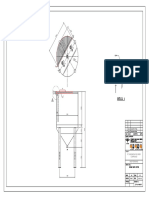

- Cone Dust Extractor IFFDokument1 SeiteCone Dust Extractor IFFdediranduNoch keine Bewertungen

- 04RJDokument2 Seiten04RJdediranduNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Blueprints Psychiatry 6th Edition Ebook PDFDokument61 SeitenBlueprints Psychiatry 6th Edition Ebook PDFpaul.tucker169100% (36)

- ANSWERDokument9 SeitenANSWERLeesaa88Noch keine Bewertungen

- Why Comics Excerpt PDFDokument9 SeitenWhy Comics Excerpt PDFGagandeep SinghNoch keine Bewertungen

- CM 3Dokument96 SeitenCM 3Janak Bahadur RokayaNoch keine Bewertungen

- Gender Studies Lecture 1Dokument30 SeitenGender Studies Lecture 1Shahzaib KhanNoch keine Bewertungen

- D 100394 X 012Dokument52 SeitenD 100394 X 012Preyas SuvarnaNoch keine Bewertungen

- Airside Capacity-Volume3Dokument18 SeitenAirside Capacity-Volume3kkrajcekNoch keine Bewertungen

- AII Grant Program: Final Report and Acquittal Form: 1.1 Name (Mandatory)Dokument5 SeitenAII Grant Program: Final Report and Acquittal Form: 1.1 Name (Mandatory)amir_hzhNoch keine Bewertungen

- Psa 700 Notes and SummaryDokument10 SeitenPsa 700 Notes and SummaryEjkNoch keine Bewertungen

- 0837 Sigma Profile Extra FineDokument2 Seiten0837 Sigma Profile Extra Fineمحمد عزتNoch keine Bewertungen

- Cosmic Voyage Video QuestionsDokument2 SeitenCosmic Voyage Video Questionsbhuwankatwal980Noch keine Bewertungen

- Hazen Williams Friction Loss Hydraulic TablesDokument78 SeitenHazen Williams Friction Loss Hydraulic TablesMisama NedianNoch keine Bewertungen

- Batch Process - MicrostationDokument6 SeitenBatch Process - Microstationakshata_ankalikarNoch keine Bewertungen

- Akira 007Dokument70 SeitenAkira 007Ocre OcreNoch keine Bewertungen

- Unit 2 Lect 1 Program StructureDokument14 SeitenUnit 2 Lect 1 Program StructureManav JainNoch keine Bewertungen

- Aluminum Alloy Options for High-Temperature Automotive ComponentsDokument18 SeitenAluminum Alloy Options for High-Temperature Automotive ComponentsFluf LvpNoch keine Bewertungen

- Utilization of Contraceptives Among Women of Reproductive Ages in Salaga MunicipalityDokument70 SeitenUtilization of Contraceptives Among Women of Reproductive Ages in Salaga MunicipalitySeyram RichardNoch keine Bewertungen

- 5 - Nissho in JapanDokument1 Seite5 - Nissho in Japanrajthakre81Noch keine Bewertungen

- Micro LaterologDokument25 SeitenMicro Laterologali_hamza223Noch keine Bewertungen

- The OZ Principle - InsightsDokument24 SeitenThe OZ Principle - InsightsJesus Camacho100% (3)

- Nine Worlds Saga 3 Crisis in AlfheimrDokument22 SeitenNine Worlds Saga 3 Crisis in AlfheimrGamer4242100% (1)

- Mphil PHD (2019 2020)Dokument9 SeitenMphil PHD (2019 2020)Praveen KumarNoch keine Bewertungen

- MIT - Sip FundamentalsDokument13 SeitenMIT - Sip Fundamentalskoalla01Noch keine Bewertungen

- Em I - Question BankDokument3 SeitenEm I - Question BankPrathamesh SagvekarNoch keine Bewertungen

- MsdsDokument9 SeitenMsdsCong khong tienNoch keine Bewertungen

- Ab at InventoryDokument32 SeitenAb at InventoryecirecirNoch keine Bewertungen

- SPSS descriptive statistics experimentDokument5 SeitenSPSS descriptive statistics experimentKertik SinghNoch keine Bewertungen

- SINUMERIK 810M NCnet 7.0 SettingsDokument3 SeitenSINUMERIK 810M NCnet 7.0 SettingsSam eagle good100% (1)

- Nursing Research Chapter3Dokument4 SeitenNursing Research Chapter3Sj Cams100% (2)

- Black Soldier Fly Larvae-Based Fish Feed Production Financial Feasibility and Acceptability AnalysisDokument117 SeitenBlack Soldier Fly Larvae-Based Fish Feed Production Financial Feasibility and Acceptability AnalysisjayaniNoch keine Bewertungen